Page 1

w

ww.PESA.com

V

IDEO

U

SING

M

ATRIX SWITCHER

M

ODEL

144X144 M

864XR

ATRIX CARD

T

ECHNICAL

M

ANUAL

Publication: 81-9059-0595-0, Rev. C

Page 2

C

HEETAH

864XR V

IDEO MATRIX SWITCHER

Publication 81-9059-0595-0, Rev. C

October 2010

Thank You !!

for purchasing your new video router from PESA. We appreciate your

confidence in our products. PESA produces quality, state-of-the-art equipment designed to

deliver our users the highest degree of performance, dependability and versatility available

anywhere. We want you to know that if you ever have a concern or problem with a PESA

product, we have a team of engineers, technicians and customer service professionals

available 24/7/365 to help resolve the issue.

Our commitment is to continue earning the trust and confidence of our customers throughout

the industry by incorporating cutting-edge technology into the highest quality, most cost

effective products on the market. And we would like to invite you to tell us how we’re doing.

If you have any comments or suggestions concerning your PESA equipment, please contact

our Customer Service Department.

Again thank you for choosing a PESA product. All of us at PESA look forward to a long-term

partnership with you and your facility.

S

ERVICE AND ORDERING ASSISTANCE

PESA

103 Quality Circle

Suite 210

Huntsville AL 35806 USA

www.pesa.com

M

AIN OFFICE

Tel: 256.726.9200

Fax: 256.726.9271

S

ERVICE DEPARTMENT

Tel: 256.726.9222 (24/7)

Toll Free: 800.323.7372

Fax: 256.726.9268

Email: service@pesa.com

© 2010 PESA Switching Systems, All Rights Reserved.

Cheetah is a trademark of PESA Switching Systems, Inc. in the United States and/or other countries.

Microsoft, Windows, and Windows NT are either registered trademarks or trademarks of Microsoft Corporation in the United States and/or

other countries.

No part of this publication (including text, illustrations, tables, and charts) may be reproduced, stored in any retrieval system, or transmitted

in any form or by any means, including but not limited to electronic, mechanical, photocopying, recording or otherwise, without the prior

written permission of PESA.

All information, illustrations, and specifications contained in this publication are based on the latest product information available at the time

of publication approval. The right is reserved to make changes at any time without notice.

Printed in the United States of America.

Proprietary Information of PESA I

Page 3

C

T

ABLE OF CONTENTS

HEETAH

864XR V

Publication 81-9059-0595-0, Rev. C

IDEO MATRIX SWITCHER

October 2010

Chapter 1: About This Manual......................................................................................... 1-1

1.1

Documentation and Safety Overview.............................................................................................1-1

1.2

Warnings, Cautions, and Notes......................................................................................................1-1

1.2.1 WARNING...............................................................................................................................1-1

1.2.2 CAUTION.................................................................................................................................1-1

1.2.3 NOTE........................................................................................................................................1-1

Chapter 2: Introduction.................................................................................................... 2-1

2.1

Cheetah 864 XR Product Overview................................................................................................2-1

2.2

Review of Core System Components.............................................................................................2-4

2.2.1 Input Circuit Card Assembly .....................................................................................................2-4

2.2.2 Matrix Circuit Card Assembly...................................................................................................2-4

2.2.3 Output Circuit Card Assembly...................................................................................................2-4

2.2.4 Power Supply Module ...............................................................................................................2-5

2.2.5 Control System..........................................................................................................................2-5

2.2.6 Backplanes................................................................................................................................2-5

2.3

864 XR Frame Specifications.........................................................................................................2-6

Chapter 3: Installation ...................................................................................................... 3-1

3.1

Unpacking and Inspection..............................................................................................................3-1

3.2

General Chassis Installation Overview...........................................................................................3-1

3.3

Choosing a Location......................................................................................................................3-1

3.4

Mounting The 864XR Chassis in an Equipment Rack ....................................................................3-2

3.4.1 Cheetah Chassis Mounting Procedure........................................................................................3-3

3.5

Connect Equipment Cables............................................................................................................3-4

3.6

Cheetah Chassis Supply Power Connections (US Models) .............................................................3-4

3.6.1 864XR Frame Primary Power....................................................................................................3-6

3.7

International Power Requirements For Cheetah Chassis.................................................................3-7

3.8

Video Input/Output Connections....................................................................................................3-9

3.9

Rear Panel System Connections...................................................................................................3-14

3.9.1 RS-232 Control Connectors COM 1 and COM 2......................................................................3-14

3.9.2 RS-422 Control Connectors COM3/PRC and COM4...............................................................3-15

3.9.3 System Control Alarm Connector............................................................................................3-16

3.9.4 PRC Loop Connector...............................................................................................................3-18

3.9.5 RCP Panel Port Connectors .....................................................................................................3-19

3.9.6 Network Connectors................................................................................................................3-20

3.9.7 Frame Alarm Connector ..........................................................................................................3-23

3.9.8 Auxiliary Frame Control Connector.........................................................................................3-24

3.9.9 House Synchronization Input Connectors.................................................................................3-25

3.9.10

Output Monitor Connectors.................................................................................................3-26

Chapter 4: Frame And Control Verification.................................................................... 4-1

4.1

System Pre-start Verification Checklist..........................................................................................4-1

4.2

System Startup...............................................................................................................................4-1

4.3

Frame Control Verification............................................................................................................4-3

4.3.1 Frame Control Verification Overview........................................................................................4-3

4.3.2 Frame Strobe Setting Verification..............................................................................................4-3

4.3.3 Frame Control Verification Procedure .......................................................................................4-3

Proprietary Information of PESA II

Page 4

C

HEETAH

T

ABLE OF CONTENTS (CONT

4.4

System Control..............................................................................................................................4-5

4.4.1 System Control Overview..........................................................................................................4-5

4.4.2 System Control Verification Procedure......................................................................................4-6

.)

864XR V

Publication 81-9059-0595-0, Rev. C

IDEO MATRIX SWITCHER

October 2010

Chapter 5: Reference Data................................................................................................ 5-1

5.1

Reference Data Introduction ..........................................................................................................5-1

5.2

DIP Switch/Rotary Switch Settings for the 864XR Frame..............................................................5-1

5.2.1 Chassis Level Codes (Strobes) Rotary Switch Settings...............................................................5-3

5.2.2 Chassis Power Supply Backplane DIP Switch Settings...............................................................5-3

5.2.3 Chassis Input/Output CCA Backplane DIP Switch Settings........................................................5-3

5.2.4 Chassis Matrix Backplane Rotary Switch Settings .....................................................................5-3

L

IST OF FIGURES

Figure 2-1 - 864XR Chasssis – Front View.....................................................................................................2-2

Figure 2-2 - 864XR Chassis – Rear View .......................................................................................................2-3

Figure 3-1 - Cables Attached To Supports ......................................................................................................3-4

Figure 3-2 - Power Supply Configuration (US Models)...................................................................................3-5

Figure 3-3 - Phase Relationships.....................................................................................................................3-6

Figure 3-4 - Pigtail Cabling Conductors..........................................................................................................3-7

Figure 3-5 - International Power Supplies Configuration.................................................................................3-8

Figure 3-6 – 864XR Chassis – Rear View.....................................................................................................3-10

Figure 3-7 - Channel Assignments – I/O Card Slots 1 - 16............................................................................3-11

Figure 3-8 - Channel Assignments - I/O Card Slots 17 - 64...........................................................................3-12

Figure 3-9 - Channel Assignments - I/O Card Slots 65 - 112.........................................................................3-13

Figure 3-10 - RS-232 Control Connectors.....................................................................................................3-14

Figure 3-11 - RS-422 COM 3/PRC and COM 4 Control Connectors.............................................................3-15

Figure 3-12 - System Control Alarm Connector............................................................................................3-17

Figure 3-13 - System Alarm Cable Set and Associated Schematic.................................................................3-18

Figure 3-14 - PRC Loop Connector..............................................................................................................3-18

Figure 3-15 - RS-422 System Expansion Cable.............................................................................................3-19

Figure 3-16 - RCP Panel Port Connectors.....................................................................................................3-19

Figure 3-17 - RS-485 Cable Construction.....................................................................................................3-20

Figure 3-18 - Network Connectors................................................................................................................3-21

Figure 3-19 - Ethernet Connector..................................................................................................................3-21

Figure 3-20 - Matrix Frame Controller and System Controller Card Locations, Slot A And Slot B................3-22

Figure 3-21 - Frame Alarm Connector..........................................................................................................3-23

Figure 3-22 - Frame Control Alarm Cable Connection and Circuit Schematic...............................................3-24

