Page 1

Source Tagging

Tester

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

User Guide

Version 1.0

. . . . .

P/N 7413286

Page 2

Published by:

Checkpoint Systems Inc.

101 Wolf Drive

Thorofare, NJ 08086

This manual refers to the Source Tagging Tester unit, Version 1.0.

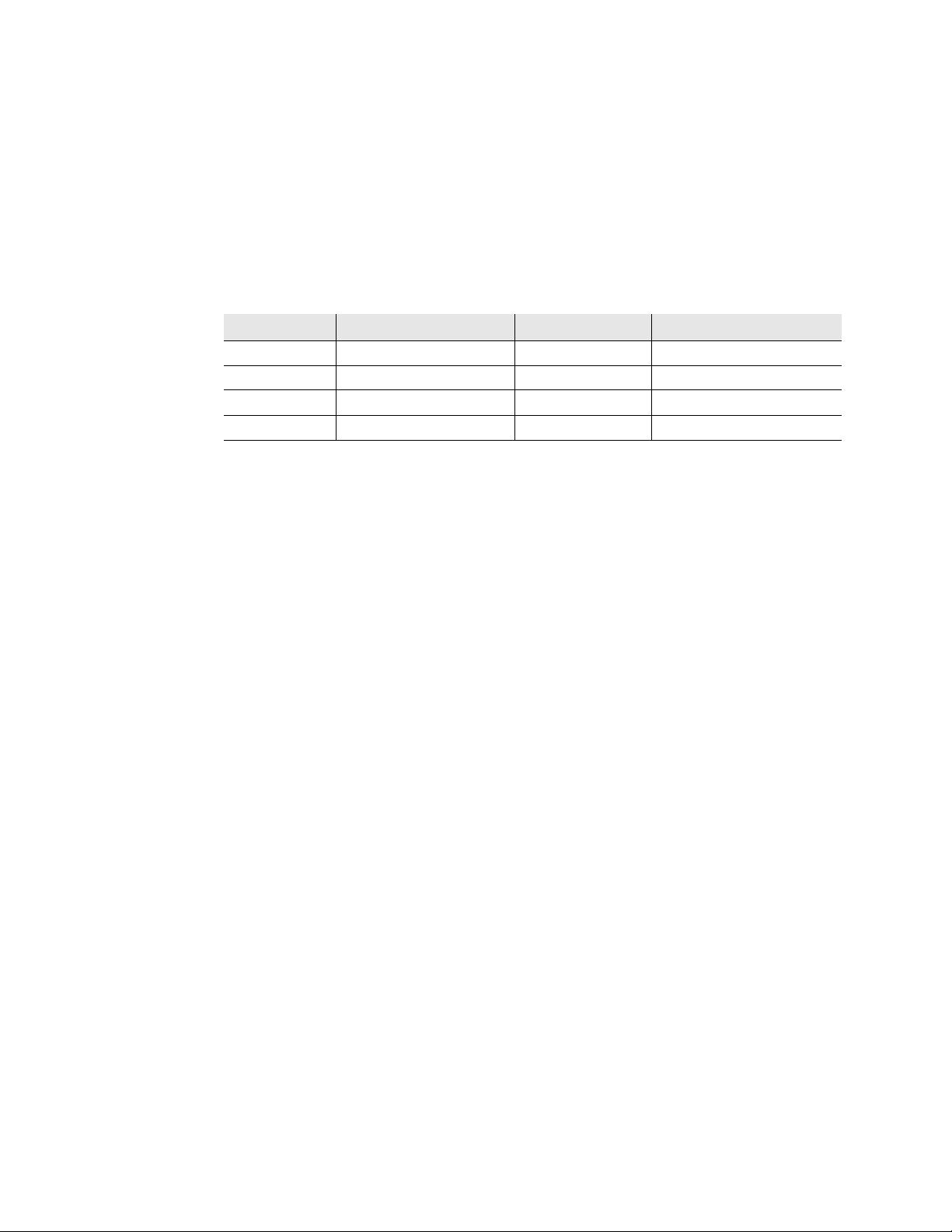

Document revision information

Source Tagging Tester

Part Number: 7413286

Rev Description Date Author

1.0 Initial Draft 11/10/2005 M. Reeves

Trademarks Copyright and Warranty Information

Checkpoint Systems, Inc. are registered trademarks of Checkpoint Systems, Inc.

Microsoft, Windows, and Windows XP are either registered trademarks or trademarks of Microsoft

Corporation in the United States

Other product and company names herein may be trademarks of their respective owners.

The information in this manual is subject to change without notice.

