Page 1

Liberty™ UHX Pedestal

for

Retail

Upgrade Guide

Page 2

Page 3

Copyright © 2004 by Checkpoint Systems, Inc.

Released May 6, 2005.

Published by:

Checkpoint Systems Inc.

101 Wolf Drive

Thorofare, NJ 08086

Document revision information

Upgrade Guide for the Liberty UHX Pedestals

4th Edition - 2-9-2005

5th Edition - 3-18-2005

6th Edition - 5-6-2005

Trademarks

Checkpoint and Strata are a registered trademark and Liberty is a trademark of Checkpoint

Systems, Inc.

Other product and company names herein may be trademarks of their respective owners.

Other products © or ® their respective manufacturers or copyright holders.

Copyright and Warranty Information

The information in this manual is subject to change without notice.

Because of the changing nature of this product information presented in the Upgrade Guide,

Checkpoint Systems, Inc. is not liable for any omissions, misstatements, or other errors of

information.

The information presented in the Upgrade Guide may not be copied, used or disclosed to others for

the purpose of procurement or manufacturing without the written permission of Checkpoint

Systems, Inc. This manual and the products discussed in this manual are the exclusive property of

Checkpoint Systems Inc. Copyright laws of the United States protect all information and products.

Copyright© 2001, 2002, 2003 and 2004 Checkpoint Systems, Inc. All rights reserved.

iii

Page 4

Important Information to our Users in North America

FCC Regulatory Compliance Statement

Checkpoint Systems, Inc., offers Radio Frequency Identification Products that have been FCC certified or

verified to 47 CFR Part 15 Subparts B/C and/or 47 CFR Part 18. Appropriately, one of the following labels

will apply to the approval:

NOTE

: This equipment has been tested and found to comply with the limits for a class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate interference to radio communications. Operation of

this equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

- OR -

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) including this device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired operation, which

may include intermittent decreases in detection and/or intermittent increases in alarm activity.

- OR -

NOTE: This equipment has been tested and found to comply with the limits for a miscellaneous type

ISM device, pursuant to Part 18 of the FCC Rules. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. However, there is no guarantee that interference

will not occur in a particular installation. If this equipment does cause harmful interference to radio

communications reception, which can be determined by turning the equipment off and on, please

contact Checkpoint Systems, Inc., at 1 (800) 257-5540 for further assistance.

Equipment Safety Compliance Statement

Checkpoint Systems Radio Frequency Identification products have been designed to be safe during normal

use and, where applicable, certain components of the system or accessory sub-assemblies have been

certified, listed or recognized in accordance with

UL 1037, UL 1310, UL 60950-1, CSA C22.2 No. 205, CSA C22.2 No. 220, CSA C22.2 No. 223, CSA

C22.2 No. 60950-1. Additional approvals may be pending.

WARNING:

equipment not expressly approved by the party responsible for assuring compliance could void the user’s

authority to operate the equipment in a safe or otherwise regulatory compliant manner.

Changes or modifications to Checkpoint’s Radio Frequency Identification (RFID)

one or more

of the following Safety standards: UL 1012,

iv

Page 5

Table of Contents

Introduction 1-1

Removing Existing Pedestals 2-1

Removing QS2000 Pedestals 2-2

Estimated completion time 2-3

Removing bumper posts 2-3

Estimated completion time 2-3

Removing Strata PX Pedestals 2-4

Estimated completion time 2-5

Removing bumper posts 2-5

Estimated completion time 2-5

Removing Liberty PX Pedestals 2-6

Estimated completion time 2-7

Installing Liberty UHX Pedestals 3-1

Cutting new wiring channel 3-1

Estimated completion time 3-1

Electrical and Network Wiring 3-2

Wiring for front entrance 3-3

Wiring for employee entrance pedestal 3-4

Estimated completion time 3-5

Installing the pedestal 3-6

Estimated completion time 3-7

Liberty UHX Installation Checklist 4-1

Installation Checklist 4-1

General Information 4-1

Project Management/Marketing Scope 4-2

Checkpoint Contractor Scope 4-2

Checkpoint Technical Scope 4-2

Target Technical Scope 4-3

System Removal 4-3

System Installation 4-3

Follow up Procedures 4-4

Sample Door Layouts 4-7

Liberty UHX AR-400 Setup

Instructions 5-1

Equipment 5-1

Post-Installation Procedure 5-1

Verification of Power Settings 5-5

1

Page 6

2

Page 7

C HAPTER

C

HAPTER

0

I

NTRODUCTION

This Guide allows you to upgrade existing installations of QS2000, Strata PX and Liberty

PX pedestals to the new Liberty UHX pedestal. The new Liberty UHX pedestals can read

both EAS and UHF/RFID tags simultaneously.

The following upgrade scenarios are covered in this document:

• Removing the existing pedestals

• QS2000 pedestals (EAS)

• Strata PX pedestals (EAS)

• Liberty PX pedestals (EAS)

• Installing the new Liberty UHX pedestals (EAS and RFID)

• Cutting the new wiring channel

• Installing the power supplies

• Running the electrical and network wiring

• Installing the new Liberty UHX pedestals

An upgrade is completed by Checkpoint in an expeditious manner from the legacy

pedestals without disruption to the store operations for extended periods of times.

All upgrades will take place outside of store hours during a period of time mutually agreed

upon by both parties.

Similar to the initial installation of either the Liberty PX, Strata PX or QS2000 pedestals,

the process of upgrading to the Liberty UHX pedestals requires the presence of

Checkpoint Technicians, Target personnel, and Checkpoint contractors. Checkpoint is

responsible for carefully screening and engaging the Checkpoint contractor prior to the

scheduled installation date. In some instances, a licensed electrician may be required.

Whether an electrician is required or not will depend on the local building codes.

An upgrade plan includes installing the Liberty UHX antennas and fully configuring and

testing the EAS functionality of the antennas prior to the store opening. Once the EAS

functionality of the antennas is confirmed, the Liberty UHX pedestals will be configured

and tuned for full UHF functionality.

