Page 1

NOTICE TO PERSONS RECEIVING THIS DRAWING

AND/OR TECHNICAL INFORMATION:

Title:

TUNING PROCEDURE

TR4022

Checkpoint Systems claims proprietary rights to the material disclosed hereon.

This draw in g and/or technical information is issued in confidence for engineering

information only and may not be reproduced or used to manufacture anything

shown or referred to hereon without direct written permission from Checkpoint

Systems to the user. This drawing and/or technical information is the property

of Checkpoint Systems and is loaned for mutual assistance, to be retur ned

when its purpose has been served.

THIS DRAWING AND/OR TECHNICAL INFORMATION IS THE

PROPERTY OF CHECKPOINT SYSTEMS, INC.

Revisions Revisions

Rev Description Date Engineer Rev Description Date Approved

01 ECN 03/28/2000 D. MERVA

USED ON

Doc Spec: Date:

Dwn: J. IANNUZZI Date: 03/29/2000

Chk: J. HUG Date: 03/29/2000

Eng: D. MERVA Date: 03/29/2000

Appd: E. ECKSTEIN Date: 03/29/2000

Size

A

Scale: N/A

Checkpoint Systems, Inc. 2000

Page

1

of

20

Page 2

TUNING PROCEDURE TR4022

TABLE OF CONTENTS

1.0 INTRODUCTION..........................................................................................................3

2.0 SYSTEM DESCRIPTION.............................................................................................3

3.0 SWITCH SETTINGS.....................................................................................................4

Switch 4 – Bin Elimination, Filters, Transmitter setting and Alarm Cycle Select.................................. 8

Switch 5 – System transmit address, Merchandise/Access Card Rejection............................................. 8

Switch 6 – Master/Slave configuration.................................................................................................... 9

Switch 7 – Sweep range select................................................................................................................. 9

4.0 LED DEFINITIONS.................................................................................................10

System Status Indicators........................................................................................................................10

Internal and external Sync and RF indicators – DS8, DS9, and DS10..................................................10

5.0 POTENTIOMETER ADJUSTMENT..........................................................................11

6.0 AUXILIARY CONNECTOR ......................................................................................12

7.0 SCREENS ....................................................................................................................13

8.0 TUNING.......................................................................................................................19

8.1 Master / Slave Setup.....................................................................................................19

8.2 Group Addressing (VERY IMPORTANT).................................................................................... 19

8.3 Slaving............................................................................................................................................ 19

____________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

Rev. 00 Page

2

Page 3

1.0 INTRODUCTION

This document describes the procedures required to properly tune a Strata System with the

TR4022 board. Many of the adjustments for the Strata are pre-tuned during the manufacturing

test process therefore adjustments required in the field have been minimized.

Adjustments such as center frequency and sweep are preset for 8.2 Mhz operation. If the system

is required to detect a different frequency tag the sweep range will need to be readjusted by the

installer.

Once properly configured, if poor performance results, the CSE should direct their efforts toward

finding the source of the interference in the environment. Several test signals are provided by the

TR4022 board, which may be viewed on an oscilloscope. These signals allow the CSE to identify

and measure ambient noise levels, resonances and other sources of environmental interference.

The DSP (digital signal processor) system automatically subtracts stationary resonances seen by

the antennas. The system offers flexibility to adjust for these circumstances. However, the

solution for environmental problems, is to determine the environmental problems and resolve

them. The options for adjusting to environmental problems are performed both in the analog and

digital realm by the technician. The analog solutions are reducing power on the transmit antennas

(2-loop and/or 3-loop), reduce the baseband gain, and adjust the sweep. In the digital toolbox

there are four user selectable filter parameters. These tools should be used only after the CSE has

attempted to correct the environment.

TUNING PROCEDURE TR4022

The Strata system is powered by a +24Vdc power supply, P/N 121878. This power supply can

power up to a maximum of three antennas.

2.0 SYSTEM DESCRIPTION

The Strata system is a transceiver design using both a 3-loop, 2-loop, and a 1-loop antenna design.

