Series GX15 Pneumatic Chemical Injection Pump

Operating Manual

CP-MAN-PRD-GX15 REV06 EFF. DATE 07/23/2019 Page 1 of 12

Louisiana, US

Aberdeen, UK

Dubai, UAE

Ras Al Khaimah, UAE

21356 Marion Lane

Unit C2 Lombard Centre

Jebel Ali Free Zone | JAFZA 1 AB810

RAK Technology Park, Shed 2, Warehouses 7 & 8

Mandeville, LA 70471

Kirkhill Place, Kirkhill Industrial Estates

PO Box 262131

Al Hamra Industrial Zone

+1 (504) 340-0770

Dyce, Aberdeen, AB21 0GU Scotland

Dubai, United Arab Emirates

PO Box 54796

+44 (0) 1224 775205

+971 (04) 880-6278

Ras Al Khaimah, United Arab Emirates

+971 (07) 223-9961

Series GX15

Pneumatic Chemical Injection Pump

Operating Manual

Series GX15 Pneumatic Chemical Injection Pump

Operating Manual

CP-MAN-PRD-GX15 REV06 EFF. DATE 07/23/2019 Page 2 of 12

TABLE OF CONTENTS

1. PUMP INSTALLATION 3

1.1 Process Design & Setup ........................................................................................................................ 3

1.2 Connecting the Chemical Supply ......................................................................................................... 5

1.3 Connecting the Supply Gas ................................................................................................................... 6

2. PUMP OPERATION 7

2.1 Bleeding/Priming the Injector Head .................................................................................................... 7

2.2 Setting the Pump Stroke Rate .............................................................................................................. 8

3. AIR/GAS CONSUMPTION 9

4. PUMP MAINTENANCE 10

4.1 Plunger Seal Replacement .................................................................................................................. 10

4.2 Lubrication ........................................................................................................................................... 10

5. TROUBLESHOOTING 10

5.1 Pump runs, but chemical does not discharge at the correct rate ................................................... 11

5.2 Pump does not stroke ......................................................................................................................... 11

5.3 Pump strokes erratically...................................................................................................................... 12

5.4 Chemical leakage ................................................................................................................................. 12

5.5 Other problems .................................................................................................................................... 12

Series GX15 Pneumatic Chemical Injection Pump

Operating Manual

CP-MAN-PRD-GX15 REV05 EFF. DATE 1/15/17 Page 3 of 12

Congratulations! You have chosen the finest, most versatile chemical injection pump made; designed to exacting

specifications for long life, reliable performance, and low maintenance. To ensure proper operation and to maximize

the Series GX15 durability, please read and follow this manual. Failure to correctly install and maintain the pump is

the primary cause of premature pump failure and voids the product warranty.

NOTE: This IOM applies to the CheckPoint GX15 Chemical Injector Pumps, part number for 1/8” plunger -

GX15G11C3XXXXX & 1/4” plunger - GX15G12C3XXXXX.

NOTE: Important illustrations, graphs, and charts are located throughout this manual.

PUMP INSTALLATION

1.1 Process Design & Setup

1.1.1 Before installation, please inspect the pump carefully. If the pump appears to have sustained damage in

transit, call your CheckPoint Authorized Distributor or CheckPoint Customer Service directly at (800) 847-7867 or

(504) 340-0770 to confirm and report damage. If it is determined that damage occurred in transit, a carrier claim

would be required.

