Page 1

Evolve F10

Installation Manual

Document Version *60

P/N 10034505

Page 2

EVOLVE F10 Installation Manual

Rev

Description

Date

Authors

00

Preliminary Release

11/29/2012

Ron Decker , Joseph Galanti,

Copyright © 2012 by Checkpoint Systems Inc.

Released 11/29/2012.

Published by:

Checkpoint Systems Inc.

101 Wolf Drive

Thorofare, NJ 08086

For use with the Checkpoint EVOLVE F10 Systems.

Trademarks

Checkpoint is a registered trademark of Checkpoint Systems, Inc.

Checkpoint, Liberty, Evolve, and VisiPlus are registered trademarks of Checkpoint Systems, Inc.

All rights reserved. Info rmation in this document is subject to change without notice.

Other products are © or ® of their respective manufacturers or copyright holders.

Companies, names and data used in examples herein are fictitious unless otherwise noted. No part

of the contents of this book may be reproduced or transmitted in any form or by any means

without the written permission of the publisher.

Copyright and Warranty Information

All rights reserved. T he information in this document is subject t o change without notice.

Because of the changing nature of this product information presented in the F10 Installation

Manual, Checkpoint Systems, I nc. is not lia ble for any omissions, misstatements, o r other errors of

information.

The information presented in this document may not be copied, used or disclosed to others for the

purpose of procurement or manufacturing without the written permission of Checkpoint Systems,

Inc. This gu i de and the pro ducts discussed in this guide are the exclus ive property of Checkpoint

Systems Inc. Copyright laws of the U nited States protect all information and products.

Copyright© 2012 Checkpoint Systems, Inc. All rights reserved.

Document Revision Information

Part Number: 10034505

EVOLVE F10 Installation Manual, version 00

Greg Plizak

F10 Installation Manual Rev.*60 2 of 71

Page 3

Statements

• The device(s) may only be used for the intended purpose designed by for the manufacturer.

• Unauthoriz ed changes and the use of spa re parts and additional devi ces which have not been sold or

recommended by the manufacturer may cause fire, electric shocks or injuries. Such unauthorized measures

shall exclude any liability by the manufacturer.

• The liability-prescriptions of the manufacturer in the issue valid at the time of purchase are valid for the

device. The manufacturer shall not be held legally responsible for inaccuracies, errors, or omissions in the

manual or automatically set parameters for a device or for an incorrect application of a device.

• Repairs may only be executed by the manufacturer.

• Installation, operation, and maintenance procedures should only be carried out by qualified personnel.

• Use of the device and its installation must be in accordance with national legal requirements and local

electrical codes.

• When worki ng on devices the valid safety regulations must be observed.

• Before touching the device, the power supply must always be interrupted. Make sure that the device is

without volt age by measuring. The fading of an oper ation control (LED) is not an indicator for an

interrupted power supply or the device being out of voltage!

• The installer or licensed electric ia n must follow all NEC and local codes.

• All wires routed in the floor per article 725 must be Class 2 and be UL Listed. UL Recognized AWM may

be employed, provided it is enclosed in Conduit or ENT.

• The F10 is not to be installed in Wet Locations. For indoor use only.

• Checkpoint is not responsible for or warrant any repairs or rework to the flooring during or after the

installation of the antenna.

Guide Conventions

Document conventions are described below:

This is a Warning icon. When it ap pears, it indicates a potentially hazardous situation, which if not

avoided, could result in d eath or serious injury.

Caution: This is a Caution icon. W hen it ap pears, it indicates a potentially hazar d o us sit ua ti on which

if not avoided, could result in property damage or malfunction of equipment.

Note: This is a Tip icon. When it appears, the corresponding text indicates a helpf ul note or tip when

using the feature.

For all measurements:

• To meet both CE and FCC requirements, all measurements will be listed in the following for mat:

Metric [Imperial], for example: 46cm [18in] or 0.9m [3ft].

• Where non-S.I. units are applicable, such as 6’ x 4’ or 3/16”, the format in this case is Unit

(metric).

Where on-screen computer instructions are given:

Button Name - This describes a button or an on-screen command or drop-down selection.

For example, the <DONE> button is represented in this document as Done.

Key Name - This describes a keystroke on a keyboard. For example, Ctrl represents the control key.

F10 Installation Manual Rev. *60 3 of 71

Page 4

Important Information to our Users in North America

FCC Regulatory Compliance Statement

Checkpoint Systems, Inc., offers Electronic Article Surveillance (EAS) or Radio Frequency

Identification Products that have been FCC certified or verified to 47 CFR Part 15 Subparts B/C.

Appropriately, one of the following labels will apply to the approval:

NOTE: This equipment has been tested and found to comply with the limits for a class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful

interference in wh ich c as e t he u ser w il l b e r equ ire d to corre ct t he i nt er fer en ce at hi s o wn expense.

- OR -

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) including this device may not cause harmful interference, and (2) this

device must accept any interference received, including interference that may cause

undesired operation, which may include intermittent decreases in detection and/or

intermittent increases in alarm activity.

Industry Canada Regulatory Compliance Statement

Under Industry Canada regulations, this radio transmitter may only operate using an antenna of a

type and maximum (or lesser) gain approved for the transmitter by Industry Canada. To reduce

potential radio interference to other users, the antenna type and its gain should be so chosen that

the equivalent isotropically radiated power (e.i.r.p.) is not more than that necessary for successful

communication.

This radio transmitter (IC: 3356B-F20) has been approved by Industry Canada to operate with

the antenna types listed below with the maximum permissible gain and required antenna

impedance for each antenna type indicated. Antenna types not included in this list, having a gain

greater than the maximum gain indicated for that type, are strictly prohibited for use with this

device.

Operation is subject to the following two conditions:

(1) this device may not cause interference, and

(2) this device must accept any interference, including interference that may cause undesired

operation of the device.

To reduce potential radio interference to other users, the antenna type and its gain should be so

chosen that the equivalent isotropically radiated power (e.i.r.p.) is not more than that permitted

for successful communication.

F10 Installation Manual Rev. *60 4 of 71

Page 5

Industrie Canada

Conformément à la réglementation d'Industrie Canada, le présent émetteur radio peut fonctionner

avec une antenne d'un type et d'un gain maximal (ou inférieur) approuvé pour l'émetteur par

Industrie Canada. Dans le but de réduire les risques de brouillage radioélectrique à l'intention des

autres utilisateurs, il faut choisir le type d'antenne et son gain de sorte que la puissance isotrope

rayonnée équivalente (p.i.r.e.) ne dépasse pas l'intensité nécessaire à l'établissement d'une

communication satisfaisante.

Le présent émetteur radio (IC: 3356B-F20) a été approuvé par Industrie Canada pour fonctionner

avec les types d'antenne énumérés ci-dessous et ayant un gain admissible maximal et l'impédance

requise pour chaque type d'antenne. Les types d'antenne non inclus dans cette liste, ou dont le

gain est supérieur au gain maximal indiqué, sont strictement interdits pour l'exploitation de

l'émetteur.

Le fonctionnement de l’ appareil est soumis aux deux conditions suivantes:

(1) Cet appareil ne doit pas perturber les communications radio, et

(2) cet appareil doit supporter toute perturbation, y compris les perturbations qui pourraient

provoquer son dysfonctionnement.

Pour réduire le risque d'interférence aux autres utilisateurs, le type d'antenne et son gain

doivent être choisis de façon que la puissance isotrope rayonnée équivalente (PIRE) ne

dépasse pas celle nécessaire pour une communication réussie.

Equipment Safety Compliance Statement

Checkpoint Systems’ EAS or Radio Frequency Identification products have been designed to be

safe during normal use and, where applicable, certain components of the system or accessory

sub-assemblies have been certified, listed or recognized in accordance with one or more of the

following Safety standards: UL 1012, UL 1037, UL 1310, UL 60950-1, CSA C22.2 No. 205,

CSA C22.2 No. 220, CSA C22.2 No. 223, CSA C22.2 No. 60950-1. Additional approvals may

be pending.

WARNING: Changes or modifications to Checkpoint’s EAS or Radio Frequency Identification

(RFID) equipment not expressly approved by the party responsible for assuring compliance

could void the user’s authority to operate the equipment in a safe or otherwise regulatory

compliant manner.

F10 Installation Manual Rev. *60 5 of 71

Page 6

Important Information to our Users in Europe

CE Regulatory Compliance Statement

Where applicable, Checkpoint Systems, Inc. offers certain Electronic Article Surveillance (EAS)

products that have CE Declarations of Conformity according to R&TTE Directive 99/5/EC,

EMC Directive 2004/108/EC, and Low Voltage Directive 2006/95/EC.

System Electromagnetic Compatibility (EMC) has been tested and notified through Spectrum

Management Authorities if necessary, using accredited laboratories, whereby, conformity is

declared by voluntarily accepted European Telecommunications Standards Institute (ETSI)

standards EN 301489-1 and EN 300330-2.

NOTE: Certain Electronic Article Surveillance (EAS) equipment have been tested and found to

conform with the CE emission and immunity requirement in Europe. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Under unusual

circumstances, interference from external sources may degrade the system performance, which

may include intermittent decreases in detection and/or intermittent increases in alarm activity.

However, there is no guarantee that interference will not occur in a particular installation. If this

equipment experiences frequent interference from external sources or does cause harmful

interference to radio communications reception, which can be determined by turning the

equipment off and on, please contact a Checkpoint Systems representative for further assistance.

Equipment Safety Compliance Statement

Checkpoint Systems Electronic Article Surveillance products have been designed to be safe

during normal use and, where applicable, certain components of the system or accessory subassemblies have been declared safe according to the European Low Voltage Directive (LVD) by

being certified, listed, or recognized in accordance with one or more of the following European

safety standards; EN 60950-1, EN 50364, EN 60742.

WARNING: Changes or modifications to Electronic Article Surveillance equipment not

expressly approved by the party responsible for assuring compliance could void the user’s

authority to operate the equipment in a safe or otherwise regulatory compliant manner additional

approvals may be pending.