1-1 Liberty UHX Upgrade Guide

Page 8

The following table outlines the responsibilities for each installation group. The tasks are

listed in the order they should be completed.

Table 0.1

Installation/upgrade task list

Responsibility (Task) Installation Group

*Acquiring replacement mat, if necessary Target

Removing existing pedestals Checkpoint

Repairing old drill holes, if necessary Checkpoint Contractor

Removing existing floor mats Checkpoint Contractor

Removing any bumper posts, if necessary Checkpoint Contractor

Filling in old bumper post holes, if necessary Checkpoint Contractor

Cutting new floor channel (trench) Checkpoint Contractor

Installing walker duct Checkpoint Contractor

Installing power supply boxes Checkpoint Contractor

Running power from ceiling to floor Checkpoint

Running power in walker duct to pedestals base Checkpoint

Crimping power wires and installing connectors Checkpoint

Running CAT 5 network cable and terminate at the power supply with

appropriate length

Running CAT 5 network cable from power supply to floor Checkpoint Contractor

Running CAT 5 network cable in walker duct to pedestal base Checkpoint

Installing connectors on the CAT 5 network cable Target

Testing network connectivity Target

Connecting CAT 5 cable to pedestal riser Checkpoint

Connection power to pedestal riser Checkpoint

Installing new pedestals Checkpoint

Replacing floor mats, if necessary Checkpoint Contractor

Testing new pedestals for EAS Checkpoint

Testing new pedestals for UHF Checkpoint

Target

*Note: Replacement mats are ordered and maintained by Target. It is important for

Checkpoint personnel to review the site survey and determine necessity of mats. If

replacement mats are required, Checkpoint personnel must notify Target to have mats

ordered and delivered in time for the upgrade to the existing pedestals. As a precautionary

measure, Checkpoint technicians will carry a 15 by 10 foot mat to all installations.

Introduction: 1-2

Page 9

C HAPTER

C

HAPTER

0

R

EMOVING

In order to install the Liberty UHX pedestals, you must first remove the existing legacy

pedestals. This chapter provides detailed instructions for removing the following legacy

pedestals:

• QS2000 (EAS) - See “Removing QS2000 Pedestals” on page 2-2.

• Strata PX (EAS) - See “Removing Strata PX Pedestals” on page 2-4.

• Liberty PX (EAS) - See “Removing Liberty PX Pedestals” on page 2-6.

Each of these procedures is very straight-forward and can be accomplished by Checkpoint

Technicians. It is estimated that removing a single pedestal would take a Checkpoint

Technician approximately 15 minutes. This time can vary.

E

XISTING

P

EDESTALS

2-1 Liberty UHX Upgrade Guide

Page 10

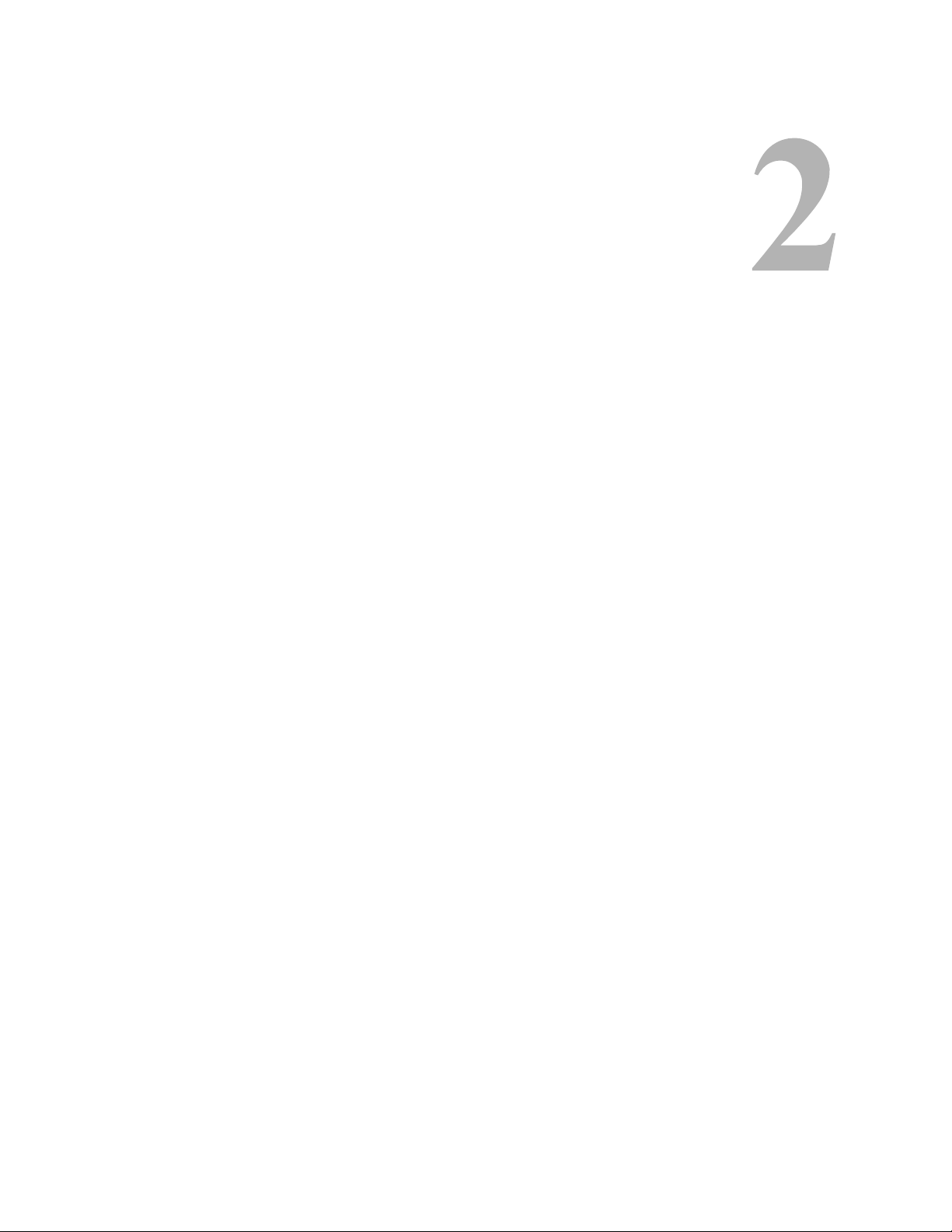

Removing QS2000 Pedestals

To remove existing QS2000 pedestals, complete the following.