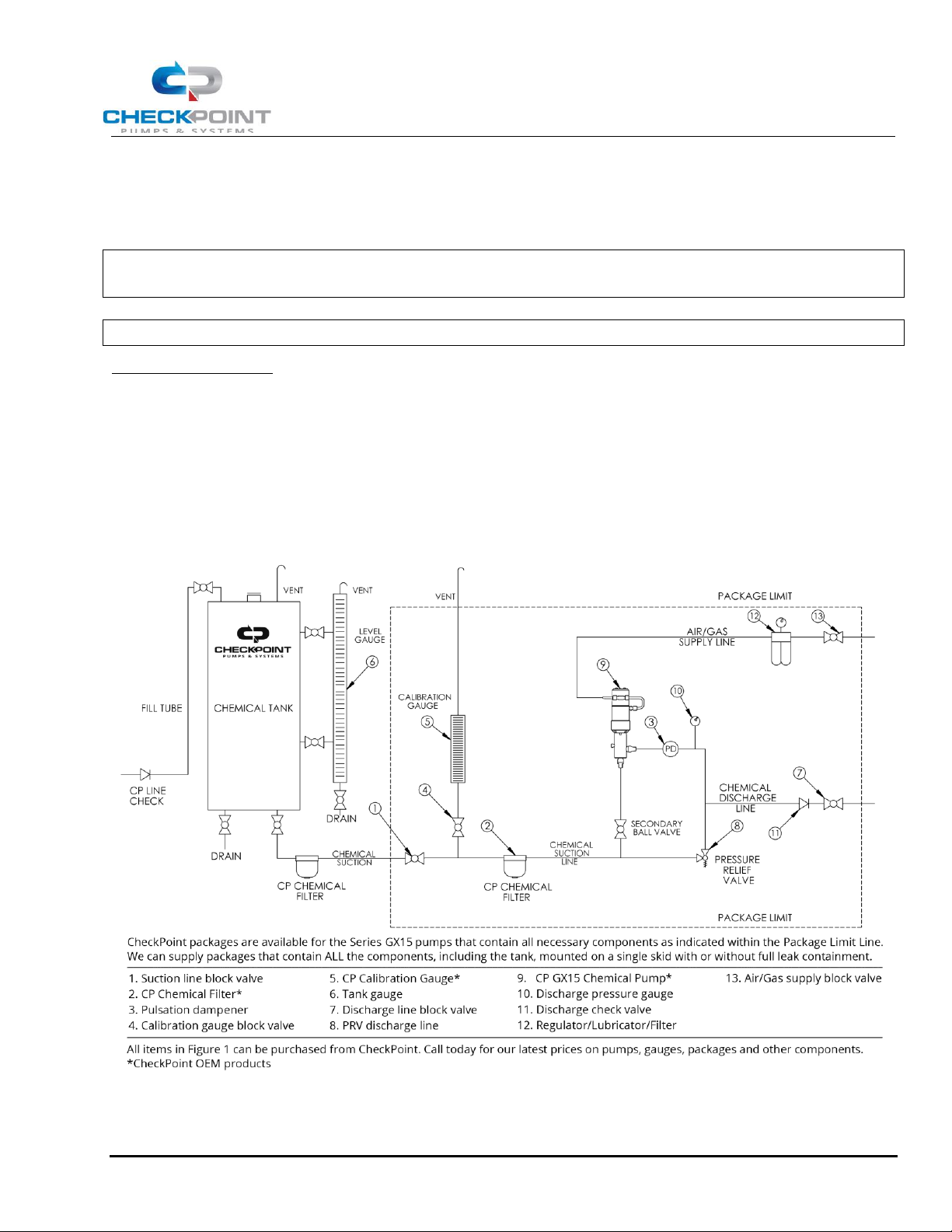

FIGURE 1: TYPICAL INSTALLATION SCHEMATIC

1.1.2 Referring to Figure 1, ensure that all necessary components are present in your injection system and are in

good working order. All the components shown above are recommended by CheckPoint to maximize pump life and

productivity. In the event that you have questions regarding best practices, or need to purchase additional

Series GX15 Pneumatic Chemical Injection Pump

Operating Manual

CP-MAN-PRD-GX15 REV06 EFF. DATE 07/23/2019 Page 4 of 12

components, please contact CheckPoint for assistance. Representatives are on staff & available to answer your

process questions. Checkpoint Engineers are also available to assist in system design. The CP Engineered Solutions

Department can be utilized for custom design and build options.

NOTE: In Figure 1, the secondary chemical filter is optional under certain conditions but highly recommended.

1.1.3 CheckPoint recommends vertical mounting for its pumps where possible. This allows gravity to assist the

suction check valve during closing. You may mount the pump in other orientations, subject to the condition the

chemical head is no higher than level with the motor. If mounting other than vertical, you must order your pump

with a spring-loaded suction check, or order and install the appropriate suction check spring prior to installation.

CheckPoint recommends using a mounting bracket designed specifically for the Series GX15 pump when attaching

to any surface.

CAUTION: Under no conditions should the pump be oriented with the suction check valve above the

centerline of the motor. Doing so may cause chemical leakage to collect in the motor, breach

the motor seals, and be atomized into the environment.

1.1.4 CheckPoint recommends use of a calibration gauge for assurance of proper pump function and chemical

delivery rate. Please read section 2.2 Setting Pump Stroke Rate on page 8 for more information. The proper position

of the calibration gauge (labeled #5) is shown in Figure 1.

NOTE: It is necessary to attach a vent tube to the top of all calibration gauges, chemical tanks, and tank level

gauges. The height of the top of each vent tube should always be greater than the highest possible

liquid level in the system. Proper vent tubes should have a means to prevent water entry, such as a 180

degree bend.

1.1.5 ALL COMPONENTS AND PIPEWORK BETWEEN THE CHEMICAL TANK AND THE SUCTION CHECK VALVE OF

THE PUMP MUST BE 100% BUBBLE-TIGHT AND FULLY COMPATIBLE WITH THE CHEMICAL AND WITH EACH OTHER.