F10 Installation Manual Rev. *60 6 of 71

Page 7

Table of Contents

TATEMENTS ............................................................................................................................................................. 3

S

GUIDE CONVENTIONS ................................................................................................................................................ 3

CHAPTER 1: INTRODUCTION ................................................................................................................................... 9

BACKGROUND ........................................................................................................................................................... 9

Overview ............................................................................................................................................................ 10

F10 SYSTEM HARDWARE......................................................................................................................................... 10

SYSTEM DIAGRAMS ................................................................................................................................................. 11

GROUPING MULTIPLE ANTENNAS ............................................................................................................................ 12

2 X 1 METER CONFIGURATION ................................................................................................................................. 12

CHAPTER 2: SITE SURV EY ....................................................................................................................................... 13

Overview ............................................................................................................................................................ 13

ANTENNA DISTANCE FROM INTERFERING ELEMENTS .............................................................................................. 13

SYSTEM PERFORMANCE CONSIDERATIONS .............................................................................................................. 14

DETERMINING THE ELECTRONICS LOCATION .......................................................................................................... 14

ENVIRONMENTAL CONSIDERATIONS ....................................................................................................................... 15

SITE SURVEY CONCLUSION ..................................................................................................................................... 15

CHAPTER 3: PHYSICAL INSTALLATION ............................................................................................................. 16

Chapter Outline.................................................................................................................................................. 16

REQUIREMENTS ....................................................................................................................................................... 16

Tools ................................................................................................................................................................... 16

Parts ................................................................................................................................................................... 17

INSTALLATION OUTLINE .......................................................................................................................................... 17

Antenna Installation ........................................................................................................................................... 17

F10, 1 METER AND 2 METER FLOOR CUTS .............................................................................................................. 18

Floor Cut Depth ................................................................................................................................................. 19

COMMON WIDER FLOOR CUTS ................................................................................................................................ 20

MOUNTING THE ELECTRONICS ENCLOSURE ............................................................................................................ 21

MOUNTING THE POWER SUPPLY .............................................................................................................................. 23

GS-599ES(R) Installation................................................................................................................................... 23

GS-599MC-KIT(R) Installation ......................................................................................................................... 23

FINISHING INSTALLATION ........................................................................................................................................ 24

CHAPTER 4: WIRING ................................................................................................................................................. 25

Overview ............................................................................................................................................................ 25

ANTENNA WIRING ................................................................................................................................................... 26

Wiring Components ............................................................................................................................................ 26

Placement ........................................................................................................................................................... 26

Wiring the F10, 2 Meter System ......................................................................................................................... 27

Wiring the F10, 1 Meter System ......................................................................................................................... 31

Adjusting Jumper Settings .................................................................................................................................. 32

WIRING THE 2 X 1 METER SYSTEM .......................................................................................................................... 32

OVERVIEW ............................................................................................................................................................... 33

Coax Cable / A1116 Wiring ............................................................................................................................... 33

Remote Voice Alarm ........................................................................................................................................... 34

Alarm Post Wiring ............................................................................................................................................. 35

24VDC Power Supply Wiring ............................................................................................................................ 36

WIRING BETWEEN F10 SYSTEMS FOR SYNC ............................................................................................................ 37

Sync Cable and Power Supply Wiring ............................................................................................................... 37

WIRING PERIPHERALS .............................................................................................................................................. 38

F10 Installation Manual Rev.*60 7 of 71

Page 8

CHAPTER 5: F10 SYSTEM CONFIGURATION VIA DM S .................................................................................... 39

Overview ............................................................................................................................................................ 39

SYSTEM SETUP USING DMS .................................................................................................................................... 39

Single-Electronic System Setup .......................................................................................................................... 39

Multi-Electronic Systems (Sync Configuration) ................................................................................................. 44

APPLICATION-BASED DETECTION MODES ............................................................................................................... 44

Standard: 8.2 and Library: 9.5

Corral: 8.2, 9.0

....................................................................................................................................................... 45

Reverse Corral: 8.2, 9.0

Apparel: 8.2, 9.2

Pharma: 8.2, 7.2

RazorKeeper: 8.2, 7.2

Immunity: 8.2

..................................................................................................................................................... 45

..................................................................................................................................................... 45

.............................................................................................................................................. 45

......................................................................................................................................................... 45

Japan I: 8.2=9.5 and Japan II: 8.2, 9.5

............................................................................................................................... 45

........................................................................................................................................... 45

................................................................................................................... 46

ALARM SEVERITY .................................................................................................................................................... 46

CONFIGURING SAM (SMART ALARM MANAGEMENT) ............................................................................................ 47

Navigating to the SAM Screen ........................................................................................................................... 47

Changing the Patterns ....................................................................................................................................... 50

Changing the Matrix .......................................................................................................................................... 52

U

PDATING THE SYSTEM

CHAPTER 6: TUNING PROCEDURES (1M AND 2M VARY) .............................................................................. 53

.............................................................................................................................................. 52

Overview ............................................................................................................................................................ 53

TR4215 FEATURES .................................................................................................................................................. 53

BASIC TUNING METHODS USING DMS.................................................................................................................... 53

NOISE SOURCES ....................................................................................................................................................... 54

ANALOG VIEW ......................................................................................................................................................... 55

Typical Tuning Procedure.................................................................................................................................. 55

EVALUATE JUMPER POSITIONS ................................................................................................................................ 56

System Specific Procedures ................................................................................................................................ 56

For 2 Meter System ............................................................................................................................................ 56

For single 1 Meter or 2 x 1 Meter System .......................................................................................................... 56

CONFIGURING THE SYSTEM FOR ASYNCHRONOUS NOISE ........................................................................................ 57

RESONANCE SOURCES ............................................................................................................................................. 59

Remedying Resonances ...................................................................................................................................... 59

Jammer Indication ............................................................................................................................................. 61

DATA RETRIEVAL .................................................................................................................................................... 61

Event History ..................................................................................................................................................... 61

Snap Shot feature ............................................................................................................................................... 61

APPENDIX A: POWER SUPPLY ................................................................................................................................ 62

POWER SUPPLY DETAILS ......................................................................................................................................... 62

Power Supply Used in United States, Canada and Europe ................................................................................ 62

Power Supply Used in Australia ........................................................................................................................ 64

APPENDIX B: PARTS LISTS ...................................................................................................................................... 65

F10 PARTS LIST ....................................................................................................................................................... 65

APPENDIX C: INTERACTIONS ................................................................................................................................. 66

F10 SYSTEM – PROXIMITY TO DEACTIVATION UNITS .............................................................................................. 66

F10 SYSTEM – PROXIMITY TO OTHER SYSTEMS ...................................................................................................... 67

APPENDIX D: DETECTION PERFORMANCE ....................................................................................................... 68

F10, 2 METER SYSTEM ............................................................................................................................................ 68

F10, 1 METER SYSTEM ............................................................................................................................................ 70

F10 Installation Manual Rev. *60 8 of 71

Page 9

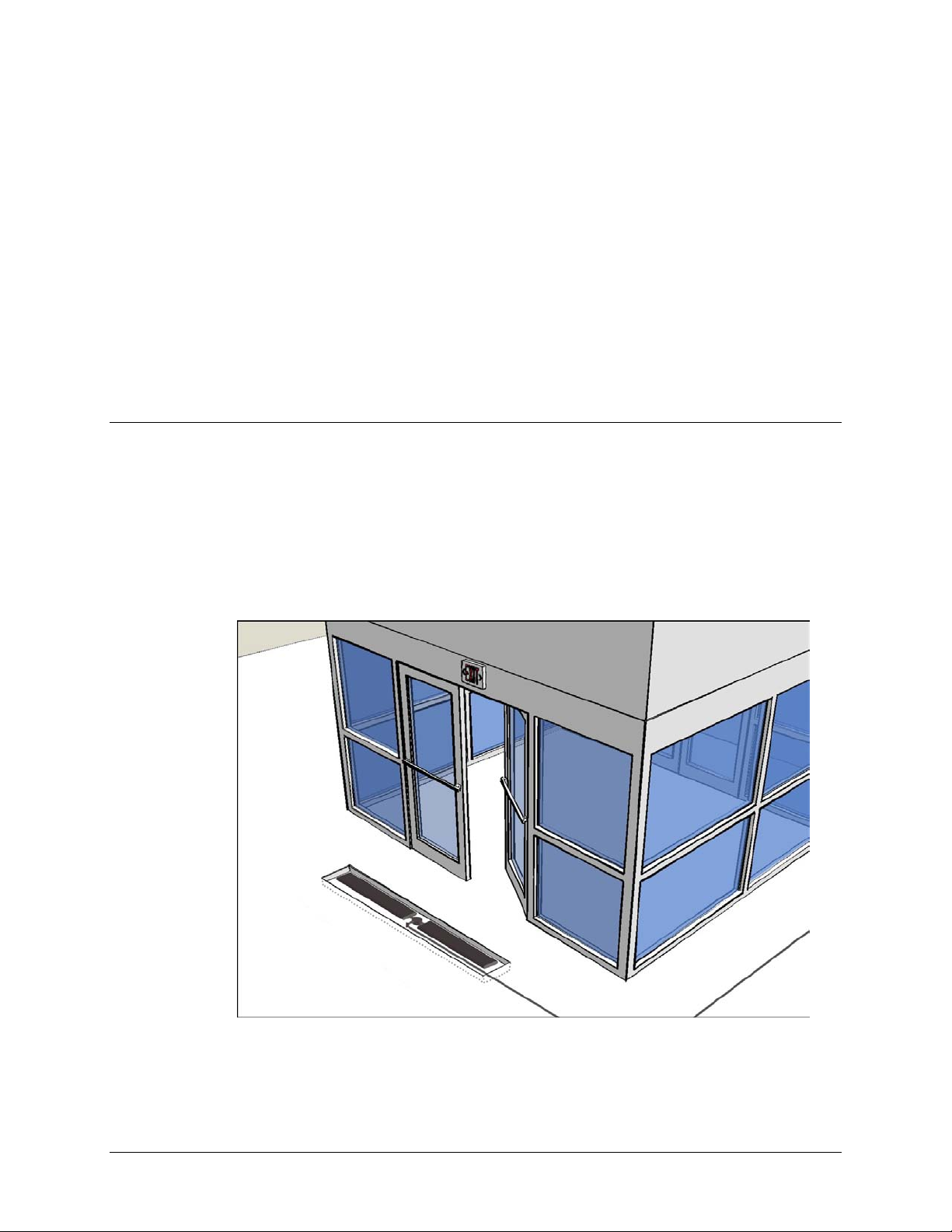

Background

Many retailers are now requiring i nvisible EAS Systems. The F10 system is Checkpoint’s latest

invisible EAS offering. This product features a unique shielded antenna design based on the

previously released, S10 product. This technology minimizes the impact of in floor noise sources

that plagued previous floor systems.

Offering better immunity to noise, Next Gen Liberty (NGL) TR4215 Electronics are utilized for

F10 systems. It is a nticipated that the next generation of Evolve electronics will eventually

replace the NGL electronics for the F10 system; thus the name “Evolve F10.” At this time, this

installation manual reflects installation and tuning for the NGL ele ctronics only.

CHAPTER

1

INTRODUCTION

This manual instructs in the planning, installation and config uration of the EVO LVE F10 System.

Figure 1.1 F10 System Introduction (F10, 2 meter installation shown)

F10 Installation Manual Rev.*60 9 of 71

Page 10

Overview

This chapter explains F10 system hardware. This genera l information is useful for initial planning

and training purposes.

