Page 1

Counterpoint iD

Quick Start Guide

Reference During Installation

CKP P/N 10073883

Page 2

CPiD - Quick Start Guide

Copyright © 2014 by Checkpoint Systems, Inc. All rights reserved.

Checkpoint® is a registered trademark of Checkpoint Systems, Inc.

Released March 21, 2014.

Published by:

Checkpoint Systems Inc.

101 Wolf Drive

Thorofare, NJ 08086

For use with Checkpoint’s Counterpoint Intelligent Deactivation System.

Checkpoint, Counterpoint, Evolve, VisiPlus and People Counter are registered

trademarks of Checkpoint Systems, Inc.

All rights reserved. Information in this document is subject to change without notice.

Companies, names and data used in examples herein are fictitious unless otherwise noted.

No part of the contents of this book may be reproduced or transmitted in any form or by

any means without the written permission of the publisher.

All other product or service names are the property of their respective owners.

Document Revision Information

Part Number: 10073883

Rev Description Date Authors

00 CR2642B March 21, 2014 G. Plizak, B. Langer, R. Decker

Page 3

Quick Start Guide: Counterpoint iD

Installation Requirements

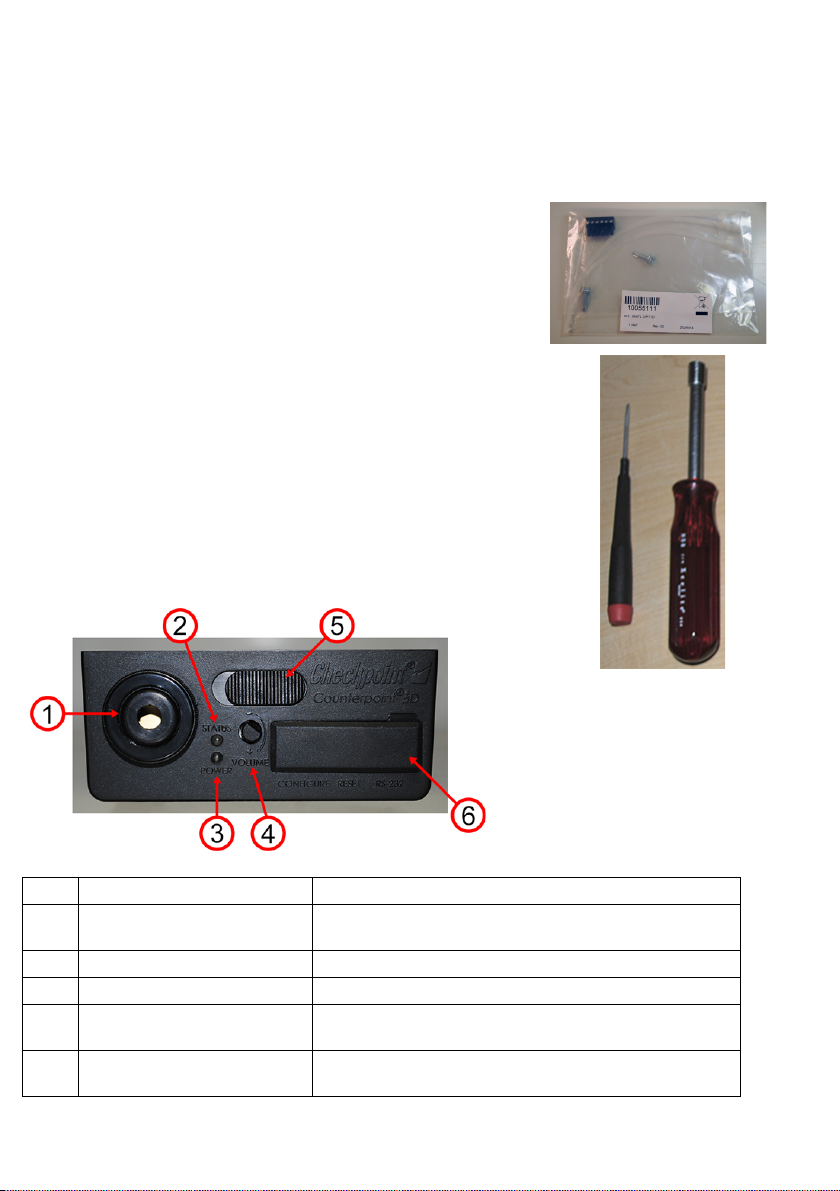

What’s In The Box

1 CPiD Chassis

1 Power Supply Unit (PSU)

Install kit including:

2 #8 hex head screws (5/8 inch long)

2 tie wraps

1 6-Pin connector

Too l s R e qu i re d

1 small flathead screwdriver

1 1/4 inch nut driver

Optional

DMS Version 1.8.95 or later (required for setup of advanced features)

Operation/Features

Front

1 Sounder Sounder for alarm annunciation

2 Status LED Informs the User about device status. LED Functions are

3 Power LED (Green only) Indicates power

4 Volume Knob Adjusts sounder volume

5 Latch Allows user to remove unit for installing external connections

6 Rubber Boot Conceals DIP Switches, Reset Button and DMS Connection

defined in the label underneath the top plate.