FAILURE TO ADHERE STRICTLY TO THIS DIRECTIVE WILL LEAD TO LOSS OF PRIME AND DAMAGE TO THE PLUNGER

AND PLUNGER SEAL.

1.1.5.1 All fittings and screw-on joints without Teflon™ tape or other equivalent sealant may allow air at atmospheric pressure to enter the suction tubing, even when no chemical leakage is visible.

1.1.5.2 Dissimilar metals in the suction side of the injection system may react with each other, creating gas

bubbles that will be carried into the pump head. All suction components; tubing, pipe, fittings, and valves must be

composed of similar or compatible materials. Please note that CheckPoint offers wetted parts comprised of 316

SS, Hastelloy C, PVC, Titanium and Alloy 20.

1.1.6 The pump may be mounted to a skid or other surface in a number of ways; however, clamping around the

outside of the pump can permanently affect the cylindricity of the injection head or motor thereby voiding the

product warranty. Proper mounting techniques increase accessibility during maintenance and troubleshooting.

1.1.7 Always check to ensure that all process block valves (labeled Nos. 1, 7 & 13 in Figure 1) are closed prior to

disconnecting or re-installing any chemical injection pump. There should always be a block valve placed between

the pump and the process flow, the gas supply, and the chemical supply. Conversely, while the pump is running, all

such block valves should always be open.

1.1.8 The pump suction line should be sized appropriately to the flow rate to avoid cavitatation. A general rule of

thumb is to size the suction line such that instantaneous flow velocity through the line does not exceed 2 feet per

second at any point. Additional allowances may be needed for multiple pump installations, extremely viscous

chemicals and for chemicals with high vapor pressures; contact CheckPoint or your Authorized CheckPoint

Distributor for design assistance.

Series GX15 Pneumatic Chemical Injection Pump

Operating Manual

CP-MAN-PRD-GX15 REV06 EFF. DATE 07/23/2019 Page 5 of 12

1.1.9 TO AVOID OVER-PRESSURING CHEMICAL DISCHARGE LINES, CHECKPOINT REQUIRES PLACING A PROPERLY

TESTED AND CALIBRATED PRESSURE RELIEF VALVE BETWEEN THE DISCHARGE PORT OF THE PUMP AND THE

PROCESS FLOW. THE PRESSURE RELIEF VALVE DISCHARGE CAN BE RUN TO A TEE UPSTREAM OF THE PUMP’S

CHEMICAL SUCTION CHECK VALVE OR RE-ROUTED TO TANK. FAILING TO USE A PRV IS EXTREMELY DANGEROUS.

EXCESSIVE PRESSURE MAY LEAD TO CATASTROPHIC FAILURE OF PROCESS EQUIPMENT OR BODILY HARM.

CHECKPOINT IS NOT RESPONSIBLE FOR ANY DAMAGE CAUSED BY OVER-PRESSURIZED CHEMICAL. CheckPoint

offers a range of pressure relief valves suitable for use with the GX15 pump..

1.1.10 Depending on a variety of factors, pulsation dampers or suction accumulators may be required in your

installation. Due to low flows associated with the GX15 pump pulsation dampers are normally not required. Consult

with CheckPoint if you have any concerns about pulsation or NPSHa

CAUTION: When using a pressure relief valve, the chemical tank MUST BE properly vented to atmosphere.

Venting helps avoid the possibility of tank over-pressurization if the pressure relief valve

actuates.

1.2 Connecting the Chemical Supply

1.2.1 Clean suction lines and check chemical containers to ensure they are free of foreign matter, sand, sludge, or chemical buildup.

NOTE: Even new chemical tanks can contain debris which may cause system damage. Removing foreign

debris from suction lines and chemical containers will substantially extend the life of the plunger seal

and other pump components.

NOTE: CheckPoint recommends using filtration to ensure a maximum particulate size of 140 microns. Multiple

stages of filtration should be considered, depending upon the initial cleanliness level of the fluid media

being pumped, to prevent cavitation and an increase in maintenance.

NOTE: If premature scoring of the pump plunger or early packing failure is observed during operation, a likely

cause is abrasive particles carried into the pump through the suction plumbing. Use of a pre-suction

in-line chemical filter such as the CheckPoint Series FSTS and/or a ceramic or HastelloyTM plunger is

recommended if symptoms continue. Call CheckPoint for appropriate filter element sizing criteria.

CAUTION: Substantial scoring of the plunger can lead to severe leakage of chemical into the surrounding

environment.

1.2.2 Connect the chemical suction line to the suction check valve on the pump head. The suction check valve is a 1/4” NPT male thread. Do not over-tighten NPT connections.

NOTE: To prevent leakage apply Teflon™ tape, or equivalent thread sealant to the check valve threads prior to

attachment.

NOTE: To operate properly, the check valves MUST remain directly attached to the chemical head. Never re-

locate the suction check valve away from the chemical head .