1 Checkpoint Technician removes the plastic covering from the QS2000 pedestal.

plastic covering

Figure 2.1

Checkpoint Technician unbolts and removes existing QS2000 pedestals.

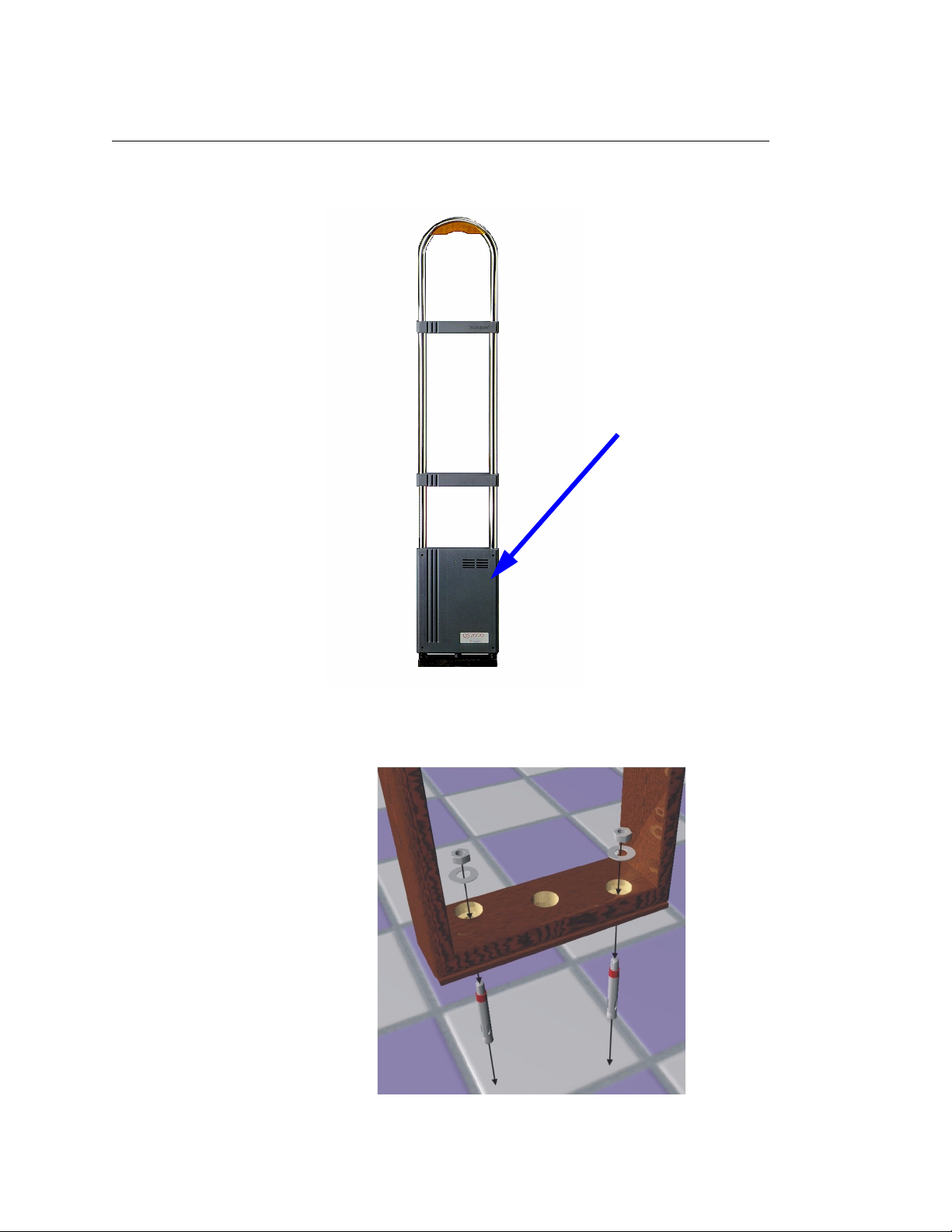

2

Figure 2.2

The QS2000 pedestal is installed with two 3 inch by 1/2 inch anchor bolts.

Removing Existing Pedestals: Removing QS2000 Pedestals 2-2

QS2000 pedestal.

Page 11

3 Checkpoint Technician removes the existing bolt anchors in one of the following ways:

• Break

• Cut

• Pound down

4 Since the footprint of all QS pedestals is 12 inches by 3 1/2 inches, the existing bolt

anchor holes will need to be filled in because these holes cannot be reused for Liberty

UHX installations.

Estimated completion time

Removal of the legacy QS2000 pedestal will take approximately 30 minutes per single

pedestal.

Removing bumper posts

QS2000 pedestal may have a bumper post installed on either side of the pedestal to protect

the pedestal from damage. These bumper posts should be removed and the post holes

filled in with concrete. Instead of bumper posts, the new Liberty UHX pedestals are

installed on top of metal risers. The riser elevates the base of the Liberty UHX pedestal off

of the floor to protect it from being damaged.

To remove the existing bumper posts:

1 Checkpoint contractors remove flooring.

2 Checkpoint contractors remove both bumper posts.

3 Checkpoint contractors fill in bumper post holes with concrete.

Estimated completion time

Removal of each bumper post will take approximately 15 minutes plus time for concrete.

This can vary by Checkpoint contractor.

2-3 Liberty UHX Upgrade Guide

Page 12

Removing Strata PX Pedestals

To remove existing Strata PX pedestals, complete the following.

1 Checkpoint Technician removes the plastic covering from the Strata PX pedestal.

plastic covering

Figure 2.3

Checkpoint Technician unbolts and removes existing Strata PX pedestals.