The Strata alternates between using the 2-loop antenna and the 3-loop antenna. The 1-loop

antenna is used as a shield that is tied to ground. This technique provides the system with

different views of the detection field allowing the system to improve detection by minimizing the

holes typically found at the crossbars of typical swept antennas.

During an antenna’s cycle, the system performs two “blasts” which are called a “bin”. There are

sixteen bins per frame. A bin consists of two “noise” cycles and two blast cycles, a blast is a

transmit cycle and then a receive cycle. During the noise cycle, the system is not transmitting,

only receiving ambient noise. This allows the system to establish the baseline noise level of the

environment for later comparison. The system then transmits or “pulses” the field and then

receives or “listens” for an echo of a tag signal. This frame is repeated on the other antenna. A tag

response need only be present on one of the antennas to cause an alarm. In effect the system

provides the best of both worlds, a 2-loop and 3-loop design.

____________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

Rev. 00 Page

3

Page 4

The switching between antenna loops minimizes the size of detection holes at the null points of

the RF field.

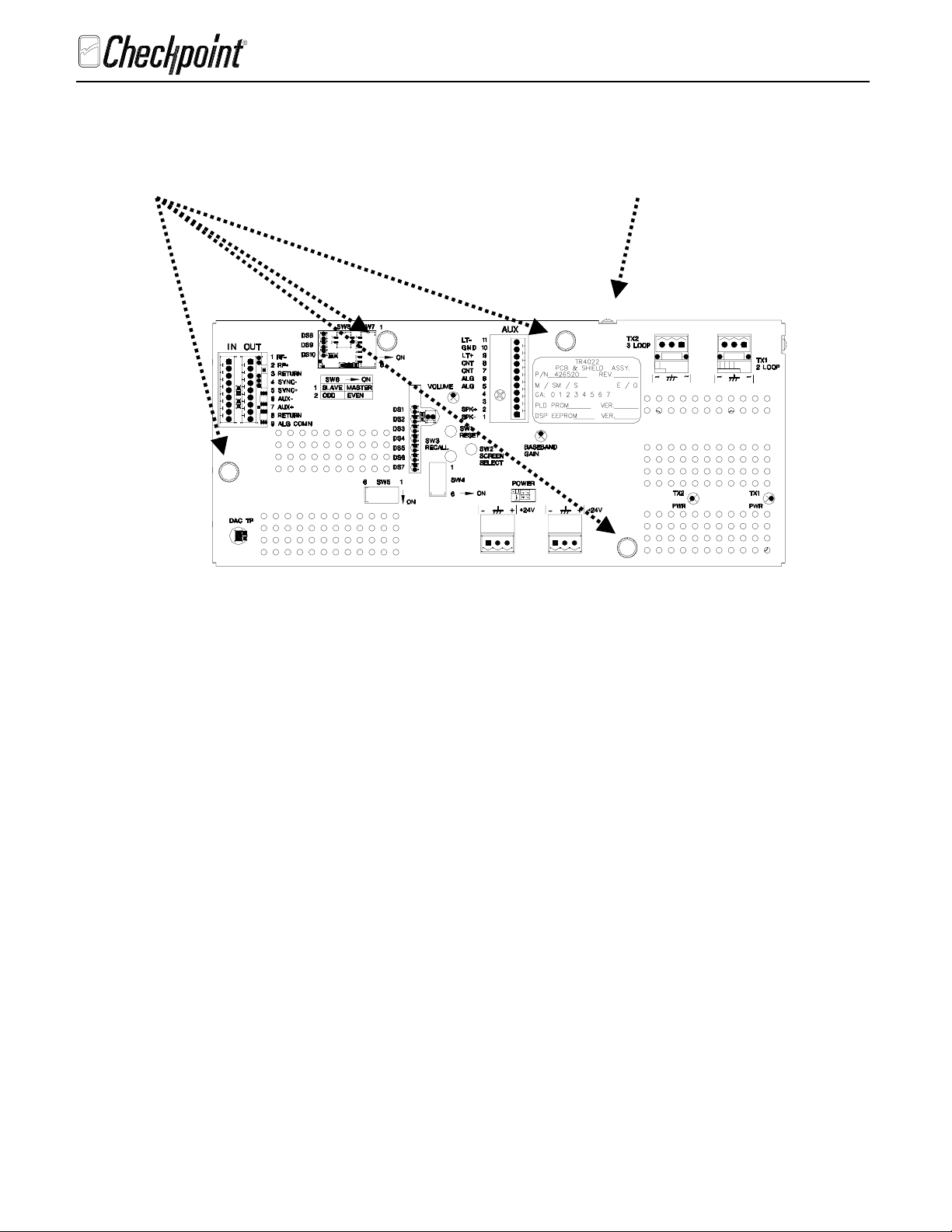

3.0 SWITCH SETTINGS

Table 1 explains each of the jumpers on the TR4022 board and 4.0 explains the switches on the

TR4022 board that must be configured before the system will operate. The illustrations on the

next pages shows the position of the jumpers, switches, and potentiometers on the TR4022 board

used during configuration. The top of the shield is held with 4 thumb turn screws. With the top of

the shield removed all the switches can be set without removing the electronics from the antenna.

If for some reason the circuit board needs to be removed from the antenna housing, remove the

three mounting screws from the backside of the board housing. Removing the rear cover of the

antenna assembly can access them. Before completely removing the electronics package from the

antenna loosen the screw near the TX1 and TX2 antenna connector and remove the spade lug.

MAKE SURE WHEN REINSTALLING THE ELECTRONICS PACKAGE THAT THE SPADE

LUG FROM THE SHORTED TURN IS REINSTALLED IN THE SAME PLACE.