Figure 3-23 - Auxiliary Frame Control Connector.........................................................................................3-24

Figure 3-24 - House Sync Input Connectors..................................................................................................3-25

Figure 4-1 - PC to Frame Controller Connection.............................................................................................4-4

Figure 4-2 - 3500 Series Card DIP Switch Locations (Set For 9,600 Baud Rate).............................................4-6

Figure 5-1 - 144x144 Matrix Crosspoint CCA I/O Channel Assignments........................................................5-2

Figure 5-2 - 864 XR Chassis And Level Code Switch Settings........................................................................5-4

Figure 5-3 - 864XR Power Supply Backplane DIP Switch Locations And Settings .........................................5-5

Figure 5-4 - Input/Output Backplane DIP Switch Settings...............................................................................5-6

Figure 5-5 - Matrix Backplane Rotary Switch Locations.................................................................................5-7

Proprietary Information of PESA III

Page 5

C

L

IST OF TABLES

HEETAH

864XR V

Publication 81-9059-0595-0, Rev. C

IDEO MATRIX SWITCHER

October 2010

Table 3-1 - Pigtail Cabling Conductor Power Connections..............................................................................3-7

Table 3-2 - AC Power Filter Assembly...........................................................................................................3-7

Table 3-3 – COM 1 and COM 2 Pin Assignments.........................................................................................3-14

Table 3-4 - CPU Link Protocols....................................................................................................................3-15

Table 3-5 - Com 3/PRC Pin Assignments.....................................................................................................3-16

Table 3-6 – COM 4 Pin Assignments............................................................................................................3-16

Table 3-7 - Ethernet LED Indicators.............................................................................................................3-21

Table 3-8 - Auxiliary Frame Control Pin Assignments..................................................................................3-25

Table 4-1 - 3500 Series Card S1 DIP Switch Settings .....................................................................................4-6

Table 5-1 - Matrix Backplane Rotary Switch Settings.....................................................................................5-8

Proprietary Information of PESA IV

Page 6

C

HEETAH

864XR V

Publication 81-9059-0595-0, Rev. C

IDEO MATRIX SWITCHER

October 2010

Chapter 1: About This Manual

1.1 D

OCUMENTATION AND SAFETY OVERVIEW

It is the responsibility of all personnel involved in the installation, operation, and maintenance

of the equipment to know all the applicable safety regulations for the areas they will be

working in. Under no circumstances should any person perform any procedure or sequence

in this manual if the procedural sequence will directly conflict with local Safe Practices.

Local Safe Practices shall remain as the sole determining factor for performing any

procedure or sequence outlined in this document.

1.2 W

ARNINGS, CAUTIONS, AND NOTES

Throughout this document, you should notice various Warnings, Cautions, and Notes. These addendum

statements supply invaluable information pertaining to the text that they address. It is imperative that

audiences read and understand the statements to avoid possible loss of life, personal injury,

destruction/damage to the equipment, and/or added information that could enhance the operating

characteristics of the equipment (i.e., Notes). The following subsections represent a description of the

Warnings, Cautions, and Notes statements contained in this manual:

1.2.1 WARNING

Warning statements identify conditions or practices that can result in loss of

life or permanent personal injury if the instructions contained in the

statement are not complied with.

1.2.2 CAUTION

Caution statements identify conditions or practices that can result in

personal injury and/or damage to equipment if the instructions contained in

the statement are not complied with.

1.2.3 NOTE

Notes are for information purposes only. However, they may contain

invaluable information important to the correct installation, operation,

and/or maintenance of the equipment.

Proprietary Information of PESA 1-1

Page 7

C

HEETAH

864XR V

Publication 81-9059-0595-0, Rev. C

IDEO MATRIX SWITCHER

October 2010

Chapter 2: Introduction

2.1 C

HEETAH

864 XR P

RODUCT OVERVIEW

PESA’s Cheetah Series Video Matrix Switcher products are manufactured using a “building block”

architecture of core components installed in a chassis frame that provides the infrastructure

requirements of circuit card capacity, power, cooling and system control I/O connections. There are

several different types of chassis frames in the Cheetah family, of which the 864XR is a member. Each

frame is designed for a specific purpose – but most are built with a degree of flexibility to accommodate

as wide a range of customer needs as possible.

While all frames do indeed serve the same basic purpose – to house the switcher “building block”

components and provide the system infrastructure – component layout, internal signal routing through

backplanes and mid-planes and frame-specific power supply components vary greatly between the

frames. For this reason each frame type in the Cheetah family has its own Technical Manual Volume.

All frame-specific data such as the items just mentioned plus connector locations, pin-outs and other

pertinent information peculiar to the 864XR frame is contained in this Technical Manual.

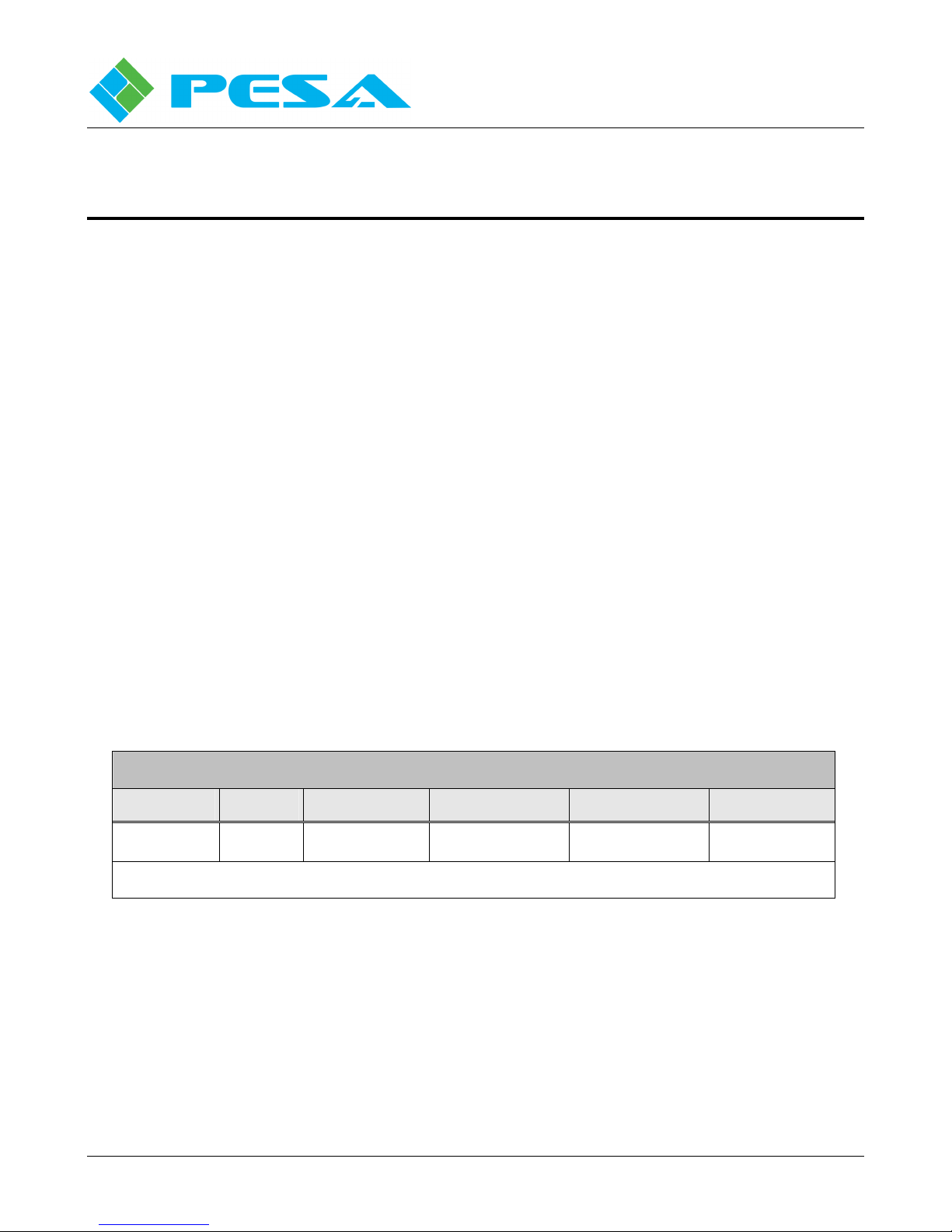

Using the 864 XR frame and the Cheetah 144X144 Matrix CCA a routing switcher with the capacity of

up to 864 inputs and 864 outputs can be configured in a single 41 rack unit (RU) frame. Table 2-1

indicates the maximum number of each core component type that can be installed in the 864XR frame.