1. Hardware: Shows hardware component s including t he antenna assembly and electronics.

2. System Diagrams: Shows overall design and component layout of the F10 system.

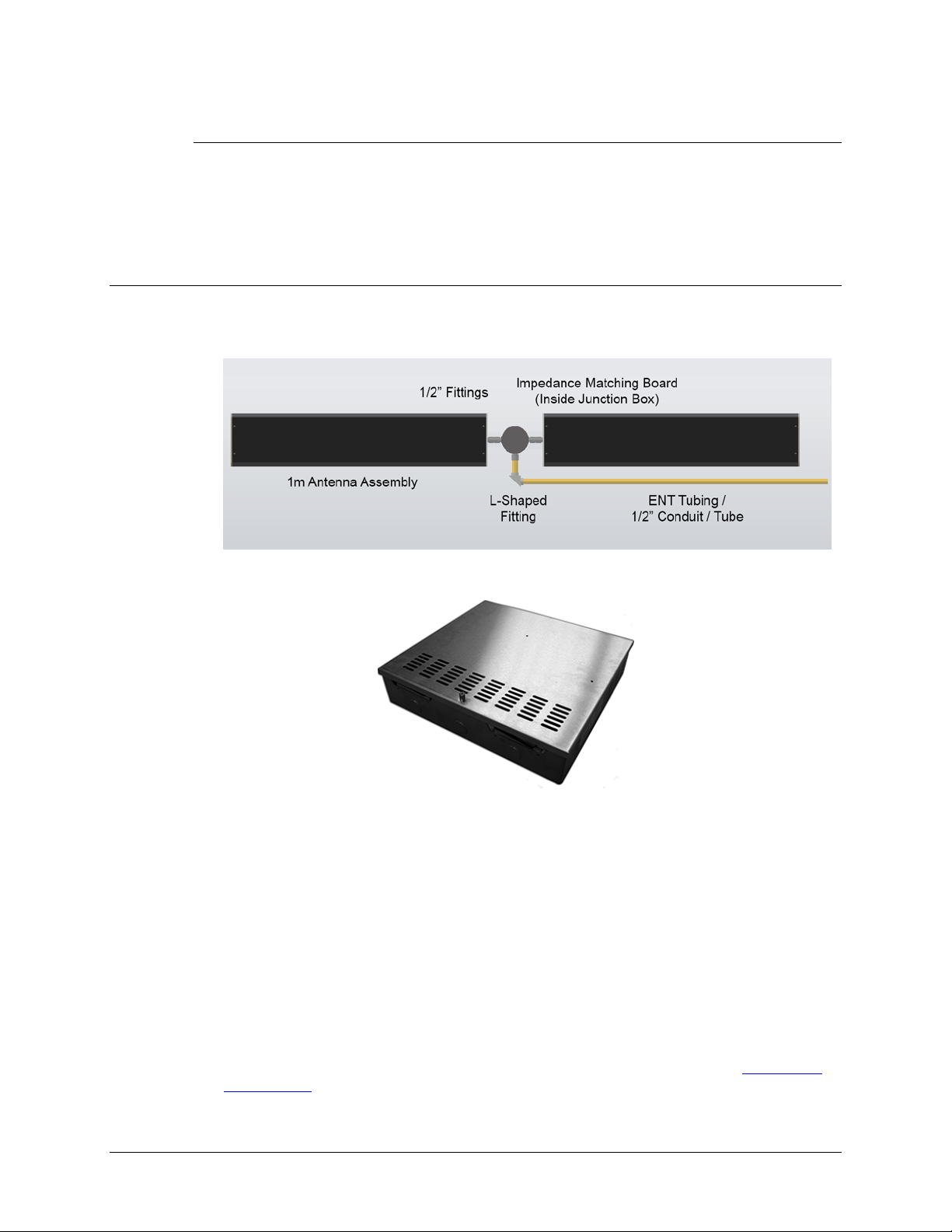

F10 System Hardware

The F10 sy stem is designed to be installed in the floor and provide an invisible EAS system. The

basic design is a 1 meter antenna assembly. Each antenna features multiple shielded coils. A

single assembly or two (2) units can be connected to a single Impedance Matching Board.

Figure 1.2 F10 Hardware

Figure 1.3 TR4215 Electronics Enclosure

The F10 system consists of a transceiver-based system using pulse/listen technology, allowing

them to work in a single antenna configuration. In the same way that the NLG FX2012 system

works, F10 antennas connect to a remote electronics enclosure via a coax cable.

The antenna is wired directly to an Impedance Matching Board, another component that is

installed in the floor (i.e. buried along with the antenna). The Impedance Matching Board

provides the link between the antenna wirin g and coax cable that connects to the remotely

located electronics enclosure. Typical EAS peripherals are able to be incorporated.

O

The electronics enclosure is designed to ensure proper ventilation in a non-condensing 0-40

environment. The wiring for the electr onics system is a low-vo lta ge, limited-energy system

(operating at 24VDC or less). All wiring must conform to applicable wiring codes.

The F10, 2 meter kit includes one (1) Impedance Matching Board for connecting the two (2)

antennas to a single Electronics Enclosure via two (2) coax cables routed through a single piece of

conduit. The power supply unit (not shown) is the standard +24VDC unit (refer to

Power Supply).

F10 Installation Manual Rev. *60 10 of 71

Appendix A:

C

Page 11

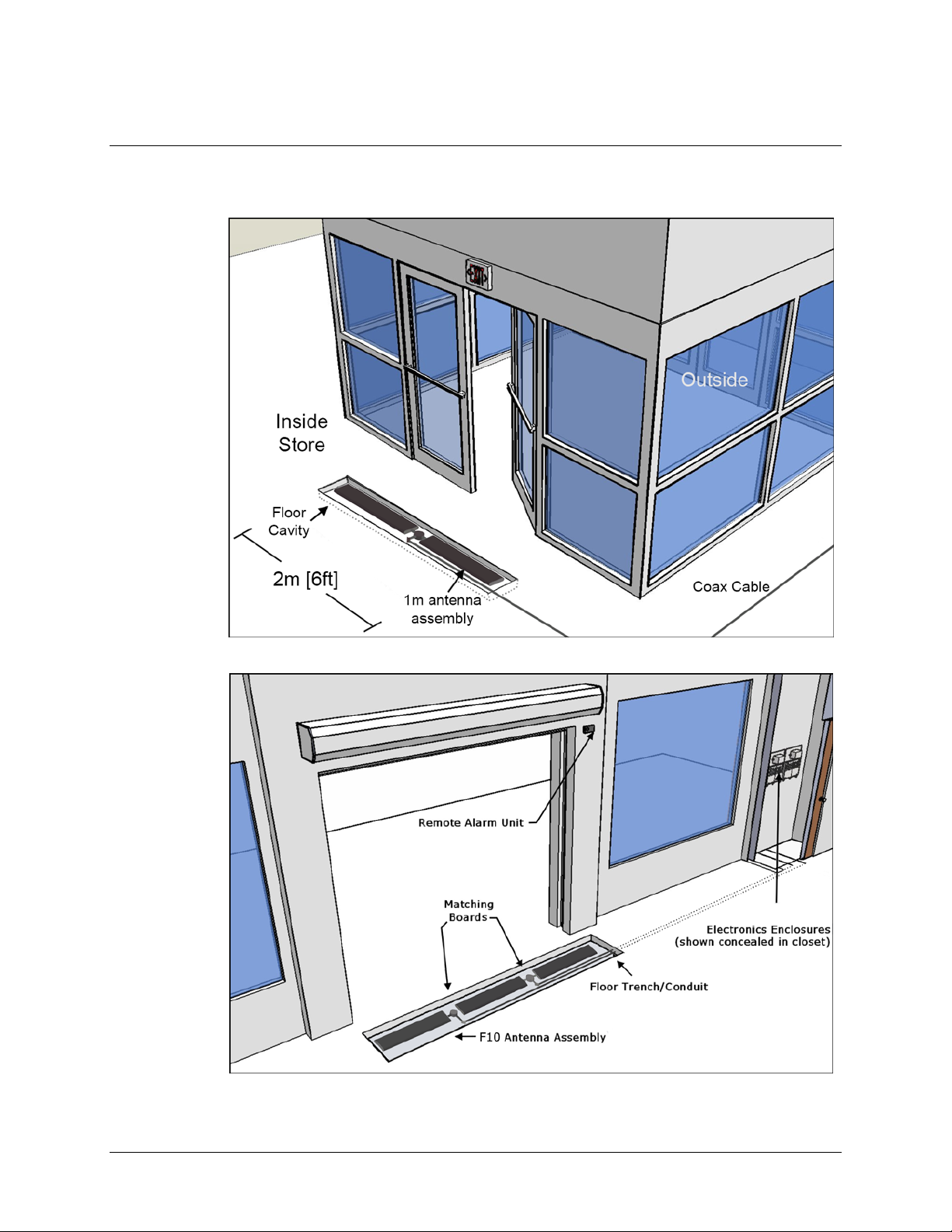

System Diagrams

The F10 system uses an antenna assembly comprised of wire coils wrapped around ferrite material

tiles. Antennas

Figures

are enclosed in PVC casings for strength and protection from environmental factors.

1.4 and 1.5 show common installation coverage widths: 2m and 3m [6 and 9ft respectively].

Figure 1.4 Typical F10, 2 Meter Installation

Figure 1.5 3m [9ft] Installation Layout wi th Compon ent Names

F10 Installation Manual Rev. *60 11 of 71

Page 12

Grouping Multiple A ntennas

Larger aisles are able to be covered using a Sync configuration. Aisle widths of any 1m increment

are possible. The 3m configuration features an F10, 2 meter system and a single 1 meter system.

Similarly, the 5m layout features two (2) F10, 2 meter systems and the standard F10 antenna.

Multiple electronics enclosures and power supplies are required, in this case, and the system

electronics must be configured for operation as a single unit. Refer to the

Systems for Sync” section.

Multiple floor trenches are cut with each length of ENT tubing (conduit) spaced 5 .1 cm [2in] from

the next closest to reduce RF interference.

Although grouping multiple installation kits together is possible, it requires approval from

Checkpoint’s Product Management. Feasibility is confirmed during the initial planning stage

known as the “Site Survey.” If the Site Survey was already performed and at present you are

prepared with installation-specific details, please skip to

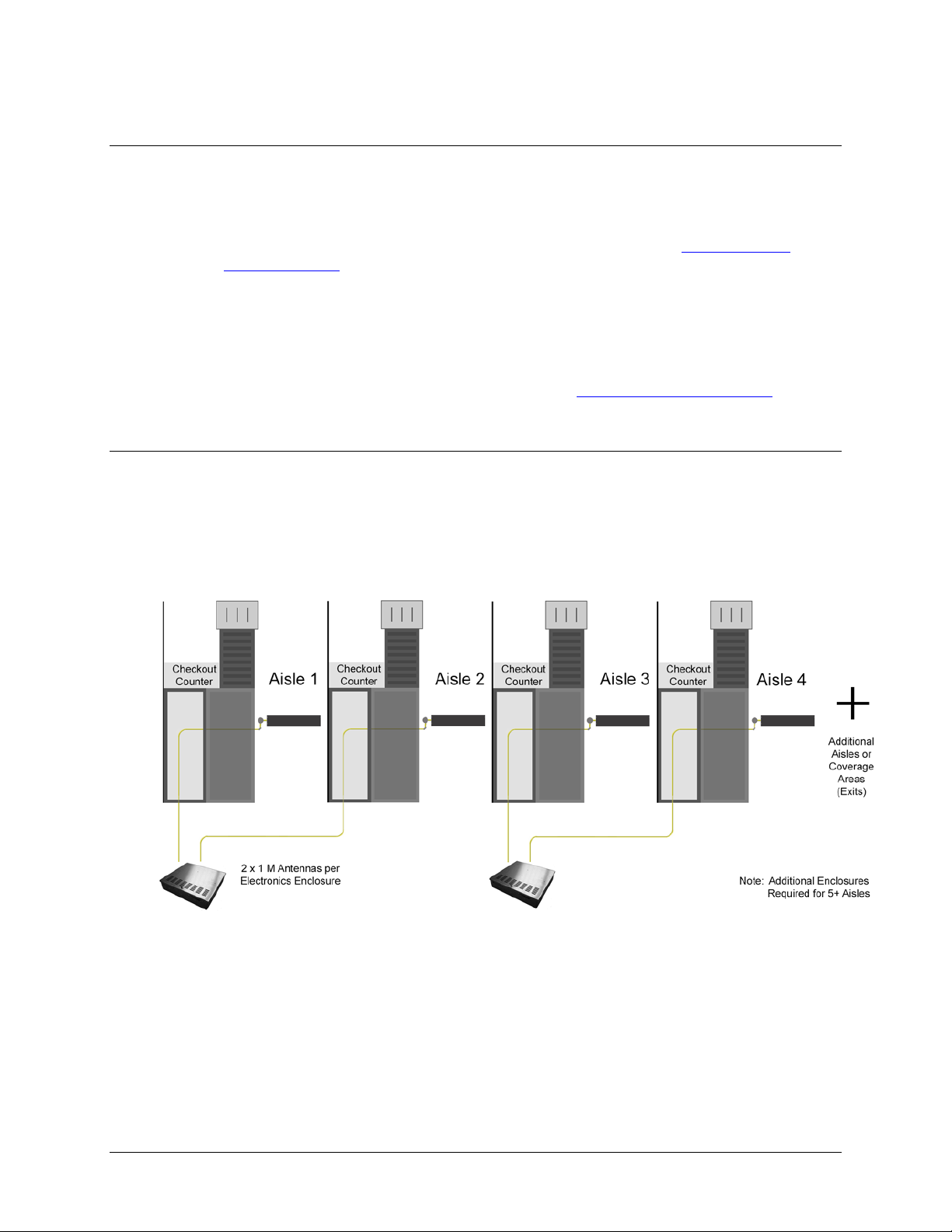

2 x 1 Meter Config uration

When necessary, two (2) standard F10, 1meter systems are connected to the same electronics

enclosure in a 2 x 1 meter configuration. The common application of the F10, 2 x 1 meter

configuration is in a grocery store or large department store. This setup allows EAS coverage

of many store checkout aisles, as well as single-door entrance / exit layouts. Each 1m antenna

assembly is fitted with a Matching Board. The layout minimizes the total number of electronics

enclosures needed when multiple F10 systems are used.