2

Figure 2.4

The Strata PX pedestal installed with two 3 inch by 1/2 inch anchor bolts.

Strata PX pedestal.

Removing Existing Pedestals: Removing Strata PX Pedestals 2-4

Page 13

Estimated completion time

Removal of legacy Strata PX pedestal will take approximately 15 minutes per single

pedestal.

Removing bumper posts

Strata PX pedestal may have a bumper post installed on either side of the pedestal to

protect the pedestal from damage. These bumper posts should be removed and the post

holes filled in with concrete. Instead of bumper posts, the new Liberty UHX pedestals are

installed on top of metal risers. The riser elevates the base of the Liberty UHX pedestal off

of the floor to protect it from being damaged.

To remove the existing bumper posts:

1 Checkpoint contractors remove flooring.

2 Checkpoint contractors remove both bumper posts.

3 Checkpoint contractors fill in bumper post holes with concrete.

Estimated completion time

Removal of each bumper post will take approximately 15 minutes plus time for concrete.

This can vary by Checkpoint contractor.

2-5 Liberty UHX Upgrade Guide

Page 14

Removing Liberty PX Pedestals

To remove existing Liberty PX pedestals, complete the following.

1 Checkpoint Technician removes the plastic covering from the Liberty PX pedestal.

plastic covering

Figure 2.5

Removing Existing Pedestals: Removing Liberty PX Pedestals 2-6

Liberty PX pedestal

Page 15

2 Checkpoint Technician unbolts and removes existing Liberty PX pedestals.

Figure 2.6

Liberty PX pedestal is installed with two 3 inch by 1/2 inch anchor bolts.

Estimated completion time

Removal of legacy Liberty PX pedestal will take approximately 15 minutes per single

pedestal.

2-7 Liberty UHX Upgrade Guide

Page 16

Notes

Removing Existing Pedestals: Removing Liberty PX Pedestals 2-8

Page 17

C HAPTER

C

HAPTER

0

I

NSTALLING

Once the legacy pedestals are removed, you are ready to install the new Liberty UHX

pedestals.

The installation of the new Liberty UHX pedestal includes the following:

• Cutting a new wiring channel

• Running the electrical and network wiring

• Installing the new Liberty UHX pedestal

Placement of the Liberty UHX pedestals coincides with normal placement of the Liberty

PX pedestals.

L

IBERTY

UHX P

EDESTALS

Cutting new wiring channel

Checkpoint contractors will cut floor trench in the center of existing EAS pedestal

infrastructure and back fill trench upon completion of wire installations.

Estimated completion time

The cutting of a 35-foot floor channel will take approximately 60 minutes. This can vary

by Checkpoint contractor.

3-1 Liberty UHX Upgrade Guide

Page 18

Electrical and Network Wiring

For the new Liberty UHX pedestal the following wiring is required:

• Electrical - 1 gauge wire (shielded). 1 wire required per pedestal.

• Network - CAT 5 or 5e cable (un-shielded twisted pairs). 1 cable required per pedestal.

To complete the network and electrical installation and wiring,

1 Checkpoint contractor installs one or two additional shelves in the ceiling on one side

of the entry way or attaches the 3 power supplies directly to the studded wall.

• Each shelf must support two (2) power supplies along with all required controls.

• Each shelf must support 1 network access point.

• Six (6) power supplies are required for a six (6) pedestal installation. Each supply

powers a single pedestal.

2 Checkpoint contractor ensures that the power supplies are within AC power cord

range (4 feet) of the outlet box.

A licensed electrician may be required for this part of the installation. Please consult local

building codes to determine if a licensed electrician is required.

Installing Liberty UHX Pedestals: Electrical and Network Wiring 3-2

Page 19

Wiring for front entrance

The network and electrical wiring for all six pedestals originate from the power supply and

network access point installed in the ceiling above side of the entry way on the studded

wall.

The power cabled are shipped in standard 100” lengths with connectors attached to one

end. The other end of the power cable will have connectors added at the site. The power

supply also ships with the connector attached.

The following tasks should be completed by Target IT staff prior to the start of the

installation by Checkpoint Technicians.

1 Target Technician runs CAT 5 cables from the homerun area and terminates at the

power supply with appropriate length.

2 Target Technician installs router and network connection near both shelves.

The following tasks are completed on the installation date by a Checkpoint Technician and

a Checkpoint contractor.

1 Checkpoint contractor runs CAT 5e network cable into a 0.5” PVC conduit to run from

power supply to floor.

2 Checkpoint Technician inserts wiring into 1.00" PVC conduit to run from ceiling to

trench. This PVC conduit is recommended, but is not electrically required. The factory

installed connector should remain at the portion of the PVC pipe nearer the ceiling.

Fish the rest of the cable through the PVC pipe towards the floor.

3 Checkpoint contractor installs walker duct in trench.

4 Checkpoint Technician runs the necessary power cable through the walker duct to the

junction boxes at the foot of each pedestal.

5 Checkpoint Technician crimps the wires into a connector.

6 Checkpoint Technician runs the CAT 5e cables through the walker duct to junction

boxes at the foot of each pedestal.

7 Plug the factory installed connector into the power supply.

The following tasks must be completed by Target IT staff after the trench has been cut and

the CAT 5 cable run in the walker duct by the Checkpoint Technician.

1 Target Technician crimps the wires into an RJ-45 surface mount jack.

• Pins 1 and 2 - orange pair - white, orange, white

• Pins 3 and 6 - green pair - white, green, white

3-3 Liberty UHX Upgrade Guide

Page 20

• Blue pair and brown pair are not used.

2 Target Technician tests the CAT 5 cable for network connectivity.

3 Checkpoint contractor back-fills floor trench (over top of wiring).

Wiring for employee entrance pedestal

Currently there are 2 antenna pedestals at the employee entrance. These 2 pedestals are

replaced by one single Liberty UHX pedestal to be installed near the wall that contains the

power supply. The following wiring instructions only apply to one pedestal.

