Page 1

The WTT-110 Pull Tester has been calibrated in accordance with factory

proceedures and is certified to perform within the stated accuracy

specifications. Assuming the unit is handled with care and operated as

detailed in this manual it should remain accurate for an extended time

period. If however, it is subjected to forces that exceed its maximum range

or if it is not properly cared for, it might need to be recalibrated.

It is recommended that the calibration is verified at least on an annual

basis and more frequently if feasible. Normally, instruments of this type

go out of tolerance from one day to the next and rarely on a regular

periodic basis.

A calibration procedure is provided in this manual, however it should only

be performed by individuals properly trained for this type of service and

with the appropriate certified standards (known weights or secondary

force measuring system such as a load cell, etc.).

1. Remove the lever by unscrewing it in a counter-clockwise

direction and move the Wire Clamp assembly out from

the path of the hanging sample.

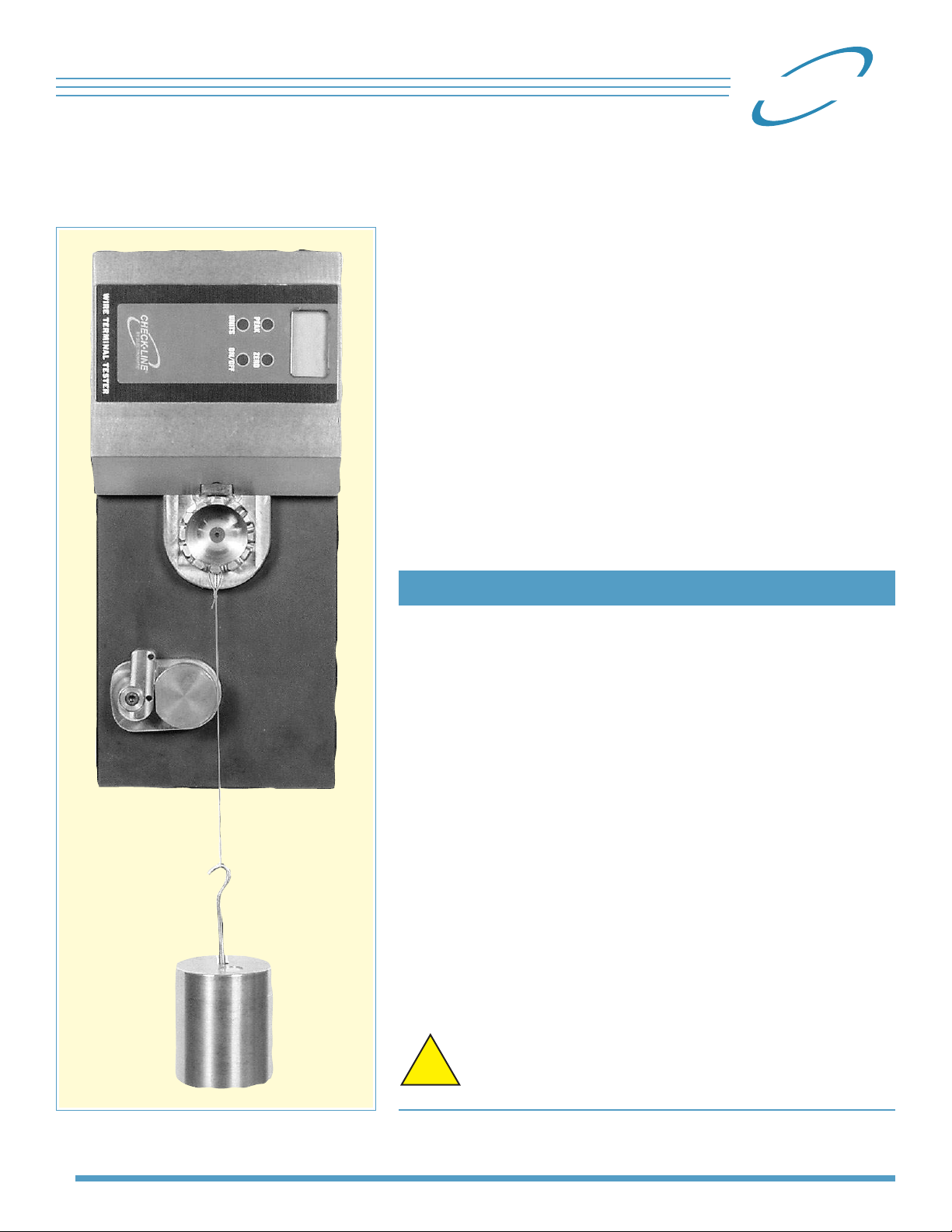

2. Position the WTT-110 in a vertical position so that the

keypad & display are at the top (refer to photo). Be sure

to secure it so it can not topple over when the weight is

attached.

3. Using a heavy-duty monofilament (fishing line), wire or

similar, suspend a 50 Kg weight from one of the teeth

on the wire terminal fixture by hooking a loop of the

material over the selected tooth.

4. Temporarily, remove the weight and follow the

Re-Calibration Procedures shown on side 2.

Re-Calibration Set-up

Make sure that the WTT-110 is well secured in the

vertical position. Select a material that is strong

enough to support 50 Kg of weight.

!

CHECK LINE

over

WTT-110 CALIBRATION INSTRUCTIONS

•

®

Page 2

Re-Calibration Procedure

01. Turn POWER off. Make sure the weight is NOT suspended from the sample.

02. Press and hold the UNIT, PEAK and ZERO keys simultaneously.

03. Press and release the On/Off key (while continuing to press UNIT, PEAK

and ZERO) until the smaller characters at the top of the display show CAL.

04. Release the UNITS, PEAK and ZERO keys.

o5. The force gauge is now in calibration mode.

o6. Press the UNITS switch. The display will show ZER after blinking SCN for 10 seconds.

07. The force gauge is now ready for zero point calibration.

08. Press ZERO key to confirm the zero calibration. Wait approximately 15–20 seconds.

The display will change to show PEK after blinking SCN. Do not press any other keys

or disturb the instrument or weight during calibration.

09. Hang the 50 Kg calibration weight from the sample which is hooked on to one of the teeth of the Wire Terminal Fixture. Make

sure that the material path is unobstructed and in a straight horizontal orientation. The force gauge is now ready for full-scale

calibration.

10. Press the PEAK key to begin full scale calibration. The display will blink SCN. Do not press any other keys or touch the weight

during calibration. After approximately 15– 20 seconds the display will blink END. Then after approximately 5 seconds the

display blinks OK.

11. If calibration was successful, the display will show OK momentarily (see above illustration). Press the UNITS key, then the

power will automatically switch off.

12. If calibration was unsuccessful, the display will show ERR. Remove the calibration weight, then press the UNIT key and repeat

the above procedure again.

CAL

–00–

“oK”

88888

“SCN”

–00–

ZER

88888

➔

“SCN”

88888

PEK

88888

➔

“SCN”

88888

“End”

88888

➔➔

CHECK•LINE is a registered trademark of ELECTROMATIC Equipment Company Inc.

CHECK•LINE®–PRECISION QUALITY CONTROL INSTRUMENTS

Electromatic Equipment Co., Inc.

600 Oakland Ave.

Cedarhurst, N Y 11516 —USA

Tel: (800) 645-4330 (USA & Canada)

Tel: (516) 295-4300

Fax: (516) 295-4399

Email: info@checkline.com

Website: www.checkline.com

FOR ADDITIONAL INFORMATION OR TO PLACE AN ORDER CALL TOLL FREE 1-800-645-4330

Loading...

Loading...