“Wiring Between

Chapter 3: Physical Installatio n.

Figure 1.6 F10, 2 x 1 Meter S ystem Diagram

F10 Installation Manual Rev. *60 12 of 71

Page 13

CHAPTER

SITE SURVEY

Overview

Checkpoint Field Service personnel vi sit the location to perform a site survey before installation.

The initial planning stage is the approp r ia te time to d e te rmine site suitability, where the antenna

loops will be located (for maximum EAS protection) and the type of systems to be installed.

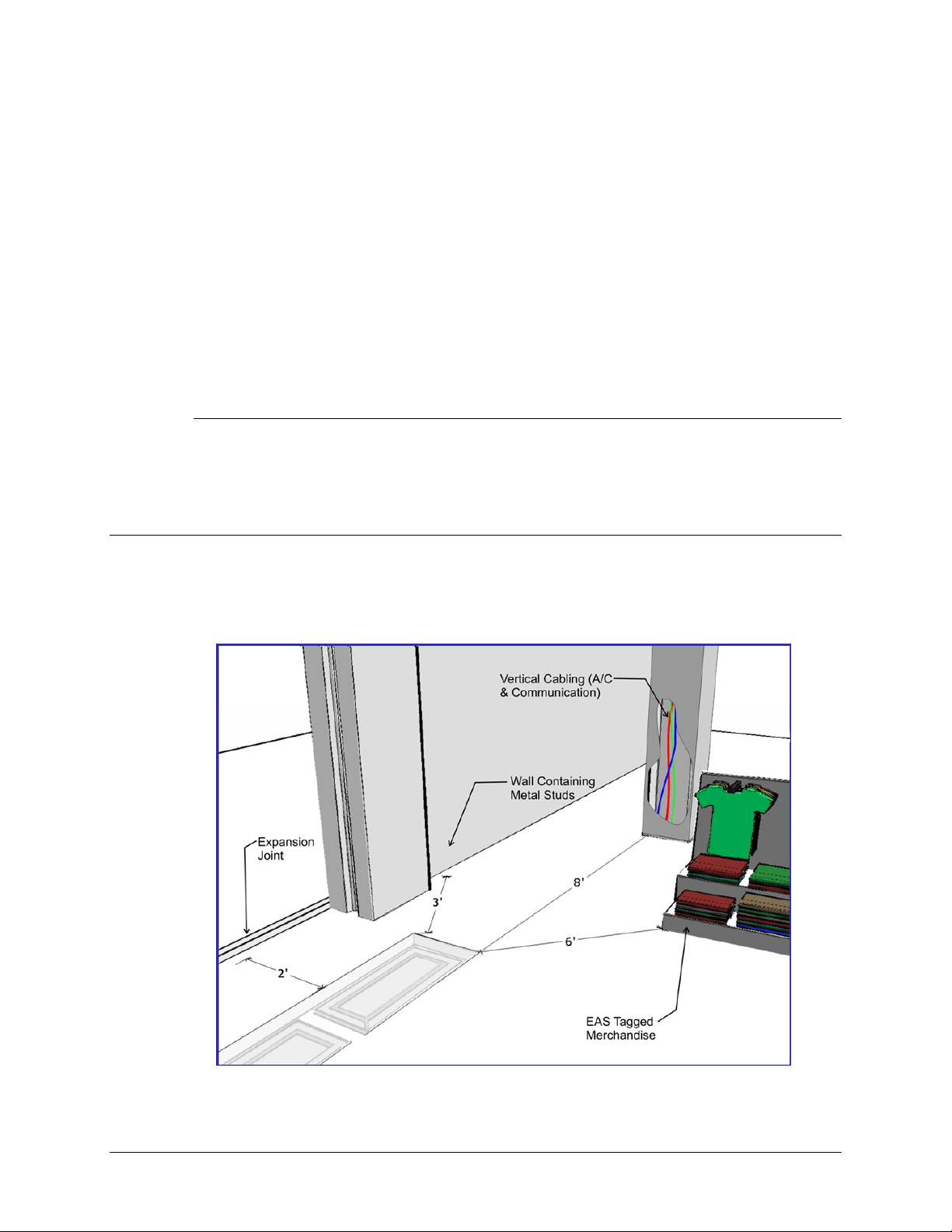

Antenna Distance from Interf ering Elements

Nearby elements and underlying flooring materials may cause interfering effects. Therefore,

antenna placement must be carefully evaluated before installation. Your goal is to ide ntify a

location where ambient noise and environmental factors do not degrade system performance.

2

For repeatability, all measurements are given at baseline (i.e. using a standard tag type).

Figure 2.1 Distances from Interfering Elements

F10 Installation Manual Rev. *60 13 of 71

Page 14

Common interfering elements and their minimum distances from F10 Antennas are listed below:

Expansion Joints: The minimum distance fr om an expansion joint is 0.6 m [2 ft].

Vertical Cabling: The minimum distance from vertical cabling is 2.4 m [8 ft].

Metal Wall Studs: The minimum distance from a metal wall stud is 0.9 m [3 ft].

Sliding Doors (Metal): The minimum distance from a metal sliding d oor is 1.2 m [4 ft].

Tagged Merchandise: The minimum distance from tagged mercha ndise is 1.8 m [6 ft].

Inward and Outward Swinging Doors (Metal): The minimum distance from either a

manual- or automatic-swinging metal door frame is 0.6 m [2 ft].

Although this last type of door is not shown in the fi gure, the fact t hat swinging metal doors can

swing toward the antenna loop must be taken into account (see below).

Note: The antenna must not be located below the door (or too near the door) when fully opened. Locate the

F10 antenna components beyond the door – with a minimum clearance gap of 0.6m [24in].

Other Checkpoint equipment could interfere with the F10 system or vice se versa (refer

Appendix C: Interactions for recommended separation distances).

to

System Performan ce C onsiderations

Nearby wiring and lighting, as well as floor construction, may affect performance. With RF

interference that is too severe and cannot be alleviated, the site may not be suitable for any

installations.

The detection field is not uniform (refer to

Each of the following alters F10 system performance:

• Spacing between the antenna and steel deck in the floor can affect performance, but it

has been observed that an increase in detection can occur when the F10 system is placed

on any metal flooring.

• Floor structure may cause detection variation for the F10 system.

• Antenna configurati on will cause an e xpected (kno wn) change in detection hei ghts and

a unique coverage pattern. Refer to

• Signal strength - The plots in the appendix have a defined height at TX = 31 (the

maximum). If TX is less than 31, detection heights will decrease.

Appendix D: Detection Performance for diagrams).

Appendix D: Detection Performance for detail.

Determining the Electronics Location

During the site survey, evaluate the store’s layout to learn what options are available for locating

the electronics enclosure and power supply. The electronics and power supply may be placed close

together, although this is not required. Both units may be placed under a cashwrap counter, under

shelving, above a drop ceiling (see special requirements), or in a utility closet.

The updated power supply can be installed in the plenum (i.e., above a drop ceiling or in HVAC

areas), but this requires a conversi on kit (refer to

If necessary, the electronics enclosure can be located in the plenum – and as long as the power

supply is located outside of the plenum – no conversion kit is required.

Appendix A: Power Supply for complete details).

Note: Since the “Hood Kit” (CKP P/N: 7367100) must be ordered separately, determine whether or not one

is needed now.

Caution: If using the conversion kit, the power supply must be installed by a licensed electrician.

F10 Installation Manual Rev. *60 14 of 71

Page 15

Electronics Enclosure Placement Requirements

• Locate the electronics enclosure no further than 12.2m (40 linear-feet) or 15.2m

(50 cable-feet) from the antenna(s) to allow for bends in the conduit run.

• If wall-mounting is ideal, mount the electronics enclosure approximately 1.8m [6ft]

above the floor to reduce RF-interaction with wiring in either the ceiling or the floor.

Electronics mounted to the ceiling can potentially have a high RF-interaction with the surrounding

environment (e.g., metal rafters or power cables), and therefore, may not perform optimally here.

Observe locations of active noise sources including deactivators.

Environmental Considerations

F10 systems are only approved for indoor installations only. For a first floor (ground level)

installation where the slab will be on grade (i.e., directly above the natural ground), we

recommend the concrete be poured above a vapor barrier to prevent moisture from rising.

The store's architect will recommend the maximum permissible loading in the floor area where

F10 antennas are physically installed. The architect must consider such factors as anticipated

traffic over the floor and the material characteristics of the flooring (if covered by concrete).

The guidelines included in this guide assume installation into concrete (typical), but the antennas

may be placed directly on concrete if flooring, such as finished hardwood, laminate, tile or stone,

conceals the system below. If a wooden floor is placed on top of the system, the weight of the

floor should not rest on the antenna(s). Mo r eover, with all installations, the concrete and other

materials above the antenna(s) cannot be metallic. For example, wire mesh cannot be used for

reinforcement above the concrete. Metallic walk-off mats should not be placed above the system.

Note: Tile grout and mortar used to fill antenna trenches MUST BE non-metallic and non-magnetic grout.

Another environmental consideration is a metal security gate. For installations where the drop

down or sliding gate could cause a phantom alarming issue, a Badge Board II (CKP P/N 7528451)

and a Gate Inhibit Switch (CKP P/N 7140188) should be installed. Discuss with P roduct

Management and customers.

As for the electronics, typical indoor conditions must be met. Operating temperature is 0°C to

+40°C [32° to 104°F]. Permissible humidity range is 10 to 75%.

Site Survey Con clusion

Overall, the site surve y is an opportunity to gather details and share information required for the

proper installation workflo w. B e for e le a vin g the test site, the location of the electronics enclosure,

floor cuts (trenche s or “channels ”), and/or conduit runs (see note) should be documented.

Using the in formation in the following chapter, draw up a plan with exact dimensions. In addition

to floor cuts, the power outlet lo c a tions (or hardwire into electrical for plenum i nstallation) should

be planned. Coordinating with site contractors facilitates easier installation.

Note: For the F10 System, it is required that the coax cable is ran through ENT Tubing (conduit).

Communicate with the contractor (and/or store personnel) before concrete has been poured. This

crucial action will allow the coax cable to be easily routed through the conduit.

Caution: Ensure wire run does not exceed the maximum distance to the electronics’ planned location.

F10 Installation Manual Rev. *60 15 of 71

Page 16

CHAPTER

3

PHYSICAL INSTALLATION

Chapter Outline

This chapter offers dia grams and lists step s for physical insta lla tion of the major system hardware:

1. Requirements: Lists the tool and part req uire ments for a typical installation.

2. Installation Outline: Lists all of the basic installation steps as a sequence.

3. Cut Diagrams: How to plan/make cuts for proper installation of the antenna assembly,

Impedance matching board, and plan/route the wiring of the coax cable.