The following tasks should be completed by Target IT staff prior to the start of the

installation by Checkpoint Technicians.

1 Target Technician runs CAT 5 cables from the homerun area and terminates at the

power supply with appropriate length.

2 Target Technician installs router and network connection near both shelves.

The following tasks are completed on the installation date by a Checkpoint Technician and

a Checkpoint contractor.

1 Checkpoint contractor runs CAT 5e network cable into a 0.5” PVC conduit to run from

power supply to floor.

2 Checkpoint Technician inserts wiring into 1.00" PVC conduit to run from ceiling to

floor. This PVC conduit is recommended, but is not electrically required. The factory

installed connector should remain at the portion of the PVC pipe nearer the ceiling.

Fish the rest of the cable through the PVC pipe towards the floor.

3 Checkpoint Technician runs necessary power cable to the junction box at the foot of

the pedestal.

4 Checkpoint Technician crimps power wires into a connector.

5 Checkpoint Technician runs CAT 5e cable to junction boxes at the foot of each

pedestal.

Installing Liberty UHX Pedestals: Electrical and Network Wiring 3-4

Page 21

6 Plug the factory installed connector into the power supply.

The following tasks must be completed by Target IT staff.

1 Target Technician crimps the wires into an RJ-45 surface mount jack.

• Pins 1 and 2 - orange pair - white, orange, white

• Pins 3 and 6 - green pair - white, green, white

• Blue pair and brown pair are not used.

2 Target Technician tests the CAT 5 cable for network connectivity.

Estimated completion time

Conduit preparation will take approximately 120 minutes. This can vary by Checkpoint

contractor.

3-5 Liberty UHX Upgrade Guide

Page 22

Installing the pedestal

Once the wiring is completed, you are ready to install the actual Liberty UHX pedestal.

New anchor bolt holes are only required if the legacy pedestals are QS2000s. The bolt

locations for the QS2000 were closer together than those of the Strata PX and Liberty PX.

Since the bolt hole locations for the Strata PX and Liberty PX are identical to those of the

Liberty UHX, the existing bolts can be reused.

1 For replacement of QS2000 pedestals only, Checkpoint Technician drills new holes

and installs anchor bolts.

2 If larger raised base plates are used, cut the floor mats or existing flooring material to

accommodate the larger raised base plates (Checkpoint contractor).

In certain instances, longer and wider raised base plates are required. This varies by store

location.

3 Checkpoint contractor repairs flooring.

It may be necessary to install new flooring or replacement mats due to cuts and holes

(from the previous pedestals).

4 Checkpoint Technician bolts down the raised base plate assembly to the previously

installed anchor bolts.

Installing Liberty UHX Pedestals: Installing the pedestal 3-6

Page 23

5 Checkpoint Technician bolts down Liberty UHX pedestals to the raised base plate

assembly.

6 Checkpoint Technician connects the power to the Liberty UHX pedestal.

7 Checkpoint Technician connects the network cable to the Liberty UHX pedestal.

8 Checkpoint Technician configures, tunes and tests the Liberty UHX pedestals.

Estimated completion time

Approximate install time for a single pedestal is 60 minutes if new anchor bolt holes need

to be drilled. This will be for an upgrade from a QS2000 pedestal. This can vary by

Checkpoint contractor.

Approximate install time for a single pedestal is 30 minutes if an upgrade from Liberty PX

or Strata PX that does not include drilling new bolt holes. In most instances, this type of

upgrade will not include drilling new bolt holes. This can vary by Checkpoint contractor.

3-7 Liberty UHX Upgrade Guide

Page 24

NOTES

Installing Liberty UHX Pedestals: Installing the pedestal 3-8

Page 25

C

HAPTER

0

L

A site survey will be conducted by a team composed of both customer and Checkpoint

personnel. Once a site survey is reviewed by both parties, Checkpoint will detail store

specific information in a customer-specific version of the sample Installation Checklist

shown below.

Installation Checklist

General Information

IBERTY

UHX I

C HAPTER

NSTALLATION

C

HECKLIST

• ___________________ and Checkpoint will collaborate on upgrading existing EAS

installed Target Stores to Liberty UHX with Riser Baseplates.

• The installation start time will be ____ PM for both Checkpoint and _____________.

• Store hours may vary; work will begin at the Store Manager’s discretion. Speaking to

the Store Manager prior to the installation time is recommended.

• If the Checkpoint contractors are not onsite by ____ PM, the Checkpoint Technician

should contact __________________’s POC (Point Of Contact).

• If Checkpoint is not onsite by ____ PM, the Checkpoint contractor should contact the

Onsite Project Coordinator.

4-1 Liberty UHX Upgrade Guide

Page 26

Project Management/Marketing Scope

• Door layouts are reviewed to verify project deliverables.

• Checkpoint personnel will be responsible for ensuring that all local building codes are

met.

• Checkpoint personnel will remind Target to buy replacement mats (if necessary) and to

ensure they are delivered in time for the upgrade of existing pedestals.

• Checkpoint personnel will work with Target to determine which riser baseplate is best

suited for this store location.

• As a precautionary measure, Checkpoint personnel will carry a 15 by 10 foot mat to all

installations.

Checkpoint Contractor Scope

• The Checkpoint contractor is responsible for the removal of any Alvarado protective

posts that are currently installed for the purpose of protecting the existing EAS

pedestals.

• Removing Alvarado posts usually requires that the posts are cut to floor level.

• The Checkpoint contractor installs walker duct and power supply boxes.

• Optional one or two additional shelves in the ceiling on one side of the entry way can

be built or Checkpoint contractor can attach the 3 power supplies directly to the

studded wall.

• The Checkpoint contractor runs the CAT 5 network cable from the power supply to the

floor.

• The Checkpoint contractor is responsible for performing floor cuts, as specified by the

Checkpoint Technician.

• The Checkpoint contractor is responsible for back filling all floor cuts after all

necessary wiring has been installed by Checkpoint.

• When performing floor cuts on ceramic tiled floors, cuts should only be made within

existing grout lines.