1.2.3 Connect the discharge line to the discharge check valve (1/4” NPT male thread).

Series GX15 Pneumatic Chemical Injection Pump

Operating Manual

CP-MAN-PRD-GX15 REV06 EFF. DATE 07/23/2019 Page 6 of 12

1.2.4 Open the process block valve (shown as number 7 in Fig 1), allowing the process pressure to reach the chemical head or in-line check valve. Observe & correct any leakage.

CAUTION: The Series GX15 chemical head is rated for a maximum working pressure of 6,500 PSIG (448

BARG). Checkpoint recommends always installing a pressure relief valve between the discharge

check and the process flow to prevent catastrophic failure of process equipment or bodily

harm. Checkpoint is not responsible for any damage caused by over-pressurization.

NOTE: Always open the process block valve prior to operating the pump. Operating the pump with a closed

process block valve may generate enough pressure to rupture the discharge line, damage process

equipment and the chemical head. Improper procedures may reduce the life of your CheckPoint pump.

1.3 Connecting the Supply Gas

1.3.1 Gas supply to the pump should be clean compressed air or natural gas at 20 PSIG (1.38 BARG) minimum, 150

PSIG (10.34 BARG) maximum. Supply gas should be free of abrasive dust, sand or other grit that could abrade the

motor seals. Checkpoint recommends installation of a pressure regulator in the supply line to ensure a constant

supply pressure and within limits.

NOTE: It is not necessary to remove most liquids from the supply gas such as distillate carryovers. The pump

will not stall no matter how much liquid reaches the air/gas inlet. However, certain chemicals, including

but not limited to methanol and corrosion inhibitor may attack the seals in the pumps motor end and

should be removed prior to reaching the pump air/gas inlet. Alternatively, if damaging chemicals or

other unusual liquids will be present in the supply gas, CheckPoint may be able to supply other motor

seal materials.

NOTE: Always use a gas pressure regulator if the possibility of supply pressure in excess of 150 PSIG (10.3

BARG) exists. Allowing gas pressures above 150 PSIG to enter the air/gas inlet may result in damage to

the motor seals and will produce excessive discharge pressures capable of rupturing chemical

discharge tubing.

1.3.2 Liquids may be used as a driver fluid but pump speed will vary widely with the liquid viscosity. Call CheckPoint for performance data for the liquid you intend to use.

1.3.3 Ensure the supply gas line is clean and free of all foreign matter and debris.

NOTE: Take care to prevent debris in the supply gas line from entering the housing where it could accelerate

seal wear and damage the main switching valve components.

NOTE: In situations where sand, dirt, and other particulate matter may be carried in with the supply gas, a

chemical filter or a gas scrubber is recommended.

1.3.4 Connect the supply gas line to the 1/4" NPT female connection on the housing. To ensure positive injection,

the supply gas pressure should be a minimum of 20 PSIG (1.38 BARG) and a maximum of 150 PSIG (10.34 BARG),

set according to the following formula:

MINIMUM REQUIRED GAS INLET PRESSURE =

[DISCHARGE PRESSURE]

X 1.3

[AMPLIFICATION RATIO]

