Page 1

476736

Title:

INSTALLATION & TUNE-UP

PROCEDURE

COUNTERPOINT IX

NOTICE TO PERSONS RECEIVING THIS

DRAWING

AND/OR TECHNICAL INFORMATION:

Checkp oint Systems claims proprietary rights to t he material disclosed

hereon.

This drawing and/or technical information is issued in confidence for

engineering information only and may not be reproduced or used to

manufacture anything shown or referred to hereon without direct written

permission from Checkpoint Systems to the user. This drawing and/or

technical information is t he property of Checkpoint Systems and is loaned

for mut ual assistance, to be returned when its purpose has been served.

THIS DRAWING AND/OR TECHNICAL INFORMATION IS THE

PROPERTY OF CHECKPOINT SYSTEMS, INC.

Revisions Revisions

Rev Description Date Engineer Rev Description Date Approved

00

Used On

Doc. Spec:

Dwn:

Chk: Date:

Eng

Appd

:

Date:

Date

Date

Date:

:

:

Size

A 476736

Scale: N/A

Checkpoint Systems, Inc. 1996 Page 1 of 28

Page 2

Rev. 00

TECHNICAL DOCUMENTATION

INSTALLATION & TUNE-UP PROCEDURE

COUNTERPOINT IX

Section Description Page

AForward. 4

1.0 System Description 5-7

1.1 System Overview 5

1.1.1 How the System Works 5

1.1.2 System Effectiveness 5

1.2 Chassis 6

1.3 Power Supply and C/PT resettable fuse 6

1.4 Remote Unit 6

1.5 Antenna 6

1.6 Target 6

2.0 Recommended Tools and Equipment 7

2.1 Electronic Test Equipment 7

2.2 Installation Tools 7

March 9, 2000

FCC ID: D04CP1900

Table Of Contents

Table 2.1 - Recommended Electronic Test Equipment 7

Table 2.2 - Recommended Installation Tools 7

3.0 Wiring the C/PT IX 8-11

3.1 Power Connection 8

Figure 3.1 - wire Connection 8

3.2 Antenna Connection 9

3.2.1 Pad Connection 9

Figure 3.2.1 - Pad Connection 9

3.2.2 Scanner Antenna Connection 10

Figure 3.2.2 - Scanner Connection 10

3.3 Slaving Connection 10

3.3.1 Wire Slaving 10

3.3.2 Fiber Slaving 11

3.3.3 Secure Cables 11

3.4 Interlock Connection 11

3.5 Remote Unit Connection 11

Table 3.5 - Remote Unit Connection 11

4.0 Install the C/PT IX 12-14

4.1 Chassis Installation 12

Figure 4.1A - Horizontal Chassis Installation 12

Figure 4.1B - Vertical Chassis installation 13

4.2 Remote Unit Installation 13

Figure 4.2A - Vertical Remote Unit Installation 13

Figure 4.2B - Horizontal Remote Unit Installation 14

_____________________________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

DWG. 476736

PAGE 2

Page 3

Rev. 00

TECHNICAL DOCUMENTATION

INSTALLATION & TUNE-UP PROCEDURE

COUNTERPOINT IX

5.0 C/PT IX DIP Switch Configuration 14-18

5.1 Antenna Matching 15

5.2 IV Mode 16

5.3 V Mode 17

5.4 VI Mode 18

6.0 C/PT IX Tune-Up and Test Procedure 19-20

6.1 Center Frequency and Deviation Verification 19

6.2 IV Mode 19

6.3 V Mode 19

6.4 VI Mode 20

6.5 Interlock Turn-On Time Adjustment 20

7.0 After the Installation 20-21

7.1 Turning the Deactivator On and Off 20

7.2 How the Deactivator Works 20

7.3 When the Tag Doesn’t Deactivate 20-21

7.4 When the Sensing System Alarms 21

7.5 Testing the Deactivator 21

7.6 Operational Problems 21

7.7 Tagging 21

March 9, 2000

FCC ID: D04CP1900

Table 5.1 - Antenna Matching Chart 15

Table 5.2 - Settings for IV Mode 16

Table 5.3 - Settings for V Mode 17

Table 5.4 - Settings for VI Mode 18

8.0 Figures and Tables 22-26

8.1 Test Points and Adjustments 22

Figure 8.1 - Test Points and Adjustments 22

8.2 Slave/Inhibit Decision Chart 23

Table - 8.2 C/PT IX Slaving/Inhibit Decision Chart 23

8.3 DIP Switch Settings 24

Table 8.3 - DIP Switch Settings 24

8.4 INTERLOCK Time Adjustment Chart 25

Table 8.4 - INTERLOCK Time Adjustment Chart 25

8.5 Performance Matrix 26

Table 8.5 - Performance Matrix 26

Appendix A Fine Tuning 27-29

A.1 Detailed Tuning in IV Mode 27-29

Figure A1.1 - AC Signal at TP2 with SW1,2 ( 1 ) On 27

Figure A1.2 - AC Signal at TP2 with SW1,2 ( 5,6 ) On 27

Figure A1.3 - AC Signal at TP2 with SW1,2 ( 3,4,5,6 ) On 28

Figure A1.4 - AC Signal at TP4 29

A.2 Detailed Tuning in V Mode 29

A.3 Detailed Tuning in VI Mode 29

_____________________________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

DWG. 476736

PAGE 3

Page 4

Rev. 00

TECHNICAL DOCUMENTATION

INSTALLATION & TUNE-UP PROCEDURE

COUNTERPOINT IX

Scope of Document

This manual describes the steps necessary to install, tune, test and operate the C/PT IX

Deactivation system.

Manual Structure

This manual is organized with the following structure:

Section 1.0 Describes the C/PT IX system components and how they work.

Section 2.0 Lists the tools recommended to install, tune and test the C/PT IX system.

Section 3.0 Lists and describes steps required to wire the C/PT IX system.

Section 4.0 Lists and describes steps required to install the C/PT IX system.

Section 5.0 Lists and describes steps to tune and test the C/PT IX system.

March 9, 2000

FCC ID: D04CP1900

Required Knowledge and Skill

This manual assumes that you have the technical skill and electronic knowledge you need to:

•

•

•

•

Read a wiring diagram

Connect and read electronic test instruments

Make electrical wiring connections

Do light construction work using hand and small power tools

Editorial Conventions

This manual numbers each paragraph and table to help you find information easily and quickly.

Two levels of decimals indicate subsections; for example: 5.1 or 2.3.3 Tables and figures

carry the number of the subsection in which they appear rather than consecutive numbers.

_____________________________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

DWG. 476736

PAGE 4

Page 5

Rev. 00

TECHNICAL DOCUMENTATION

INSTALLATION & TUNE-UP PROCEDURE

COUNTERPOINT IX

1.0 System Description

1.1 System Overview

Checkpoint's C/PT IX deactivation system dramatically cuts inventory shrinkage

losses from customer shoplifting and employee pilferage when used in conjunction

with a Checkpoint electronic article merchandising system. Although not foolproof,

C/PT IX can reduce losses in retail stores so effectively that the savings will quickly

exceed the system's cost. This manual describes how to install, tune, and test the

C/PT IX system.

A complete C/PT IX system consists of one chassis, one or two pads or scanner

antennas and targets attached to protected inventory. The pad rests on the top of the

checkout counter where tagged merchandise can pass over it. The chassis is usually

mounted under or inside the checkout counter. Clerks deactivate these targets at

checkout. If someone should try to exit through the sensing system with an active

target, an alarm sounds. The manager can then intercept and verify the item has been

properly purchased.

March 9, 2000

FCC ID: D04CP1900

1.1.1 How the System Works

One chassis can drive up to two pads or up to two scanner/deactivators or a

combination of both. A random pulsed-RF signal is generated by the chassis.

This signal is sent through a cable or cables connected to one or two pads

creating a RF field above the pad(s). When a Checkpoint target enters the

field, it responds to the chassis' signal by resonating and emitting a signal of its

own. Depends on its operating modes, the chassis either picks up the target's

signal, and amplifies the subsequent pulses to destroy or deactivate the target,

or operates in the high power mode to destroy or deactivate the target all the

time.

1.1.2 System Effectiveness

It is possible to subvert the C/PT IX system. For example, targeted

merchandise can be deactivated by customers, then concealed. Customers

could also remove targets from protected merchandise. Customers can learn

these and other tricks to evade security measures.

Most theft loss arises from impulsive shoplifters, who sense an opportunity to

steal and spontaneously act to take advantage of it. C/PT IX, in conjunction

with a sensing system, acts effectively to discourage these casual shoplifters,

and they seldom learn how to defeat this system.