4. Mounting the Electro nics: How to install the electronics enclosure and power supply.

Requirements

Tools

The following tools may be required for F10 system installations:

Arrow T-25 Staple Gun

Diagonal wire cutter

Hammer drill with 3/16” and 1/2 ” bits

Extension cord

Tape Measure

Hammer

Marker, Black Felt

Ratchet driver with 9/16” socke t

Screwdrivers: mini, regular and #2 Phillips

Hacksaw

Utility knife

Wire Snake

Wire Strippers

Wrench, combination end 9/16”

Checkpoint Systems Field Service Diagnostic Management Software (DMS version

1.8.31 or later version) installed on a laptop with the appropriate cables.

F10 Installation Manual Rev. *60 16 of 71

Page 17

Parts

Quantity will vary according to syste m type.

18 AWG 2-conductor (STP) Power

22 AWG 4-conductor (STP) (5594) Sync

PVC cement

*DekDuct (wire chase)

*Wiremold (1500 or 2600 series)

*Wiremold anchor bolts

Note: *Wire routing methods will vary by installation.

Note: Complete parts lists with OEM Part Numbers are included in Appendix B: Part Lists.

Installation Outline

Follow this sequence to successfull y i nstall the components and validate system op e r a tion:

1. Determine optimal antenna placement:

a. Perform a site survey now, or

b. Use the resul ts of a previous survey.

2. Determine power supply req uirements and the ideal location for s ystem electronics.

3. Physically install the antenna(s).

4. Route/connect the antenna (coax cable) and applicable wiring (sync, alarm, power).

5. Install the peripherals and wire the device(s) to the electronics enclosure.

6. Configure the system using DMS.

7. Perform system specific tunin g (te st jump positions).

Antenna Installation

Antenna installation and tuning is performed by trained Checkpoint personnel. You have already

determined the system model(s) and number of assemblies for install, or you recently received this

key infor mation from a prior survey. If you are unsure of any specifics, contact Checkpoint Projec t

Management.

During Construction

If the floor has not been poured yet, a pre-fabricated trough can be constructed. Refer to Figures

3.3 and 3.4. In the event of a new construction, please convey the following information to the site

contractors (construction team’s foreman) or the manager responsible for pouring the concrete:

• Location where antenna (s) will be placed; define a reference point (such as a door frame).

• The exact dimensions of antenna(s); provide the appropriate Floor Cu t diagram(s).

• The depth, length and pathway of the 1/2” ENT Tubing (conduit), if installed ahead of

After Constructi on

For sites where floor cuts must b e made, convey the fo llowing instructions to the installing

technician. Communicate all known specifics to the installer, referring to the diagram(s). Be sure

to convey plans and instructions for the correct system type. Only provide the floor layout(s) for

required antenna configuration(s). If using a chisel, rough / uneven floor cuts may occur. Flatten

the bottom surface on which the antenna rests with either leveling sand or a layer of concrete fill.

Install the antenna(s) i n the proper location(s) discovered during the site survey.

time; depth of the trench for routing the cable is 3.8cm [1.5in] deep.

F10 Installation Manual Rev. *60 17 of 71

Page 18

Caution: Prevent uneven stress on the fragile electronic components inside the assembly by ensuring the

127.6cm [50.25in]

35.5cm

[14in]

F10 Matching

Board Location

F10 Matching

Board Location

21.8cm [8.6in]

234.5cm [92.33in]

35.5cm

[14in]

floor trough is smooth and level. Fill in uneven areas or gaps with leveling sand or concrete filler.

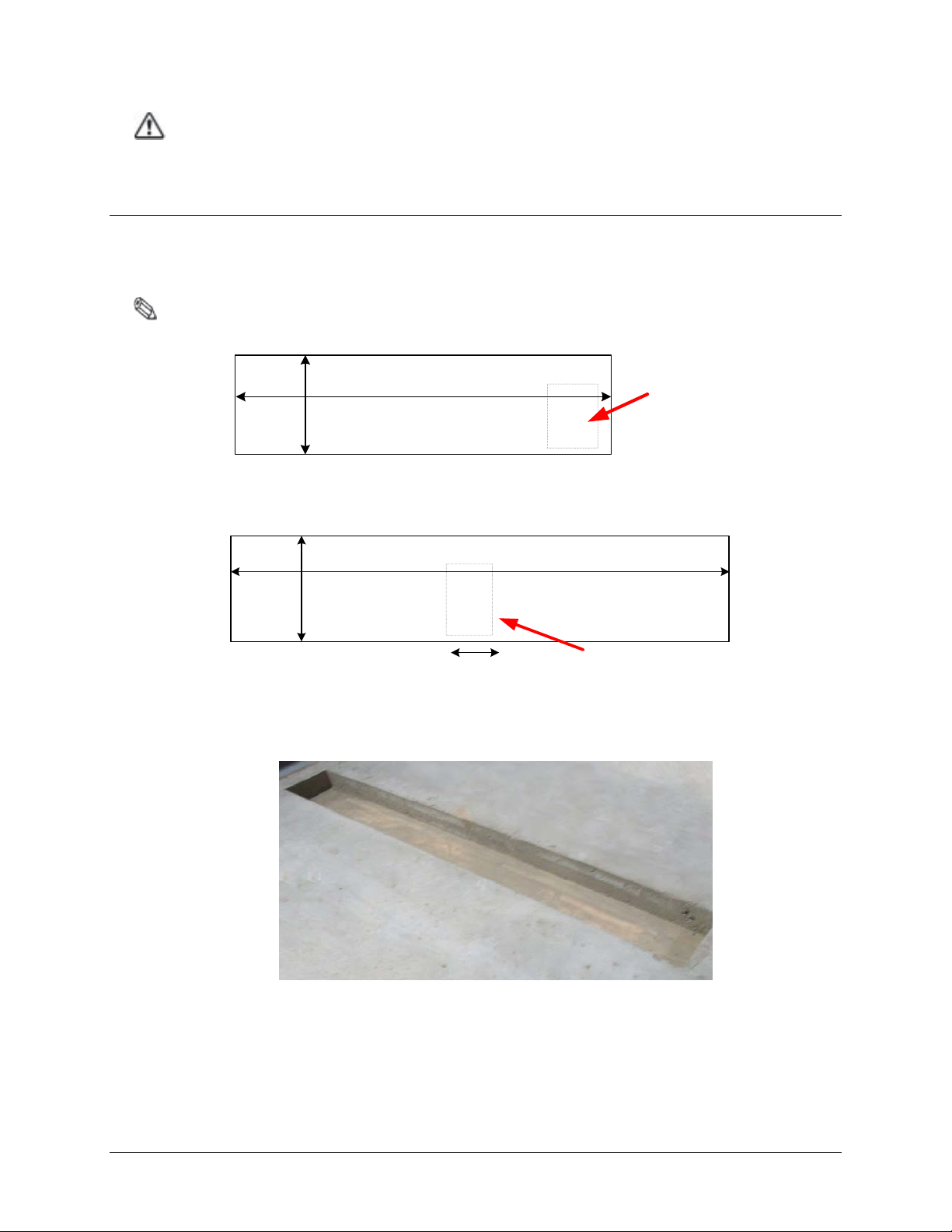

F10, 1 Meter and 2 Meter Floor Cuts

Installing the F10 antenna assembly in an existing store requires a trough to be cut in the floor.

If the site is under construction, it is easier to mold the system into the floor (explained above).

These diagrams include details o n the size of the trough cuts required for each configuration.

Note: Figures are Not Drawn to Scale

Figure 3.1 Top View of F10, 1 Meter Floor Cut

Figure 3.2 Top View of F10, 2 Meter Floor Cut

Figure 3.3 Trough for t he 2 Meter assembly

F10 Installation Manual Rev. *60 18 of 71

Page 19

Floor Cut Depth

F10, 1 meter and 2 meter Antennas are identical, so the trough’s floor cut de pth (height) is always

consistent. Recommended depth is 7.6cm [3in] for optimum structural integrity. T his allows

approximately 3.75cm [1.5in] of concrete top fill covering each antenna (as shown in Figure 3.3).

Figure 3.3 Side View of Trough

Figure 3.4 Antenna Installed (not buried until a f te r testing)

In scenarios where the flooring does NOT physically allow such depth, it is acceptable to cover

the antenna assembly with less than 1.5 inches of concrete fill. Although it is uncommon, whe n

covering with tile or wood floo ring, the system can be installed flush to the concrete’s surface.

Figure 3.5 Flush Depth

Note: If installing in a location that violates the recommended 7.6cm [3in] depth specification, inform

Checkpoint Project Management.

F10 Installation Manual Rev. *60 19 of 71

Page 20

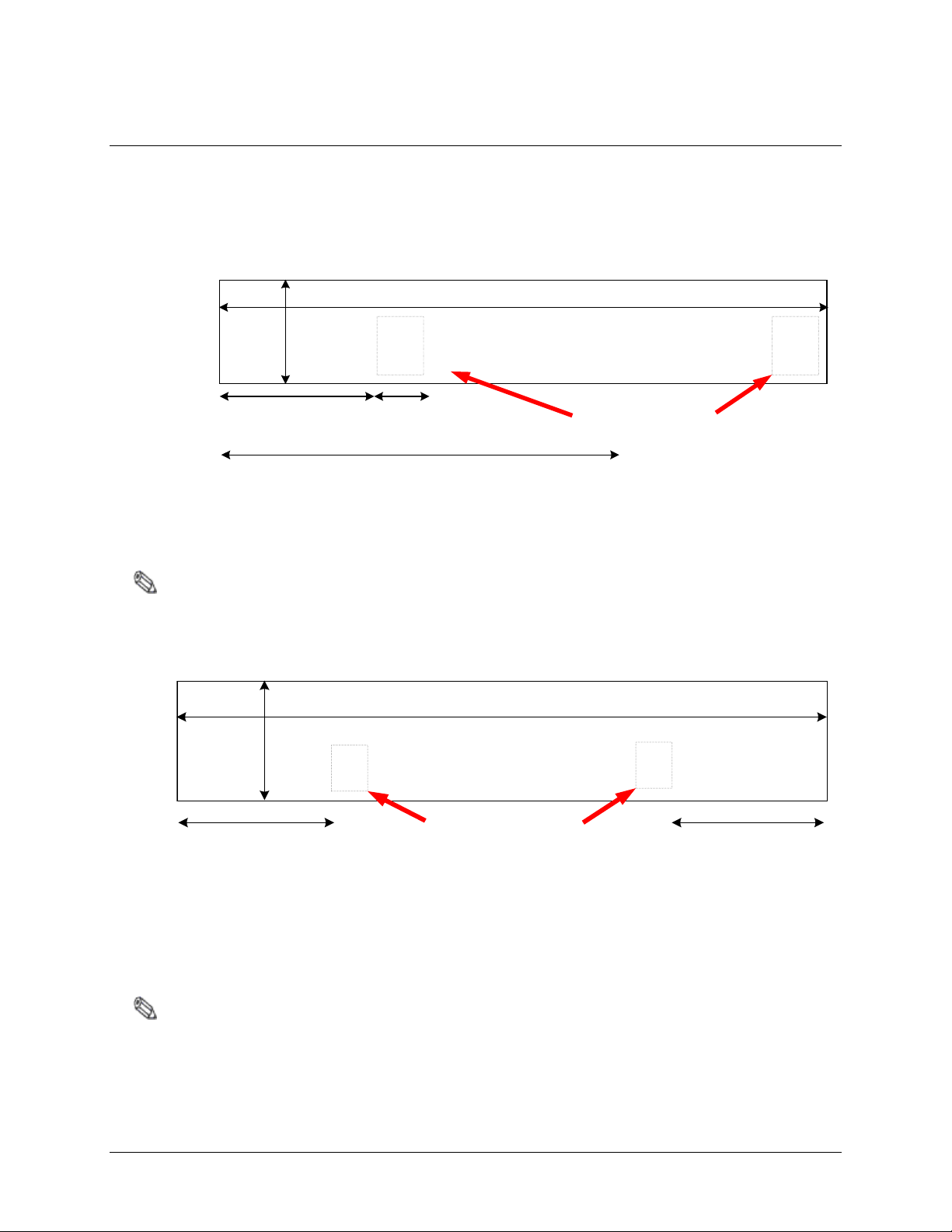

Common Wider Floor Cuts

354.5cm [139.6in]

Matching Board

Locations

117.5cm

[46.27in]

224.2cm [88.3in]

35.5cm

[14in]

21.8cm

[8.6in]

461cm [181.5in]

Matching Board

Locations

35.5cm

[14in]

117.5cm

[46.27in]

117.5cm

[46.27in]

It is possible to create a wider system by combing either of the smaller two floo r kits (refer to

Figures 3.1 and 3.2 above). For example, to cover a 3m mall op eni ng, a 1 m and 2m kit are ordered.