Because of the changing nature of this product information presented in the Installation Manual,

Checkpoint Systems, Inc. is not liable for any omissions, misstatements, or other errors of

information.

The information presented in the Installation Manual may not be copied, used or disclosed to others

for the purpose of procurement or manufacturing without the written permission of Checkpoint

Systems, Inc. This manual and the products discussed in this manual are the exclusive property of

Checkpoint Systems Inc. Copyright laws of the United States protect all information and products.

Copyright © 2005 by Checkpoint Systems, Inc. All rights reserved.

ii

Page 3

Contact Information

USA

Checkpoint Systems, Inc.

101 Wolf Drive

Thorofare, NJ 08086 USA

http://www.checkpt.com

Technical Assistance/Service Requests: 800-253-7580

FAX: 856-384-2328

Europe

Checkpoint Systems International GmbH

Von-Humboldt-Strasse 10

Heppenheim

Hessen

64 646

Germany

+49 6252 798 300

Document Conventions

Warning This is a Warning icon. When it appears, the corresponding text indicates a cautionary statement

which you must abide by.

Caution This is a Caution icon. When it appears, the corresponding text indicates a cautionary statement

which you must abide by.

Note This is a Tip icon. When it appears, the corresponding text indicates a helpful note or tip when using

the feature.

The following usage conventions are used throughout the manual.

Button Name - This describes a button or selection on the screen. For example, the

<DONE> button is represented in this document as Done.

Key Name - This describes a keystroke on a keyboard. For example Ctrl represents the

control key.

iii Source Tagging Tester User Guide

Page 4

Regulatory St atement

Important Information to our Users in North America

FCC Regulatory Compliance Statement

Checkpoint Systems, Inc. offers certain Electronic Article Surveillance (EAS) products that have been FCC

certified or verified to 47 CFR Part 15, Subparts B/C and/or 47 CFR Part 18. Appropriately, one of the

following labels will apply to the approval:

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FC C R u l es. Th e se limits are designed to provide reasonable protection against

harmful interference w hen the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause harmful interfe re nce in which case the user will be required to correct

the interference at his own expense.

- OR -

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and (2) this device must accept any interference

received, including interference that may cause undesired operation.

- OR -

NOTE: This equipment has been tested and found to comply with the limits for a miscellaneous type ISM

device, pursuant to part 18 of the FCC Rules. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to rad io co m m u ni ca tio n s. Ho w e v er, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful interference to radio communications

reception, which can be determined by turning the equipment off and on, please contact Checkpoint

Systems, Inc. at (800) 257-5540 for further assistance.

Equipment Safety Compliance Statement

WARNING

party responsible for assuring compliance could void the user’s authority to operate the equipment in a safe

or otherwise regulatory compliant manner.

: Changes or modifications to Checkpoint’s EAS equipment not expressly approved by the

iv

Page 5

Important Information to our Users in Europe

CE Compliance Statement

Where applicable, Checkpoint Systems, Inc. offers certain Electronic Article Surveillance (EAS) products

that have CE Declarations of Conformity to Council Directive(s) EMC 89/336/EEC, LVD 73/23/EEC, and

R&TTE 99/5/EC Radio and Te lecommunications Terminal Equipment, as amended by 92/31/EEC and 93/

68/EEC.

System Electromagnetic Compatibility (EMC), has been tested and notified through Spectrum Management

Authorities using accredited laboratories and, in a few cases, EC type examination certified through a

Notified Body using Competent Body laboratories in Europe, whereby, conformity is declared to voluntary

accepted European T elecommunications Standards In stitute (ETSI) standards EN 301 489 and EN 300 330.

In other cases, conformity is declared to the generic emission and immunity standards EN 50081-1 / EN

55022 / EN 50082-1 and EN 55024.

NOTE: Certain Checkpoint EAS equipment has been tested and found to conform with the CE emission and

immunity requirements in Europe. This equipment generates, uses, and can radiate radio frequency energy

and, if not installed and used in ac co rda n c e wi th th e inst ru c tion m a nu a l, m ay ca use h arm fu l in te rfe ren ce to

radio communications. Under unusual circumstances, interference from external sources may temporarily

degrade the system performance. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment experiences frequent interference from external sources or does

cause harmful interference to radio communications reception, which can be determined by turning the

equipment off and on, please contact a Checkpoint representative for further assistance.

Equipment Safety Compliance Statement

Checkpoint’s Electronic Article Surveillance (EAS) products have been designed for safeness during

normal use and, where applicable, certain components of the system or accessory sub-assemblies have been

declared safe according to the European Low Voltage Directive (LVD) by being certified, listed, or

recognized in accordance with one or more of the following European safety standards; EN 60950-1

(Amendments 1 & 2), EN60742, and EN50364. Additional approvals may be pending.