(e.g., cable for Antenna Pad, key switch or lock/trigger)

port

Page 1 of 7

Page 4

Checkpoint Systems, Inc. – Field Service Installation Document – CKP P/N 10073883

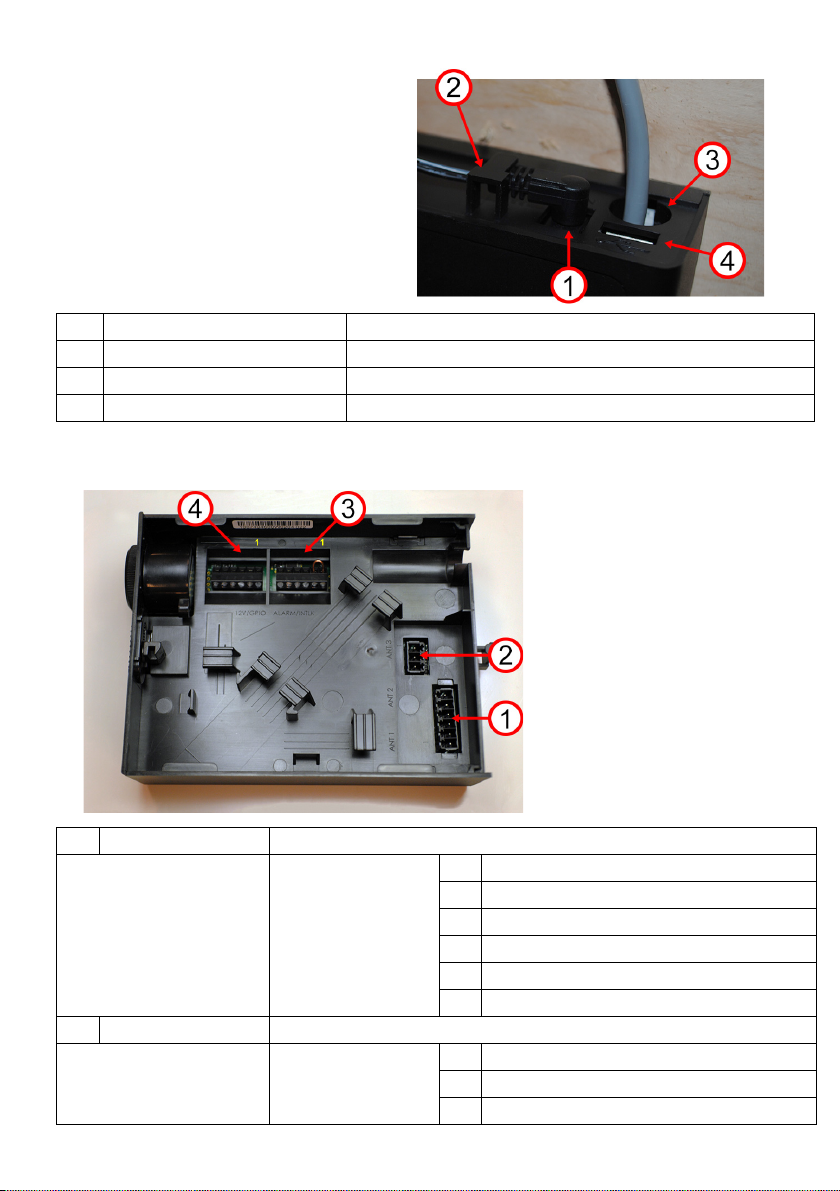

Rear

1 Input Power Connector Connector for +12V DC input power

2 DC Jack Strain Relief Strain relief for power cord

3 Internal Cabling exit Opening for all cables that connect internally (e.g., Antenna Cable)

4 USB Connector Connector for future USB functionality

Inside

This is what you find,

pre-install with chassis

cover (plate) removed.