Figure 3.6 below shows exact dimensions of the trough (floor cuts) when the F10, 1 meter and 2

meter systems are combined. Figure 3.7 shows two (2) F10, 2 meter systems installed side-by-side.

Figure 3.6 2m and 1m System for 3m Opening

Note: Figures are Not Drawn to Scale

Figure 3.7 Side-by-Side 2m Systems for 4m Opening

Note: The Impedance Matching Board placement for the F10, 2 meter system is between the assemblies.

For the F10, 1 meter system, board placement is beside the antenna assembly. The ENT Tubing

(with coax cable) can be routed in any direction from antenna to electronics. A minimum spacing of 2”

between the antenna and tubing is required.

F10 Installation Manual Rev. *60 20 of 71

Page 21

Mounting the Electronics Enclosure

Detailed instructions for mounting the Electronics Enclosure are below. Before installing the

enclosure, review the fol lowing requirements and i f necessary, consult the Sit e Survey res ults.

It is suggested if the location is difficult to access, wire the system before mounting, but keep the

power suppl y unpl u gged unt il fi nis he d wir in g all per ipherals and mounti ng the support brackets.

The electronics enclosure must be located no further than 12.2 linear-meters [40 linear-feet ] from

the antenna(s) to allow for bends in the 15.2 cable meters run [50 cable feet]. The enclosure, which

weighs 5.17kg [11.4lbs], has keyhole slots at its edges to facilitate wall-mounting, but the

enclosure must have 2.5cm [1 in] clearance on all sides. Do not mount the electronics enclosure

beneath potential water sources (e.g. a sprinkler or pipe).

It is suggested to locate the enclosure directly above (or nearest to) the conduit’s endpoint, so the

length of exposed coax cable is minimal. Limiting exposed cable prevents RF interference, but do

not cut the coax cable (refer to the

Using the includ ed ENT Tubing (flexible conduit is supplied in the kit), route the cable from the

matching board to the arrival point near the electronics enclosure.

Installation procedures are listed for each type of material on which the enclosure can be in stalle d:

• Wood Surface,

“Placement” section in Chapter 4: Wiring).

• Drywall, and

• Concrete.

F10 Installation Manual Rev. *60 21 of 71

Page 22

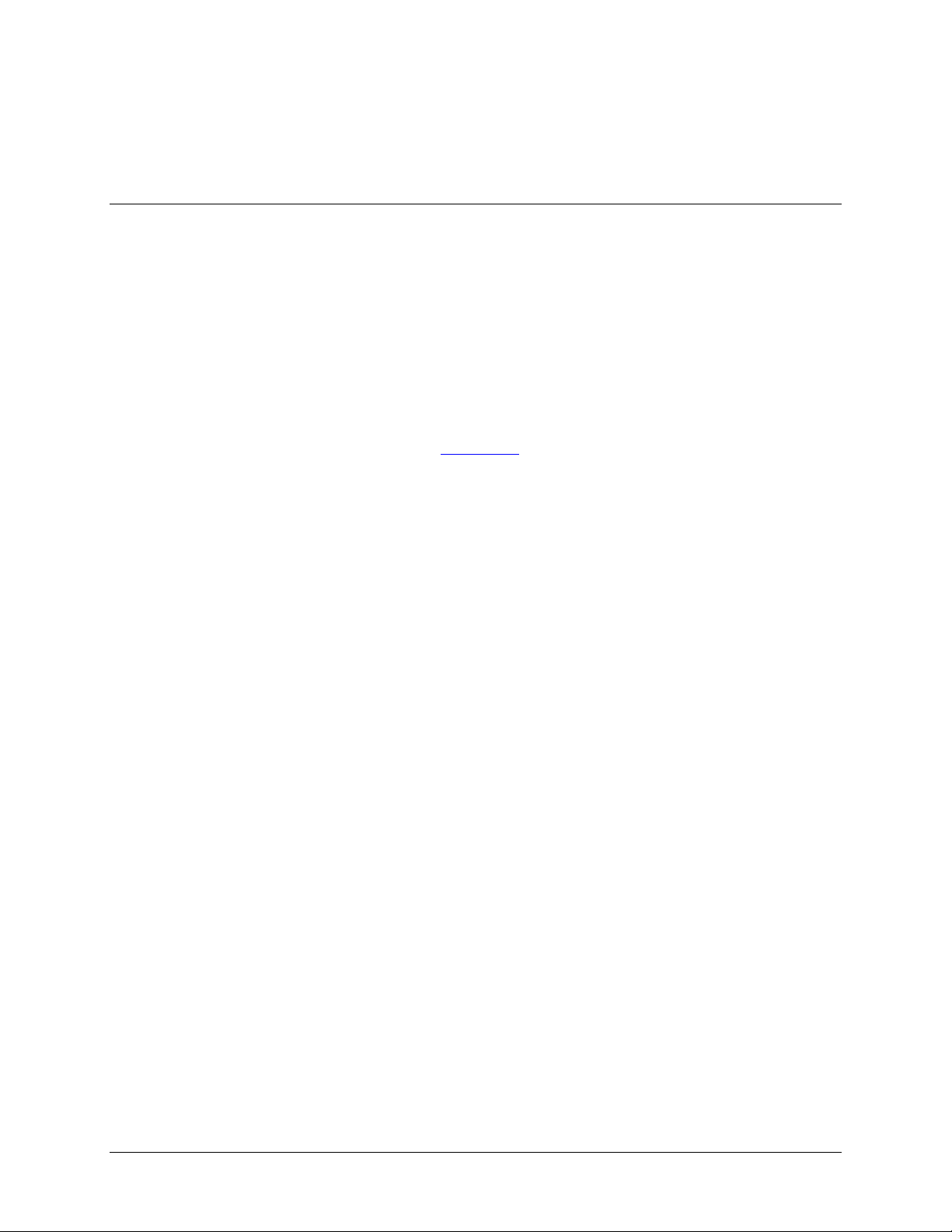

Wood Surface Installation

1. Using the proper diameter bit, drill a hole into

1. Insert either # 2 or # 3 Phillips driver bit into

For mounting to wood, use a #7 x ½” (0.38cm x 1.3cm) hex head screw (CKP P/N 7939172).

the base material to a depth of at least 0.6cm

[1/4”] deeper than the embedment required.

Blow the hole clean of dust and other material.

2. Select the installation tool and drive socket to

be used. Insert the head of the screw into the

hex head socket driver.

3. Place the point of the screw through the fixture

into the pre-drilled hole and drive the anchor in

one steady continuous motion until it is fully

seated at the proper embedment.

Figure 3.8 Wood Surface Installation

Drywall Surface Installation

For mounting to drywall, use a #8 x 1” (0.42cm x 2.5cm) panhead screw (CKP P/N 7308823),

which is a Power Fastener Zip-it (P/N 02348).

the recess of the ZiP-It anchor head. Use a

manual screwdriver or a low-rpm

battery-powered electr ic s crew gun.

2. Push the ZiP-It anchor into the surface of the

wallboard until the two cutting blades

penetrate the surface. Usi ng gentl e forw ar d

pressure, rotate the ZiP-It until the collar sets

flush to the surface of the wall.

3. Put the fixture in place, insert screw and

tighten until it feels secure. As the screw is

threaded into the nylon versions, the point will

expand resulting in increased load capacity in

thicker wallboard.

Note: When using an electric screw gun for

application, set clutch and use a slow speed

(do not exceed approximately 300-400 RPM).

Figure 3.9 Drywall Installation

F10 Installation Manual Rev. *60 22 of 71

Page 23

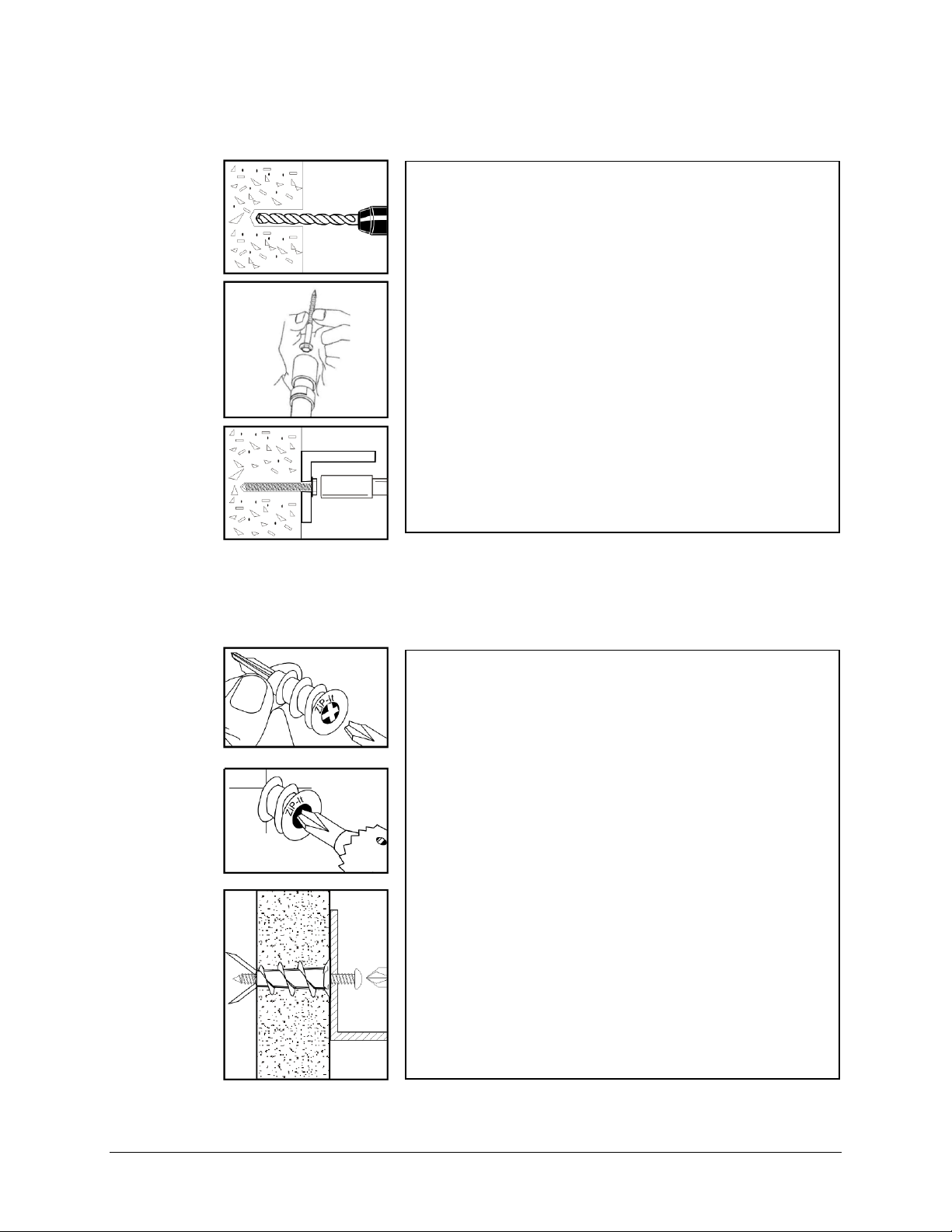

1. Drill a hole into the base material to the depth

Concrete Surface Installation

For mounting to concrete, use a 5/16” lead anchor and a #12 x 1 ½” panhead screw (CKP P/N

366291). Lead anchor (0.79cm) is a Power Fastener (P/N 09439). Screw is 0.55cm x 3.8cm.

required. The tolerances of the drill bit used

should meet the requirements of ANSI

Standard B212.15.