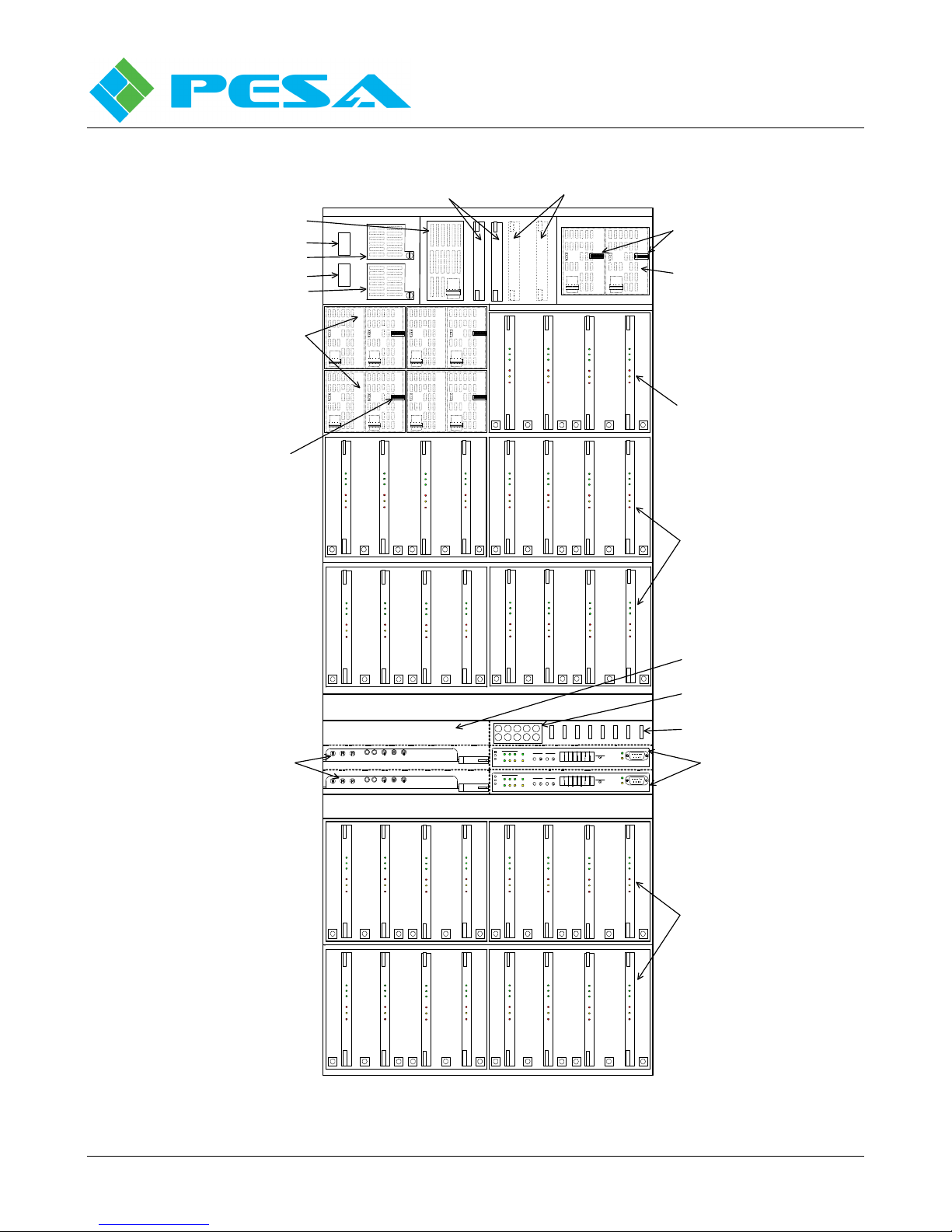

Figure 2-1 is a front view of the chassis layout with the access door open. Figure 2-2 is a rear view of

the 864XR frame.

Table 2-1 Cheetah Series Active Components Matrix

C

ORE COMPONENT MAXIMUM QUANTITIES FOR THE

Input Buffer

CCA 1

Matrix

CCA 1

Output Combiner

54 36 54 2 2 8

1

Indicated quantities are maximum number of cards each frame can support. Quantities of each CCA type will vary by

matrix configuration.

Proprietary Information of PESA 2-1

CCA 1

Matrix Frame

Controller CCA

864XR C

HASSIS FRAME

System Controller

CCA

Power Supply

Module

Page 8

C

HEETAH

864XR V

IDEO MATRIX SWITCHER

Publication 81-9059-0595-0, Rev. C

October 2010

Power Filter Module

Power Breake r 1

Rectifier Module 1

Power Breake r 2

Rectifier Module 2

Power Supply Modules (8)

and Power Supply

Backplanes (4)

(Power Supply Modules

Shown In Phantom, To Allow

View Of 8-Position DIP

Switch Located On Each

Power Supply Backplane)

8-Position DIP Switch

System Controller CCA

One or Two (For Redundancy)

Fan Controller CCA (2)

PWR OK

PWR OK

PWR OK

ALERT

ALERT

28V

28V

GND

GND

PS600

PS600

PWR OK

PWR OK

ALERT

ALERT

28V

28V

GND

GND

PS600

PS600

Matrix

Matrix

+28 V

+28 V

+2. 5 V

+2. 5 V

+1. 2 V

+1. 2 V

CTRL

CTRL

ERR

ERR

IN

IN

USE

USE

FAN

FAN

ERR

ERR

S1 S2 S3 S4 S5 S 6

Matrix

Matrix

+28 V

+28 V

+2. 5 V

+2. 5 V

+1. 2 V

+1. 2 V

CTRL

CTRL

ERR

ERR

IN

IN

USE

USE

FAN

FAN

ERR

ERR

S1 S2 S3 S4 S5 S 6

ACTIVE

STANDBY

RUN ACTIVE

GND +5V + BA TTER Y

GND +5V + BA TTER Y

BATTERY RE SET MODE

ACTIVE

STANDBY

RUN ACTIVE

BATTERY RE SET MODE

PWR OK

ALERT

ALERT

28V

28V

GND

GND

PS600

PS600

PWR OK

PWR OK

ALERT

ALERT

28V

28V

GND

GND

PS600

PS600

Matrix

Matrix

+28 V

+28 V

+2. 5 V

+2. 5 V

+1. 2 V

+1. 2 V

CTRL

CTRL

ERR

ERR

IN

IN

USE

USE

FAN

FAN

ERR

ERR

Matrix

Matrix

+28 V

+28 V

+2. 5 V

+2.5 V

+1. 2 V

+1.2 V

CTRL

CTRL

ERR

ERR

IN

IN

USE

USE

FAN

FAN

ERR

ERR

Card Slots Not Populated

(For Future Use)

PWR OK

PWR OK

ALERT

ALERT

28V

28V

GND

GND

PS600

PS600

Matrix

Matrix

+28 V

+28 V

+2.5 V

+2. 5 V

+1.2 V

+1. 2 V

CTRL

CTRL

ERR

ERR

IN

IN

USE

USE

FAN

FAN

ERR

ERR

Matrix

Matrix

+28 V

+28 V

+2. 5 V

+2. 5 V

+1. 2 V

+1. 2 V

CTRL

CTRL

ERR

ERR

IN

IN

USE

USE

FAN

FAN

ERR

ERR

S1 S2 S3 S4 S5 S6

Matrix

Matrix

+28 V

+28 V

+2.5 V

+2. 5 V

+1.2 V

+1. 2 V

CTRL

CTRL

ERR

ERR

IN

IN

USE

USE

FAN

FAN

ERR

ERR

Matrix

Matrix

+28 V

+28 V

+2. 5 V

+2. 5 V

+1. 2 V

+1. 2 V

CTRL

CTRL

ERR

ERR

IN

IN

USE

USE

FAN

FAN

ERR

ERR

S1 S2 S3 S4 S5 S6

Matrix

Matrix

+28 V

+28 V

+2. 5 V

+2. 5 V

+1. 2 V

+1. 2 V

CTRL

CTRL

ERR

ERR

IN

IN

USE

USE

FAN

FAN

ERR

ERR

Matrix

Matrix

+28 V

+28 V

+2. 5 V

+2. 5 V

+1. 2 V

+1. 2 V

CTRL

CTRL

ERR

ERR

IN

IN

USE

USE

FAN

FAN

ERR

ERR

S1 S2 S3 S4 S5 S 6

+28

+5

+3

+28

+5

+3

COMMUNICA TIO NS

RX RX LNK VT2

TXPRC

TX422 A CTNET

COMMUNICA TIO NS

RX RX LNK VT2

TXPRC

TX422 A CTNET

VT1

VT1

RESETACTIVE

RESETACTIVE

CONTR OL S TATU S

8 8 8 8 8 8 8 8

MATRIX FRA ME CO NT RO LLER

CONTR OL S TATU S

8 8 8 8 8 8 8 8

MATRIX FRA ME CO NT RO LLER

RX

SCROLL

TX

RX

SCROLL

TX

8-Position DIP Switch (2)

