Chef's Choice SteelPro 470 Series Manual

SteelPro

®

Model 470 Series

CZGB

SteelPro

®

Congratulations!

As an owner of the Chef’sChoice® SteelPro®, you will be able to experience for

the first time the pleasure of cutting and slicing with perfectly steeled edges. The

SteelPro® creates a unique cutting edge much superior to that obtainable with

conventional steels. The SteelPro® edge will consistently have a good “bite” and

will, uniquely, stay very sharp as you continue to use the SteelPro®. No skill is

required and even a first time user will find it easy to use.

The SteelPro® eliminates the uncertainty, inconsistency and intimidation of the

age-old method of unguided manual steeling. With the SteelPro® you will in just

seconds be able to consistently obtain superior edges with that extra “bite” and

sharpness unmatched by even the most experienced professionals.

You will quickly realize how much less intimidating it is to use the SteelPro®

compared to conventional uncontrolled manual steeling.

2

Description of SteelPro

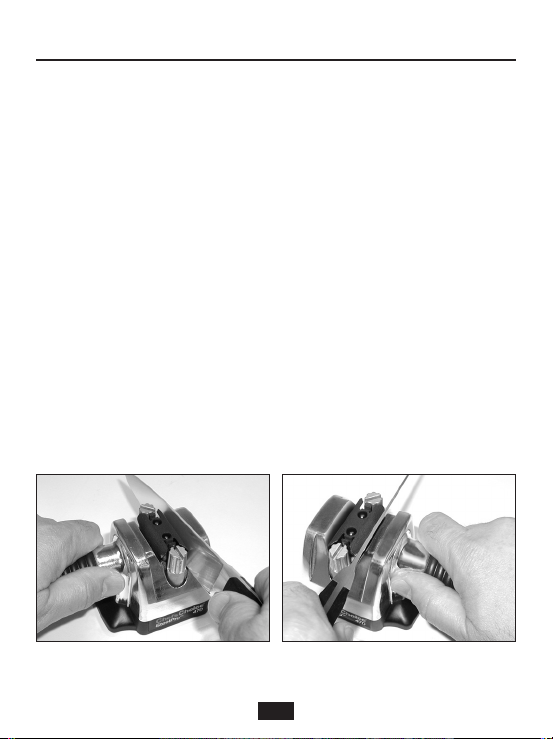

The SteelPro® is designed to be used either right or left handed (Figure 1 and 2).

The soft-touch handle is shaped and sized for a comfortable hold. The SteelPro®

can be hung by the metal ring attached to the handle or stored flat in a drawer

or on a shelf.

The SteelPro® contains two unique rods made of a special high carbon steel

hardened to about Rockwell C-65, which is much harder than any commercially

available cutlery. Consequently these special rods will show very little wear from

the repeated contact with the edge of your finest and hardest knives.

Two precision knife guides, with planes set at about 23 degrees to the vertical

center line of the hardened rods, control and precisely align the face of the knife

as the blade is inserted into the slot between the guide and the blade retention

spring. In use, the blade is inserted alternately into the left and then the right

slots and pulled forward so that the knife edge slides along the surface of the

hardened steel rod.

The steel rods are supported by elastomeric materials that allow the rods to

deflect when excessive force is applied to the blade. This feature and the

ultra-precise and consistent angular contact maintained stroke after stroke

between the knife edge and the hardened steel rods are key to optimizing the

edge structure. Viewed under a microscope, the SteelPro® edge presents a

uniform formation of exceedingly fine and super-sharp micro-serrations.

Furthermore, even after many uses of the SteelPro® on a knife, the original

®

Figure 1. Right-handed use. Figure 2. Left-handed use.

3

edge geometry is maintained and the edge does not round-off like it would

using a conventional steel with no angle control.

Because of the consistent angular relationship between the individual facets

on each side of the knife edge and the steel rods, the SteelPro® simultaneously

maintains a shaving sharp edge while it creates the uniform row of microscopic

serrations along the edge. If the edge is damaged when used for cutting, the

SteelPro® will restore the edge micro-serrations while maintaining the sharpness

of the edge. This type of edge conditioning is unique to the SteelPro®.