• Any specific instruction regarding mats, carpets, tiles, and any other special flooring

consideration will come from Target. (___________)

• The Checkpoint contractor should be prepared to replace VCT tiles in certain stores.

The tiles will be provided by Target.

Checkpoint Technical Scope

• Checkpoint Technician removes all legacy pedestals and related equipment.

• Checkpoint Technician is responsible for inserting wiring into 1.00” PVC conduit

(recommended) to run from ceiling to trench. Factory installed connector should remain

at the portion of the PVC pipe nearer the ceiling.

• Ensures that both the Cat 5 cable and power wiring is run in the walker duct from base

of stud wall to bottom of each pedestal.

• Checkpoint Technician crimps the wires into a connector.

Liberty UHX Installation Checklist: Installation Checklist 4-2

Page 27

• Once network connectivity is confirmed by Target, Checkpoint Technician connects

Cat 5 cable and power connection to pedestals.

• All Liberty UHX antennas are installed, configured and tested for full EAS

functionality by the Checkpoint Technician prior to store opening.

• Once EAS functionality of the antennas is confirmed, the Liberty UHX pedestals

will be configured and tuned for full UHF functionality.

• Checkpoint Technician ensures that completed checklist is faxed to Onsite Project

Coordinator and leaves a voice mail message for the Installation Scheduler, Onsite

Project Coordinator, Account Representative and the Project Manager.

Target Technical Scope

• Target is responsible for obtaining replacement mat prior to installation.

• Target IT staff must install router and network connections prior to the start of the

installation by Checkpoint technicians.

• Target IT staff is responsible for running Cat 5 network cable and terminating at the

power supply, installing connectors on the network cable and testing network

connectivity.

System Removal

• Do not remove any systems until the following conditions have been met:

1 The intended Checkpoint shipment is verified.

2 All Checkpoint contractors are present or accounted for, to include the individual

responsible for performing floor cuts, and the flooring contractor.

3 The intended layout is assessed and shown to the Target store manager or person in

charge.

4 Ensure that any new mats do not interfere with the motion of in-swinging doors.

• All removed equipment will be placed in a dumpster or compactor (ask the store

manager or person in charge).

System Installation

• Reference the appropriate configuration drawing later in this document. Each drawing

lists the relative store numbers.

• Systems should not exceed 72” on center.

• If there are layout issues, the store manager or person in charge should be consulted and

given options first. If a decision is not reached then the Onsite Project Coordinator

should be contacted, and then the Target Project Manager.

4-3 Liberty UHX Upgrade Guide

Page 28

Follow up Procedures

• Ensure that the installation checklist is filled out and initialed by Checkpoint, the

Checkpoint contractor, and the onsite Target representative. The checklist should be

faxed to the Onsite Project Coordinator.

• At the completion of the installation, a voice mail message must be left for the

Installation Scheduler, Onsite Project Coordinator, Account Representative, and

the Project Manager.

Table 4.1

Project contact information

Title Name Office Ext. Cell Pager

Account Scheduler

Onsite Project

Coordinator

[Customer Name]

Project Manager

[Checkpoint

Contractor Name]

Point of Contact

Account Manager

Project Manager

Table 4.2

Item

#

A New layout agreed upon?

B Replacement mat acquired? (if necessary)

C Existing pedestals removed and disposed of?

D Old drill holes repaired? (if necessary)

E Floor mats removed?

F Alvarado posts removed and disposed of?

G Alvarado bumper post holes filled in? (if necessary)

H New floor channel cut?

I Walker duct and power supply boxes installed?

J Power run from ceiling to floor?

K Power run through walker duct to pedestal riser?

L Power wires crimped and connectors installed?

M CAT 5 cable run and terminated at pedestal riser?

N CAT 5 cable crimped and connectors installed?

O Floor cut filled in?

P Floor covering repaired/installed/replaced?

Q Work area is clean and ready for store opening?

R Pedestals tested and properly functioning for EAS?

S Pedestals tested and properly functioning for UHF?

Door installation checklist

Door Designation (i.e., North Door)

No? Explain

Below

Customer

Initials

Checkpoint

Initials

Checkpoint

Contractor

Initials

Liberty UHX Installation Checklist: Installation Checklist 4-4

Page 29

Table 4.2

Door installation checklist

Item

#

Door Designation (i.e., North Door)

Explanation of negative responses or further comments

No? Explain

Below

Customer

Initials

Checkpoint

Initials

Checkpoint

Contractor

Initials

Table 4.3

Door installation checklist

Item

#

Door Designation (i.e., North Door)

A New layout agreed upon?

B Replacement mat acquired, if necessary

C Existing pedestals removed and disposed of?

D Old drill holes repaired? (if necessary)

E Floor mats removed?

F Alvarado posts removed and disposed of?

G Alvarado bumper post holes filled in? (if necessary)

H New floor channel cut?

I Walker duct and power supply boxes installed?

J Power ran from ceiling to floor?

K Power ran from walker duct to pedestal riser?

L Wires crimped and power connectors installed?

M Cat 5 cable ran and terminated at pedestal riser?

N Floor cut caulked and/grouted?

O Floor covering repaired/installed/replaced?

P Work area is clean and ready for store opening?

Q Pedestals tested and properly functioning for EAS?

R Pedestals tested and properly functioning for UHF?

Explanation of negative responses or further comments

No? Explain

Below

Customer

Initials

Checkpoint

Initials

Checkpoint

Contractor

Initials

4-5 Liberty UHX Upgrade Guide

Page 30

Table 4.4

Door installation checklist

Item

#

Door Designation (i.e., North Door)

A New layout agreed upon?

B Replacement mat acquired, if necessary

C Existing pedestals removed and disposed of?

D Old drill holes repaired? (if necessary)

E Floor mats removed?

F Alvarado posts removed and disposed of?

G Alvarado bumper post holes filled in? (if necessary)

H New floor channel cut?

I Walker duct and power supply boxes installed?

J Power ran from ceiling to floor?

K Power ran from walker duct to pedestal riser?