Series GX15 Pneumatic Chemical Injection Pump

Operating Manual

CP-MAN-PRD-GX15 REV06 EFF. DATE 07/23/2019 Page 7 of 12

1.3.5 Faster pump speeds can be obtained by increasing the above minimum required gas inlet pressure.

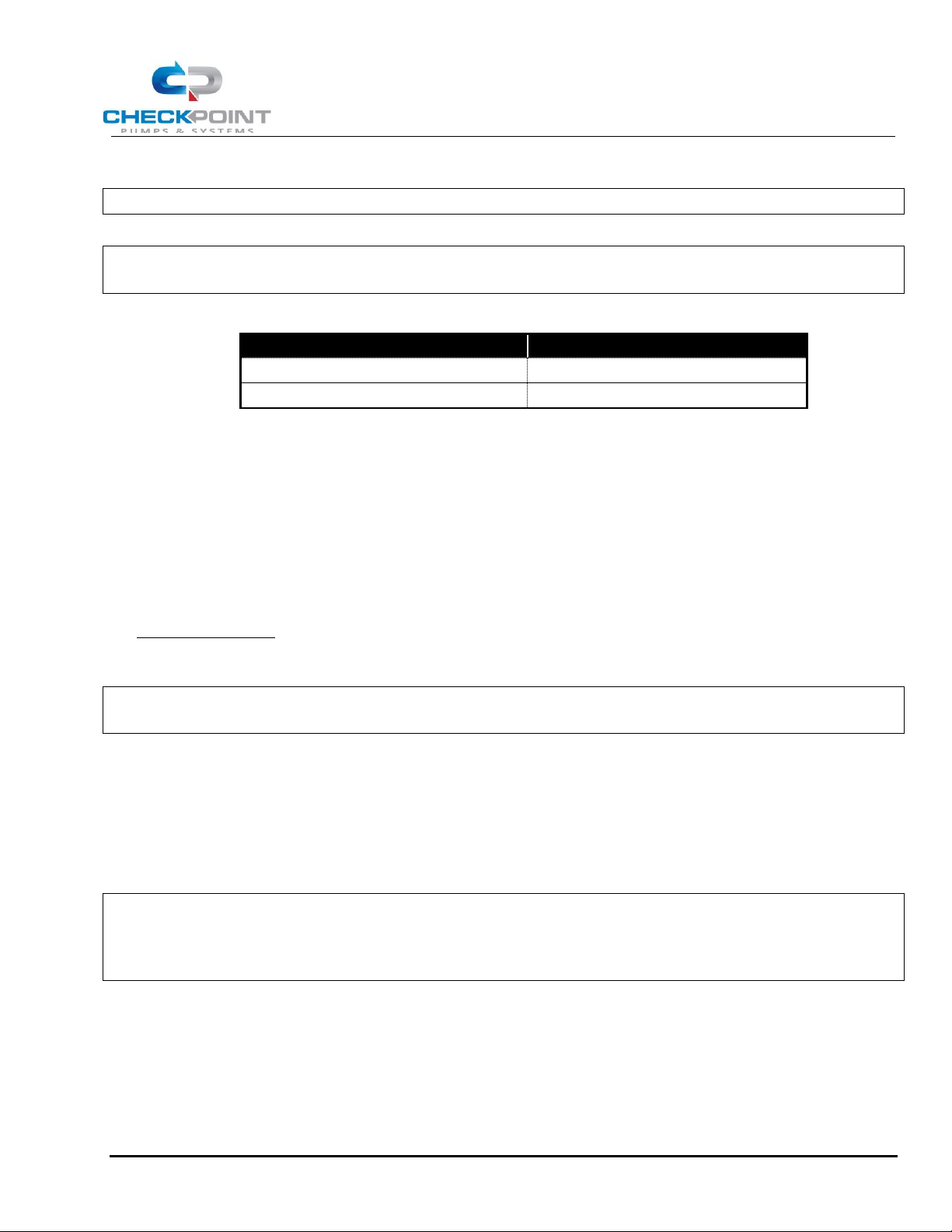

NOTE: To find the Amplification Ratio for your pump, please see Figure 2 below.

NOTE: If the formula in Section 1.3.5 yields a result less than 20 PSIG (1.38 BARG), use a minimum supply

pressure of 20 PSIG (1.38 BARG).

FIGURE 2: AMPLIFICATION RATIO TABLE, Series GX15

PLUNGER DIAMETER (IN)

AMPLIFICATION RATIO

1/8

144

1/4

36

1.3.6 Series GX15 pumps are Gas Recovery (GR) Models. Connect the gas recovery line from the process to the

open ¼” tubing connector on the lower branch tee of the motor. The pressure in the recovery line (“recovery

pressure”) must be lower than the supply pressure. To calculate the maximum recovery pressure given your supply

pressure in PSIG, use the following formula:

RECOVERY PRESSURE = SUPPLY PRESSURE - 30 PSIG

1.3.7 The maximum recovery pressure based on a maximum supply pressure of 150 PSIG is 120 PSIG.

2. PUMP OPERATION

2.1 Bleeding/Priming the Injector Head

NOTE: Prior to initial pump operation ensure the suction check valve is connected to adequate chemical

supply per Section 1.2.

2.1.1 Open the chemical supply block valve

2.1.2 Open the process block valve.

2.1.3 Open the air supply block valve.

CAUTION: OTHER THAN DURING BRIEF TESTING, NEVER OPERATE THE PUMP WITHOUT CHEMICAL

SUPPLY FLOWING FREELY. DOING SO WILL CREATE UNDUE FRICTION AND HEAT, DECREASE

THE LIFE OF THE PLUNGER SEAL, HASTEN CHEMICAL LEAKAGE AND VOID THE PUMP

WARRANTY.

2.1.4 Open the speed control valve by turning the knob counterclockwise. The pump will pick up speed as the

speed control valve is opened. Continue to turn the knob until the pump is cycling a minimum of 60 strokes/minute.

This may take several turns of the speed control valve.

2.1.5 Open the bleed screw 1/2 to 2 1/2 turns. The pump will begin to pull air and chemical through the chemical

supply plumbing, into the head, and out the port in the bleed valve. Leave the valve open until a solid stream of

chemical pumps out of the bleed port each stroke.