_____________________________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

DWG. 476736

PAGE 5

Page 6

Rev. 00

TECHNICAL DOCUMENTATION

INSTALLATION & TUNE-UP PROCEDURE

COUNTERPOINT IX

1.2 Chassis

The chassis is mounted inside or under the checkout stand so that it is within 8 feet of

an AC power outlet, 7 feet of a pad, 5 feet of a scanner antenna.

On the unit’s face are:

•

a recessed power switch,

•

an access hole to the internal volume control,

•

a green LED (

•

a red LED (

•

a green LED (

•

a yellow LED (

1.3 Power Supply and C/PT resettable fuse

On the unit’s back are:

•

a 6-pin female connector for antenna connection,

•

three access holes for power, slaving, interlock, inhibit, and remote unit cables.

The standard C/PT IX chassis operates on 90 - 264 VAC 50/60Hz /15 VDC supply

with a current rating of over 1.0 A. The C/PT IX uses a resettable fuse. To reset this

fuse, turn off power, wait 1 minute and turn on power.

1.4 Remote Unit

When the C/PT IX is configured in IV or VI mode, a remote unit is needed.

On the remote unit’s face are:

•

a recessed power switch,

•

a green LED that lights when power is on,

•

a sonalert that beeps when a live tag is detected by the C/PT IX.

POWER

ALARM

SLAVE

DISABLE

March 9, 2000

FCC ID: D04CP1900

) that lights when power is on,

) that lights when a live tag is detected,

) that lights when the C/PT IX is locked in slaved mode,

) that lights when the C/PT IX is inhibited.

1.5 Antenna

The C/PT IX chassis can be used with a variety of antenna configurations.

Checkpoint or some scanner manufacturers produce these antennas.

1.6 Target

The C/PT IX system is compatible with all 8.2 MHz deactivatable tags. In addition,

the C/PT IX will alarm when a non-deactivatable tag is placed in its field, but it will

not deactivate the tag. Occasionally, non-deactivatable paper tags ( those with lower

than average breakdown voltage ) will be deactivated, especially when placed near a

corner of the pad where field strength is greatest. The CSE should be aware of this

rare event.

_____________________________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

DWG. 476736

PAGE 6

Page 7

Rev. 00

TECHNICAL DOCUMENTATION

INSTALLATION & TUNE-UP PROCEDURE

COUNTERPOINT IX

2.0 Recommended Tools and Equipment

2.1 Electronic Test Equipment

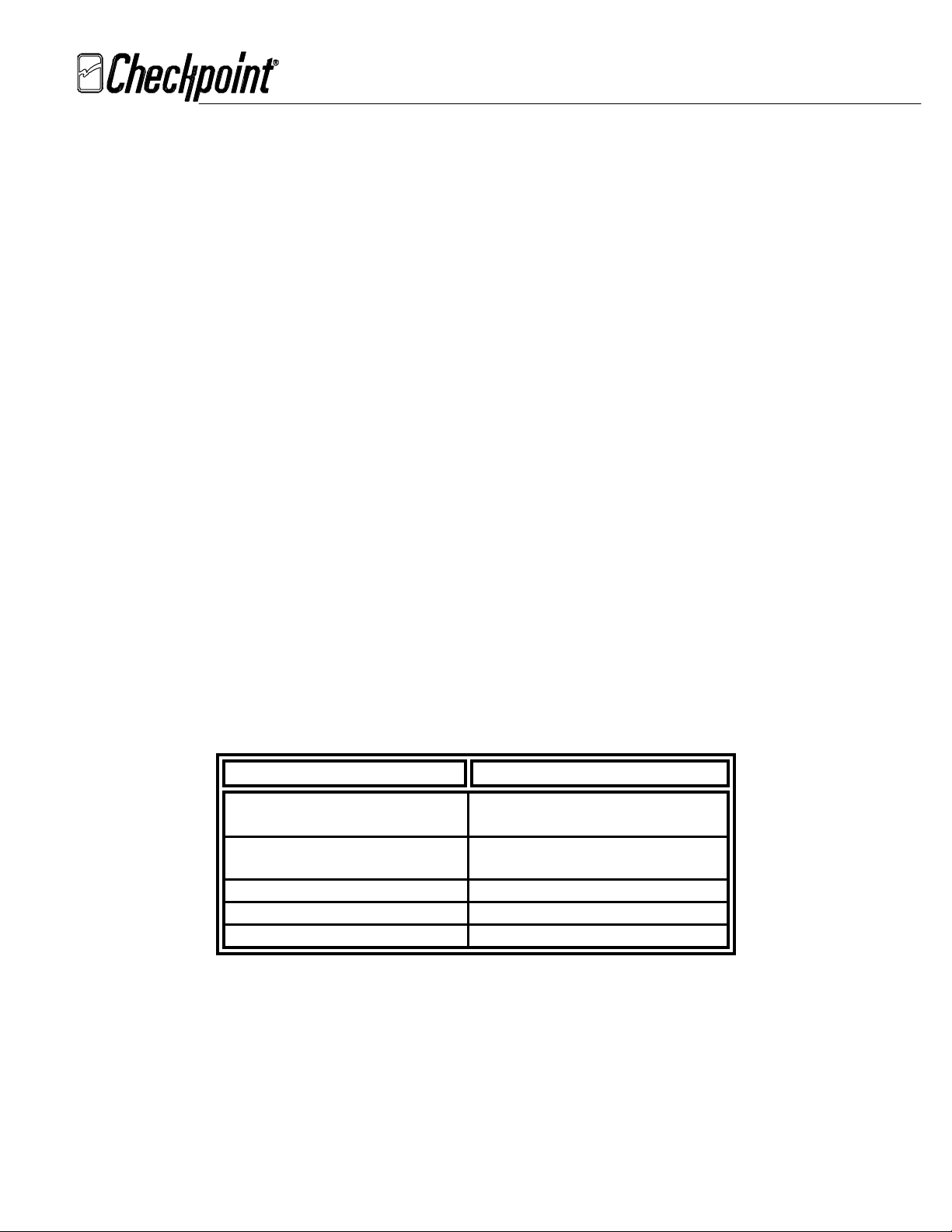

Table 2.1 lists the electronic equipment recommended for tuning the C/PT IX system.

Equipment Comments

_________________________________________________________________________________

Oscilloscope Minimum 20 MHz bandwidth, battery powered or filtered

Solid State Dip Meter Or some type of oscillator to tune bandwidth. Delica MC200,

Multimeter with Fluke 79 Series II Multimeter or equivalent.

frequency counter

_________________________________________________________________________________

March 9, 2000

FCC ID: D04CP1900

DC power supply, Two X10 probes, HITACHI V209

or equivalent.

or equivalent.

Table 2.1 Recommended Electronic Test Equipment

2.2 Installation Tools

The tools listed in Table 2.2 are recommended for installing the C/PT IX

system.

___________

____________________________________________________________________

Arrow Staple Gun, T-25 Penlight

Diagonal cutter, regular and midget Coaxial wire strippers

Wire stripper Crimper for RG58/59 coax cable

Electronic hand drill and bits: Heyco bushing pliers - Heyco # 0022 (optional)

•

•

Steel bits, assorted sizes Screwdriver, regular

Wood bits, assorted sizes Screwdriver, #2, Phillips

25' heavy duty extension cord, 3-conductor Tape measure, 25'

Marker, black felt Tuning tool, plastic/non-conductive

Nut driver, 1/4" and 5/16" Outlet tester

Wire snake Wiremold removal tool

400 series test tag A 300 Kohm or greater resistor

( Used to bleed off capacitors )

______________________________________________________________________________

Table 2.2 Recommended Installation Tools

_____________________________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

DWG. 476736

PAGE 7

Page 8

Rev. 00

TECHNICAL DOCUMENTATION

INSTALLATION & TUNE-UP PROCEDURE

COUNTERPOINT IX

3.0 Wiring the C/PT IX

3.1 Power Connection

The

connected to the

power supply should be connected to the

If a switch is being used to cycle the power, the switch should be connected to the

SWITCH

pins of

BLACK/WHITE

PWR+

J2.

of

SWITCH.

If no switch is being used, place a jumper wire between those two

See Figure 3.1 for the detail.