L Wires crimped and power connectors installed?

M Cat 5 cable ran and terminated at pedestal riser?

N Floor cut caulked and/grouted?

O Floor covering repaired/installed/replaced?

P Work area is clean and ready for store opening?

Q Pedestals tested and properly functioning for EAS?

R Pedestals tested and properly functioning for UHF?

Explanation of negative responses or further comments

No? Explain

Below

Customer

Initials

Checkpoint

Initials

Checkpoint

Contractor

Initials

Table 4.5

Project Signoff Sheet

Representative Name (Print) Signature

Target

Checkpoint

Checkpoint

Contractor

Table 4.6

Store # City: State: Date:

Store specific information

***Please Fax completed checklist to _______________ at _________________.

Liberty UHX Installation Checklist: Installation Checklist 4-6

Page 31

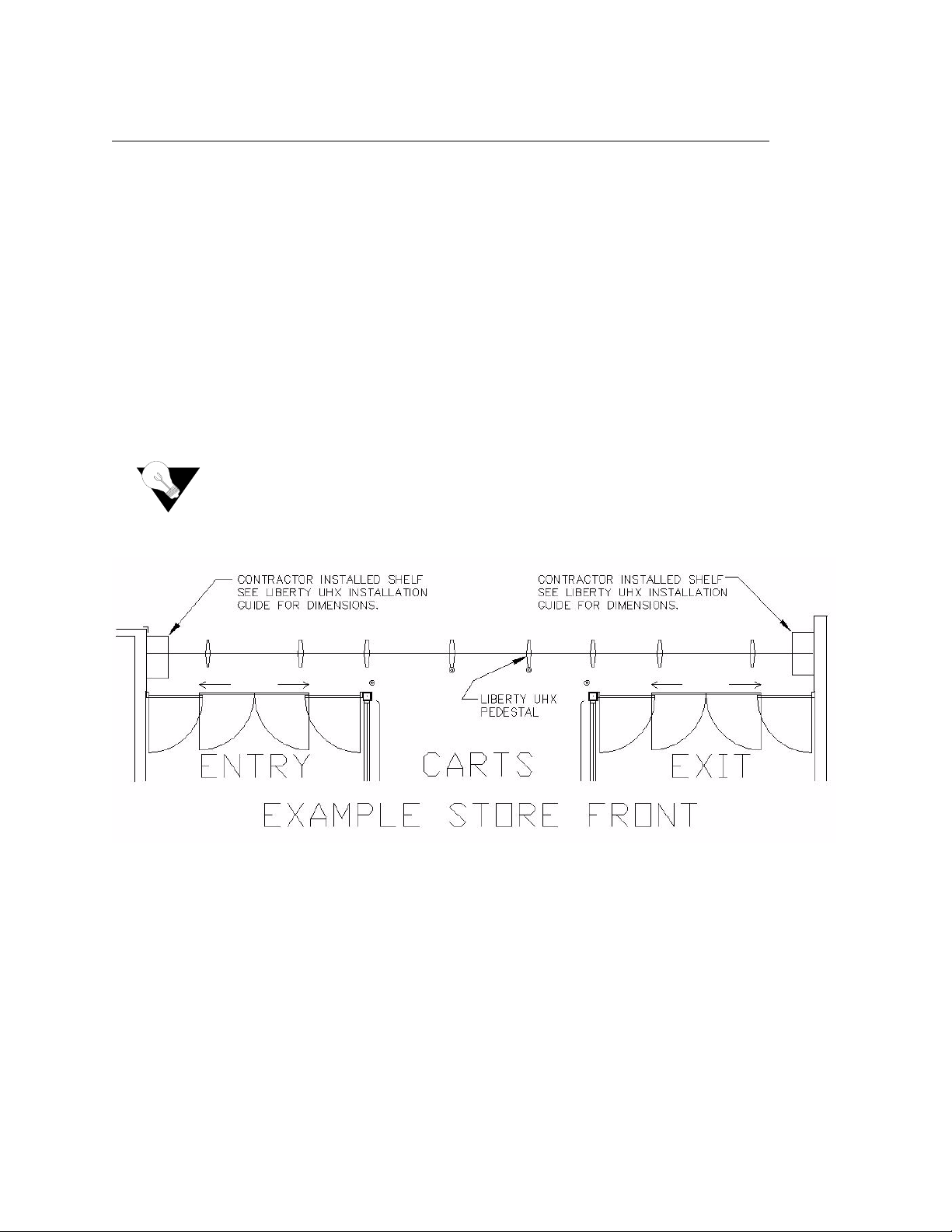

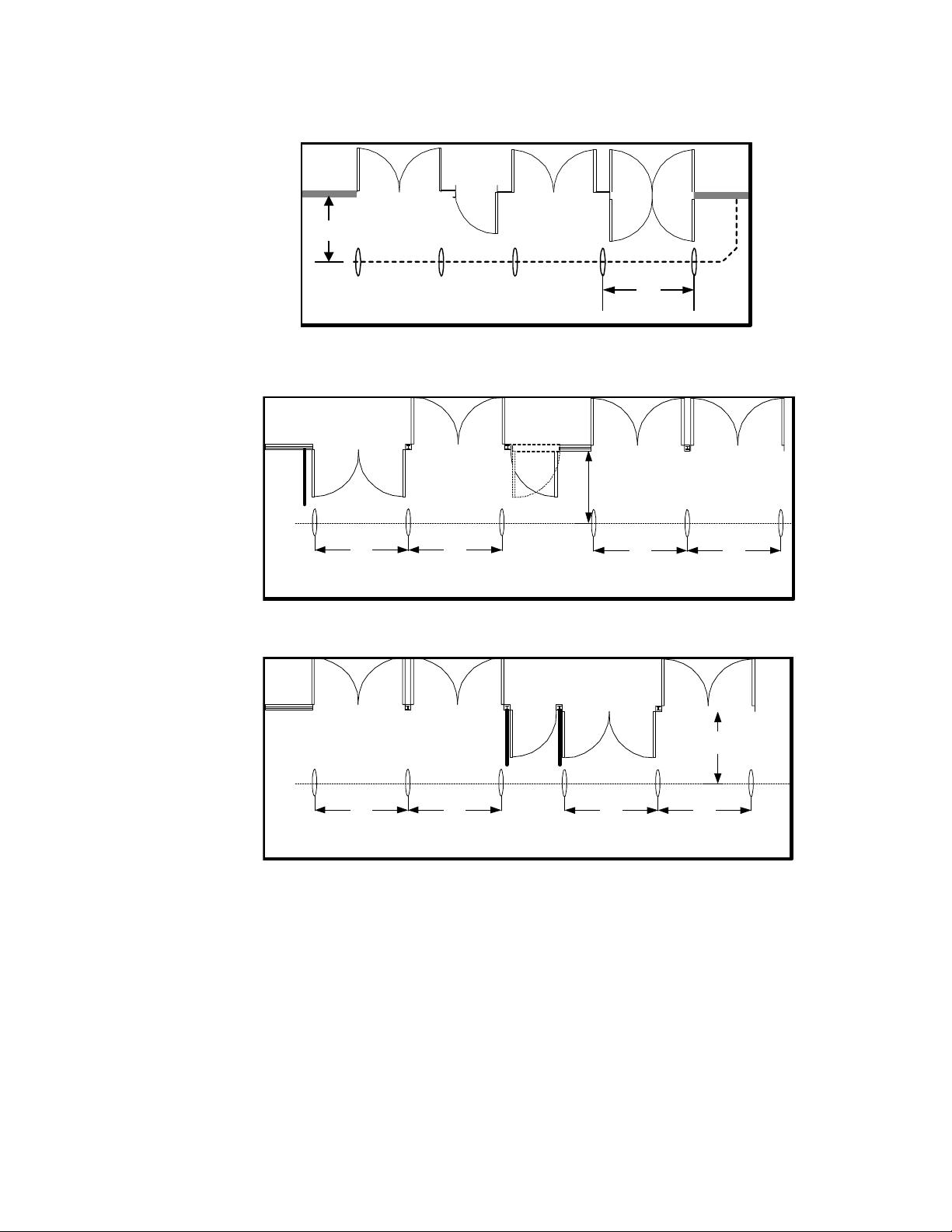

Sample Door Layouts

56"

#175,

#282

4'-0"

72"72"

56"

5'-9"

72" 72"

14' to Registers

72" 72"72"72"

#11, #26 [Mirrored Config: #12]

4-7 Liberty UHX Upgrade Guide

72"

72"

56"

72"

Page 32

56"

#51

56"

72"72"

72"

72" 72"

#346, #696, #748 - [Mirrored Config: #764, #826]

#339

56"

72" 72"72"72"

Liberty UHX Installation Checklist: Installation Checklist 4-8

Page 33

The Liberty UHX AR-400 is configured via the configuration computer after installation

of the Liberty UHX pedestals.

Equipment

• Configuration computer, functional and powered

• Cat5 Cable, 3 ft. or longer

C

HAPTER

0

L

IBERTY

UHX AR-400 S

ETUP INSTRUCTIONS

C HAPTER

• Liberty UHX Pedestal

• Power Supply, Checkpoint Part No. 7375784

• Power Cord, Checkpoint Part No. 623532

Post-Installation Procedure

1 Connect the Cat5 cable to AR-400 Ethernet port (using the access door).

2 Connect the opposite end of the Cat5 cable to the configuration computers Ethernet

port.

3 Power-up the computer.

4 Change the IP address of the configuration computer to 192.168.0.1.

5 Change the Subnet Mask of the configuration computer to 255.255.0.0.

6 Open Internet Explorer and type HTTP://192.168.127.254 in the address box and then

press Enter.

5-1 Liberty UHX Upgrade Guide