Series GX15 Pneumatic Chemical Injection Pump

Operating Manual

CP-MAN-PRD-GX15 REV06 EFF. DATE 07/23/2019 Page 8 of 12

NOTE: If the pump is not new, it’s possible for dried or solidified chemical to be present in the bleed

assembly. If your pump does not bleed when following the directions above, try cleaning these items

in solvent and replace.

2.1.6 Close the bleed screw until chemical flow through the bleed port stops. Torque the bleed screw to 10 in lb. Reduce the stroke rate via the speed control to your desired rate.

NOTE: DO NOT OVER-TIGHTEN THE BLEED SCREW. Tighten the bleed screw ONLY to 10 in lb max. Applying

excess torque to the bleed valve may impair future valve operation.

2.2 Setting the Pump Stroke Rate

The following directions are for setting the pump speed using a calibration gauge. There are a variety of calibration

gauges available, including a complete line of appropriately-sized CheckPoint gauges for every CheckPoint pump.

To ensure that your pump is working as it should and that chemical is being delivered at the rate you need, it is

important to use a calibration gauge.

2.2.1 Most calibration gauges are designed to read properly using a one-minute test. However, if the liquid level

drops too fast to allow a full minute test, shorter periods are acceptable. Size the gauge so that at least a 15 second

test can be achieved. Tests shorter than 15 seconds will result in a loss of accuracy.

2.2.2 Proper gauge placement and plumbing is important. Please refer to Figure 1 (#5 calibration gauge) for appropriate valving, placement, and reference numbers as used in this section.

2.2.3 With the pump either running or stopped, open the Gauge Fill Valve (shown as #4 in Figure 1). The gauge

should begin to fill. Continue filling until the chemical level is at or near the top markings on the gauge, then close

the Gauge Fill Valve.

2.2.4 With the CheckPoint pump running take note of the level of chemical in the gauge using the appropriate

scale for the volume units to be measured. Usually the gauge will show liters on one scale and quarts or gallons on

the other. It is best to write down the number so that you can calculate flow accurately.

2.2.5 Open the Gauge Fill Valve (#4), and simultaneously close the Chemical Supply Valve (#1, Figure 1). The pump now draws chemical directly from the calibration gauge.

2.2.6 The level in the gauge should begin to fall. (If it does not, or if the level seems to go down and then back up

with each stroke, refer to troubleshooting in Section 4.2.1 on page 11). Stop timing when the liquid level in the gauge

approaches the bottom of the gauge, or when one minute has expired, whichever comes first. Note the ending level

on the gauge, and reopen the Chemical Supply Valve while closing the Gauge Fill Valve.

2.2.7 Write down the amount of time in seconds and the final gauge reading.

NOTE: Failure to reopen the Chemical Supply Valve will result in the pump quickly depleting the remaining

chemical in the gauge and running on air, necessitating pump re-priming.

NOTE: In cases where the chemical flow rate is extremely low, you may need to time for longer than one

minute to allow an adequate amount of chemical to move out of the gauge.

2.2.8 The pumping volume (in the units specified on the gauge scale) will be given by the following equation:

PUMPING VOLUME =

[END READING] – [BEGINNING READING]

X 60

[DURATION OF READING IN SECONDS]

Series GX15 Pneumatic Chemical Injection Pump

Operating Manual

CP-MAN-PRD-GX15 REV06 EFF. DATE 07/23/2019 Page 9 of 12

NOTE: To ensure accurate stroke rate measurement, allow sufficient measurement duration. Where possible,

allow at least 15 seconds of gauge drawdown.

NOTE: At extremely slow stroke rates, a small turn of the speed control valve will alter the stroke rate. Initial

adjustments to the pump stroke rate should use only a few degrees of rotation with the speed control

knob.

3. AIR/GAS CONSUMPTION

If emissions are a concern, refer to Section 1.3.6 for details on how to use the gas recovery feature of your

CheckPoint pump.

Use the following equation along with the appropriate gas consumption factor from Figure 3 to calculate air/gas

consumption.

Gas Consumption [SCFM] @ 68F = Chemical Flow Rate [GPH] * Gas Supply Pressure [PSIA] * English Gas

Consumption Factor

Gas Consumption [Nm3/Hr] @ 0C = Chemical Flow Rate [LPH] * Gas Supply Pressure [BARA] * SI Gas

Consumption Factor

NOTE: Gas supply pressure value must be absolute pressure, not gauge pressure (Absolute pressure =

gauge pressure + atmospheric pressure). For reference, the Earth's atmospheric pressure at sea level

is approximately 1 atm or 14.696 psi or 1.0133 bar.

NOTE: This is a theoretical consumption rate that will vary depending on gas density and other actual field

conditions. Air/Gas consumption can be minimized by using the minimum supply pressure required

to achieve the target application. Please contact CheckPoint for assistance estimating optimal supply

pressure and associated consumption rate for a particular application.