POSITIVE

or

of J2 and the

March 9, 2000

FCC ID: D04CP1900

conductor from the power supply should be

BLACK

PWR-

GROUND

or

J2.

of

conductor from the

Figure 3.1 Wire Connections

_____________________________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

DWG. 476736

PAGE 8

Page 9

Rev. 00

TECHNICAL DOCUMENTATION

INSTALLATION & TUNE-UP PROCEDURE

COUNTERPOINT IX

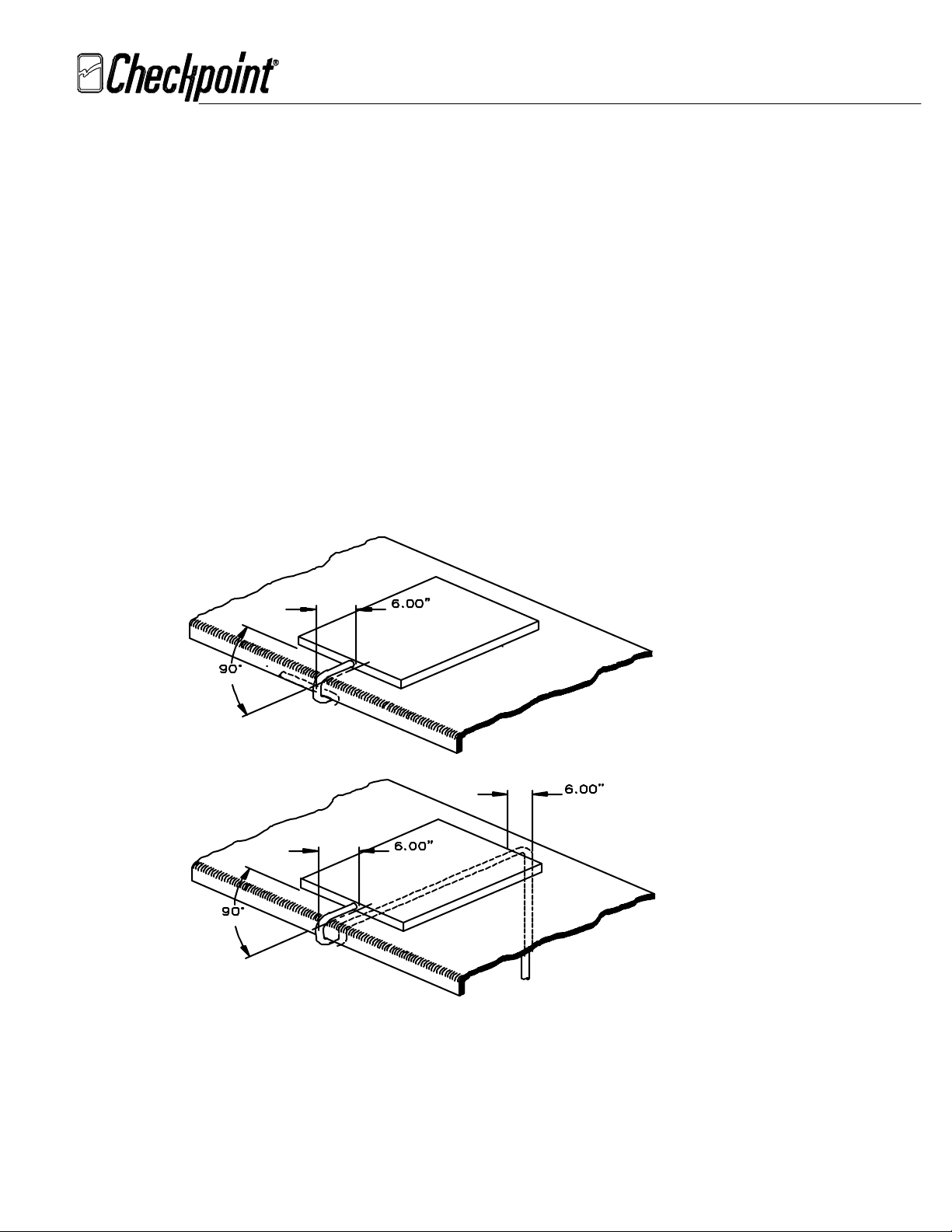

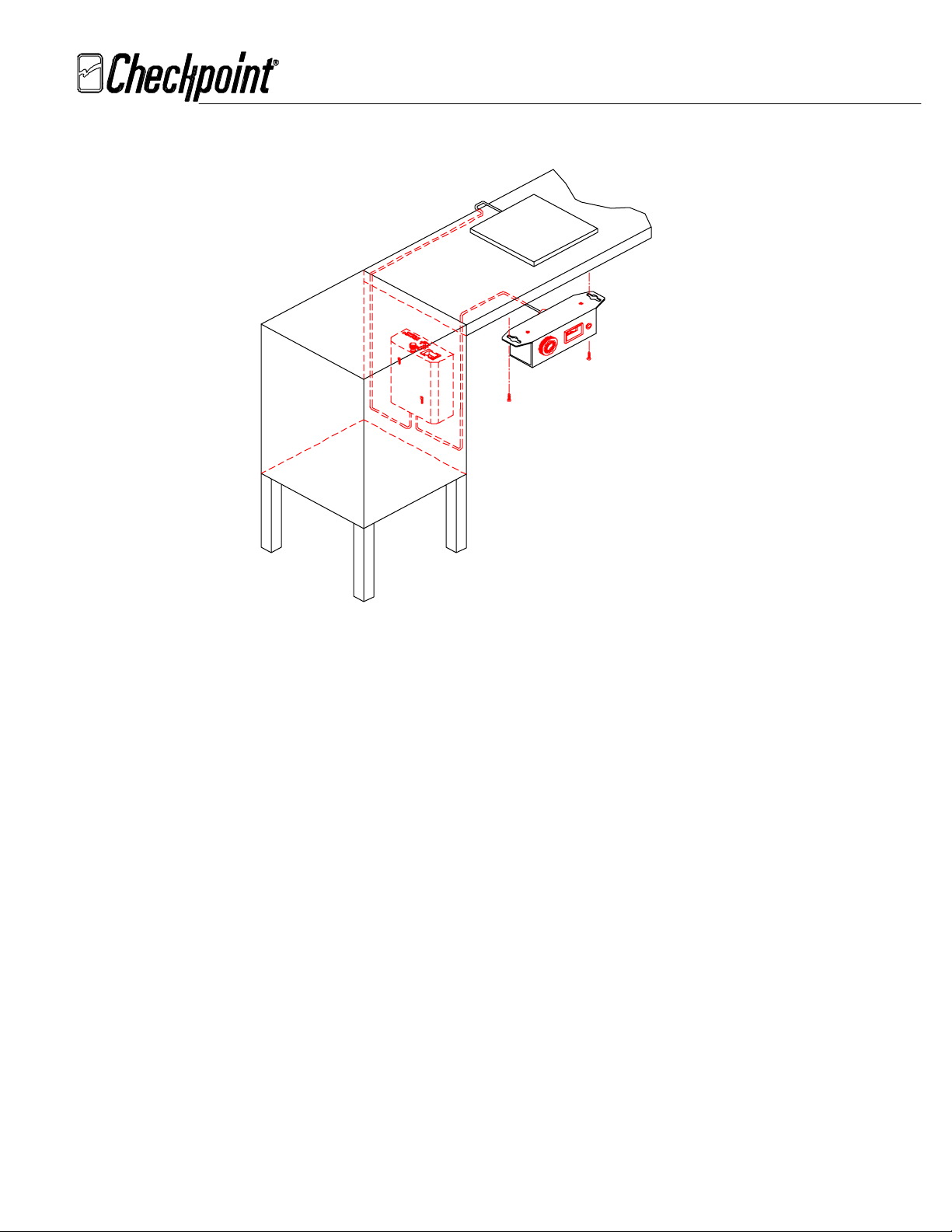

3.2 Antenna Connection

3.2.1 Pad Connection

March 9, 2000

FCC ID: D04CP1900

C/PT IX can drive one or two pads or scanner/deactivators. The cable length

for the pad is 8 feet.

(Don’t alter the cable length under any circumstance)

Place each pad in position on its counter. The maximum distance between the

two pads that are connected to a single chassis is 12 feet. The best performance

can be achieved if the pad cable run straight out of the pad for at least 6”

(15 cm) before it changes direction. See Figure 3.2.1. If the direct pad-chassis

route takes the cable back under the pad, beneath the counter top, it’s best to

route the cable along the center of the pad. See Figure 3.2.1. Ensure that

deactivation remains as transparent to the checkout process as possible. Connect

the pads cables to either

drain wires to

GND

(pin 2 or 5 of J1) on the C/PT IX. See Figure 3.1 for the

ANT1

(pin 1,3 of J1) or

ANT2

(pin 4,6 of J1) with

detail.