WARNING

party responsible for assuring compliance could void the user’s authority to operate the equipment in a safe

or otherwise regulatory compliant manner.

v Source Tagging Tester User Guide

: Changes or modifications to Checkpoint’s EAS equipment not expressly approved by the

Page 6

Table of Content s

Contact Information......................................................... ... ................................................................................ i-iii

Document Conventions...................................................................................................................................... i-iii

Regulatory Statement......................................................................................................................................... i-iv

Introduction..............................................................................................................................................1-1

Sample Layout Diagram....................................................................................................................... 1-2

Using Source Tagging Tester.................................................................................................................2-3

Initial Configuration of STT Software.................................................................................................... 2-3

Tag Testing Line Preparation................................................................................................................ 2-6

Fixed Tag Testing Amount..................................................................................................... ............................ 2-6

Unlimited Tag Testing Amount........................................................................... ... ............................................. 2-7

Reports......................................................................................................................................................3-9

Report Procedure................................................................................................................................. 3-9

Create a Report ................................................................................................................................................ 3-9

Email the Report............................................................................................................................................................... 3-10

Print the Report..................................................................................................................................................................3-11

Sample Report ................................................................................................................................... 3-12

vi

Page 7

C HAPTER

C

HAPTER

0

I

NTRODUCTION

The Checkpoint Source Tagging Tester is designed to help Source Tagging Customers test

and verify Checkpoint labels in real time. The Source Tagging Tester tests every series of

Checkpoint labels and comes equipped with a counter mechanism that records the number

of good, bad, and total Checkpoint labels run on the production line.

The customer records the number of good, bad, and total number of Checkpoint labels

before resetting the counters. Each individual counter comes equipped with a manual hard

reset button, enabling the customer to reset the counters.

This user guide contains the following information:

• Introduction

• Configuring and Using the Source Tagging Tester

• Report Generation

Introduction: 1-1

Page 8

Sample Layout Diagram

The following diagram illustrates a sample installation of the Source Tagging Tester. Your

installation is entirely custom and dependent upon your individual requirements.

Source Tagging Tester

Antenna

Photo Eye

Figure 1.1

Sample Layout

1-2 Source Tagging Tester User Guide

Page 9

C

HAPTER

0

U

SING

This chapter instructs how to use the Source Tagging Tester software.

S

Initial Configuration of STT Sof tware

Before testing starts, the software must be configured for use.

1 Launch the Source Tagging Tester by double-clicking the Tag Tester icon on the

desktop.

OURCE

T

C HAPTER

AGGING

T

ESTER

2 Click File > User Preferences to access the User Preferences.

Figure 2.1

User Preferences

Using Source Tagging Tester: Initial Configuration of STT Software 2-3

Page 10

3 If not using email, the SMTP and Email fields can be ignored. Type in the following

information to customize the software for the production line:

Table 2.1

User Preferences

Field Description

Time Format Select either Standard or Military time.

Date Format Select the type of date format.

No. of Units Select the number of production lines to be monitored.

SMTP Host If necessary, enter the SMTP Host information. Contact IT for the

SMTP Port If necessary, enter the SMTP Port information. Contact IT for the

Email Address If necessary, type the email address to which the program sends

Shifts Select the time for each shift. You cannot leave more than a 10

Target Tag Count Type the number of tags that are to be tested for each run. Once the

information.

information.

results.

minute interval between each shift.

count has reached the limit specified here, the program stops

counting.

4 Once complete, click Save and Exit to save the information. Otherwise, click Exit to

exit without saving your changes.

5 Next, click File > Yield Settings to access Yield Settings.

2-4 Source Tagging Tester User Guide

Figure 2.2

Yield Settings

Page 11

The yield is the amount of good tags you wish to achieve for each line and each roll.

For example, in Unit 1 above, the program is set for 95% yield, which only allows for

5% of tags to fail.

6 Type the yield you wish to maintain for each unit you are programming. If not using all

units (as programmed in step 3), leave the default value in the field.

7 In the Overall field, type the final successful yield for all of the units.

8 Once complete, click Save and Exit to save the information. Otherwise, click Exit to

exit without saving your changes.

9 Next, click File > Yield COM Setup to access COM Port Setup.

Figure 2.3

COM Port Setup

Note: Multiple COM Ports refers to the usage of an RS232/COM port expansion unit.

10 Select only the COM ports you will use for tag testing. Otherwise, leave the

checkboxes blank. The COM ports must be selected sequentially and COM1 must

always be selected, as that is the computer itself. COM2-COM8 refers to the COM port

hub.