Power Supply Modules (2)

and Power Supply

Backplane (1)

(Power Supply Modules

Shown In Phantom, To Allow

View Of 8-Position DIP

Switch Located On Each

Power Supply Backplane)

144X144 Matrix CCAs (4) and

Matrix Backplanes (1)

(Matrix CCAs Shown Smaller

Than Actual Size To Allow View

Of Rotary Switches, S1 Thru S6,

Located On Matrix Backplane)

144X144 Matrix CCAs (16) and

Matrix Backplanes (4)

(Matrix CCAs Shown Smaller

Than Actual Size To Allow

View Of Rotary Switches, S1

Thru S6, Located On Each

Matrix Backplane)

Card Slot Not Populated

(For Future Use)

Rotary Switches (10) For Chassis

Strobe Configuration

Fuses (Blade Type)

Frame Controller CCA

One or Two (For Redundancy)

Proprietary Information of PESA 2-2

Matrix

Matrix

Matrix

+28 V

+2. 5 V

+1. 2 V

CTRL

ERR

IN

USE

FAN

ERR

Matrix

+28 V

+28 V

+2. 5 V

+2.5 V

+1. 2 V

+1.2 V

CTRL

CTRL

ERR

ERR

IN

IN

USE

USE

FAN

FAN

ERR

ERR

S1 S2 S3 S4 S5 S 6

Matrix

Matrix

+28 V

+2. 5 V

+1. 2 V

CTRL

ERR

IN

USE

FAN

ERR

Matrix

+28 V

+28 V

+2. 5 V

+2.5 V

+1. 2 V

+1.2 V

CTRL

CTRL

ERR

ERR

IN

IN

USE

USE

FAN

FAN

ERR

ERR

S1 S2 S3 S4 S5 S 6

Matrix

Matrix

+28 V

+2. 5 V

+1. 2 V

CTRL

ERR

IN

USE

FAN

ERR

+28 V

+28 V

+2.5 V

+2. 5 V

+1.2 V

+1. 2 V

CTRL

CTRL

ERR

ERR

IN

IN

USE

USE

FAN

FAN

ERR

ERR

S1 S2 S3 S4 S5 S6

Matrix

+28 V

+2. 5 V

+1. 2 V

CTRL

ERR

IN

USE

FAN

ERR

+28 V

+28 V

+2.5 V

+2. 5 V

+1.2 V

+1. 2 V

CTRL

CTRL

ERR

ERR

IN

IN

USE

USE

FAN

FAN

ERR

ERR

Matrix

Matrix

S1 S2 S3 S4 S5 S6

Matrix

+28 V

+2. 5 V

+1. 2 V

CTRL

ERR

IN

USE

FAN

ERR

Matrix

+28 V

+2. 5 V

+1. 2 V

CTRL

ERR

IN

USE

FAN

ERR

Figure 2-1 - 864XR Chasssis – Front View

Matrix

+28 V

+2. 5 V

+1. 2 V

CTRL

ERR

IN

USE

FAN

ERR

144X144 Matrix CCAs (16) and

Matrix Backplanes (4)

(Matrix CCAs Shown Smaller

Than Actual Size To Allow

Matrix

+28 V

+2. 5 V

+1. 2 V

CTRL

ERR

IN

USE

FAN

ERR

View Of Rotary Switches, S1

Thru S6, Located On Each

Matrix Backplane)

Page 9

C

HEETAH

864XR V

IDEO MATRIX SWITCHER

Publication 81-9059-0595-0, Rev. C

October 2010

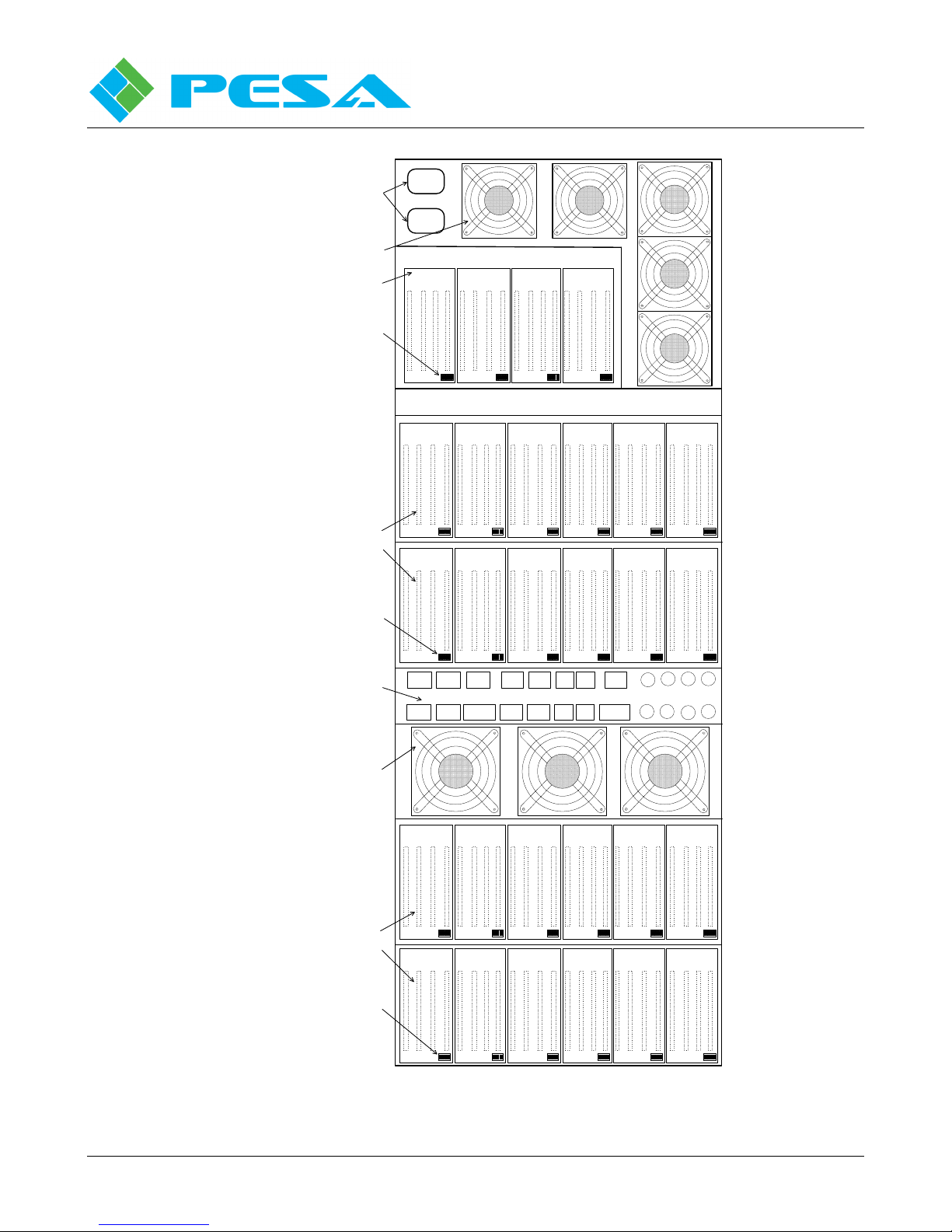

PWR

Primary Power

Input Cables

Chassis Cooling

Fans

I/O CCAs (16) and

I/O Backplanes (4)

8-Position

DIP Switch

1

PWR

2

INPUT/OUTPU T CARD SLOT NUM BER

4 3 2 116 15 14 13 12 11 10 9 8 7 6 5

I/O CCAs (48) and

I/O Backplanes (12)

8-Position

DIP Switch

System Connectors

Panel

Chassis Cooling

Fans

40 39 38 37

1

64 63 62 61

1

COM1

COM4

8

8

8

RCP1 RCP2

RCP3 RCP4

1

1

1

8

8

8

NET

NET NET

1

8

8

COM3

PRC

1

8

INPUT/OUT PUT CARD SLOT NU MBER

36 35 34 33 32 31 30 29 28 27 26 25

1

INPUT/OUT PUT CARD SLOT NU MBER

60 59 58 57 56 55 54 53 52 51 50 49

1

Alarm AlarmCOM2

CONTROL INPU T / OUTPUT CONNECTORS

PRC Loop

1

8

171824 23 22 21 20 19

Mon1

Mon3

Mon2

Mon4

81

414248 47 46 45 44 43

81

181

8

181

8

NET

REF1 REF2

AUX F.C.