Figure 3.2.1 Pad Connection

_____________________________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

DWG. 476736

PAGE 9

Page 10

Rev. 00

uttsplice

TECHNICAL DOCUMENTATION

INSTALLATION & TUNE-UP PROCEDURE

COUNTERPOINT IX

March 9, 2000

FCC ID: D04CP1900

3.2.2 Scanner Antenna Connection

To achieve optimized performance, the cable length from the chassis to 4_WAY

connector or buttsplice should be kept to 6 feet in length. (

length under any circumstance)

Extend the scanner antenna cable by 6 feet

Don’t alter this

using the 4-WAY connector or the buttsplice and the cable (Belden 8760 #18)

provided with the installation kit. See Figure 3.2.2. Connect the antenna cable

to either

GND

ANT1

(pin 1,3 of J1) or

(pin 2 or 5 of J1) on C/PT IX. See Figure 3.1 for the detail.

C/PT IX

ANT2

6 feet

(pin 4,6 of J1) with the drain wire to

Scanner

Connector

Or

B

Figure 3.2.2 Scanner Connection

3.3 Slaving Connection

Whether or not the C/PT IX should be slaved to other EAS systems or deactivation

systems depends on the environment of the site, the layout of the system, and the

settings of the system. Refer to Table 8.1 as a guideline for the minimum distances

required between the various EAS systems and the C/PT IX. If you are not sure,

temporarily plug in and turn on the C/PT IX, attach the oscilloscope probe to the

appropriate test point of the EAS systems receivers as you test for poor detection and

phantoms.

NOTE: The C/PT IX doesn’t have MASTER SLAVE OUTPUT.

It cannot be slaved to each other unless a master source such as

an EAS system or fiber master exists.

3.3.1 Wire Slaving

Connect the slaving input cable from the master source to

of J4). Connect the slaving output cable (daisy chain) to

of J4). Ground for wire slave is pin 2 of J4. See Figure 3.1 for the detail.

Slave In

Slave Out

(pin 5, 6

(pin 3,4

_____________________________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

DWG. 476736

PAGE 10

Page 11

Rev. 00

TECHNICAL DOCUMENTATION

INSTALLATION & TUNE-UP PROCEDURE

COUNTERPOINT IX

3.3.2 Fiber Slaving

3.3.3 Secure Cables

3.4 Interlock Connection

If the interlock function is used, connect the interlock input cable either directly from

the scanner or from the audio interlock board to

See Figure 3.1 for the detail.

March 9, 2000

FCC ID: D04CP1900

When fiber slaving, you need the fiber receiver found in Fiber Slave Kit

(P/N 469022). Plug the fiber receiver into U15 and tie wrap it. Connect the

fiber cable with the connector from the fiber master to the fiber receiver.

Secure slave/inhibit wiremold, measure, cut, and lay the cable. Secure the

pad- chassis and power cables to the sales counter surfaces with cable ties.

Use plastic wiremold where cables are visible to the store personnel. Secure

the excess of either cable under the counter by bundling it. Do not coil it.

Make sure to leave enough cable slack at the chassis end to allow service

access. Leave the chassis unplugged. Install Heyco bushings at each cable

entry on the rear of the deactivator chassis.

INTLK

at J4. Notice the polarity.

3.5 Optional Remote Unit Connection

When configured in IV and VI modes, an optional remote unit containing a sonalert

and the power

ON/OFF

switch can be connected to the C/PT IX chassis. The

purpose of this unit is to provide easy access to power

the remote unit, remove the wires from

off the exposed leads. Install the wires from the remote unit following Table 3.5.

Install Heyco Bushing at the entry of the cable. See Figure 3.1 for the detail.

Cable From the Remote Unit Connection to C/PT IX Chassis

Red, Brown and Yellow SWITC H Pin 4 at J2

Black and Green SWITCH Pin 3 at J2

White SPKR ( + ) at J3

Blue SPKR ( - ) at J3

Orange PWR ( - ) at J2

Table 3.5 Remote Unit Connection

SWITCH

( next t o SP K R )

( next t o PWR )

ON/OFF

switch. To connect

at J2 of the C/PT IX chassis and cut

_____________________________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

DWG. 476736

PAGE 11

Page 12

Rev. 00

TECHNICAL DOCUMENTATION

INSTALLATION & TUNE-UP PROCEDURE

COUNTERPOINT IX

4.0 Install the C/PT IX

4.1 Chassis Installation

The C/PT IX chassis can be installed vertically and horizontally. Ensure to install

the chassis at a convenient location where the customer has easy access to

switch. Unscrew and slide the cover out of the chassis, install the cover horizontally

as shown in Figure 4.1A and vertically as shown in Figure 4.1B, and slide the chassis

back on. Ensure to allow enough space so the chassis can slide in and out easily.

March 9, 2000

FCC ID: D04CP1900

ON/OFF

Figure 4.1A Horizontal Chassis Installation

_____________________________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

DWG. 476736

PAGE 12

Page 13

Rev. 00

TECHNICAL DOCUMENTATION

INSTALLATION & TUNE-UP PROCEDURE

COUNTERPOINT IX

March 9, 2000

FCC ID: D04CP1900

Figure 4.1B Vertical Chassis Installation

4.2 Remote Unit Installation

When a remote unit is used, it should be installed at a location where the customer has

easy access to the unit. Figure 4.2A and 4.2B show examples.

Figure 4.2A Vertical Remote Unit Installation

_____________________________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

DWG. 476736

PAGE 13

Page 14

Rev. 00

TECHNICAL DOCUMENTATION

INSTALLATION & TUNE-UP PROCEDURE

COUNTERPOINT IX

March 9, 2000

FCC ID: D04CP1900

5.0

Figure 4.2B Horizontal Remote Unit Installation

C/PT IX DIP Switch Configuration

The C/PT IX can be configured as master or slave unit, operating in IV, V, or VI modes. This

is done by the settings of SW1, SW2, SW3, SW4, and SW5.

In IV mode, the C/PT IX detects the tag first and switches from the low power mode to the

high power mode to destroy the tag.

In V mode, the C/PT IX operates in the high power mode all the time to destroy the tag and

will not detect the tag.

In VI mode, the C/PT IX operates in the high power mode all the time to destroy the tag but

will detect the hard tags and any missed soft tags.

Almost all the C/PT IX’s functions are configured by three banks of DIP switches. Refer to

Table 8.3 for a complete listing of the DIP switches and their functions. A simplified table

can also be found on the back of the chassis.

5.1 Antenna Matching

_____________________________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

DWG. 476736

PAGE 14

Page 15

Rev. 00

TECHNICAL DOCUMENTATION

INSTALLATION & TUNE-UP PROCEDURE

COUNTERPOINT IX

To achieve optimized performance, the C/PT IX’s output impedance needs to be matched

Note 1: The cable length is 8 feet for the pads and 6 feet for the scanners.

Note 2: The table is for single pad or scanner. If double, refer to Section 8.0 for details.

SCANNERS SW1,2 (1) SW1,2 (2) SW1,2 (3) SW1,2 (4) SW1,2 (5) SW1,2 (6)

HS1250

LS5000

LS5700

LS9100

MAGELLAN

MAGELLAN SL

NCR7820

NCR7824

NCR7870

NCR7875

ORION

PADS

SP750F

SP760SLS

SP960LS

VS1000

VS1000S

WAND

March 9, 2000

FCC ID: D04CP1900

to the scanner antenna or the pad it connects to. This is done by using DIP switches SW1

and SW2.

Table 5.1 applies to CP IV, V, or VI mode

.

