Page 1

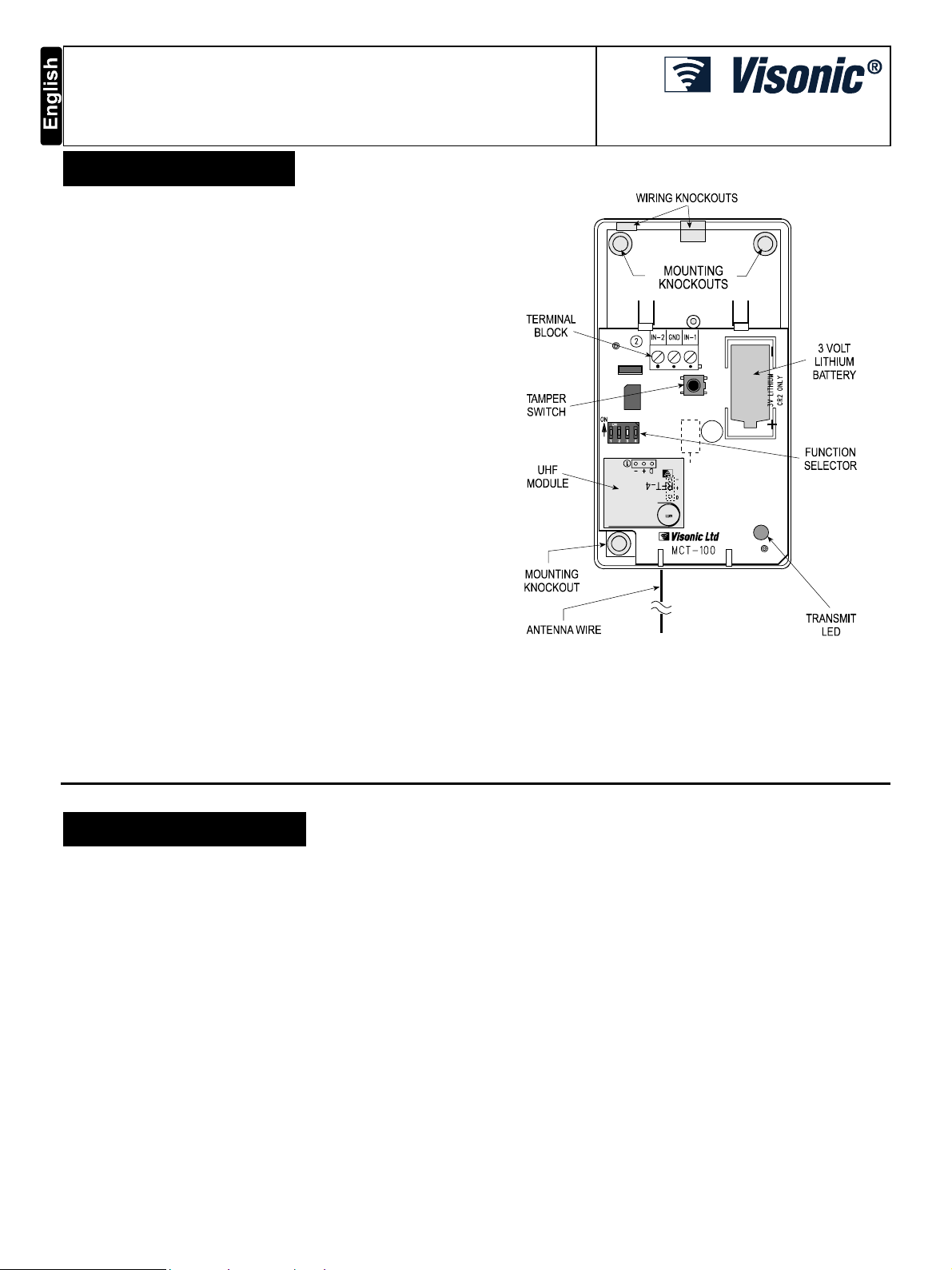

MCT-100, MCT-100T (3V)

Supervised 2-Input PowerCode Wireless Transmitter

1. INTRODUCTION

The MCT-100 is a fully supervised, two-input PowerCode wireless transmitter designed for electronic security applications. Both

inputs can be set to operate with a normally closed (N.C.) loop, or

with an end-of-line (E.O.L.) loop in which both N.C. and N.O.

sensors can be used. An on-board programming DIP switch

allows the installer to disable input No. 1 (IN1) in applications

where only a single input is needed.