1 Antenna 1 and 2 Primary RF Connection for 2 antennas max. (parallel)

Pin-out 1 ANT2+

2GND

3ANT2-

4ANT1+

5GND

6ANT1-

2 Antenna 3 Secondary RF Connection for another supported antenna

Pin-out 1 ANT3+

2GND

3ANT3-

Page 2 of 7

Page 5

Quick Start Guide: Counterpoint iD

3 Alarm and Interlock Connection for Interlock and Alarm

Interlock Description / Pin-out

4 +12V Auxiliary Output

and GPIO

Interlocks are external

devices that relay

control signals to the

device

Alarm Description / Pin-out

The alarm output

supports generic

sounder devices and

external LEDs

Connection for GPIO and +12V output

GPIO Description / Pin-out

General Purpose

Input Output

+12V Description / Pin-out

This set of terminal

pins is used to

connect devices that

require 12V

1 Interlock Input. Default is shorted to Pin 2 using

2GND

3 Interlock Opto, polarity independent (jumper

4 Interlock Opto, polarity independent (jumper

5+12V

6Alarm -

1 GPO RLY, 1A max resistive load

2 GPO RLY, 1A max resistive load

3 GPI+, 3.3V through 10k Ohm

4GND

5 +12V, 100mA max

6GND

wire jumper

must be removed prior to use).

must be removed prior to use)

DIP Switch Functions

Selection Switch 1 Selection Switch 2 Switch 3 Selection Switch 4 Switch 5 Switch 6

High Power OFF Mode 5 OFF OFF Min Gain OFF OFF OFF

Low Power ON Mode 6 ON ON Gain 2 OFF OFF ON

Page 3 of 7

Mode 4 OFF ON Gain 3 OFF ON OFF

Verification ON OFF Gain 4 OFF ON ON

Gain 5 ON OFF OFF

Gain 6 ON OFF ON

Gain 7ONONOFF

Max Gain ON ON ON

Page 6

Checkpoint Systems, Inc. – Field Service Installation Document – CKP P/N 10073883

Status LED Functions

Status LED Function Red Yellow Blue Teal White Violet Green

Detection (Tag Alarm) X

Waiting for Interlock X

Keyswitch disabled X

AutoTune Blink

Auto Tune Window

Auto Tune Error X

Antenna Overvoltage Blink

Mistuned Blink Blink

Verification Mode X

Mode 4 X*

Mode 5 X*

Mode 6 X*

Factory Default Settings

Blink at

power up

0.5s after

reset is

pressed

*Future Release

Reset Button

This button resets the unit and auto-tunes the

antenna under certain conditions. See

Tuning

on page 7.

DMS Setup

Some features of CPiD are able to adjusted / applied without DMS, others are

not. For example, DMS is required to enable the secondary transmitter.

(Click here for FSWP link. Download DMS Version 1.8.95 or later.)

GPIO

The default system configuration has the following GPIO functions:

• GPO – Primary Alarm Relay

• GPI – Disabled

Any other functionality needs require DMS.

Page 4 of 7

Page 7

Quick Start Guide: Counterpoint iD

Mounting

A secure location, such as behind an access door below the register, is ideal for

mounting. Plan routing and location so the unit will not be struck by anything.

When possible, locate unit such that user has ability to interface with device.

Consult the SOW when provided. Customer may prefer / request no access.

Volume can only be muted in DMS. Choose 1 of the following orientations:

Figure 1: Typical Orientations

Top plate has front and rear. Install with edge in rear (away from user). User

can remove entire chassis to change configuration or adjust power.

If mounting permanently, install 2 hex head

screws using top plate as a template for the

2 screw locations.

• Do not install chassis with front

against a surface that can block

access or prevent assembly.

• Always release the front latch to

remove the chassis or top plate.

• View front labels to ensure unit will achieve correct orientation. An

easy visual cue is with the Sounder on the left.

Page 5 of 7

Page 8

Checkpoint Systems, Inc. – Field Service Installation Document – CKP P/N 10073883

Wiring Procedure

1. Connect antenna cable(s) according to Table on page 2. Plug into ANT1 ANT2

connector, then route cable(s) through the clips for strain relief. Dog-bone excess

antenna cable with provided tie wrap.

Figure 2: Antenna Wiring, Primary Connection (Cable Routing on right)

2. If there are peripherals such as a Key Switch or an external scanner Interlock to

connect, use the following table for the wiring pin-out:

Pin # Interlock/Alarm (J6) GPIO/12V (J5)

1 INTLK+ GPO RLY

2 GND GPO RLY

3 INTLK (OPTO) GPI+

4 INTLK (OPTO) GND

5ALARM+ +12V

6 ALARM- GND

3. Connect AC cord to PSU. Connect PSU to chassis rear

DC Input and slide jack behind the strain relief as

shown in Figure 4 below. Route cabling to avoid

snags. If necessary, use tie wrap to bundle excess.