ON OFF OFF OFF ON OFF

OFF OFF ON OFF OFF OFF

ON OFF OFF OFF OFF OFF

OFF OFF ON OFF OFF OFF

OFF OFF ON OFF OFF OFF

ON OFF OFF OFF OFF OFF

ON OFF OFF OFF ON OFF

ON OFF OFF OFF ON OFF

ON OFF OFF OFF OFF OFF

OFF OFF OFF OFF OFF ON

OFF OFF OFF OFF ON OFF

ON OFF OFF OFF OFF OFF

ON OFF OFF OFF ON OFF

ON OFF ON OFF OFF ON

ON OFF ON OFF OFF OFF

ON OFF ON OFF OFF OFF

ON OFF OFF OFF OFF OFF

OFF OFF OFF OFF OFF OFF

Table 5.1 Antenna Matching Chart

_____________________________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

DWG. 476736

PAGE 15

Page 16

Rev. 00

TECHNICAL DOCUMENTATION

INSTALLATION & TUNE-UP PROCEDURE

COUNTERPOINT IX

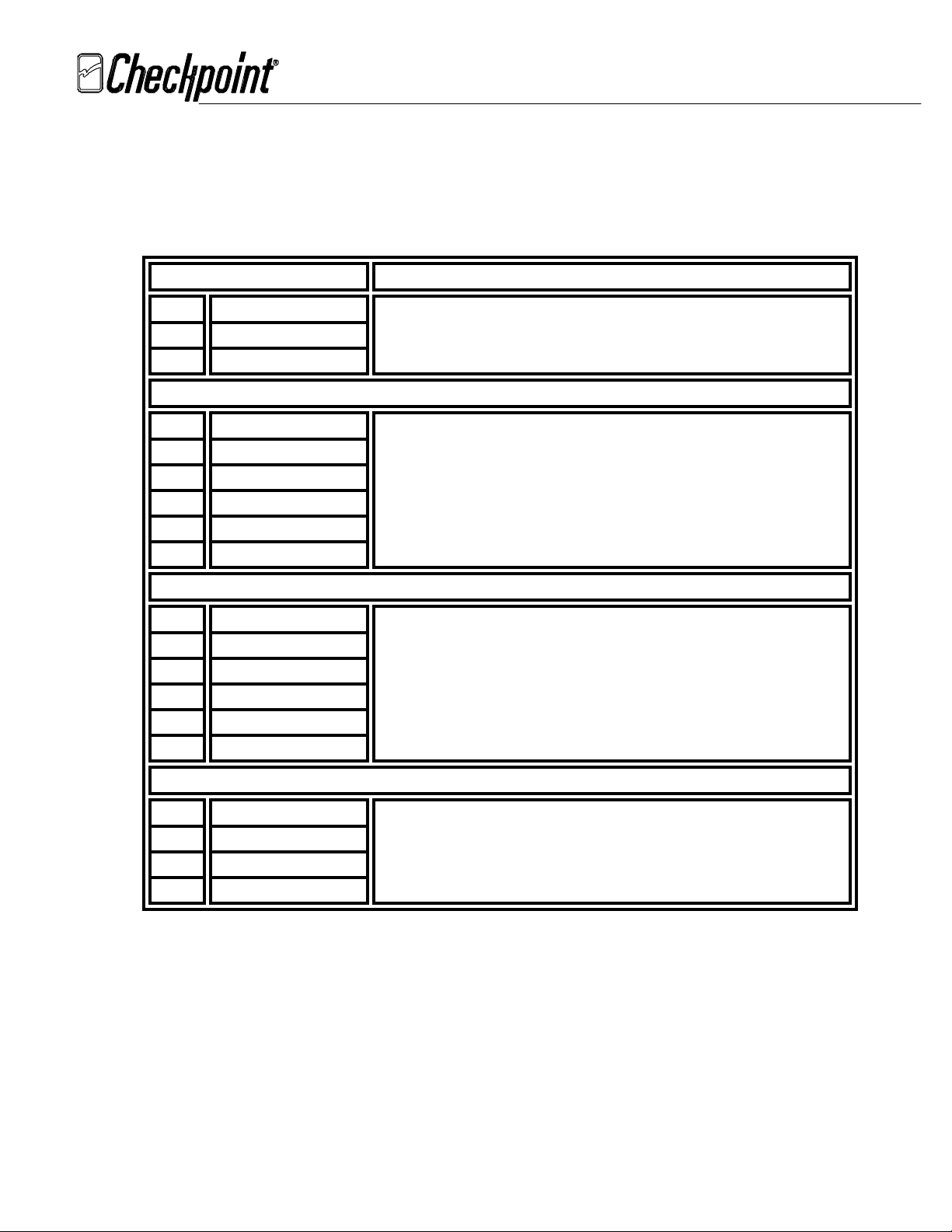

5.2 IV Mode

When configured as IV mode, SW1, SW2, SW3, SW4, and SW5 need to be set

as follows:

SW1,2 DESCRIPTION

1,2 See Table 5.1

3,4 See Table 5.1

5,6 See Table 5.1

SW3

1 OFF See Note 3

2 OFF See Note 4 Note 4: This is for interlock function. See Table 8.3.

3 OFF See Note 4

4 OFF See Note 6 Note 6: This is a default setting for MASTER mode, see Table 8.3 for

5 OFF See Note 6

6 OFF See Note 6

March 9, 2000

FCC ID: D04CP1900

slaving

SW4

1OFF

2OFF

3ON

4OFF

5 ON See Note 7 Note 7: This is a default setting for MEDIUM detection, see Table 8.3

6 OFF See Note 7

for different settings.

SW5

1 OFF See Table 8.3

2 OFF See Note 8 Note 8: This is the default freq. band (7.6 – 8.7 MHz), see Table 8.3

3 OFF See Note 8

for different bands.

4 OFF See Note 8

Note 3: This is a default setting for Medium deactivation. ( 44 VDC at VPA TP2 for FCC, CE/UK

compliance ) For non- regulated market, please see Table 8.3 for the settings.

Table 5.2 Settings for IV Mode

_____________________________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

DWG. 476736

PAGE 16

Page 17

Rev. 00

TECHNICAL DOCUMENTATION

INSTALLATION & TUNE-UP PROCEDURE

COUNTERPOINT IX

5.3 V Mode

When configured as V mode, SW1, SW2, SW3, SW4, and SW5 need to be set

as follows:

SW1,2 DESCRIPTION

1,2 See Table 5.1

3,4 See Table 5.1

5,6 See Table 5.1

SW3

1 OFF See Note 9

2 OFF See Note 10 Note 10: This is for interlock function in IV mode

3 OFF See Note 10

4 OFF See Note 11 Note 11: This is a default setting for MASTER mode, see Table 8.3 for

5 OFF See Note 11

6 OFF See Note 11

March 9, 2000

FCC ID: D04CP1900

slaving

SW4

1OFF

2OFF

3OFF

4OFF

5 N/A See Note 12 Note 12: Not used in V mode.

6 N/A See Note 12

SW5

1 OFF See Table 8.3

2 OFF See Note 13 Note 13: This is a default setting for MASTER mode, see Table 8.3

3 OFF See Note 13

for slaving

4 OFF See Note 13

Note 9: This is a default setting for Medium deactivation ( 44 VDC at VPA TP2 for FCC, CE/UK compliance )

For non- regulated market, please see Table 8.3 for the settings.

Table 5.3 Settings for V Mode

_____________________________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

DWG. 476736

PAGE 17

Page 18

Rev. 00

TECHNICAL DOCUMENTATION

INSTALLATION & TUNE-UP PROCEDURE

COUNTERPOINT IX

5.4 VI Mode

When configured as VI mode, SW1, SW2, SW3, SW4, and SW5 need to be set

as follows:

SW1,2 DESCRIPTION

1,2 See Table 5.1

3,4 See Table 5.1

5,6 See Table 5.1

SW3

1 OFF See Note 14

2 OFF See Note 15 Note 15: This is for interlock function. See Table 8.3.

3 OFF See Note 15

4 OFF See Note 16 Note 16: This is a default setting for MASTER mode, see Table 8.3 for

5 OFF See Note 16

6 OFF See Note 16

March 9, 2000

FCC ID: D04CP1900

slaving

SW4

1 ON Note 18: This is for interlock function. See Table 8.3 for settings.

2OFF

3N/A

4ON

5 ON See Note 19 Note 19: This is a default setting for MEDIUM detection, see Table 8.3

6 OFF See Note 19

for different settings.

SW5

1 OFF See Table 8.3

2 OFF See Note 20 Note 20: This is the default freq. band (7.6 – 8.7 MHz), see Table 8.3

3 OFF See Note 20

for different bands.

4 OFF See Note 20

Note 14: This is a default setting for Medium deactivation. ( 44 VDC at VPA TP2 for FCC, CE/UK compliance )

For non- regulated market, please see Table 8.3 for the settings

Table 5.4 Settings for VI Mode

_____________________________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

DWG. 476736

PAGE 18

Page 19

Rev. 00

TECHNICAL DOCUMENTATION

INSTALLATION & TUNE-UP PROCEDURE

COUNTERPOINT IX

6.0

C/PT IX Tune Up and Test Procedure

If you haven’t already done so, follow the standard procedure to tune the sensing system to

Checkpoint’s specifications

6.1 Center Frequency and Deviation Verify

Since the C/PT IX uses pulse-listen technology, it’s difficult to measure the center

frequency and the deviation using regular tools. Also, since the C/PT IX uses DDS