11 Once complete, click Save and Exit to save the information. Otherwise, click Exit to

exit without saving your changes.

Using Source Tagging Tester: Initial Configuration of STT Software 2-5

Page 12

Tag T esting Line Prep aration

This procedure assumes that all the initial configuration of the software has been

completed. If not, see “Initial Configuration of STT Software” on page 2-3 for details.

Before configuring the software, the tags must be ready to be run on the production line.

Follow your company’s procedures for the correct installation method.

Fixed Tag Testing Amount

This procedure explains how to configure the STT program for a finite amount of tags.

Choose this option when testing a set number of tags for a particular product code, for

example 1,000 tags for a line of shirts. If you are testing an unlimited amount of tags, see

“Unlimited Tag Testing Amount” on page 2-7.

1 Launch the Source Tagging Tester by double-clicking the Tag Tester icon on the

desktop.

2 If you need to customize the Yield, see page 2-4 for details on how to adjust the

settings.

3 Click Shift. The Shift window displays.

The Shift window allows you to customize each production line to match the name of

the operator and the Product Code of the labels. The Shift # is automatically

determined based on the User Preference and the computer’s clock.

4 Type the Production Date to be run.

5 For each Unit you are testing, type the name of the operator of the line and the

applicable Product Code.

2-6 Source Tagging Tester User Guide

Figure 2.4

Shift Window

Page 13

6 If necessary, type the name of the Shift Manager for the Overall Shift.

7 Click Prod. The Production window displays.

Figure 2.5

Production Window

The Production window allows you to enter a preset amount of labels to test. The

numbers that appear here can appear in the Final Report.

8 Type the Start and Finish dates.

9 Type the total amount of labels for all units to be tested in the Target No. of Labels

field.

10 For each line to be tested, type the Product Code for each Unit.

11 Click Start to begin testing.

12 Start the tag testing line. The STT program counts the tags for each Unit selected.

13 When the counting is complete, click Stop. See “Create a Report” on page 3-9 for

details on how to save the information.

Unlimited Tag Testing Amount

This procedure explains how to configure the STT program for an unlimited amount of

tags. Choose this option testing many rolls of tags. If you are testing a limited amount of

tags, see “Fixed Tag Testing Amount” on page 2-6.

1 Launch the Source Tagging Tester by double-clicking the Tag Tester icon on the

desktop.

2 If you need to customize the Yield, see page 2-4 for details on how to adjust the

settings.

Using Source Tagging Tester: Tag Testing Line Preparation 2-7

Page 14

3 Click Shift. The Shift window displays.

Figure 2.6

Shift Window

The Shift window allows you to customize each production line to match the name of

the operator and the Product Code of the labels. Only those COM ports you selected in

“Initial Configuration of STT Software” on page 2-3 will appear here. The Shift # is

automatically determined based on the User Preference and the computer’s clock.

4 Type the Production Date to be run.

5 For each Unit you are testing, type the name of the operator of the line and the

applicable Product Code.

6 If necessary, type the name of the Shift Manager for the Overall Shift.

7 Click Start to begin testing.

8 Start the tag production line. The STT program counts the tags for each Unit selected.

9 When the counting is complete, click Stop. See “Create a Report” on page 3-9 for

details on how to save the information.

2-8 Source Tagging Tester User Guide

Page 15

This chapter provides a sample Report which can be used to record tag counts.

Report Procedure

Prior to running each roll of tags, record the number of bad tags per roll, which can be

found on the inside of the tag core. Then at the end of each roll of tags record the number

of good, bad, and total tags run.

C HAPTER

C

HAPTER

0

R

EPORT S

Create a Report

You can archive your testing data in either print or electronic format.

1 From the Production screen, select only those Units (by selecting Final Report) whose

numbers you want to appear in the Report.

Figure 3.1

This can be changed as needed as well. For example, if you ran all 8 units with two

different types of tags, you can produce one report for units 1, 2, 3, and 4 and another

for report for units 5, 6, 7, and 8. When you produce the Report, you can select either

group as needed.

Final Report Selected

Reports: Report Procedure 3-9

Page 16

2 After testing is complete, click Report.

Figure 3.2

Type in the information necessary for your report. The last four fields are

3

Report Window

automatically filled with the results from the Production page.

4 Click either Print or Email, depending upon how you want to save the information.

See “Email the Report” on page 3-10 or “Print the Report” on page 3-11 for details.

Email the Report

This option requires that the email settings in User Preferences (configured on page 2-3)

are correctly configured before you can use this option.

1 If you clicked Email, the Email Recipients dialog box appears.

2

Type in the necessary email address and click Email. The report is delivered to the

email address specified.