Each input has an individual 24-bit PowerCode ID which

identifies it to the target receiver as if it were a separate

transmitter. Each ID is randomly selected in the factory from 16

million possible code combinations.

Disturbing an input loop of the MCT-100 initiates transmission of

the specific input's PowerCode ID followed by various status and

mode designators. Alarm information and other data are thus

forwarded to the alarm control panel or to the head-end

computer, depending on the type of system in which the MCT100 is used.

Since messages transmitted by the MCT-100 might collide with

messages sent by other PowerCode transmitters, a "smart" anticollision transmission sequence is used (see Appendix A).

The MCT-100 is protected by a tamper switch, activated when

the cover is removed. Once the tamper switch contacts open, a

message will be transmitted from input 1 with the “tamper alert”

marker ON. If the installer disables input 1, the tamper situation

will be automatically reported by input 2 instead.

The MCT-100T includes an "under-board" tamper switch that

opens if the unit is forcibly removed from the mounting place. In

this case, a tamper message is transmitted.

A periodic supervision message, distinguished by a specific

marker, is transmitted automatically from input 1 only (if enabled)

or from input 2 only (if input 1 is disabled). The supervision

message is transmitted once per 15 minutes by all models,

except for the 315 MHz model which sends this message once

per 60 minutes. The receiver is thus informed, at regular

intervals, of the MCT-100 active participation in the system.

An indicator LED lights during transmission whenever alarm or

tamper events are reported. The LED does not light while a

supervision message is being transmitted.

Operating power is obtained from an on-board 3 V Lithium ThionylChloride battery. A weak battery will cause a "low battery"

designator to be added to any message transmitted (see Appendix

A for details).

Installation Instructions

Figure 1. MCT-100, Cover Removed

2. SPECIFICATIONS

Frequency (MHz): 315, 433.92, 868.95 and 869.2625 or other

frequencies according to local requirements

Transmitter's ID Code: 24-bit digital word, over 16 million

combinations, pulse width modulation.

Overall Message Length: 36 bits

Alarm Inputs: 2, each with a separate 24-bit transmitter ID

Input Circuit Type: N.C. / E.O.L., selected with on-board DIP

switch

E.O.L. Resistor Required: 47 kΩ

Message Repetition: Repetitive transmission (once every 3

minutes) or one-shot, as selected with on-board DIP switch.

Supervision: Signaling at 15-minute intervals (60 minute intervals

for the 315 MHz model) or according to the local standards from

input 1 if enabled, or from input 2 if input 1 is disabled.

D-300586 1

Response to Tamper Event: Tamper report every 3 minutes

(until the tamper switch is restored).

Power Source: 3 V Lithium Thionyl Chloride (LiSOCl

Panasonic CR-2 or equivalent.

Battery Life Expectancy: 3 years (for typical use)

Battery Supervision: Automatic transmission of battery

condition data as part of any status report.

Operating Temperature: 0°C to 49°C (32°F to 120°F).

Dimensions: 110 x 63 x 25 mm (4-5/16 x 2-1/2 x 1 in.).

Weight: 66.5 g (2.34 oz)

Compliance with Standards: Meets FCC Part 15, MPT1349

and Directive 1999/5/EC. EN50131-1 Grade 2, Class II (MCT-100T

only).