(Direct Digital Synthesis), the frequency band can not be adjusted. Use dip meter and

the ear phone to verify the center frequency and the deviation. You should

hear the clicking sound with your earphone from 7.6 –8.7 MHz when you sweep the

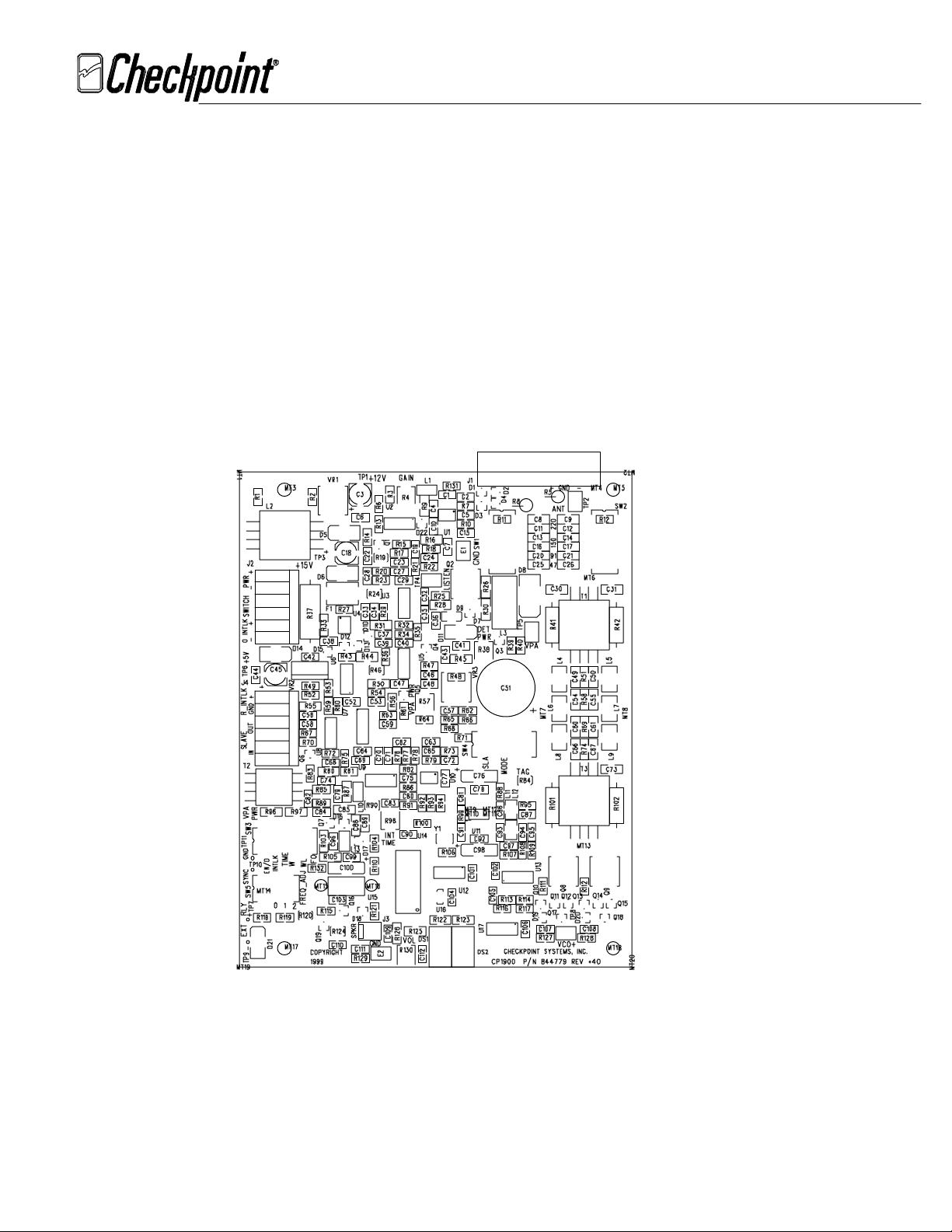

frequency using the dip meter. See Figure 8.1.

6.2

IV Mode

Follow step 5.2 to configure the chassis

March 9, 2000

FCC ID: D04CP1900

BEFORE

tuning the deactivators.

Detection Field Adjustment

When in IV mode, the detection field should be adjusted properly to achieve

the best performance.

6.3 V Mode

Follow step 5.3 to configure the chassis. Test the deactivation height using live 410

tags. The deactivation height should be comparable to the numbers listed in Table

8.2. If the deactivation height is worse than expected, go to Appendix A for the

detailed tuning.

To insure that tags will be detected before they are deactivated adjust R11 to

its minimum setting which is approximately 0.7 VDC. See Figure 8.1.

Sensitivity adjustment

When in IV mode, the sensitivity of the receiver should be adjusted properly

to achieve the best performance.

Adjust GAIN (R4) all the way clockwise (maximum) to achieve better

detection. If phantoms occur, adjust GAIN (R4) counterclockwise slightly

until the phantoms stop.

Test the detection height using standard 410 test tag. The detection height

should be comparable to the numbers listed in Table 8.2. If the detection

height is less than expected, go to Appendix A for the detailed tuning.

_____________________________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

DWG. 476736

PAGE 19

Page 20

Rev. 00

TECHNICAL DOCUMENTATION

INSTALLATION & TUNE-UP PROCEDURE

COUNTERPOINT IX

6.4 VI Mode

Follow step 5.4 to configure the chassis. Test the deactivation height using live 410

tags. The deactivation height should be same or better compared to the numbers

listed in Table 8.2. If the deactivation height is worse than expected, go to Appendix

A for the detailed tuning. Test the detection height using standard 410 test tag, it

should be at least 6” or higher if a pad is used.

6.5 Interlock Turn-On Time Adjustment

When the interlock function is used, adjust INT TIME (R98) clockwise to increase

the interlock Turn-On time from 0.2 - 10 seconds in LO mode (SW3-3 OFF) and 1min

– 10 min in HI mode (SW3-3 ON). See Figure 8.1.

7.0

After The Installation

Wait until after installation and tuning to show the customer personnel how the deactivator

operates. Ensure that site management is present and let them designate which site

employees will attend. If you have just installed a sensing system and deactivators, explain

the sensing system operation first, then follow with the deactivator operations, as follows:

March 9, 2000

FCC ID: D04CP1900

7.1 Turning the Deactivator On and Off

The deactivator should be turned off when not in use to prevent unauthorized

personnel from deactivating tags.

Show the operation of the power switch, and point out the green light on the chassis,

which shows that the power is on. If the sensing system control module is Model N or

later, mention that a key is required to activate the system. If the sensing system is

the master in a slaved configuration, indicate that it must be on before the

deactivators will function.

7.2

How the Deactivator Works

Show how the deactivator operation is similar to the sensing system in that both

systems transmit radio signals which cause tags to respond with their own radio

signals when they come into range. Explain that each system's receiver recognizes the

tag signal then verifies it. Then explain that the difference between the two is what

each does with the verified tag signal. The sensing system alarms loudly upon tag

verification. The deactivator alarms softly at the chassis and disables the tag. When

deactivation is immediate, there will be no audible alarm.

7.3 When the Tag Doesn't Deactivate

Explain that tags vary in length of time required to deactivate. Some tags deactivate

instantly, while others take longer. It may be that a very few wouldn't deactivate

automatically. If this should occur, just place a Thank You label over the tag.

Mention that any hard tags, hang tags, or non-deactivatable stickers also will not

deactivate automatically. Clerks must either remove these tags, or mask them with a

_____________________________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

DWG. 476736

PAGE 20

Page 21

Rev. 00

TECHNICAL DOCUMENTATION

INSTALLATION & TUNE-UP PROCEDURE

COUNTERPOINT IX

Thank You label. For these tags, the deactivator acts as a point of sale detector. It

continues to alarm softly until the tag is removed or masked.

7.4 When the Sensing System Alarms

Employees should follow their management's standard procedure for handling sensing

system alarms, just as if there were no deactivators in the store. If there is no

standard procedure, make a mental note to encourage management to set one. Wait

until after you conclude the training meeting to avoid embarrassing management in

front of the employees.

7.5 Testing the Deactivator

Employees should turn on the deactivator before use and turn off the deactivator

when unattended. An employee verifies power by viewing the green light on the

chassis. Beyond checking the power on switch, there isn't much need to test the

deactivator's function because it will be immediately apparent should a unit fail to

disable tags.

Show employees how to test for deactivation in case site management should want to

test a unit. In IV and VI modes, use a hard tag, hang tag or non-deactivatable sticker.

Hold it about 18" (46 cm) above each deactivator pad and bring it down slowly to the

pad's surface. Point out alarm occurs at about 10.5" (27 cm) height. Take a

deactivatable sticker and move it down in the same manner. Observe the signal stops

as the tag gets closer. Try to alarm the deactivator again with the same tag to verify

that it has been disabled. Make sure that this activity doesn't alarm any other

deactivator or sensing system. In V mode, use DV1000 and live 410 tags to test the

system.

March 9, 2000

FCC ID: D04CP1900

7.6 Operational Problems

Give site management the telephone numbers used for calling Checkpoint service

about equipment problems. Detail how to avoid potential problems by keeping

permanent tags and stickers and also metal objects away from the deactivator pads.