FIGURE 3: GAS CONSUMPTION FACTORS

GAS CONSUMPTION FACTOR

PUMP

SERIES

PLUNGER

DIAMETER

[IN]

ENGLISH

SCFM

@ 68F

SI METRIC

NM3/HR

@ 0C

GX15

1/4

0.0115

1.0128

Series GX15 Pneumatic Chemical Injection Pump

Operating Manual

CP-MAN-PRD-GX15 REV06 EFF. DATE 07/23/2019 Page 10 of 12

4. PUMP MAINTENANCE

The CheckPoint Series GX15 is designed to provide trouble-free operation for many years with little adjustment,

lubrication, or other routine maintenance. However, like any other device, proper maintenance can extend the life

of the product. This can include periodic cleaning of the gas and chemical inlets, and lubrication.

Plunger Seal Replacement

Follow the steps below to change the seal.

NOTE: The Series GX15 pump uses a non adjustable plunger seal. Once installed it requires no maintenance.

4.1.1 Close the chemical, process and supply gas block valves.

4.1.2 Disconnect the chemical supply from the pump suction check valve, and disconnect the process line from the pump discharge check.

4.1.3 Remove the chemical head by removing the four screws through the head flange then separate the head from the main body.

4.1.4 Remove the seal from the head.

4.1.5 Examine the new seal for defects before installation. NOTE: The grease should be a premium quality multi-purpose, lithium-base NLGI No 2 grease

recommended for general industrial applications which meets or exceeds the requirements of DIN

51825: (2004-06) 2K-30. Avoid products containing Xylene.

4.1.6 Lightly coat the new seal elastomers’ outer diameter with grease. Install seal in head, elastomer end first.

4.1.7 Lightly grease the plunger prior to reinstalling the head.

4.1.8 Carefully insert the plunger into the seal as the head is reinstalled.

4.1.9 Install four head bolts and torque to 18 in lb.

4.2 Lubrication

The CheckPoint Series GX15 motor was designed to run under completely dry internal conditions. However, regular

lubrication will maximize the life of the pump. Lubrication minimizes motor seal friction and flushes out foreign

debris reducing internal wear and tear.

4.2.1 Periodic Lubrication To lubricate the pump periodically, block off and then disconnect the air/gas supply

line by unscrewing the fitting at the pump air/gas inlet. Introduce approximately 1cc of lubricant into the air/gas

inlet. Reconnect the air/gas supply line and reintroduce gas pressure. Lubricant will become evenly distributed

throughout the motor end of the pump within a few cycles.

4.2.2 Continuous Lubrication Lubricator bottles can be placed anywhere in the gas supply line prior to the pump’s

air/gas inlet. Set the lubricator rate as low as possible, one to two drops per minute, unless cold conditions dictate

more in order to prevent freezing of the gas supply. CheckPoint offers both a small and a large in -line lubricator;

call CheckPoint or your authorized CheckPoint distributor for details.

4.2.3 Recommended Lubrication Type A light hydraulic oil bearing the designation ISO 3448 viscosity no. 20-32

should be used. If atmospheric or other supply air/gas conditions present exhaust freezing issues, a similar type

lubricant with an antifreeze component such as glycol may be used.

Series GX15 Pneumatic Chemical Injection Pump

Operating Manual

CP-MAN-PRD-GX15 REV06 EFF. DATE 07/23/2019 Page 11 of 12

5. TROUBLESHOOTING

5.1 Pump runs, but chemical does not discharge at the correct rate

5.1.1 Suction check valve may be clogged with debris To flush suction check, allow pump to cycle at maximum

rate for at least 60 seconds. If no improvement is noted, remove the suction check valve from pump head. Blow the

check out with air or water pressure. If the first attempts are unsuccessful, a check rebuild could be necessary.

NOTE: CheckPoint FailSafe

TM

check valves do not need replacement when they do not check properly. A

simple rebuild kit is available to replace the O-rings, which corrects all but the most severe check

problems. Corrosion of the valve seat, retainer or poppet indicates an incorrect check valve material.

Please contact CheckPoint to request chemical compatibility information.

NOTE: Always replace Teflon

TM

tape or other appropriate thread sealant on check valve threads during

reinstallation to avoid chemical leakage or the introduction of air to the chemical head.

5.1.2 Pump may have lost prime/become “air locked” Check to ensure that there are no leaks in any process

lines, particularly upstream of the pump within the chemical suction lines. If air is introduced through the suction

side, the pump may lose prime. Read Section 2.1 and its subparagraphs carefully for details. A common source of

air in the supply is the block valve ahead of the suction check. Check this valve to make sure the stem packing is

tight and that the materials of construction are compatible with the chemical being pumped. Also, check that the

pump’s packing is not leaking. Finally, on pumps supplying chemical into gas lines, it is possible that the discharge

port may be leaking. A leaky discharge port may allow gas under pressure to “back into” the chemical head.