I/O CCAs (48) and

I/O Backplanes (12)

Proprietary Information of PESA 2-3

INPUT/OUT PUT CARD SLOT NU MBER

INPUT/OUT PUT CARD SLOT NU MBER

108 107106105 104 103102 101 100 99 98 97

8-Position

DIP Switch

112 111 110109

Figure 2-2 - 864XR Chassis – Rear View

656672 71 70 69 68 6788 87 86 85 84 83 82 81 80 79 78 77 76 75 74 73

8181818181 81

89

9096 95 94 93 92 91

8181818181 81

Page 10

C

HEETAH

864XR V

Publication 81-9059-0595-0, Rev. C

IDEO MATRIX SWITCHER

October 2010

2.2 R

The 864XR Frame is configured using combinations of the following Core System Components:

Input Circuit Card Assembly

Matrix Circuit Card Assembly

Output Circuit Card Assembly

Power Supply Module

Control System (System Controller CCA and Frame Controller CCA)

Each core component is identified and a very brief look at the function of each is provided in the

following paragraphs.

2.2.1 I

As the name implies, the Input Circuit Card Assembly (CCA), often referred to simply as the input card,

is the entry point for video signals into the routing switcher matrix. Each input card accepts up to 16

video input signals from various sources. There are six input card variations in the Cheetah Series

product line, to accommodate different input signal types.

Each input card, regardless of signal type, contains the cable equalization circuitry, buffer amplifiers

and signal drivers used to condition the incoming signal prior to entering the switching matrix. Each

input card also contains circuitry to monitor the status of the input channels, power rails and other

operational functions.

EVIEW OF CORE SYSTEM COMPONENTS

NPUT CIRCUIT CARD ASSEMBLY

Input cards are physically attached to the rear panel of the chassis frame and provide the input

connectors for attaching signals to the switcher. Each card is equipped with two status LEDs on the edge

of the assembly close to the bottom input connectors. The user can very quickly perform a visual

assessment of the status of the input cards by observing the state of the LEDs.

2.2.2 M

Each Matrix Card is where the actual crosspoint switching function takes place. In all Cheetah

variations, the matrix cards are installed inside the chassis frame and are accessible by opening the front

access door. Each card is equipped with LEDs on the assembly edge so that the user can quickly assess

the status of each matrix card in the system with a visual inspection.

2.2.3 O

The Output Card is the exit point for video signals leaving the routing switcher and each card provides

up to 16 video output channels. There are seven output card variations to accommodate different signal

output types.

Each output card contains the necessary channel combiner circuitry, buffer amplifiers, re-clocking

circuitry and driver amplifiers to generate the signal output for each channel. Voltage comparators

monitor the status of the power rails. On-board programmed logic circuitry interprets data from the

comparators along with data relevant to the status of the output channels and other card operational

functions to provide a real-time status monitor as to the health of each output card.

Output cards are physically attached to the rear panel of the chassis frame and provide the connectors

for accessing the signal outputs from the switcher. Each card is equipped with two status LEDs on the

edge of the assembly close to the bottom connectors. The user can very quickly perform a visual

assessment of the status of the output cards by observing the state of the LEDs.

ATRIX CIRCUIT CARD ASSEMBLY

UTPUT CIRCUIT CARD ASSEMBLY

Proprietary Information of PESA 2-4

Page 11

C

HEETAH

864XR V

Publication 81-9059-0595-0, Rev. C

IDEO MATRIX SWITCHER

October 2010

2.2.4 P

Cheetah video routing switchers use common 600 Watt power supply modules that provide a fully

regulated source of +28 VDC @ 22A for powering system components. The number of power supply

modules used in a frame is dependent on several factors including the number of input, matrix and

output cards required for system capacity and whether or not power redundancy is desired. Up to 8

Power Supply Modules may be installed in the 864XR Frame.

All of the power supply modules are physically and electrically identical. Each module is “hotswappable” for easy removal and replacement without any disruption of switcher outputs. Circuitry

internal to the power supply continuously monitors the operational parameters, output voltage and

current level and the module operating temperature. Three LED display devices on the front panel of

each module allow the user to quickly perform a visual assessment of the status of each supply module

by observing the state of the LEDs.

2.2.5 C

Every switcher configuration requires a Control System. In the Cheetah family there are two core

components of the control system that reside within the chassis frame: the System Controller Card and

the Frame Controller Card.

The System Controller Card resides in the matrix switcher frame, however the term System Controller

refers collectively to the System Controller CCA and its associated board-resident firmware and a

software application that runs on a Microsoft Windows based PC platform. In the Cheetah product line

there are two variations of System Controllers: the 3500PRO and the PERC2000. Regardless of which

control system is used (3500 or PERC), at least one system controller card must be installed in the

chassis frame. Each chassis frame can support up to two system controller cards although only one

controller card is required. A second system controller card may be installed for redundancy capability.

OWER SUPPLY MODULE

ONTROL SYSTEM

The Frame Controller Card also resides in the matrix switcher frame. Just as with the system controller

card, each chassis frame can support up to two frame controller cards, although only one is required. A

second frame controller card may be installed for redundancy capability.

Consider the System Controller to be the master overseer of the entire system. The system controller

card communicates bi-directionally with the frame controller circuitry. Think of the Frame Controller

as a slave that is subservient to its master – the System Controller. The Frame Controller circuitry

orchestrates all system switching commands and all other control functions for the entire switcher

frame. It is the job of the System Controller to keep the entire system running as it is programmed to

do. The System Controller provides programming functions and interface functions to various types of

control panels that may be used by facility operators to control operations of the entire switching

system. Also, the system may be operated from a Windows based PC interfaced to the system

controller and running the controller software application.

2.2.6 B

Note in Figure 2-1 that there are two power supply modules residing on each power supply backplane

along with an 8-position DIP switch; and four matrix cards residing on each matrix backplane along

with six rotary switches (S1 thru S6). In addition to the switches on the backplanes, also note the ten

rotary switches used for chassis strobe configuration.

Figure 2-2 illustrates the rear panel of the chassis frame where the input and output cards are installed.

Note in this figure that up to four input or output cards may reside on each I/O Backplane and that each

backplane contains an 8-position DIP switch.

ACKPLANES

Proprietary Information of PESA 2-5

Page 12

C

HEETAH

864XR V

Publication 81-9059-0595-0, Rev. C

IDEO MATRIX SWITCHER

October 2010

The DIP switches and rotary switches on the various backplanes and in the chassis frame are factory set

to assign operational parameters to the system components. The switch settings assign such things as

what channel numbers a bank of input or output cards will service, frame type, number of cooling fans,

etc. Although the switches are set at the factory for every system, a guide to the proper settings for each

switch peculiar to the 864XR Frame is included in Chapter 5 of this manual. This scheme of assigning

identification to the backplane and interface ports allows full interchangeability between like CCAs in

the system.

In every frame variation the input cards and the output cards are loaded through the rear panel card

chassis into mating connectors located on an I/O backplane. Each card chassis is configured using I/O

backplanes with four cards installed to each. All slots may or may not be used in a particular system

dependent on the number of input and output channels and whether or not the output cards are fitted

with option cards. When option cards are used, each output card will occupy two slots in the card

chassis. In a typical Cheetah system, the input cards and output cards will be co-resident in the card

chassis. Be aware that although input cards and output cards can be co-resident in the card chassis, they

CAN NOT be co-resident on the same backplane. Each I/O backplane in the chassis is designated as

either an input or an output backplane.