Page 34

You see the Reader Administrator Console screen.

Figure 5.1

Next to User Name:, type in the admin.

7

8 Next to Password, type in the admin.

9 Click Login.

User Login screen of the Reader Administrator Console

OR

Press Enter.

Figure 5.2

Liberty UHX AR-400 Setup Instructions: Post-Installation Procedure 5-2

Reader Administrator Console screen

Page 35

10 Click the Maintenance link on the left hand navigation bar.

You see the Reader Maintenance Console screen.

Figure 5.3

Click the Communication link on the left hand navigation bar.

11

Reader Maintenance Console screen

You see the Communication Configurations screen.

5-3 Liberty UHX Upgrade Guide

Figure 5.4

Communication Configurations screen

Page 36

12 Change the IP address to the specified IP address.

13 Change the Subnet Mask to the specified Subnet Mask.

14 Change the Default Gateway to the specified Default Gateway.

15 Click Set TCP/IP Properties.

16 Click the Main link on the left hand navigation bar.

17 Click the Commit/Revert link.

18 Click Commit.

19 Click the Logout link.

20 Power cycle the AR-400.

21 Verify the IP address change by opening Internet Explorer.

22 Type the specified IP address in the address box (HTTP://xxx.xxx.xxx.xxx) and then

press enter.

The following screen should appear.

Figure 5.5

Close Internet Explorer.

23

24 Unplug the cat-5 cable from the AR-400.

25 Close the access door.

Liberty UHX AR-400 Setup Instructions: Post-Installation Procedure 5-4

User Login screen

Page 37

Verification of Power Settings

To verify the power settings, complete the following:

1 Click the Read Point Class link on the left hand navigation bar.

2 Select Area (from class list on the right hand side).

3 Click Select Class.

4 Verify Gain is set to 50%.

5 Verify Retry is set to 1.

6 Verify Air Protocol is set to ALL.

A Gain setting of 50% corresponds to a setting of 256 7 in the ART (Advanced Reader

Test console) program contained in the reader.

5-5 Liberty UHX Upgrade Guide

Figure 5.6

Read Point Classes screen

Page 38

Notes

Liberty UHX AR-400 Setup Instructions: Verification of Power Settings 5-6

Loading...

Loading...