2) battery,

Page 2

3. INSTALLATION

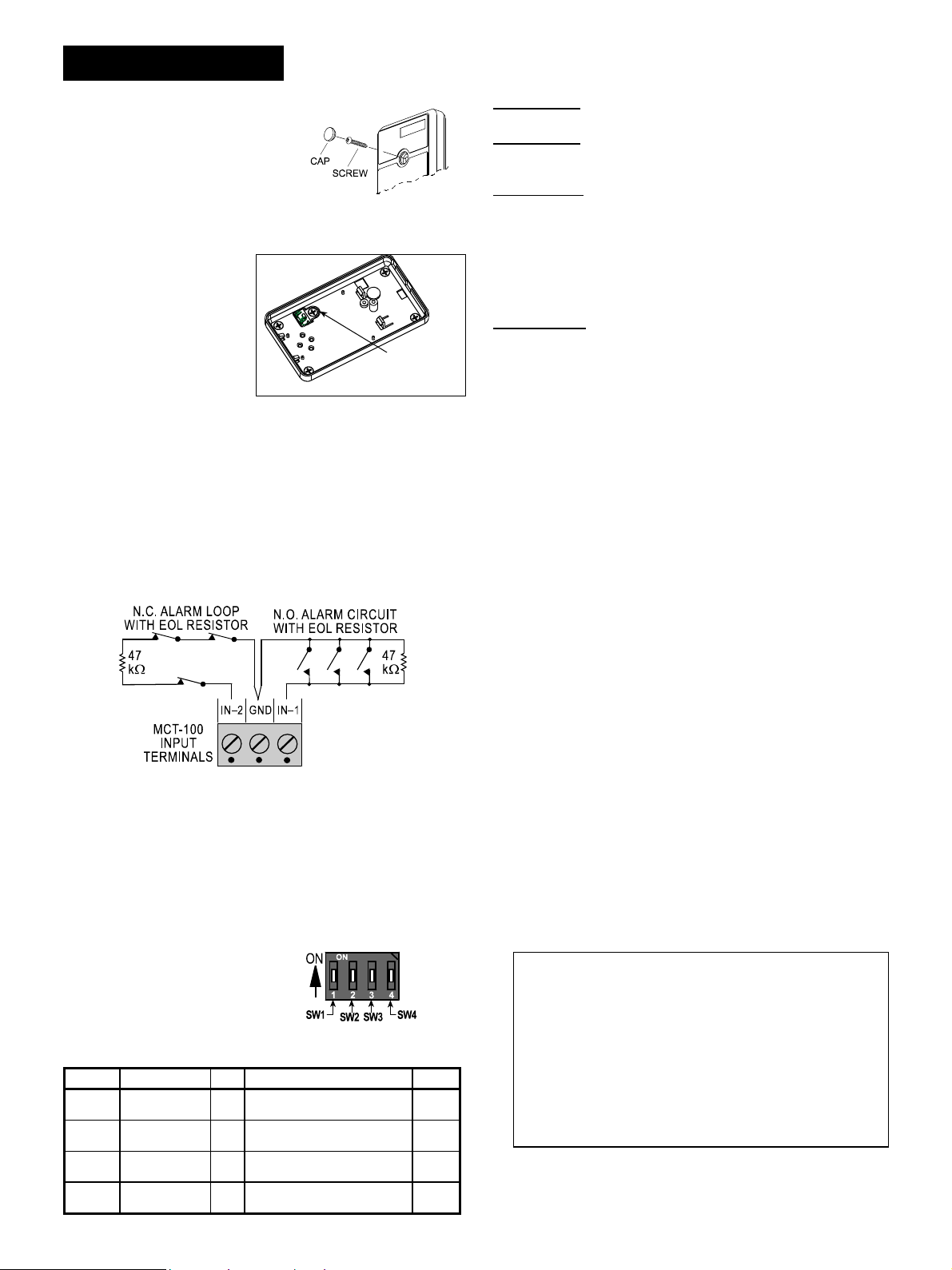

3.1 Mounting

Remove the screw from the front

cover (Fig. 2) and separate the front

cover from the base.

The plastic cap shown is supplied

separately in a small nylon bag keep it for later use. Mount the base

equipped with the printed circuit

Figure 2. Cover Assembly

board in the selected location, using the mounting and wiring

knockouts shown in Fig. 1.

Attention! The MCR-100T

includes an additional tamper

switch (under the board) that is

actuated by a leaf spring. A

screw that fastens the tamper

switch actuator to the

mounting surface must be

used, as shown. If the actuator

is secured and the unit is

MCT-100T

Back tamper

switch fixing screw

forcibly removed from its mounting place, the actuator breaks

away from the base, causing the tamper switch opening - a

tamper alarm is consequently transmitted.