TUNING PROCEDURE TR4022

____________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

Rev. 00 Page

4

Page 5

Thumb

screws for

top cover

TUNING PROCEDURE TR4022

Spade lug for

shorted turn

attaches here

____________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

Rev. 00 Page

5

Page 6

TUNING PROCEDURE TR4022

Slave In/Out

Connections

DS8 – DS10

SW6

DS1 –DS7

SW7

Sounder

Volume

Auxiliary

Connector

Antenna

Connections

R89

Baseband

Gain

DAC

TP16

SW 5 Group Address

& Q Selection

SW 4

SW 1,2,3

DS11 Power

TX1 & TX2

Power Adjust

+24 VDC

In/Out

____________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

Rev. 00 Page

6

Page 7

TUNING PROCEDURE TR4022

Table 1: Jumper Definitions

Jumper Label Function

J12 Alarm Group On: Will allow all the alarm group relays to

close when any pedestal within the group

alarms.

Off: Will not allow the alarm group signal to

pass to the next pedestal.

J16 (NO LABEL) Engineering Jumper.

The access panel must be removed to set all of the above jumpers

Table 2: Pushbutton Switch Definitions

Switch Function

SW-1 Reset software

SW-2 Screen select.

SW-3 Screen recall.

Depressing SW2 repeatedly will allow you to toggle from Screen 1 thru Screen 7. The second

pulse of the display found at the DAC test point TP16 identifies the screen being observed. See

Screen 1 on page 11.

Depressing and holding SW3 will cause the display at the DAC test point TP16 to show the

results of the last alarm for the screen being viewed.

____________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

Rev. 00 Page

7

Page 8

TUNING PROCEDURE TR4022

Switch 4 – Bin Elimination, Filters, Transmitter setting and Alarm Cycle

Select

Switch 4-1

Switch 4-2

Switch 4-3

Switch 4-4

Switch 4-5 OFF –

Switch 4-6 OFF -

OFF

OFF

Band Edge Bins

Eliminated

OFF

OFF

A FILTER

Software controlled transmitter

feature disabled

Short Alarm cycle

ON

OFF

High Band Bins

Eliminated

ON

OFF

B FILTER

OFF

ON

Low Band Bins

Eliminated

OFF

ON

C FILTER

ON -

Software controlled transmitter feature

enabled

ON –

Long alarm Cycle

ON

ON

Full Band Detect

No Bin Elimination

ON

ON

D FILTER

Switch 5 – System transmit address, Merchandise/Access Card Rejection

SW 5-3 SW 5-2 SW 5-1 Group

Addressing

OFF OFF OFF Address 0 Strata ‘98 Compatible (200hz, sweep down)