2.3 864 XR F

Physical

RUs....................................................................................................................................... 41

Height .............................................................................................................................71.75"

Width ...................................................................................................................................19"

Depth....................................................................................................................................23"

Weight...........................................................................................625 lbs. (281.25 kg) nominal

............................................................................ (May weigh less depending on configuration)

Supply Power Requirements

Operating voltage ..................................................................................95-240 VAC, 47-63 Hz

Power consumption .................................................................... 2500W Nominal, 6000W Max

Power Supplies

DC Input (from the source rectification filter/breaker assy.) .......................95 VDC to 240 VDC

DC Output.................................................................................................................... 28 VDC

Maximum Output Watts ............................................................................................ 600 Watts

Digital Electrical Signals for Inputs

Standards:.................................................. High Definition video conforming to SMPTE 292M

......................................................................Serial Digital video conforming to SMPTE 259M

Connector Type: .......................................................................................................75Ω BNC

Impedance: ..........................................................................................................75Ω nominal

Return Loss:...................................................................... HD >15 dB from 5MHz to 1.5 GHz

......................................................................................... SD >15 dB from 5 MHz to 540 MHz

Cable Equalization: ............................................HD Automatic up to 100 meters, Belden 8281

...........................................................................SD Automatic up to 300 meters, Belden 8281

RAME SPECIFICATIONS

Proprietary Information of PESA 2-6

Continued

Page 13

C

HEETAH

864XR V

Publication 81-9059-0595-0, Rev. C

IDEO MATRIX SWITCHER

October 2010

864 XR Specifications (cont.)

Electrical Signals for Outputs

Connector Type: ...................................................................................75Ω BNC (output card)

...................................................................................................... 75Ω BNC (dual output card)

Signal Level: ..............................................................................................800 mV p-p, ±10%

Signal Polarity: ..........................................................Non-inverting with respect to input ports

Impedance: ...........................................................................................................75Ω nominal

Return Loss:....................................................................... HD >15 dB from 5MHz to 1.5 GHz

.......................................................................................... SD >15 dB from 5MHz to 540 MHz

Optical Signals (Fiber Optics) for Inputs (Receivers)

Connector Type: .............................................................. SFP modules w/LC-type (fiber card)

Data Rates:...........................................................................................1.0 Mbps to 1.485 Gbps

Optical Input Wavelength...........................................................Single Mode, 1200 to 1600 nm

Input Power............................................................................................... -20 dBm (minimum)

Optical Signals (Fiber Optics) for Outputs (Transmitters)

Connector Type.................................................................SFP modules w/LC-type (fiber card)

Data Rates:..............................................................................................1 Mbps to 1.485 Gbps

Optical Output Wavelength....................................................... Single Mode, 1310 nm, ±20 nm

Output Power ...............................................................................................................-11 dBm

Optical Loss Budget

10,000 km (minimum), Single Mode fiber w/2 optical couplings...................... 9 dB (minimum)

Signal Operational Specifications

Polarity: ............................................................................................... All paths non-inverting

Re-clocking SD: ...................................Automatic selection of 143 Mb/s, 177 Mb/s, 270Mb/s,

...................................................................................................................360 Mb/s, 540 Mb/s

Re-clocking HD: ................. Automatic selection of 143 Mb/s, 177 Mb/s, 270 Mb/s, 360 Mb/s,

.............................................................................................................. 540 Mb/s and 1.5 GB/s

Reference (Sync) Inputs

No. of Inputs: ............................................................................................................ 2 standard

Connector: .................................................................................................................75Ω BNC

Return Loss: ............................................................................... > 40 dB, 100 KHz to 30 MHz

Signal Formats: ..................................................... NTSC, PAL (Black Burst), or HD Tri-Level

....................................................................................... Sync per SMPTE 274, SMPTE 276 M

Signal Level: .......................................................................................Nominal 1.0 V p-p ±6dB

Continued

Proprietary Information of PESA 2-7

Page 14

C

HEETAH

864XR V

Publication 81-9059-0595-0, Rev. C

IDEO MATRIX SWITCHER

October 2010

864 XR Specifications (cont.)

DAC Card Specifications

Connector Type: .......................................................................................................75Ω BNC

Connection/Card: ................................................................................... 16 Individual Outputs

Conversion: ................................................................................10 bit Serial Digital to Analog

Over sampling:..................................................................................................................... 4X

Output:....................................................................................................................NTSC/PAL

Cooling

Internal cooling fans with auto sensing speed adjustments

Control

Panel Com:...........................................................................RS-485, 3 pin WECO, 4 per frame

Control Com:...................................................... RS-232 or PESA PRC for 3500 Series System

Connector Type:......................................................................................... 9 pin, D sub, female

Network Connector: ......................................................................RJ-45, Ethernet, 2 per frame

Environmental

Operating Temperature:.................................................................................................0-40 °C

Operating Humidity:.............................................................................10-90% non condensing

Standard Analog Video Input Characteristics

Level:....................................................................................1.0V P-P nominal, 2.0V P-P max.

............................................................................................. (Without obvious distortion)

Impedance:.........................................................................................75Ω internally terminated

Return Loss:..................................................................................................> 40 dB to 5 MHz

.....................................................................................................................> 15dB to 50 MHz

Coupling:.................................................................................................................Direct (DC)

Type:...........................................................................................................................Balanced

Connector:......................................................................................................................... BNC

Standard Analog Video Output Characteristics

Level:....................................................................................1.0V P-P nominal, 2.0V P-P max.

............................................................................................. (Without obvious distortion)

Impedance:.........................................................................................75Ω internally terminated

Return Loss:............................................................................................... > 40 dB to 5.0 MHz

.................................................................................................................... > 15 dB to 50 MHz

Coupling:.................................................................................................................Direct (DC)

DC on Out:................................................................................................................. <±30 mV

Connector:......................................................................................................................... BNC

Number:.....................................................................................................One (Two Optional)

Proprietary Information of PESA 2-8

Continued

Page 15

C

HEETAH

864XR V

Publication 81-9059-0595-0, Rev. C

IDEO MATRIX SWITCHER

October 2010

864 XR Specifications (cont.)

Standard Analog Video Gain Characteristics

Gain: ................................................................................................................................ Unity

Gain Stability: .................................................................................................... <±0.1 dB max.

Gain Adjust Range: .......................................................................................................±0.5 dB

Standard Analog Video Linear Distortion

Frequency Response:................................................................................... ±0.1 dB to 10 MHz

.................................................................................................................... ±0.5 dB to 35 MHz

..................................................................................................................... -3.0 dB @50 MHz

Vertical Tilt:.................................................................................. 0.25% (50 Hz Square Wave)

Horizontal Tilt:................................................................................................................ 0.25%

Low Frequency:................................................................ +0.2% /ms max with 10% Overshoot

.......................................................................................................(10-90% or 90-10% change)

Standard Analog Video Pulse and Bar Responses

Factor (2T) Bar Slope:................................................................................................... 0.2% K

Pulse/Bar Ratio:............................................................................................................. 0.2% K

Pulse Sharp:................................................................................................................... 0.2% K

Standard Analog Video Chrominance/Luminance

Gain Inequity:......................................................................................................... ±1.0% max.

Delay Inequity:...............................................................................................................±1.0 ns

Standard Analog Video Non-Linear Distortions

Note: All tests: 10 to 90% @ 3.58MHz or 12.5 to 87.5% @ 4.43Mhz.

Differential Gain:........................................................................................ 0.25% @ 4.43 MHz

Envelope Delay:...............................................................................<2.0ns, 50MHz to 85 MHz

Differential Phase:........................................................................................0.25° @ 4.43 MHz

Line Time Non-Linearity:..................................................................................................0.2%

Transient Gain:......................................................... 1.0% (Luminance, Chrominance, or Sync)

Video o Video Crosstalk:..........................≤ -60 dB to 5.0 MHz (all Inputs and Outputs Hostile)

.................................................................................................................. ≤ -35 dB @ 35 MHz

Standard Analog Video Switching Characteristics

Switching Time:............................................................................................................≤ 1.0 µs

Switching Transient:................................................................................22 mV (30 IRE Units)

Differential Delay (any Input to any Output)........................................................ Approx. 8.5ns

........................................................................................................................11° @ 3.58 MHz

......................................................................................................................13.5° @4.43 MHz

Standard Analog Video Signal to Noise

Video Filter:.........................................................-70 dB RMS Noise to P-P Signal to 5.0 MHz

Proprietary Information of PESA 2-9

Continued

Page 16

C

HEETAH

864XR V

Publication 81-9059-0595-0, Rev. C

IDEO MATRIX SWITCHER

October 2010

864 XR Specifications (cont.)

High-Level Analog Video Input Characteristics

Level:..............................................................................................±5.0 V, Referred to Ground

Impedance:.........................................................................................75Ω internally terminated

Return Loss:............................................................................................... > 40 dB to 5.0 MHz

.................................................................................................................... > 15 dB to 50 MHz

Coupling:.................................................................................................................Direct (DC)

Type:...........................................................................................................................Balanced

Connector:......................................................................................................................... BNC

High-Level Analog Video Output Characteristics

Level:..............................................................................................±5.0 V, Referred to Ground

Impedance:.........................................................................................75Ω internally terminated

Return Loss:............................................................................................... > 40 dB to 5.0 MHz

.................................................................................................................... > 15 dB to 50 MHz

Coupling:.................................................................................................................Direct (DC)