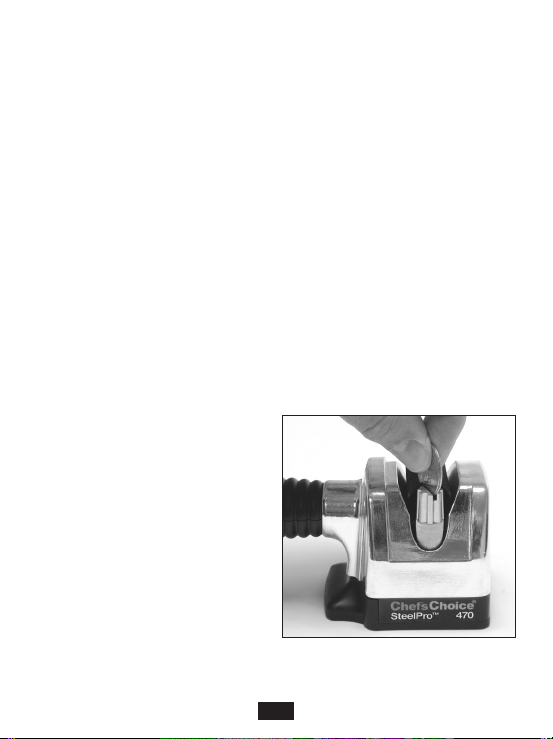

On top of each steel rod is a slotted cap that accepts a coin or other tool so you

can rotate the steel rod slightly to expose a fresh area of the steel rod surface

(Figure 3). This is necessary only if the rod becomes sufficiently worn that the

edge conditioning process slows significantly. When the rod is rotated, fresh

surfaces are made available in both the left and right slots. A spring finger

extends from each end of the knife retention spring and clicks into a shallow

groove in the cap on top of each steel rod. When necessary to use a new

surface on the steel, rotate the slot counter-clockwise one click. By this means

approximately 55 pairs of “steeling” areas are available over the lifetime of the

rods. You will find with use that the rod closest to you will experience the most

wear. The rod to the rear need not be rotated as often. Because the knife edge

can be pulled over a given pair of areas on the rods several thousand times

before the wear affects the rate or

precision of the edge formation, the

rods need not be rotated very often

and they can last a lifetime in normal

household use. Replacement rods

are, however, available from the

EdgeCraft Corporation.

The SteelPro® features small rubber

feet for a secure hold to any dry

surface. The soft-touch handle is

designed to improve the grip and

reduce hand slippage.

Figure 3.

4

Using the SteelPro

You will find the SteelPro® can maintain an exceedingly effective razor sharp

edge on all of your cutlery. While it is extremely simple to use, we urge you to

read the instructions in order to optimize your results.

Knife manufacturers have for years suggested steeling as a good way to maintain the knife edge. Users and manufacturers alike know however that knives

must be professionally sharpened before steeling and periodically thereafter

when the steeling process becomes too slow or ineffective. Consequently,

whether you are steeling with a conventional steel or the SteelPro®, you will

need to resharpen the edge periodically with a professional sharpener.

If you are uncertain of the angle of your knife edges, we recommend that you

presharpen the edge at a total angle of 40° before using the SteelPro®. Most new

factory edges are sharpened in the range of 30 to 40 degrees but a very few are

sharpened as low as 20 degrees total. Any edge angled at 40° or less can be

effectively maintained with the SteelPro®. Similarly if your edge is very dull we

recommend that it be sharpened first with a quality knife sharpener angled at

about 40 degrees. The SteelPro® can then swiftly and repeatedly create an

extremely effective microstructure along the edge while maintaining its

sharpness. You will be impressed with the how effective this type of edge can be.

Chef’sChoice® manual and professional electric sharpeners, recognized world

wide for their premium angle control, have a first sharpening stage that is ideal

for presharpening the knife for the SteelPro®. If you are uncertain about the

sharpening angle of your sharpener, contact the manufacturer and inquire what

angles are used.

To use the SteelPro®, if you are right handed (Figure 1), grip and steady the

SteelPro® handle with your left and hold the knife in your right. Move the blade

forward as you insert it between one guide plane and the blade retaining spring

as close as possible to the bolster or handle. The face of the blade should be in

intimate contact with the guide plane. Pull the blade toward you as you press

down lightly on the blade so that the edge makes good contact with the steel

rod. Make sure that the edge maintains steady contact with the steel rod from

the handle to the tip of the blade. Repeat this procedure, making a full stroke in

the opposite slot between that guide and the spring. You should repeat this

motion, making alternating pairs of pulls until the edge is fully conditioned.

®

5

Loading...

Loading...