3-10 Source Tagging Tester User Guide

Figure 3.3

Email Dialog Box

Page 17

Print the Report

1 If you clicked Print, a sample of the Report displays.

Figure 3.4

At the top left, click either the Print or Export button.

2

3 If you clicked Print, the Report is sent to the printer.

4 If you clicked Export, the Export dialog box appears.

Report Sample

Figure 3.5

Select a destination for the file, type a file name, and select the file type (HTML or

5

Export Dialog Box

TXT) for the Report and click Save.

Reports: Report Procedure 3-11

Page 18

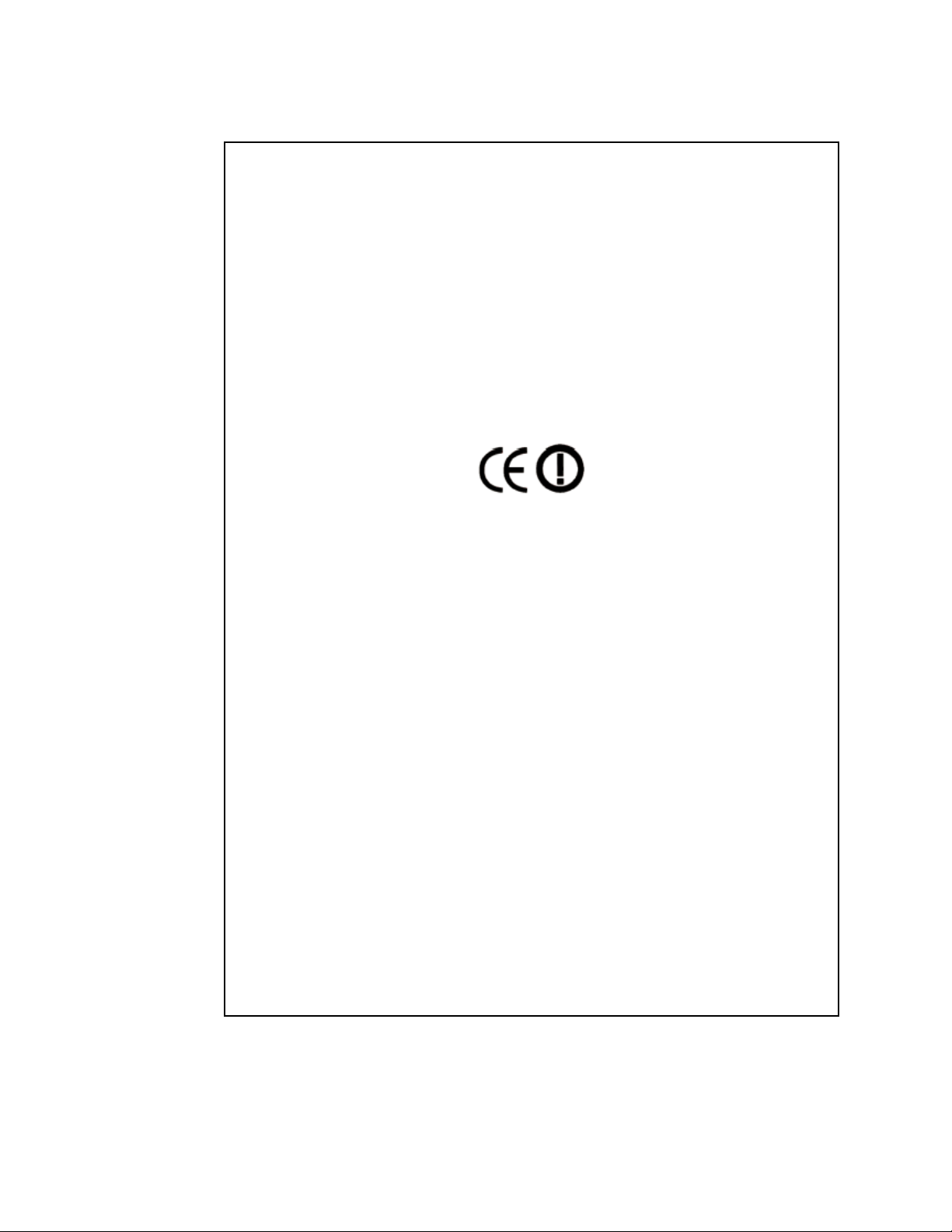

Sample Report

You can use this sample report to record your results if desired.

Table 3.1

Roll # Factory Bad Labels

Checkpoint Source Tagging Tester Report

Bad Production

Labels

Good Production

Labels

Total # of Production

Labels

3-12 Source Tagging Tester User Guide

Loading...

Loading...