7.7 Tagging

Show how deactivatable stickers can now be hidden in protected merchandise.

Remind the customer that metal and foil objects usually can't be protected by pressure

sensitive tags. Detail that all procedures for tagging merchandise covered in the

User's Guide apply also to deactivatable tags. Detail the necessity of maintaining a

tagging system, use of merchandise value or theft activity to decide which

merchandise to tag, and the need for following an established procedure when the

sensing system alarms.

8.0 Figures and Tables

_____________________________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

DWG. 476736

PAGE 21

Page 22

Rev. 00

TECHNICAL DOCUMENTATION

INSTALLATION & TUNE-UP PROCEDURE

COUNTERPOINT IX

8.1

Test Points and Adjustments

RX GAIN

Potentiometer

March 9, 2000

FCC ID: D04CP1900

Antenna TP

Listen TP

VPA TP

Detection Power

Adjustment (4mode)

Deactivation Power

Adjustment

Sounder Volume

Figure 8.1 Test Points and Adjustment

Interlock TP

Interlock Time

Adjustment

Potentiometer

_____________________________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

DWG. 476736

PAGE 22

Page 23

Rev. 00

TECHNICAL DOCUMENTATION

INSTALLATION & TUNE-UP PROCEDURE

COUNTERPOINT IX

8.2 Slaving Decision Chart/All testing have been done with pads.

System C/PT IX

Power

Hi 15 ft 35 ft 20 ft 50 ft 20 ft 50 ft

Condor Med 15 ft 30 ft 20 ft 40 ft 20 ft 40 ft

Low 15 ft 20 ft 20 ft 35 ft 20 ft 35 ft

Hi 9 ft 9 ft 2 ft 4 ft 3 ft 4 ft

QS4000 Med 9 ft 9 ft 2 ft 3 ft 3 ft 3 ft

Low 9 ft 9 ft 2 ft 3 ft 3 ft 3 ft

Hi 8 ft 8 ft 2 ft 5 ft 2 ft 5 ft

QS2000 Med 8 ft 8 ft 2 ft 4 ft 2 ft 4 ft

Low 8 ft 8 ft 2 ft 3 ft 2 ft 3 ft

Hi 8 ft 8 ft 2 ft 5 ft 2 ft 5 ft

QuickSilver Med 8 ft 8 ft 2 ft 4 ft 2 ft 4 ft

Low 8 ft 8 ft 2 ft 3 ft 2 ft 3 ft

Hi 7 ft 7 ft 2 ft 5 ft 2 ft 5 ft

Inca Med 7 ft 7 ft 2 ft 4 ft 2 ft 4 ft

Low 7 ft 7 ft 2 ft 3 ft 2 ft 3 ft

Hi 7 ft 7 ft 13 ft 13 ft 13 ft 13 ft

CP IV Med 7 ft 7 ft 7 ft 7 ft 7 ft 7 ft

Low 7 ft 7 ft 4 ft 4 ft 4 ft 4 ft

CPV Hi 8 ft 8 ft 0 ft 0 ft 5 ft 5 ft

High Power Med 8 ft 8 ft 0 ft 0 ft 5 ft 5 ft

Low 8 ft 8 ft 0 ft 0 ft 5 ft 5 ft

Hi 18 ft 18 ft 1 ft 1 ft 6 ft 6 ft

CP VI Med 18 ft 18 ft 1 ft 1 ft 6 ft 6 ft

Low 18 ft 18 ft 1 ft 1 ft 6 ft 6 ft

C/PT IX in Hi 15 ft 15 ft 18 ft 18 ft 18 ft 18 ft

IV Mode Med 15 ft 15 ft 15 ft 15 ft 15 ft 15 ft

Low 15 ft 15 ft 14 ft 14 ft 14 ft 14 ft

C/PT IX in Hi 18 ft 18 ft 0 ft 0 ft 5 ft 5 ft

V Mode Med 15 ft 15 ft 0 ft 0 ft 3 ft 3 ft

Low 14 ft 14 ft 0 ft 0 ft 3 ft 3 ft

C/PT IX in Hi 18 ft 18 ft 5 ft 5 ft 5 ft 5 ft

VI Mode Med 15 ft 15 ft 3 ft 3 ft 3 ft 3 ft

Low 14 ft 14 ft 3 ft 3 ft 3 ft 3 ft

March 9, 2000

FCC ID: D04CP1900

C/PT IX Slaving Decision Chart

C/PT IX Operating Mode

IV V VI

Slaved Non-Slaved Slaved Non-Slaved Slaved Non-Slaved

Table 8.2 C/PT IX Slaving decision Chart

_____________________________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

DWG. 476736

PAGE 23

Page 24

Rev. 00

TECHNICAL DOCUMENTATION

INSTALLATION & TUNE-UP PROCEDURE

COUNTERPOINT IX

8.3 DIP Switch Settings

SW1,2 ON Position OFF Position

1,2 220 pF enabled 220 pF disabled Note: Use SW1 and SW2 to tune the antennas. Refer to Table 5.1

3,4 150 pF enabled 150 pF disabled and Appendix A for the details

5 91 pF enabled 91 pF disabled

6 47 pF enabled 47 pF disabled

SW3 ON Position OFF Position

1 ADJ. VPA (50–90V) 44V VPA Use R57 to adjust VPA

2 Interlock enabled Interlock disabled

3 HI (Intlk. Time) LO (Intlk. Time) LO (0.2 – 10 sec), HI (1- 10 min)

4 Wire slave ON Wire slave OFF If no slave source is used 4,5, and 6 should kept OFF.

5 Wireless slave ON Wireless slave OFF

6 Fiber slave ON Fiber slave OFF

SW4 123456

March 9, 2000

FCC ID: D04CP1900

Description

Description

Description

10Hz/ 16 pulse OFF OFF --- --- --- --- 10Hz is the average frequency when not slaved

164Hz/ single pulse ON OFF --- --- --- --- 164Hz is the average frequency when not slaved

Pulse Listen N/A ON --- --- --- --4 Mode --- --- ON OFF --- --5 Mode --- --- OFF OFF --- --6 Mode --- --- N/A ON --- --Fast Detection --- --- --- --- OFF OFF 2 tags in sequence

Medium Detection --- --- --- --- ON OFF 4 tags in sequence

Slow Detection --- --- --- --- N/A ON 16 tags in sequence

SW5 1 2 3 4

Disable Dual Band OFF --- --- --- This feature is used to enable a second frequency band. Dual Band

Enable Dual Band ON --- --- --- can’t be used in the US. The software disables Dual band in 5Mode.

7.6 - 8.7 MHz --- OFF OFF OFF This is the default setting for the US.

7.4 - 9.0 MHz --- ON OFF OFF

7.4 - 8.8 MHz --- OFF ON OFF This is the default setting for the Europe.

7.8 - 9.4 MHz --- ON ON OFF

7.8 - 9.8 MHz --- OFF OFF ON

7.5 - 8.6 MHz --- ON OFF ON

7.7 - 8.8 MHz --- OFF ON ON

8.5 - 9.8 MHz --- ON ON ON

Table 8.3 DIP Switch Settings

_____________________________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

DWG. 476736

PAGE 24

Page 25

Rev. 00

TECHNICAL DOCUMENTATION

INSTALLATION & TUNE-UP PROCEDURE

COUNTERPOINT IX

8.4

INTERLOCK Time Adjustment Chart

The chart below specifies the voltage on the INTLK TP (Figure 8.1) to set the INTERLOCK

time using INTERLOCK Adjustment potentiometer .

INTLK TP

(Vdc +/-0.2Vdc)

0.25 0.2 sec 1 min

0.75 1 sec 2 min

1.25 2 sec 3 min

1.75 3 sec 4 min

2.25 4 sec 5 min

2.75 5.5 sec 6 min

3.25 7 sec 7 min

3.75 8 sec 8 min

4.25 9 sec 9 min

4.75 10 sec 10 min

INTLK TIME LO

SW3-3 OFF

March 9, 2000

FCC ID: D04CP1900

INTLK TIME HI

SW3-3 ON

Table 8.4 INTERLOCK Time Adjustment Chart

_____________________________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

DWG. 476736

PAGE 25

Page 26

Rev. 00

TECHNICAL DOCUMENTATION

INSTALLATION & TUNE-UP PROCEDURE

COUNTERPOINT IX

8.5 Performance Matrix

SCANNER ANTENNA

MGR. NU MBER DETECTION DEACTIVATION

NCR

7820 231088 3" - 4" 7-1/2" - 9"

7824 231088 3" - 4" 7-1/2" - 9"

7870 EAS ready 8-1/2" - 10" 13" - 15"

7875 EAS ready 6" - 8" 11" - 13"

Symbol

LS5000-V 994026 6" - 8" 16" - 19"

LS5700 EAS ready 6" - 7" 13" - 15"

LS9100 076635 3" - 4" 4" - 5"

Spectra-Physics

MAGELLAN 098409 4-1/2" - 6" 10" - 12"

MAGELLAN SL EAS ready 4" - 6" 6" - 8"

VS1000 EAS ready 4-1/2" - 5-1/2" 8" - 10"

VS1000-Shroud 881777 6" - 8" 14" - 18"

HS1250 EAS ready 3-1/2" - 4" 6" - 8"

750F 231088 3-1/2" - 4-1/2" 8" - 9-1/2"

760SLS-M 881367 8" - 9" 15" - 18"

960LS 984483 4" - 5" 9" - 11-1/2"

ICL

ORION 431727 9" - 10-1/2" 14" - 17"

MISC.