OFF OFF ON Address 1 100 Hz, jitter enabled, random sweep

OFF ON OFF Address 2 100 Hz, jitter enabled, random sweep

OFF ON ON Address 3 100 Hz, jitter enabled, random sweep

ON OFF OFF Address 4 100 Hz, jitter enabled, random sweep

ON OFF ON Address 5 100 Hz, jitter enabled, random sweep

ON ON OFF Address 6 100 Hz, jitter enabled, random sweep

ON ON ON Address 7 100 Hz, jitter disabled, linear sweep down

(Reserved, Engineering mode)

Systems that are ‘slaved’ together MUST have the group addressing switches set to the same

address. Conversely systems that are ‘unslaved’ but in close proximity must have unique

addresses. Address 0 is reserved for compatibility with older (Strata ’98) Strata systems and

should not be used in other installations. Address 7 is reserved for observing the analog input

signal.

SW 5-6 SW 5-5 SW 5-4 ‘Q’ Band

OFF OFF OFF All Tags - No M/A Rejection

OFF OFF ON 410/710 Tags (Merchandise Rejection)

OFF ON OFF 310/Access Card Rejection (Merchandise Rejection)

ON OFF OFF Hard Tags (Merchandise Rejection)

ON ON ON All Tags – (Merchandise Rejection)

____________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

Rev. 00 Page

8

Page 9

Switch 6 – Master/Slave configuration

ON OFF

Switch 6-1 Master (generates and

distributes RF and Sync)

The Master/Slave switch controls how the system will handle the sync and rf signals in

and out. A system MUST be in slave mode to use these input signals. In Master mode

these signals must be absent (refer to ‘Sync and RF indicators’ section).

ON OFF

Switch 6-2 ‘EVEN’ pedestal ‘ODD’ pedestal

The Even/Odd switch controls the transmit signal phase. This allows for a improved

received signal in the weaker carries. For rf slaved systems this switch is alternately set

even-odd-even-odd ….etc. For compatibility with older Strata systems ‘On’ is the same

as having the Even/Odd link installed.

Switch 7 – Sweep range select

TUNING PROCEDURE TR4022

Slave (system must receive

Sync signal)

The Strata 99-4022 board introduces the digital synthesis of the sweep frequencies from a DDS

chip. Without any test equipment the system can be setup without tuning for specific sweep

ranges.

SW 7-1 SW 7-2 Upper Band Edge

Off Off No shift

Off On Shift down 200 kHz

On Off No shift

On On Shift up 200 kHz

SW 7-3 SW 7-4 Lower Band Edge

Off Off No shift

Off On Shift down 200 kHz

On Off No shift

On On Shift up 200 kHz

SW 7-5 SW 7-6 Center Frequency Range Select Target

Off Off 8.2 MHz (nominal 7.6-8.7 MHz) 8.2 tags

Off On 8.6 MHz (nominal 7.8-9.4 MHz) 8.2 and 9.0 tags

On Off 9.0 MHz (nominal 8.5-9.5 MHz) 9.0 tags

On On 9.5 MHz (nominal 8.9-9.8MHz) 9.5 tags

____________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

Rev. 00 Page

9

Page 10

4.0 LED DEFINITIONS

System Status Indicators

DS1 – Inhibit Indicator

This LED indicates that a condition exists that would prevent normal detection of a tag,

typically excessive environmental noise. (At the end of an alarm cycle the inhibit LED

will light momentarily)

DS2 – Alarm

This LED indicates the system is alarming (useful for when the sounder and lights are

disconnected).

DS3 - Heartbeat

This LED indicates the system is operating normally. This LED blinks at an approximate

1 Hz rate. If the led is not blinking, it is a catastrophic failure and the board should be

replaced.

DS4 – Transmitter Status

This LED indicates the ‘power’ level of the transmitter, this led is normally on. When

the system detects an event above the alarm threshold it reduces the transmitter power

output and extinguishes the led.

DS5, DS 6 – Spare

(During development DS5 indicates the status of the external sync on power up)

(During development DS6 indicates the status of the external rf on power up)

DS7 – Q Disqualification Indicator

This LED indicates the system has detected a resonance however the ‘Q” of the resonance is

either above or below the limits selected by the ‘Q’ qualification switches.