DC on Out:................................................................................................................. <±50 mV

Connector:......................................................................................................................... BNC

Number:.....................................................................................................One (Two Optional)

High-Level Analog Video Gain Characteristics

Gain: ................................................................................................................................ Unity

Gain Stability: .............................................................................................................<±0.1 dB

Gain Adjust Range: .......................................................................................................±0.5 dB

High-Level Analog Video Linear Distortion

Frequency Response:................................................................................... ±0.1 dB to 10 MHz

.................................................................................................................... ±0.5 dB to 35 MHz

..................................................................................................................... -3.0 dB @50 MHz

Vertical Tilt:.................................................................................. 0.25% (50 Hz Square Wave)

Horizontal Tilt:................................................................................................................ 0.25%

Crosstalk: ............................................. <± -60 dB to 5.0 MHz (All Inputs and Outputs Hostile)

................................................................................................................ <± -35 dB @ 35 MHz

High-Level Analog Video Signal to Noise

Signal to Noise:.................................................. -70 dB, RMS Noise to P-P Signal to 5.0 MHZ

Proprietary Information of PESA 2-10

Page 17

C

HEETAH

864XR V

Publication 81-9059-0595-0, Rev. C

IDEO MATRIX SWITCHER

October 2010

All Cheetah video matrix switchers offer alarm support, switch confirmation, block checking, and

power-out-of-range indicators. Features include:

• Full feature control system using either standard PESA PRC Control or PESA Network Control

• Video and data signal from 3Mb/s to 1.5 GB/s

• Conforms to SMPTE 259M and 292M

• Input EQ to 300M SD, 100M HD

• Bypass mode for non-standard data signals

• Full redundant controllers available

• N+1 redundant internal DC power; full redundant AC power

• All modules are hot-swappable for on-air maintenance

Proprietary Information of PESA 2-11

Page 18

C

HEETAH

864XR V

Publication 81-9059-0595-0, Rev. C

IDEO MATRIX SWITCHER

October 2010

Chapter 3: Installation

3.1 U

3.2 G

NPACKING AND INSPECTION

This equipment contains electrostatic sensitive devices (ESD). Use a grounded

wrist strap, grounding mat, and/or comply with local established ESD

procedures when handling the internal circuit cards to prevent destruction

from electrostatic discharge.

Immediately upon receipt, inspect all shipping containers. Carefully unpack the equipment and

compare the parts received against the packing list. If any parts appear to be missing or damaged,

please contact PESA immediately.

ENERAL CHASSIS INSTALLATION OVERVIEW

The physical size of each Cheetah Series Switcher chassis is determined by the chassis input/output

capabilities. If specified when ordered, each Cheetah Switcher will be configured for the intended

system at the factory. Before attempting to install any frame, matrix card, controller card, or power

supply, carefully read and understand this section.

All Cheetah Switchers contain electrostatic sensitive devices (ESD). Care

should be used when it is necessary to handle the internal circuit cards. It is

recommended that a grounded wrist strap and grounding mat be used before

attempting any equipment installations.

3.3 C

HOOSING A LOCATION

For local electrical compliance, this equipment should be located near the

primary power disconnect/breaker so that the AC supply disconnect is

easily accessible.

This equipment is designed for installation in a standard 19" equipment rack located in an environment

conforming to the specifications for each chassis. Locate each unit as close as possible to its associated

equipment to minimize cable runs.

Consider the connection from this equipment to the supply circuit, and the effect that possible

overloading can have on overcurrent protection circuits and supply wiring. Refer to nameplate ratings

when addressing this concern.

Proprietary Information of PESA 3-1

Page 19

ully loaded 864XR chassis frame exceeds 650 lbs nominal.

airflow around these fans. Replace all service panels and blank filler plates.

C

HEETAH

864XR V

Publication 81-9059-0595-0, Rev. C

IDEO MATRIX SWITCHER

October 2010

3.4 M

OUNTING THE

864XR C

HASSIS IN AN EQUIPMENT RACK

The weight of a f

Installation or removal of this equipment requires at least four persons in

order to avoid possible personal injury or equipment damage. Install this

equipment in such a manner as to avoid any tipping hazard from uneven

loading of the equipment.

Make sure that all power is disconnected and the chassis breakers are in the

OFF position before installing the specific frame into the rack.

Fans mounted on this equipment provide forced-air cooling. Do not block

Keep the front access door closed during normal operation.

This equipment is designed for installation in a standard 19" equipment rack. Provide sufficient space

behind the equipment racks to allow for control, signal, and power cables. Use all chassis mounting

holes, and tighten mounting hardware securely by using the rack equipment manufacturer’s suggested

torque settings.

This unit is extremely heavy. Maneuvering and installation of this unit

requires caution, planning, and adequate resources in order to prevent injury

to personnel and/or damage to the equipment. It is strongly suggested to

implement as many persons, jacks, blocks, etc., as possible to eliminate any

unsafe condition that could result during the chassis mounting phase of

installation.

Proprietary Information of PESA 3-2

Page 20

C

HEETAH

864XR V

Publication 81-9059-0595-0, Rev. C

IDEO MATRIX SWITCHER

October 2010

3.4.1 C

HEETAH CHASSIS MOUNTING PROCEDURE

The following steps should be performed to reduce the weight of the system thus making it slightly

easier to maneuver.

1. Have the wooden shipping crate standing upright before opening the crate.

2. Remove all the lag bolts from the top and sides of the wooden crate.

3. Using ESD precautions, remove the power supply modules from the top of the unit.

Prior to performing the next sequence, careful measurements should be

completed to insure the proper location and alignment of equipment rack’s

screw holes to the Cheetah chassis.

4. Using a pallet jack or similar equipment, align and place the 864XR Chassis as close as possible

to the equipment rack opening where it will be installed.

5. Using as much manpower as necessary, CAREFULLY move the 864XR chassis from the

wooden pallet to the equipment rack and slide the chassis into position in the rack.

6. With the chassis installed in the equipment rack, install the rack screws in the chassis ensuring

that the unit is firmly and adequately secured to the equipment rack.

Proprietary Information of PESA 3-3

Page 21

C

HEETAH

864XR V

Publication 81-9059-0595-0, Rev. C

IDEO MATRIX SWITCHER

October 2010

3.5 C

ONNECT EQUIPMENT CABLES

Once the Cheetah Video Matrix Frame is installed in the equipment rack, the associated system

connections can be completed. The order of completion of installation steps is not critical, however,

DO NOT apply power to a frame until all of the video signal, sync and control cables have been

installed and their connections verified for proper placement and accuracy. Use the following guide to

insure that all connections are made properly and that power, system interconnect and video signal

cables are correctly installed.

Use the following guidelines when connecting equipment cables:

Install the equipment in the rack before connecting cables.

Relieve strain on all cables to prevent connector separation.

To the greatest extent possible, separate control, signal, and power cables to minimize any possible

crosstalk or interference.

Use as many cable ties as necessary to secure cables to the rack, as shown in Figure 3-1. This will

provide cable strain relief and help route cables away from hazardous areas.

Route cables away from physical traffic areas to avoid creating a safety hazard (trip or shock).

3.6 C

HEETAH CHASSIS SUPPLY POWER CONNECTIONS

The 864XR chassis frame has two AC (or DC) primary power input cables. As shown in Figure 3-2,

each AC power input is rectified and routed to the filter assembly.

Proprietary Information of PESA 3-4

Figure 3-1 - Cables Attached To Supports

(US M

ODELS

)

Page 22

across both AC power inputs must not exceed 250VAC at any time.

C

HEETAH

864XR V

IDEO MATRIX SWITCHER

Publication 81-9059-0595-0, Rev. C

October 2010

D

Perform voltage measurements A thru D, between the

C

points indicated by arrows using an AC Voltmeter. ALL

B

measurements must be less than, or equal to, 250VAC.

A

PRIMARY

POWER

INPUT 1

(PIGTAI L)

PRIMARY

POWER

INPUT 2

(PIGTAI L)

RECTIFIER MODULE 1

CHASSIS

FRAME

AC BREA KER 1

RECTIFIER MODULE 2

CHASSIS

FRAME

AC BREA KER 2

POWER FILTER MODULE

V DC OUT TO

POWER SUPPLY

MODULES

Figure 3-2 - Power Supply Configuration (US Models)

WARNING: The maximum applied voltage to either of the AC power

inputs must not exceed 250VAC. In addition, the maximum applied voltage

Whenever two phases of a three-phase power source are applied using

different phases on each power input, the voltage between the phases must

not exceed 250VAC. Failure to heed this warning will result in serious

equipment damage.