3.2 Wiring

Route the wires through a wiring knockout in the base.

If an input is defined as a Normally Closed (N.C.) type (SW-1 or

SW-2 are set to OFF), series connected normally closed sensor

contacts must be used exclusively.

If an input is defined as an E.O.L. type, Normally Closed (N.C.)

as well as Normally Open (N.O.) sensor contacts can be used. A

47 kΩ resistor must be wired at the far end of the E.O.L. zone

loop, as in Figure 3.

Figure 3. Wiring Example with E.O.L Resistors

Notes:

1. An alarm message will be transmitted once the loop is opened

or short circuited.

2. If you do not need input No. 2, connect it to the GND terminal

with a short length of jumper wire (in case of N.C.) or with a

Ω

resistor (in case of E.O.L.).

47 k

3.3 Setting the Function Selector

Before testing, set DIP switches SW1 through SW4 as required

for the particular application.

The MCT-100 is equipped with

a 4-position DIP switch function

selector (Fig. 4). Each switch

lever allows you to select one

of two options, as explained in

the following table:

Table 1. Getting acquainted with the function selector

Switch Function Pos. Selected Option Default

SW1

SW2

SW3

SW4

IN1 enable/

disable

EOL for IN1

and IN2

Restore reports

enable/disable

Transmit mode

selector

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Figure 4. Function Selector

Input No. 1 is enabled

Input No. 1 is disabled

Inputs are E.O.L. (47 kΩ)

Inputs are N.C.

Restore events reported

Restore events not reported

Alarms reported every 3 min.

Alarms reported only once

ON

OFF

ON

OFF

SWITCH SW1: Determines whether input 1 (IN1) will be enabled

or disabled.

SWITCH SW2

: Determines whether both inputs will behave as

47 kΩ end-of-line (E.O.L.) circuits or as normally closed (N.C.)

inputs.

SWITCH SW3

: Determines whether the transmitter will report

“restore” events.

Note: If the MCT-100 is used in conjunction with motion

detectors, there is no point in setting SW3 to ON, because the

detector restores automatically after an alarm. However, when

the MCT-100 is used with a door or window magnetic switch,

selecting the ON position will enable you to find out whether the

door or window under surveillance are open or closed.

SWITCH SW4

: In non-supervised systems, it is sometimes

required to report an alarm repeatedly at short intervals, until the

disturbed input reverts to its normal (undisturbed) state. Switch

SW4 is used to select between repetitive and one-shot

transmission.

Note: Transmissions initiated by "tamper” events will be repeated

once every 3 minutes, regardless of SW4 setting.

3.4 Battery Insertion and Test

A. Insert the battery between the battery clips, making sure that

the polarity is correct. For proper operation, only Lithium

Thionyl Chloride battery (as specified in Section 2)

should be used.

Note: Before each supervision report, the battery voltage is

tested. If a low battery condition is detected, a "low battery"

alert signal will be included in the supervision message.

If the battery is not replaced, all following transmissions will

include the "low battery" alert signal, which has to be acted

upon without delay.

B. Since the cover is removed and power is applied, a tamper

situation exists. Verify that the MCT-100 transmits (the LED

lights briefly) once every 3 minutes.

C. When you are satisfied that tamper transmissions are carried

out properly, put the cover back on to return the tamper

switch to its normal undisturbed position. Wait slightly over 3

minutes to verify that tamper transmissions cease.

D. Momentarily disturb any one of the sensors connected to the

first input (IN1) and verify that the transmitter LED lights,

indicating that transmission is in progress. IF SW4 is on, wait

3 minutes to verify that the transmission is repeated at 3minute intervals.

E. Restore the sensor to the undisturbed state and watch the

LED. If SW3 is set to ON, another transmission will take place

upon restoral.

F. Repeat Steps D and E above with the second input (IN2).

G. Refer to the target receiver's installation instructions, and let

the receiver "learn" the ID codes associated with both inputs

of the MCT-100.

ATTENTION! Because each input of the MCT-100 acts as

an independent transmitter with an individual ID, make sure

that both input IDs are learned by the receiver.