TUNING PROCEDURE TR4022

Internal and external Sync and RF indicators – DS8, DS9, and DS10

On power up or reset the system ‘reads’ the sync, rf, and switch status and configures the

board appropriately. The configuration algorithm is as follows.

M/S

Switch

(SW 6-1)

Master Absent Absent OK – self generating sync and RF

Master Absent Present ERROR Off Blink Off

Master Present Absent ERROR Blink Off Off

Master Present Present ERROR Off Off Blink

Slave Absent Absent ERROR Blink Blink Blink

Slave Absent Present OK – External sync and Self

Slave Present Absent ERROR Blink Blink Blink

Slave Present Present OK – External sync and External

____________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

External

RF

Source

External

Sync Source

Condition DS10

(Master)

Green

On Off Off

(system is a master)

Off On Off

generating RF (system is a submaster)

Off Off On

RF (system is a slave)

Rev. 00 Page

(Sub-master)

DS9

yellow

DS8

(Slave)

Red

10

Page 11

The system will not operate in any of the above ‘ERROR’ conditions. If an error

condition is indicated the transmitter will be shut down and the system will not ‘pass through’ the

sync pulse.

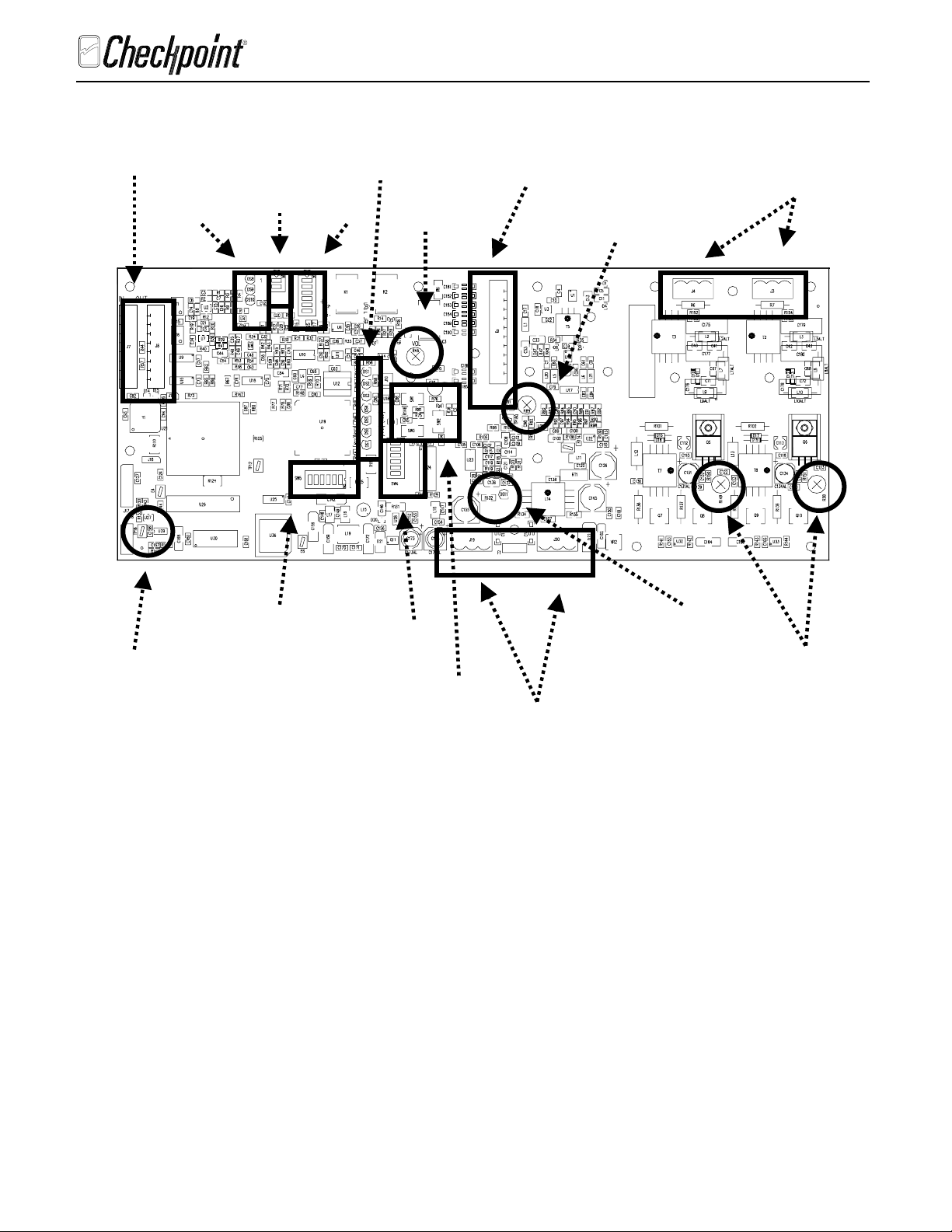

5.0 POTENTIOMETER ADJUSTMENT

The table below provides all of the adjustment pots on the TR4022 board along with their

function and how to adjust each pot. The factory should set all of these pots and field adjustment

should not be necessary.

Table 6: Definition of Adjustment Potentiometers

Label Function Proper Adjustment

TUNING PROCEDURE TR4022

TX1 PWR (R38) 2-loop Antenna Power

(TX1)

TX2 PWR (R149) 3-loop Antenna Power

(TX2)

BASEBAND GAIN

(R89)

VOLUME (R46) Sonalert Volume Adjust to desired level (CW-increases volume)

Baseband Gain Usually set fully CW (maximum gain) Adjust for a maximum of

DO NOT ADJUST HIGHER, SET BY FACTORY

(to decrease power turn R38 clockwise)

DO NOT ADJUST HIGHER, SET BY FACTORY

(to decrease power turn R149 clockwise)

1.5V on screen 1

____________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

Rev. 00 Page

11

Page 12

TUNING PROCEDURE TR4022

6.0 AUXILIARY CONNECTOR

LABEL PIN NUMBER FUNCTION

LT- 11 11 Negative of lights