Figure 3-3 depicts a typical two-phase and three-phase AC line-phasing scenario. Note that in the threephase line voltage, each voltage phase is 120 degrees out of phase with the other two voltage phases.

Proprietary Information of PESA 3-5

Page 23

has an interface solution to address your needs.

protection devices in the supply circuitry of any Cheetah series systems.

C

HEETAH

864XR V

IDEO MATRIX SWITCHER

Publication 81-9059-0595-0, Rev. C

October 2010

A B

250VAC

MAX

A C

250VAC

MAX

B C

250VAC

MAX

A B C

AC Power IN

3 Phase; 120 degrees apart

MAX 250VAC between any two phases

Figure 3-3 - Phase Relationships

Additionally, systems with one AC power input supplied from a normal, “in-house” AC line

and the other AC power input supplied from an external generator must insure that, regardless

of the voltage-phase relationship between the external generator and the “in house” AC line,

the maximum applied voltage between the two AC power inputs does not exceed 250VAC.

3.6.1 864XR F

If your application requires two independent phases, which exceed the

250VAC maximum, PESA

Please contact your PESA dealer or Area Sales Manager.

Additionally, it is NOT recommended to use single-phase GFCI circuit

Due to unbalanced currents in the neutral circuitry, single-phase GFCI

devices will typically trip. However (if employed), a three-phase GFCI

breaker will not trip except under fault conditions.

RAME PRIMARY POWER

Make sure that all power is disconnected and the chassis breakers are in the

OFF position before completing the specific power connections.

To prevent damage to the equipment:

•

Read all instructions for proper input voltage ranges.

•

Use only a power circuit with the specified current capacity.

•

Follow static prevention precautions prior to handling equipment.

Proprietary Information of PESA 3-6

Page 24

Green/Yellow

3.6.1.1 Power Cabling and Circuit Breakers

The 864XR chassis is supplied with a power cabling assembly (see Figure 3-4) that meets and/or

exceeds the requirements for dedicated input service lines rated for 200-240VAC at 30 amps

minimum. Two main circuit breakers are mounted on the front side of the 864XR frame in the

upper left corner. Table 3-1 describes the power connections for the associated pigtail cabling

conductors.

Table 3-1 - Pigtail Cabling Conductor Power Connections

Color Code 200-240V

Green/Yellow Stripe Safety Ground

Blue AC Line

Brown AC Line

Stripe

C

HEETAH

864XR V

Publication 81-9059-0595-0, Rev. C

IDEO MATRIX SWITCHER

October 2010

Blue

Brown

Figure 3-4 - Pigtail Cabling Conductors

3.6.1.2 External AC Power Requirements

Each 864XR chassis is supplied with pigtail cabling (see Figure 3-4 and refer to Tables 3-1) rated for

200-240VAC at 30 amps. The router is to be connected only to a dedicated service line capable of

providing the power source specified in Table 3-2.

Table 3-2 - AC Power Filter Assembly

Minimum Amps

AC Power Cable

Required

200-240V Attached Power Cable Pigtails 30A Service

Service Drops

1-Standard

1-Redundant

3.7 I

NTERNATIONAL POWER REQUIREMENTS FOR CHEETAH CHASSIS

All 864XR frames have two AC (or DC) main power feeds. For international use only, these power

feeds are isolated from each another through a special wiring configuration that is completed at the

factory (Figure 3-5).

Proprietary Information of PESA 3-7

Page 25

the other AC power input must not exceed 380VAC nominal at any time.

C

HEETAH

864XR V

IDEO MATRIX SWITCHER

Publication 81-9059-0595-0, Rev. C

October 2010

AC

AC

2

Filter

1

AC 1

Breaker

AC 2

Breaker

Bridge

Rectifier

Bridge

Rectifier

Output VDC

Filter

Output VDC

(-)

(+)

(-)

(+)

½ of

Cheetah’s

Power

Supply Bank

½ of

Cheetah’s

Power

Supply Bank

Figure 3-5 - International Power Supplies Configuration

In each Cheetah assembly, the entire power supply backplane is divided in half and each half is powered

and isolated separately. The following apply to the Cheetah international supply power inputs:

•

Two banks of power supplies are required in each Cheetah switcher assembly and each bank

must be capable of supplying ALL of the power that is required by the specific Cheetah

switcher.

•

Both banks must be powered under normal conditions.

•

Loss of either AC supply power feed is considered a fault condition.

•

When experiencing a loss of one AC supply power feed (fault condition), the remaining

supplies will typically operate at 100% of their rated load. An increase in chassis operating

temperature is normal as the supplies are typically changing from approximately 50% load to

approximately 100% of their rated load.

WARNING: The maximum applied voltage between any leg of either of

the isolated AC power inputs must not exceed 250VAC. In addition, the

maximum applied voltage between any leg of one AC input and any leg of

That is, whenever two phases of a three-phase power source is applied using

different phases on each power input, the voltage between the phases must

not exceed 380VAC nominal. Failure to heed this warning will result in

serious equipment damage.

Proprietary Information of PESA 3-8

Page 26

C

HEETAH

864XR V

Publication 81-9059-0595-0, Rev. C

IDEO MATRIX SWITCHER

October 2010

3.8 V

IDEO INPUT/OUTPUT CONNECTIONS

Once the rack frame is mounted and primary power connections have been completed, connecting the

video input and output signals is the next step. Figure 3-6 illustrates the entire rear panel of the router

and features a quick reference guide to the input and output connector configuration. Figures 3-7, 3-8

and 3-9 provide a closer and more detailed view of the rear panel input and output connectors divided

into sections from the top of the switcher to the bottom. Use these references when making video I/O

connections to the 864XR router.

PESA recommends that you make a layout plan and connection drawing to document I/O connections

to the router and follow this drawing when attaching video connectors to the input and output cards.

Retain this documentation in a safe place in the event that service to the router should ever be needed.

PESA also recommends that you label each video cable to identify its source or destination.

Proprietary Information of PESA 3-9

Page 27

C

HEETAH

864XR V

IDEO MATRIX SWITCHER

Publication 81-9059-0595-0, Rev. C

October 2010

CHEETAH 864XR FRAME - REAR VIEW

PWR

1

PWR

2

INPUT/OUTPUT CARD SLOT NUMBER

OUTPUT CHANNELS: 1 - 256

40 39 38 37

INPUT

1 - 64

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50

INPUT/OUTPUT CARD SLOT NUMBER

35 34 33 32 31 30 29 28 27 26 25

OUTPUT CHANNELS 257 - 576

INPUT/OUTPUT CARD SLOT NUMBER

INPUT CHANNELS: 65 - 448

COM1

COM4

COM3

PRC

RCP1 RCP2

Alarm AlarmCOM2

CONTROL INPU T / OUTPUT CONNECTORS

PRC Loop

RCP3 RCP4

NET

NET NET

NET

128 7 6 5 4 316 15 14 13 12 11 10 9

2136

48 47 46 45 44 43 42 41

49

REF1 REF2

AUX F.C.

Mon1

Mon3

Input/Output Connector Channels By I/O Card Slot Number

Quick Reference Chart

INPUT CHANNELS

Input/Outpu t

Card Slot

Number

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

NOTE

Channels

305 - 320

321 - 336

337 - 352

353 - 368

369 - 384

385 - 400

401 - 416

417 - 432

433 - 448

449 - 464

465 - 480

481 - 496

497 - 512

513 - 528

529 - 544

545 - 560

561 – 576

577 – 592

593 - 608

Input

On Card

Input/Outp ut

Card Slot

Input Card Slots are i ndicated by BOLD outlines and

BOLD ITALICS text on the fi gure and in this char t.

Number

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

Input

Channels

On Card

1 - 16

17 -32

33 - 48

49 - 64

65 - 80

81 - 96

97 - 112

113 - 128

129 - 144

145 - 160

161 - 176

177 - 192

193 - 208

209 - 224

225 - 240

241 - 256

257 - 272

273 - 288

289 - 304

Input/Out put

Card Slot

171824 23 22 20 19

OUTPUT CHANNELS

Mon2

Mon4

Input/Outpu t

Card Slot

Number

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Output

Channels

On Card

1 - 16

17 -32

33 - 48

49 - 64

65 - 80

81 - 96

97 - 112

113 - 128

129 - 144

145 - 160

161 - 176

177 - 192

193 - 208

209 - 224

225 - 240

241 – 256

257 - 272

273 - 288

289 - 304

Input/Ou tput

Card Slot

Number

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

93

94

Output

Channels

On Card

305 - 320

321 - 336

337 - 352

353 - 368

369 - 384

385 - 400

401 - 416

417 - 432