2. Blow the hole clean of dust and other material.

Insert the anchor into the hole until the flange

is seated flush with the surface of the base

material.

3. Position the fixture. Insert the screw tip

through the fixture into the anchor and tighten.

Mounting the Power Supply

The power supply should be mounted near the electronics enclosure, or in a remote location, when

available space is limited. If the power supply is installed above a drop ceiling, the Conversion Kit

is required (see below). For the unit’s weight and dimensions, refer to

GS-599ES(R) Installation

Hold the unit in place and mark the screw hole locations. Secure the power supply in its location

in the same manner as before (refer to the

GS-599MC-KIT(R) Installation

Refer to Appendix A: GS-599MC-KIT(R) for the complete hood kit instr uctions.

Figure 3.10 Concrete Installation

Appendix A: Power Supply.

“Mounting the Electronics Enclosure” section).

F10 Installation Manual Rev. *60 23 of 71

Page 24

Finishing Installation

Wiring the electronics, and configuring and tuning t he antennas must occur be fore finishing the

physical installation. Proceed to Chapters 4, 5 and 6, complete the setup and validation, and then

return to this section when ready to finish the physical installation.

Filling Trenches

The floor c uts or cavities are filled with concrete mortar, grout, and/or sealants during this final

step, ensuring the antenna locations are not visible. It is crucial that the grout be non-metallic and

non-magnetic. Occasionally (F10 system below wooden flooring), the antenna system is not

covered by Checkpoint personnel, as it will later be covered with flooring. Protect, as necessary.

The F10 system has been tested and is approved to be used with the following concrete repair

mortars and mixes:

1. Ardex TRM – Transportation Repair Mortar

2. QUIKRETE® Concrete Mix (No. 1101)

3. QUIKRETE® Fast-Setting Concrete Mix (No. 1004)

Note: Detection performance of the system may be temporarily affected by the water content in the repair

mortar. As the mortar mix cures, detection performance improves.

F10 Installation Manual Rev. *60 24 of 71

Page 25

Overview

CHAPTER

4

WIRING

This chapter instructs on the wiring of the entire floor system. There is a progression from the

antenna to the electronics enclosure and common peripherals. Chapter 4: Wiring concludes with

the DC power supply connections and system sync (optional) wiring sc he mes for multi-antenna

configurations (i.e., when two or more electronics enclosures are synced – to operate as a unit).

CAUTION: This system uses TR4215

that only TR4215 electronics can be used in conjunction wit h this system.

DMS versio n 1.8.31 or la te r must be used to configure the system after wiring is complete (refer

Chapter 5: F10 System Configuration via DMS).

to

The outline below is a sequence of the F10, 1 and 2 meter system wiring procedures :

1. Antenna Wiring

a. Components and Placement

b. Wiring the F10, 1 and 2 meter Antennas to the I mpedance Matching Board

2. Electronics Chassis

a. Coax cable Wiring to the Coax Adapter Board

b. Remote Voice Alarm Group Wiring

c. Alarm Post Wiring

d. DC Power Supply Wiring

e. Sync Cable and Power Wiring

†

electronics with firmware version 4.00 or higher. It is critical to note

F10 Installation Manual Rev. *60 25 of 71

Page 26

Antenna Wiring

Wiring Components

The components involved in Antenna Wiring and Coax Cable routing are shown below.

Note: The Impedance

Matching Board (right)

only fits in the junction

box in one position. Do

NOT it force into place.

Placement

Unpack the antenna (s). Each antenna has four (4) colored wires that stick out from an end.

1. Apply the rubber o-ring over the threads of t he ½” inch male fitting. Do NOT apply PVC

cement. Feed the antenna wires through the male fitting, then tighten. Screw one (1) fitting in

per antenna until rubber o-ring is compressed.

2. Position the antenna(s) in the floor trough, carefully lowering each into place.

3. Install the 1/2” ENT tubing (conduit). The tubing must cover the entire coax cable run from

the electronics to the antennas. Cut the tubing as required.

F10 Installation Manual Rev. *60 26 of 71

Page 27

4. Route the coax cable from the Electronics Enclosure to the floor trough. Do not cut the cable

yet, but note that excess will be removed after the true length is determined.

Caution: Cable must not be cut shorter than 30’.

5. Unpack the remaining system components including the Junction Box, lid, Impedance

Matching Board, PVC fittings and ferrite cores.

Wiring the F10, 2 Meter System

Perform the following to wire the F10, 2 meter system to the Impedance Matching Board.

1. Identify the “top” of the J unction Box (with the Carlon® logo facing up) and position the box

as shown. Remove the left, right and bot tom knockouts from the Junction Box. Use a hammer

and a large screwdriver as shown.

Caution: Ensure the correct knockouts (3 sides shown) are removed for the 2 meter system (only 2 for 1

meter system). Since the 2 meter uses both TX1 and TX2 sets of input connectors, set up is different.

2. Apply the rubber o-ring over the threads of t he ½” inch male fitting. Do NOT apply PVC

cement. Screw the fitting into the opening wher e the knockout was located until rubber o-ring

is compressed. Repeat for the other locations; tighten three (3) fittings in total.

3. Identify the colored antennas wires. Twist together loose strands of any frayed wire.

4. Select any four (4) small ferrite cores (CKP P/N 7221412).

5. Group the Yellow and Green wires together. Thread each individual lead through the same

opening in each of two (2) Ferrite cores. Repeat for the set of Red and Black wires as shown.

6. Using a utility knife

(shown at far right),

cut two (2) pieces of

conduit with six (6) ring s

for each (approximately

2.54cm [1in] in length).

Cut a third piece approx.

7.5cm [3in] long. This

section connects at the Lshaped fitting (see Step 10).

F10 Installation Manual Rev. *60 27 of 71

Page 28

7. Align the four (4) ferrite cores in a row; they fit when sta gge r ed (i.e., positioned end-to-end).

Thread the antenna wires through the piece of conduit. P ush two (2) of the Ferrite cores into

the antenna fitting. Apply PVC cement t o the outside surface of the tubing, then push hard on

the tubing, securing it t o the antenna fitting.

Note: Follow PVC cement instructions for proper surface preparation and use.

8. Apply PVC cement to the exposed piece of tubing. While holding the antenna in place,

push the Junction Box in until the fittings touch and form a tight seal.

9. Repeat this process for the other 1m antenna assembly. Refer to Steps 3 - 4 and 6 - 8.

Note: The four (4) antenna wires are later attached to the left side connector shown below.

Attach the coax cables first to provide better access and ensure no wires come loose.

F10 Installation Manual Rev. *60 28 of 71

Page 29

10. Route the coax cable through the L-shaped fitting and 3 inch piece Tub ing (cut to length).

After antenna placement is finalized, apply PVC cement and secure the section of Tubing.

11. To prepare the coax cable, strip the outer insulator, then twist the conductor into a wire lead.

12. Next, cut the inner insulator flush with the outer and strip ¼ inch of the s heathing around the

inner cond uctor (above right). Ensure that conductors are short enough to prevent touching.

13. Using a small screwdriver, gently hold the connectors open and then insert the coax wire

leads. Repeat for the second coax cable. Ensure that both inner and outer conductors match.

14. Make the antenna wiring connections to the matching board as shown (or refer to Table 4.1).

F10 Installation Manual Rev. *60 29 of 71

Page 30

15. The right side antenna is wired in reverse. Red connects to pin 1, yellow to pin 2, etc.

Side Pin Number Antenna Wiring

Antenna 1

(Left)

J2-1

J2-2

J2-3

J2-4

Antenna 2

(Right)

J2-1

J2-2

J2-3

J2-4

Table 4.1 F20 Antenna Wire Pinout

16. Verify the correct pin-out using the above table.

Green

Black

Yellow

Red

Red

Yellow

Black

Green

Note: Before closing the lid, it is necessary to first evaluate system performance. Refer to Evaluate Jumper

Positions.

17. Ensure that all the connections are secure (gently pull on the leads at the connection point to

the circuit board). Carefully position the wires inside, then close the Junction Box lid (tighten

all 4 screws). Be careful not to tear or twist the foam gasket on the lid when tightening the

screws.

Note: In instances where multiple electronics and coax cables are used, ensure that floor trenches or

conduits are spaced 5cm [approx. 2in] apart.

F10 Installation Manual Rev. *60 30 of 71

Page 31

Wiring the F10, 1 Meter System

The procedure for wiring the F10, 1 meter system is consistent with the 2 meter procedure with

two (2) important differences. First, preparing the junction box; second, wiring the matching board.

Instead of three (3) of the knockouts being removed, only two (2) are removed (see below)

Antenna wiring is different; only one (1) coax cable is utilized, howeve r, both connectors

(left and right) on the Impedance Matching Board are used (see Table 4.2 for F10 system).

Varied Procedure Steps

1. Identify the “top” of the Junction Box (with the Carlon® logo facing up) and position the box

as shown. Instead of removing both sides, remove ONLY one (1) knockout from the Junction

Box (side closer to antenna) a nd the bottom knockout. Use a ha mmer and a large screwdriver.

Note: You may remove the left or right, but ONLY one (1) side knockout is removed.

2. Only one (1) small piece of conduit needs to be cut.

3. Perform Steps 2 – 10, but skip Step 8 and unnecessary actions (related to the second antenna).

4. Prepare one (1) coax cable for the 1 meter system. Wire the coax cable leads to Pins 1 and 2

(left side) on the top connector.

5. Connect the antenna wires according to Table 4.2 below.

Side Pin Number Antenna Wiring

Antenna 1

(Left)

J2-1 Green

J2-2 N/A

J2-3 Yellow

J2-4 N/A

Antenna 1

(Right)

J3-1 Black

J3-2 N/A

J3-3 Red

J3-4 N/A

Table 4.2 F10 Antenna Wire Pinout

F10 Installation Manual Rev. *60 31 of 71

Page 32

Adjusting Jumper Settings

The default jumper settings for the F10, 2 meter system are OUT for J5 - J10.

The settings are adjusted for the F10, 1 meter system. Insert the red J5 and J6 jumpers.

Note: Later on, after the system is initially configured, each of the jumper positions are tested in order to

optimize the tuning of the F10 antenna. Refer to

Evaluate Jumper Positions and complete the test.

Wiring the 2 x 1 Meter System

For the 2 x 1 meter configuration, the wiring to each antenna is consistent with the F10, 1 meter

procedure. The main difference is there are two (2) coax cables routed to the electronics enclosure.

Route each coax cable separately through two different pieces of ENT Tubing. The lengths of

coax cable are connected to the two (2) male connectors on the A1116 Coax Adapter Board.

Note: In instances where multiple electronics and coax cables are used, ensure that floor trenches or

conduits are spaced 5cm [approx. 2in] apart.