GND 10 10 Board ground (be very careful what is connected to this pin, so as not to create

ground loops)

LT+ 9 9 Positive of lights

CNT 8 * 8 Relay normally open contact (closure upon alarm, same duration as lights)

CNT 7 * 7 Relay common contact

ALG 6 * 6 Relay normally open contact (triggered by alarm group, momentary closure)

ALG 5 * 5 Relay common contact

SPK+ 2 2 Positive of speaker

SPK- 1 1 Negative of speaker

____________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

Rev. 00 Page

12

Page 13

7.0 SCREENS

Transmitter power

Bin 11

TUNING PROCEDURE TR4022

Screen 1

2 Loop

Screen 1

2 Loop Threshold

3 Loop Threshold

2 Loop

“ANALOG SCREEN”

Frame Field Current Activity

Display Area Display Area

3 Loop

____________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

Rev. 00 Page

13

Page 14

7.1 Frame Field Display Area

The first two horizontal divisions of ALL screen displays contains the following

information:

(each vertical division has a value of 2 units)

Pulse 1 – Scope Trigger

Pulse 2 – Screen currently displayed (Previous page shows screen 1 being displayed)

Pulse 3 – Bin Number (Displays in which Bin the last alarm occurred)

Pulse 4 – Antenna (2 loop or 3 loop)

Pulse 5 – Transmitter Power Output (pulse at top of screen shows transmitter at full

Power)

TUNING PROCEDURE TR4022

The remaining display is the

Current Activity Display Area

for that screen.

____________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

Rev. 00 Page

14

Page 15

Screen 2

TUNING PROCEDURE TR4022

Screen 2

Screen 3

Similar to early Strata DA C output for the 2 loop

Screen 3

Similar to early Strata DA C output for the 3 loop

____________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

Rev. 00 Page

15

Page 16

TUNING PROCEDURE TR4022

Blast 1 ArtifactPlateau

Blast 2 ArtifactPlateau

Blast 1 Sample to Sample Signal Plateau

Blast 1 Sample to Sample Noise Plateau

Blast 2 Sample to Sample Signal Plateau

Blast 2 Sample to Sample Noise Plateau

Blast 1 Bin to Bin Signal Plateau

Blast 1 Bin to BinNoise Plateau

Blast 2 Bin to Bin Signal Plateau

Blast 2 Bin to BinNoise Plateau

Blast 1 AlarmPlateau

Blast 2 AlarmPlateau

Blast 1 & Blast 2 Alarm Thresholds (1 & 2 Locked)