5.1.3 Check valves may have been re-located away from the chemical head of the pump The checks must stay directly attached to the head in order to facilitate chemical movement.

5.1.4 Chemical may be obstructed from entering the pump Plumbing upstream of the chemical head may have

blockage preventing chemical from getting to the suction check valve. A common example is an in-line chemical

filter becoming clogged with debris. Solution - clean out suction plumbing and clean or replace chemical filter.

5.1.5 Chemical supply line size or configuration may cause NPSHa to drop below NPSHr.

5.1.6 Calibration gauge may read incorrectly due to clogged air vent If the calibration gauge is not reading correctly, it may appear chemical is not getting into the process. Check for an obstruction in the gauge or in the air vent atop the gauge.

5.2 Pump does not stroke

5.2.1 Pump speed control valve may be closed Open the speed control valve (counterclockwise) until the pump

actuates. Then set desired stroke rate as described in Section 2.2.

5.2.2 Air/Gas supply pressure may be too low to overcome the chemical discharge pressure Open the chemical

head bleed port. If the pump starts stroking, ensure the air/gas supply pressure is sufficient to overcome the

chemical discharge pressure. Possible cause could be a faulty pressure gauge or regulator. See Section 1.3.4 on page

6 to determine minimum supply pressure.

5.2.3 Gas recovery pressure is too high relative to gas supply pressure The pump requires a minimum of 30

PSIG differential pressure. Refer to Section 1.3.6 on page 6 to determine the appropriate recovery pressure.

5.2.4 Pump switching valve may be clogged or "gummed-up" with paraffin or trash Disconnect air/gas supply,

then introduce any type of oil or solvent into the pump air/gas inlet. Re-connect air/gas supply and open speed

Series GX15 Pneumatic Chemical Injection Pump

Operating Manual

CP-MAN-PRD-GX15 REV06 EFF. DATE 07/23/2019 Page 12 of 12

control valve. Repeat two to three times if necessary. When pump runs normal, reset pump stroke rate per Section

2.2 on page 8.

5.2.5 Spool may be swollen Certain chemicals introduced into the motor through the air/gas inlet may be

absorbed by the standard spool material, causing it to swell. Remove the top cover to inspect if the spool moves

with light finger pressure. If the spool does not move call CheckPoint to order an exchange.

5.2.6 Seals may be worn in the motor If the pump has been in service for some time, the motor seals may have

worn to the point where the pump can no longer switch. If air leakage is constant during stall, worn or damaged

seals are indicated. Replace all motor seals.

5.3 Pump strokes erratically

5.3.1 Supply pressure may be fluctuating Check supply pressure with an accurate pressure gauge to ensure

constant supply pressure. If fluctuations are observed, replace gas pressure regulator, or, if none exist s, add a

pressure regulator ahead of the air/gas inlet.

5.3.2 Seals may be worn in the motor.

5.4 Chemical leakage

5.4.1 Chemical may be attacking plunger seal elastomer A plunger seal attacked by chemical will appear swollen or badly damaged. Contact CheckPoint or your authorized CheckPoint distributor.

5.4.2 Chemical may be attacking plunger material The plunger will be severely worn, pitted, or corroded when inspected.

5.4.2.1 Chemical may have abrasives suspended in it The plunger will appear scored and the seal will appear severely worn. CheckPoint offers high performance chemical filters appropriate for GX15 Series applications.

5.5 Other problems

If you are experiencing an operating problem not listed above, or if none of the above troubleshooting actions solve

your operating problem, please contact your Authorized CheckPoint Distributor or call CheckPoint directly at (800)

847-PUMP or (504) 340-0770. We will work to assist you determine appropriate next steps. Once CheckPoint has

had the opportunity to help you troubleshoot your problem, please keep in mind the following regarding repairs:

CheckPoint offers exchange programs to keep you in service We will ship you a rebuilt pump, which you will be

able to install prior to sending us your existing pump. Upon receipt of your pump, we will tear it down, rebuild, and

report our findings. We offer a fixed-price exchange plan, an actual-cost plan, and a consigned exchange. Please

contact CheckPoint to learn more about our unique exchange services.

Nothing beats factory-direct repairs Although the Series GX15 pump has been designed to be easy to operate

and repair, the best way to ensure continued reliable service is to have your pump repaired by the factory. OEM

repair services ensure CheckPoint quality and reliability.

Remember that after you repair your CheckPoint pump, it should perform like new If your pump is anything less than awesome, call us to determine what can be done to restore the pump to “like-new” performance.

Training sessions are available CheckPoint strives to maintain excellence in all that we do & we are happy to share. If you would like to train your employees on CheckPoint Pumps & Systems, please contact us to discuss training options.

Loading...

Loading...