F10 Installation Manual Rev. *60 32 of 71

Page 33

Overview

Electronic interfaces / connections to the TR4215 reader board are shown below. This section

describes how to wire all cables and ma k e the appro priate connections at the Electronics Enclosure.

Figure 4.1 TR4215 Board with all interfaces labeled

Coax Cable / A1 116 Wiring

The A1116 Coax Adapter Board connects to the F10 antenna via 15m [50ft] coax cable(s).

1. Connect the coax cable to the A1116 adapter board, then clip the Ferrite core (CKP P/N

7784420) over the cable(s).

Note: Ensure that the two (2) output jumpers

are in the Remote Position. J37 and J38

on the TR4215 board are located just

above the A1116 Adapter Board.

F10 Installation Manual Rev. *60 33 of 71

Page 34

Remote Voice Alarm

1. Connect the remote voice alarm wiring as shown below (or refer to Table 4.3).

Figure 4.2 Electronics Wiring: Alarm Group Relay

Note: Sync connections are shown. Not all systems will be synced.

Remote Voice Alarm / Alarm Counter

Wire Color TR4215 Connections

WHITE (RLY) J9-5

GREEN (RLY) J9-6

RED (+24V DC) J18-3

BLACK (Ground) J18-1

Table 4.3 Alarm Group Wiri ng Conne c ti o ns

2. Install the device and complete wiring at the peripheral device(s).

Refer to the peripheral’s Installation Instructions.

F10 Installation Manual Rev. *60 34 of 71

Page 35

Alarm Post Wiring

1. Connect the alarm post wiring as shown below (or refer to Table 4.4).

Figure 4.3 Alarm Post and Sound Wiring

Note: Sync connections are shown. Not all systems will be synced.

2. Install the device and complete wiring at the peripheral device(s).

Refer to the peripheral’s Installation Instructions.

Alarm Post Wiring

Wire Color TR4215 Connections

RED (Light + ) J43

BLACK (Light – ) J43

RED (Sounder + ) J11

BLACK (Sounder – ) J11

Table 4.4 Alarm Post Wiring Connections

F10 Installation Manual Rev. *60 35 of 71

Page 36

24VDC Power Supply Wiring

Wire Color

Description

Black

GND

Red

+24 V

Below are ins tr uct i ons fo r wir ing the 24VDC power supply to the TR4215 board’s DC Input Filter.

1. Cut the MC Armored cable (or generic AWG18 plenum-rated power cable) to length.

2. Strip the 2 (two) leads exposing about 0.6 cm [0.25 in] of the conductors.

3. Apply a Ferrite Core (CKP P/N 7284760) on the power wire near the DC Filter board;

complete 3 loops.

4. Apply the Ferrite Core (CKP P/N 7284760) to the AC power cord.

Figure 14.4 AC Power Cord Ferrite

5. Connect the lea ds to the DC inputs as shown (or refer to Table 5.5 below).

Figure 4.5 Power Supply connections

(for a Single-Antenna System)

Figure 4.6 DC Power Filter

_______ (Parallel outputs on left and right)

F10 Installation Manual Rev. *60 36 of 71

Table 4.5: Power Cable Wiring

Connections

Page 37

Wiring Between F10 Systems for Sync

Where multiple-antennas are installed, a secondary electronics enclosure is connected to a primary

via a sync cable. The RF Sync cable is installed prior to configuration. Use 22 AWG 4-conductor

(STP) (5594) cable for sync cable. Parallel or “Daisy Chain” wiring configuration allows a single

power supply to operate both units. Use 18AWG plenum-rated cable for the power connection.

Caution: If there are more than two (2) electronics enclosures, additional power supplies are required.

Figure 4.7 Multi-Antenna Systems

Sync Cable and Power Supply Wiring

1. Connect the Sync output cable to terminal (J22) to Sync Input terminal (J20) on the secondary

electronics unit.

Figure 4.8 Sync In / Out

Terminals

Note: This would be a combined

system (with both IN and OUT

connections made).

F10 Installation Manual Rev. *60 37 of 71

Page 38

Sync Input/Output Connections

SYNC -

SYNC +

GND

Wire Color Description TR4215 Connections

White

Green

Black & Drain

Table 4.6 Sync Input/Output Wiring Connections

2. Prepare the short length of power cable and connect via Daisy Chain to the second electronics

enclosure’s DC +24V Input . Use MC Armored or generic AWG18 plenum-rated power cable.

Wiring peripher als

Use the appropriate installation manual for wiring to the peripheral devices.

For wiring and configuring th e Wireless Voice Alarm, refer to the Installation Instructions:

EAS Audible Alarm/Alarm Counter (CKP P/N 7186802)

For hardwiring the EAS Voice Alarm/Counter peripheral, refer to Section 3.1, “Wiring the liberty

PX,” of the Installation Instru c tions (CKP P/N 7226881).

J20/J22-1

J20/J22-2

J20/J22-3

F10 Installation Manual Rev. *60 38 of 71

Page 39

CHAPTER

5

F10 SYSTEM CONFIGURATION

VIA DMS

Overview

This chapte r reviews the c onfiguration steps for the F10 system using DMS. There are slight

differences between the 1m and 2m systems. Antenna tuning is covered in Chapter 6: F10 Tuning.

Please follow the tuning guide to optimize system performance after configuring the F10 syst em.

Note: Please use DMS version 1.8.31 or later. TR4215 firmware version must be 4.00 or later.

System Setup Using DMS

The DMS setup procedure varies between the two overall system configurations:

• Single-Electronics System (i.e. only one or two antenna assemblies) and

• Multi-Electronics System (more than two antennas must be synced when less than 12m

[40ft] apart).

Note: 12m [40ft] is the minimum distance where a sync cable is not required between two (2) separate

single-electronics systems, but this should be taken on a case by case basis. See

minimum distances to avoid interactions.

The instructions below emphasize which parameters should be setup for the TR4215 board. In

either case, setup is similar but an extra step is needed for Multi-Antenna configuration. A basic

knowledge of the DMS tool is assumed.

Note: Refer to the Field Service Diagnostic Management User’s Guide for general help using the DMS tool.

Single-Electronic System Setup

The basic setup process consists of following steps:

1. Make a new DMS connection.

2. Configure the electronic(s) for Detector mode.

3. Set up alarm responses based on customer needs.

Appendix C for

F10 Installation Manual Rev. *60 39 of 71

Page 40

Make a New DMS Connection

1. Connect the service PC laptop to the J48 serial port on the TR4215 board.

2. Launch the D MS program (version 1.8.31 or later) and enter your logi n in formation.

3. Make a new Connection for connecting to the TR4215 board. Be sure to select "(Direct)

Serial" for the Type and "Evolve" as the Device.

Unlike pre vio us Li be r t y Systems, NGL doe s no t use the "TR4024/26" Device Connection.

Figure 5-1 shows the "Add Connection" window with the appropr i ate NGL settings.

Figure 5.1 New Connection Setup

4. Click Next, a serial port selection window appears. Fill in the COM port parameters and

then click Next. The fina l connection summary window appears.

5. Click Finish to complete the new connection setup. A new ic on titled “NGL board”

appears in the DMS Connections window (shown in Figure 5-2).

Figure 5.2 NGL board Added as a New Connection

F10 Installation Manual Rev. *60 40 of 71

Page 41

Configure to ECO Mode

1. Using the DMS tool, connect to the TR4215 board. Figure 5-3 shows the opening screen

with the Network view expanded to show all devices.

Figure 5.3 DMS Network and Task Manager View

2. Navigate to the Switch Settings window (click Configure Settings, shown ab ove).

3. Under the Detection Tab, fill in the following parameters:

• RF Group Address: choose a n Address between 1 and 6. The address should

match any ot her reader.

• Sync Mode: set to "ECO Mode" for the F10, 1 meter system or 2 x 1m syste m.

For the 2 meter system, set the sync mode to “Detector” or “Primary Non ECO.”

• TX Control: set to Enabled, Mode 2.

Figure 5.4 Detection Tab, Switch Setting Parameters

F10 Installation Manual Rev. *60 41 of 71

Page 42

4. Click Apply.

5. Under the Tuning Tab, fill in the following p a rameters:

• Sampling Holdoff: Set to 13.

6. Click Apply.

Figure 5.5 Tuning Tab, Switch Setting Parameters

7. Under the Band Tab, fill in the following parameters:

• Frequency Band: Set to the application required by the customer. For more

information about the choices, refer to the "

Application-Based Detection

Modes" section.

• Edge Blanking: Set to 0-15.

• Master/Submaster: Set to "Master" for any Single-System.

Note: If configuring a Multi-Electronic System, later refer to "Multi-Electronic Systems (Sync Configuration)”.

• Q Band Detection: Choose a setting based on the type of tags used by the

customer (Hard tag, 410, etc.).

• Threshold Adjust: Set to either 16 or 0.

8. Click Apply.

F10 Installation Manual Rev. *60 42 of 71

Page 43

Figure 5.6 Band Tab, Switch Setting Parameters

9. Navigate to the Antenna Settings window.

10. Under each Antenna Tab, fill in the following parameters:

• Antenna Type: Set to Detector.

• Jammer Threshold: Set to 0.

• TX Maximum: Set to 31.

Note: The FCC requirement is TX=31 (same parameters as CE).

• RX Gain: Set to 31.

• RX Hardware Gain: Set to 31.

• Port Control: Check RX, TX and Port. Do not check AGC.

11. Click Apply.

Figure 5.7 Antenna Set t ings

F10 Installation Manual Rev. *60 43 of 71

Page 44

Note: If this is a single antenna configuration, click Antenna 2 tab, then set TX Maximum Power to 0 to turn

off the Transmitter.

Multi-Electronic Systems (Sync Configuration)

1. Repeat Steps 1-11 above (switch serial p ort connection to the other board). For the second

electronics system, set to Submaster on the Band tab.

2. Repeat with additional TR4215 boards until all units are configured for sync operation.

Application-Based Detection Modes

This section details the steps and options for device configuration with respect to specialized

application and SAM settings. The Evolve Firmware 4.0 supports both single- and dual-tag

detection modes. These modes allow the system to look for two different tag frequencies while

providing customized alarms for each

This section describes:

• Application mode concept and how it replaces earlier frequency band settings

• Extended alarming capability based on alarm severity levels

• Smart Alarm Management (SAM)

The framework for this capability is a new Application-based configuration model introduced wit h

Evolve Waimea firmware. The approach is a change from previous Liberty versions and will be

described in detail in the following paragraphs. With the new approach, an application is selected

rather than a specific frequency band.

Figure 5.8 Switch Settings Frequency Bands

Currently there are 10 supported tag / frequency ba nds, some supporting dual-tag detection while

the traditional applications still supp ort a single tag. In the case where an applicatio n supports two

tags, there is a primary tag and a secondary tag. The primary tag is most common (typically 8.2

MHz) and the secondary tag is typically used for higher prio r ity items or higher-cost items. In the

dropdown menu, the application name includes the center frequency for the supported tag(s).

F10 Installation Manual Rev. *60 44 of 71

Page 45

Standard: 8.2 and Library: 9.5

These are the standard applications and remain unchange d from the pre vi ous version o f the

firmware. Each application uses a ta g that falls wit hin a single contiguous RF frequency range.

• Standard: 8.2 is the most common a nd most generic application.

• Library: 9.5 mode is used primarily in libraries.

Corral: 8.2, 9.0

This application is used in Toys-R-Us stores where the 8.2 MHz tags are placed on general

merchandise throughout the store and 9.0 MHz tags are placed on electronics located in a special

“Corral” area in the store.

Reverse Corral: 8.2, 9.0

This is used in Barnes & Noble and is similar to the Toys-R-Us implementation but t he tag