Figure 3: PSU and Regional AC Cord

Page 6 of 7

Page 9

Quick Start Guide: Counterpoint iD

Figure 4: PSU DC Cord Strain Relief

4. Configure the DIP Switches on the front panel for the desired operation.

Note: For details on “Mode Configurations”, see DIP Switch Functions on page 3 above.

5. System is ready to power ON. With no advanced features required, the final step is

to press Reset button, wait for the Violet LED, then press reset again to tune.

6. Optional: Connect field service laptop to front RS-232 port via patch cable, then

perform any FW upgrades or advanced tuning with DMS. See Help File for more.

Tuning

CPiD needs to be tuned upon installation or it will not function.

Using DMS SW features (see below), advanced antenna tuning may help

achieve desired detection, but keep in mind:

• Avoid interactions when located near EAS pedestal/antennas.

• Tune system for immunity/ False Alarms for the detector.

See Also

DMS version 1.8.95 and later will feature a help file to cover all SW-based

configurations and settings for using CPiD. To access the instructions, click

Help (or press F1) > Help Files > Counterpoint ID.

Page 7 of 7

Page 10

Appendix A: Regulatory and Safety

Important Information to our Users in North America

FCC Regulatory Compliance Statement

Checkpoint Systems, Inc., offers Electronic Article Surveillance (EAS) or Radio Frequency

Identification Products that have been FCC certified or verified to 47 CFR Part 15 Subparts B/C.

Appropriately, one of the following labels will apply to the approval:

NOTE: This equipment has been tested and found compliant within the limits for a class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate interference to radio communications. Operation of

this equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at own expense.

- OR -

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) including this device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired operation, which

may include intermittent decreases in detection and/or intermittent increases in alarm activity.

Industry Canada Regulatory Compliance Statement

This device complies with the Industry Canada license-exempt RSS standard(s). Operation is subject to the

following two conditions:

1. This device may not cause interference, and

2. This device must accept any interference, including interference that may cause undesired operation of the device.

Under Industry Canada regulations, this radio transmitter may only operate using an antenna of a type

and maximum (or lesser) gain approved for the transmitter by Industry Canada. To reduce potential

radio interference to other users, the antenna type and its gain should be so chosen that the equivalent

isotropically radiated power (e.i.r.p.) is not more than that necessary for successful communication.

This radio transmitter (IC: 3356B-CPID) has been approved by Industry Canada to operate with the

antenna types listed below with the maximum permissible gain and required antenna impedance for

each antenna type indicated. Antenna types not included in this list, having a gain greater than the

maximum gain indicated for that type, are strictly prohibited for use with this device.

Antenna Type Antenna Structure Antenna Size

Counterpoint pad 1 turn loop 12” x 12”

Royston antenna 1 turn loop 13” x 6”

NCR 7876 2 turn loop 8.5” x 6.5”

NCR 7878 1 turn loop 6” x 6”

Page A-1

Page 11

Antenna Type Antenna Structure Antenna Size

Conveyor

Deactivation Pad

Handheld deactivator 1 turn loop 10” x 8”

Hand scan antenna 1 turn loop 6.8” x 1.5”

Sheet deactivator 1 turn loop 9.4” x 9.4”

Magellan 8400/9800 1 turn loop 8” x 8”

Metrologic MS2420 1 turn loop 8” x 8”

Motorola MP6000 1 turn loop 8” x 8”

1 turn loop 9.8” x 9.8”

Equipment Compliance Statement

Checkpoint’s Electronic Article Surveillance (EAS) products have been designed for safeness during normal

use and, where applicable have been certified, listed, or recognized in accordance with one or more of the

following safety standards; UL 60950-1, CSA C22.2 No. 60950-1-07. Additional approvals may be pending.

WARNI NG:

equipment not expressly approved by the party responsible for assuring compliance could void the user’s

authority to operate the equipment in a safe or otherwise regulatory compliant manner.

Changes or modifications to Checkpoint’s EAS or Radio Frequency Identification (RFID)

Page A-2

Page 12

Appendix A: Regulatory and Safety

Important Information to our Users in Europe

CE Regulatory Compliance Statement

Where applicable, Checkpoint Systems, Inc. offers certain Electronic Article Surveillance (EAS)

products that have CE Declarations of Conformity according to R&TTE Directive 99/5/EC, EMC

Directive 2004/108/EC, and Low Voltage Directive 2006/95/EC.