With the target receiver in the LEARN mode, an alarm

transmission from each input will enroll the input’s ID in the

receiver’s memory.

A tamper transmission will also work if you remember this:

- If the Input No. 1 is enabled (SW1 is ON), the tamper

message will be sent with Input 1’s ID.

- If Input No. 1 is disabled (SW1 is OFF), the tamper

message will be sent with Input 2’s ID.

H. Secure the front cover with the screw and screw cap (Fig. 2).

2 D-300586

Page 3

4. MISCELLANEOUS COMMENTS

4.1 Product Limitations

Visonic Ltd. wireless systems are very reliable and are tested to

high standards. However, due to low transmitting power and

limited range (required by FCC and other regulating authorities),

there are some limitations to be considered:

A. Receivers may be blocked by radio signals occurring on or near

their operating frequencies, regardless of the digital code used.

B. A receiver can only respond to one transmitted signal at a time.

C. Wireless equipment should be tested regularly to determine

whether there are sources of interference and to protect

against faults.

4.2 Statements

This device complies with Part 15 of the FCC Rules and RSS210 of Industry and Science Canada. Operation is subject to the

following two conditions: (1) This device may not cause harmful

interference, and (2) this device must accept any interference

received, including interference that may cause undesired

operation.

The user is cautioned that changes or modifications to the

unit, not expressly approved by Visonic Ltd., could void the

user's FCC or other authority to operate the equipment.

This device complies with the essential requirements and

provisions of Directive 1999/5/EC of the European Parliament and

of the Council of 9 March 1999 on radio and telecommunications

terminal equipment.

4.3 Frequency Allocations for Wireless

Devices in European (EU) Countries

• 433.92 MHz has no restriction in any EU member state.

• 315 MHz is not allowed in any EU member state

• 868.95 MHz (wide band) is allowed in all EU member states.

• 869.2625 MHz (narrow band) are not restricted in any EU

member state.

APPENDIX A. THE VISONIC LTD. POWERCODE SYSTEM

A-1. The PowerCode Message Format

The PowerCode message transmitted by the MCT-100 includes

the 24-bit ID of the input of origin and a status report (see Fig. A1).

Figure A1. Transmitted Data

A message includes the following data:

• Input ID: The 24-bit ID of the input sending the message.

• Tamper / Restore: Upon removal of the unit's front cover,

Input 1 (or input 2 if input 1 is disabled) will send out a

message with a "tamper marker" set to ON. If the unit's cover is

put back, the “input in charge of reporting” will initiate a

message with the tamper marker OFF ("Tamper Restore").

• Alarm / Restore: Once the input loop is disturbed, a message

will be transmitted with an "Alarm marker" ON. Upon restoral of

the input loop, a message will be transmitted with the alarm

marker set to OFF (provided that restore transmission is

desired - SW-3 has been set to ON - see Para. 3.3.).

Low Battery: A special battery condition marker is used to

report the battery status in any message. The battery is tested

once an hour and if found low, Input 1 will initiate a message in

which the "Low Battery” marker is set to ON. This marker will

be ON in all messages that follow, whatever the cause for

transmission. Once the battery is restored to normal,

this

marker will be OFF in all messages that follow (“Battery

Restore”).

• Supervision Report: A special "supervision message” marker,

when set to ON, identifies the periodic supervision messages

transmitted automatically at 60 minute intervals. This marker

will be OFF in all other messages. Supervision messages are

sent by input 1 (if enabled) or by input 2 (if input 1 is disabled).

• Transmitter Type: A special marker indicates the type of the

transmitter:

Supervised or non-supervised

Reports or does not report restorals after alarm

• Checksum: Checksum bits at the end of the message allow

the receiver to determine whether an incoming message is

valid (error-free). This feature considerably upgrades the

reliability of the wireless communication link.

A-2. Anti-Collision

To overcome message collisions at the receiving end, PowerCode transmitters transmit 3 data bursts at random intervals, with

6 repetitions of the same message in each burst (Fig. A2). This

redundancy improves the probability of reception.

Note: Periodic supervision messages are an exception to this

rule - they consist of a single

Figure A2. Anti-Collision Transmission Sequence

6-message burst.