SCREEN 2 AND SCREEN 3 (DETAILED FORMAT)

Screen 2 and Screen 3 have similar formats providing further detail on their respective

2 Loop and 3 Loop DAC signals. Using Screen 2 as an example, the individual 2 Loop DAC

signals are detailed below. The same format would apply for the 3 Loop DAC signals found on

Screen 3.

____________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

Rev. 00 Page

16

Page 17

Screen 4

TUNING PROCEDURE TR4022

Screen 4 (Engineering Use)

“Q” of last alarm event

Screen 5

“Q” Shape of last event

Screen 5 (Engineering Use)

Live “Q” Qualification Display

____________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

Rev. 00 Page

17

Page 18

3 Loop Threshold

2 Loop Threshold

Screen 6

TUNING PROCEDURE TR4022

Screen 6

2 Loop

Bin to Bin

3 Loop

Bin to Bin

____________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

Rev. 00 Page

18

Page 19

Screen 7

TUNING PROCEDURE TR4022

Screen 7

8.0 TUNING

8.1 Master / Slave Setup

The first step in the process for tuning a Strata pedestal with the TR4022 board is to

configure SW 6-1 according to how the pedestal is used in conjunction with other

pedestals. Configure either as a Master (ON) , or Slave (OFF). See Switch 6 –

Master/Slave configuration

8.2 Group Addressing (VERY IMPORTANT)

If the pedestal is working as part of a group of pedestals and connected together by the

interpedestal cable, set the group address at SW5-1, 2, 3 the same for all the pedestals in

the group. See Table 4. If a pedestal or group of pedestals is installed within 40’ of one

another then they may have to be slaved. When slaving is required the group address for

all the pedestals must be set the same.

8.3 Slaving

Slaving can be accomplished by attaching a two wire shielded cable with a drain wire to

the OUT connector J8 terminals 4 & 5 (drain wire to terminal 3) on the last pedestal in the

group to the IN connector J7 terminals 4 & 5 (drain wire to terminal 3) on the first

pedestal of the next group. NOTE: Polarity of the wires is important.

Alarm Counter Display

(above shows

29)

____________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

Rev. 00 Page

19

Page 20

TUNING PROCEDURE TR4022

Apply 24 VDC power and check that DS11 is illuminated. DS3 should also be flashing

intermittently.

The transmitter output is preset at the factory and should not require adjustment.

Adjust the baseband gain potentiometer R89 for a noise level of less than 1.5V at Screen

1. This can be viewed by attaching an oscilloscope to the DAC test point TP16 and

selecting Screen 1 by depressing SW2. Scope setting: 1V/DIV; 200uS/DIV.

While viewing Screen 1 check the sweep setting of the transmitter for the frequency of the

tags being used. Standard retail systems are set to sweep from 7.6 – 8.7 Mhz. Using a

Grid Dip Meter placed flat on the floor approximately 1.5 to 2 feet from the antenna check

the sweep range by varying the frequency dial on the meter. The following illustrations

will give you an idea of what the induced signal from the Dip Meter will look like at

Screen 1.

8.7 Mhz 8.2 Mhz 7.6 Mhz

Set the detection parameters at SW4-3 & 4 to OFF/OFF. This is the same as the ‘C’ filter

on earlier Strata. If more filtering is required because of environmental influences see

Table 3.

Set SW5-4, 5, 6 for the type of tags being used. See Table 4. All OFF has no ‘Q’

qualification and thereby will not defeat alarms caused by merchandise.

Set the volume of the Sonalert by adjusting potentiometer R46.

No other adjustments are required. Test the system with several of the customers’ tags to

insure that the system is detecting properly. The sensitivity of the system may vary due to

environmental influences and the selection of the filtering set by SW4-3 & 4.

____________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

Rev. 00 Page

20

Loading...

Loading...