System Electromagnetic Compatibility (EMC) has been tested and notified through Spectrum

Management Authorities if necessary, using accredited laboratories, whereby, conformity is declared

by voluntarily accepted European Telecommunications Standards Institute (ETSI) standards EN

301489-3 and EN 302208 and/or EN 300330, as applicable.

NOTE: Certain Electronic Article Surveillance (EAS) equipment have been tested and found to

conform to the CE emission and immunity requirement in Europe. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications. Under

unusual circumstances, interference from external sources may degrade the system

performance, which may include intermittent decreases in detection and/or intermittent

increases in alarm activity. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment experiences frequent interference from external sources

or does cause harmful interference to radio communications reception, which can be

determined by turning the equipment off and on, please contact a Checkpoint Systems

representative for further assistance.

RoHS Compliance Statement

The RoHS Directive stands for "the restriction of the use of certain hazardous substances in electrical

and electronic equipment." A RoHS compliant product means that electrical and electronic equipment

cannot contain more than maximum permitted levels of lead, cadmium, mercury, hexavalent

chromium, polybrominated biphenyl (PBB) and polybrominated diphenyl ether (PBDE). Checkpoint is

in compliance with the RoHS directive.

WEEE Compliance Statement

The Waste Electrical and Electronic Equipment Directive (WEEE) applies to companies that

manufacture, sell, distribute, or treat electrical and electronic equipment in the European Union. There

are a number of obligations imposed on Checkpoint as a supplier of electrical and electronic

equipment. Checkpoint's compliance approach for each of these obligations is provided below.

Page A-3

Page 13

WEEE Marking

All products that are subject to the WEEE Directive supplied by Checkpoint are compliant with the WEEE

marking requirements. Such products are marked with the "crossed out wheelie bin" WEEE symbol shown

below in accordance with European Standard EN 50419.

Information for Users

According to the requirements of European Union member state WEEE legislation, the following user

information is provided in English for all Checkpoint supplied products subject to the WEEE directive.

This symbol on the product or on its packaging indicates that the product must not

be disposed of with normal waste. Instead, it is your responsibility to dispose of

your waste equipment by arranging to return it to a designated collection point for

the recycling of waste electrical and electronic equipment. By separating and

recycling your waste equipment at the time of disposal you will help to conserve

natural resources and ensure that the equipment is recycled in a manner that

protects human health and the environment. For information about how to recycle

your Checkpoint supplied waste equipment, please contact the Checkpoint

Systems, Inc. Field Service office in your region. Customers can obtain this

information from their system User’s Guide.

REACH Compliance Statement

The European REACH Regulation 1907/2006 on Registration, Evaluation, Authorization, and Restriction of

Chemicals (REACH), Annex XVII entered into force in June 2009, and affects all companies producing,

importing, using, or placing products on the European market. The aim of the REACH regulation is to

ensure a high level of protection of human health and the environment from chemical substances.

Checkpoint Systems’ substances management system follows and complies with the current revision of the

REACH Regulation on the substances as identified by ECHA (European Chemical Agency).

Checkpoint Systems’ products are considered articles as defined in REACH Article 3 (3).

These products/articles under normal and reasonable conditions of use do not have intended release of

substances. Therefore the requirement in REACH Article 7 (1) (b) for registration of substances contained in

these products/articles does not apply.

Checkpoint Systems’ products/articles do not contain Substances of Very High Concern or if there are

SVHC in the product/article, the content is less than the 0.1% (wt/wt) as defined by REACH Article 57,

Annex XIV, Directive 67/548/EEC. Therefore the requirement in REACH Article 7 (2) to notify ECHA if a

product/article contains more than 0.1% wt/wt of an SVHC and tonnage exceeding 1 tonne per importer per

year is not applicable.

Checkpoint Systems’ European operations do not manufacture or import chemicals, therefore Checkpoint

Systems has no obligation to register substances.

Packaging Compliance Statement

No CFCs (chlorofluorocarbons), HCFCs (hydrofluorocarbons) or other ozone depleting sub-stances are

used in packaging material. Chromium, lead, mercury, or cadmium are not intentionally added to packaging

materials and are not present in a cumulative concentration greater than 100 ppm as incidental impurities.

No halogenated plastics or polymers are used for packaging material. Checkpoint complies with the EU

Directive 94/62/EEC.

Page A-4

Loading...

Loading...