CP WAND 076658 4-1/2" - 5-1/2" 5-1/2" - 6-1/2"

12 X 12 PAD 251281 8-1/2" - 9-1/2" 25" - 27"

LOW PROFILE 256279 7" - 8" 20" - 22"

March 9, 2000

FCC ID: D04CP1900

C/PT IX - 4 Mode C/PT IX - 5/6 Mode

V ---- Vertical H ---- Horizontal P ---- Plastic M ---- Metal W ---- Weigh Scale

Table 8.5 Performance Matrix

_____________________________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

DWG. 476736

PAGE 26

Page 27

Rev. 00

TECHNICAL DOCUMENTATION

INSTALLATION & TUNE-UP PROCEDURE

COUNTERPOINT IX

Appendix A Fine Tuning

DIP switch settings in Table 5.1 and Performance Matrix in Table 8.4 are based on the tests

performed in the lab under following conditions:

1. Use of 6 feet, #18 cables for the scanners

2. Use of 8 feet, #18 cables for the pads

3 Free of any interfering RF systems in an open environment

4. Use of standard 410 test tag in V mode testing

5. Use of standard 410 tags in IV mode testing

In actual installation, these settings may be changed for proper performance of the C/PT IX due to

environmental variations. If you are not able to tune the C/PT IX following the normal tuning

procedure detailed in previous chapters, refer to this chapter for fine tunings.

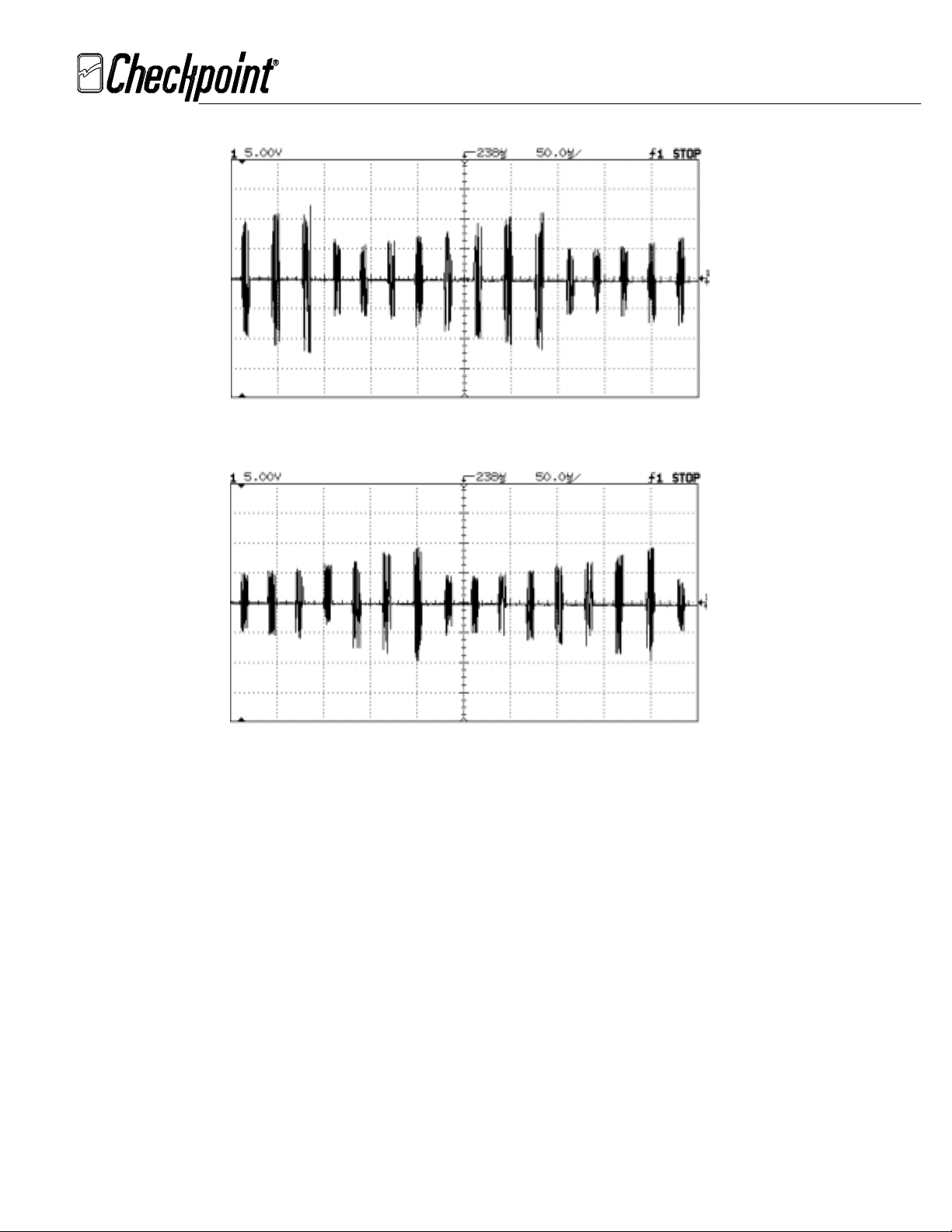

A.1 Detailed Tuning in IV Mode

To fine tune the C/PT IX in IV mode, change switches SW1 and SW2 so that the average

amplitude of the AC signal at ANT (TP2) is both maximized and as flat as possible. Start

with SW1 and SW2 all off and turn on the DIP switches two at a time beginning at position

(1). The following is an example of tuning 12 x 12 pad.

March 9, 2000

FCC ID: D04CP1900

Scope Settings:

Ch1: Voltage: 5.00v/div Triggered on Ch1

Time: 50us/div

Test point: TP1

Maximized Intensity

A1.1 AC Signal at ANT (TP2) with SW1, 2 ( 1 ) On

_____________________________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

DWG. 476736

PAGE 27

Page 28

Rev. 00

TECHNICAL DOCUMENTATION

INSTALLATION & TUNE-UP PROCEDURE

COUNTERPOINT IX

March 9, 2000

FCC ID: D04CP1900

A1.2 AC Signal at ANT (TP2) with SW1, 2 ( 5,6 ) On

A1.3 AC Signal at ANT (TP2) with SW1, 2 ( 3,4,5,6 ) On

From A1.1 to A1.3 it's clear that SW1 and SW2 position (1) should be set to on (A1.1) for

12x12 pad because the average amplitude of the AC signal at ANT (TP2) is highest

and more flat compared to the others.

_____________________________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

DWG. 476736

PAGE 28

Page 29

Rev. 00

TECHNICAL DOCUMENTATION

INSTALLATION & TUNE-UP PROCEDURE

COUNTERPOINT IX

If the C/PT IX phantoms, check the sensitivity as follows:

Scope Settings:

Ch1: Voltage: 100mv/div Triggered on Ch1

Time: 200us/div

Test point: LISTEN (TP4)

Maximized Intensity

Ensure the peak amplitude of the AC signal without the tag at LISTEN (TP4) is below 0.5Vp-p as

shown in A1.4.

March 9, 2000

FCC ID: D04CP1900

A1.4 AC Signal at LISTEN (TP4)

Readjust SW1 and SW2 if the signal at LISTEN (TP4) is over 0.5Vp-p.

A.2 Detailed Tuning in V Mode

Follow step A.1 to fine tune SW1 and SW2 without checking sensitivity.

A.3 Detailed Tuning in VI Mode

Follow step A.1 to fine tune the C/PT IX in VI mode for deactivation. If phantoms occur, reduce

the sensitivity by adjusting GAIN (R4) counterclockwise all the way.

_____________________________________________________________________________________________________________________________________________

CHECKPOINT SYSTEMS, INC. CONFIDENTIAL AND PROPRIETARY INFORMATION, FOR INTERNAL USE ONLY.

DWG. 476736

PAGE 29

Loading...

Loading...