D-300586 3

Page 4

WARRANTY

Visonic Ltd. and/or its subsidiaries and its affiliates ("the Manufacturer") warrants its

products hereinafter referred to as "the Product" or "Products" to be in conformance with

its own plans and specifications and to be free of defects in materials and workmanship

under normal use and service for a period of twelve months from the date of shipment by

the Manufacturer. The Manufacturer's obligations shall be limited within the warranty

period, at its option, to repair or replace the product or any part thereof. The Manufacturer

shall not be responsible for dismantling and/or reinstallation charges. To exercise the

warranty the product must be returned to the Manufacturer freight prepaid and insured.

This warranty does not apply in the following cases: improper installation, misuse,

failure to follow installation and operating instructions, alteration, abuse, accident or

tampering, and repair by anyone other than the Manufacturer.

This warranty is exclusive and expressly in lieu of all other warranties, obligations or

liabilities, whether written, oral, express or implied, including any warranty of

merchantability or fitness for a particular purpose, or otherwise. In no case shall the

Manufacturer be liable to anyone for any consequential or incidental damages for breach

of this warranty or any other warranties whatsoever, as aforesaid.

This warranty shall not be modified, varied or extended, and the Manufacturer does not

authorize any person to act on its behalf in the modification, variation or extension of this

warranty. This warranty shall apply to the Product only. All products, accessories or

attachments of others used in conjunction with the Product, including batteries, shall be

covered solely by their own warranty, if any. The Manufacturer shall not be liable for any

damage or loss whatsoever, whether directly, indirectly, incidentally, consequentially or

otherwise, caused by the malfunction of the Product due to products, accessories, or

attachments of others, including batteries, used in conjunction with the Products.

W.E.E.E. Product Recycling Declaration

For information regarding the recycling of this product you must contact the company from which you orignially purchased it. If you are discarding this product and not

returning it for repair then you must ensure that it is returned as identified by your supplier. This product is not to be thrown away with everyday waste.

Directive 2002/96/EC Waste Electrical and Electronic Equipment.

The Manufacturer does not represent that its Product may not be compromised and/or

circumvented, or that the Product will prevent any death, personal and/or bodily injury

and/or damage to property resulting from burglary, robbery, fire or otherwise, or that the

Product will in all cases provide adequate warning or protection. User understands that a

properly installed and maintained alarm may only reduce the risk of events such as

burglary, robbery, and fire without warning, but it is not insurance or a guarantee that

such will not occur or that there will be no death, personal damage and/or damage to

property as a result.

The Manufacturer shall have no liability for any death, personal and/or bodily injury

and/or damage to property or other loss whether direct, indirect, incidental,

consequential or otherwise, based on a claim that the Product failed to function.

However, if the Manufacturer is held liable, whether directly or indirectly, for any loss or

damage arising under this limited warranty or otherwise, regardless of cause or origin, the

Manufacturer's maximum liability shall not in any case exceed the purchase price of the

Product, which shall be fixed as liquidated damages and not as a penalty, and shall be

the complete and exclusive remedy against the Manufacturer.

Warning: The user should follow the installation and operation instructions and among

other things test the Product and the whole system at least once a week. For various

reasons, including, but not limited to, changes in environmental conditions, electric or

electronic disruptions and tampering, the Product may not perform as expected. The user

is advised to take all necessary precautions for his/her safety and the protection of his/her

property.

6/91

VISONIC LTD. (ISRAEL): P.O.B 22020 TEL-AVIV 61220 ISRAEL. PHONE: (972-3) 645-6789, FAX: (972-3) 645-6788

VISONIC INC. (U.S.A.):

VISONIC LTD. (UK): FRASER ROAD, PRIORY BUSINESS PARK, BEDFORD MK44 3WH. PHONE: (0870) 730-0800 FAX: (0870) 730-0801

INTERNET: www.visonic.com

VISONIC LTD. 2006 MCT-100, MCT-100T D-300586 (REV. 1, 9/06)

65 WEST DUDLEY TOWN ROAD

, BLOOMFIELD CT. 06002-1376. PHONE: (860) 243-0833, (800) 223-0020. FAX: (860) 242-8094

4 D-300586

Loading...

Loading...