Page 1

Series TT05

DIGITAL TORQUE TESTERS

User’ s Guide

Page 2

Series TT05 Digital Torque Testers User’s Guide

Thank you…

Thank you for purchasing a Mark-10 Series TT05 digital

torque tester, designed to measure bottle cap application

and removal torque.

With proper usage, we are confident that you will get

many years of great service with this product. Mark-10

instruments are ruggedly built for both laboratory and

industrial environments.

This User’s Guide provides setup, safety, and operation

instructions. Dimensions and specifications are also

provided. For additional information or answers to your

questions, please do not hesitate to contact us. Our

technical support and engineering teams are eager to

assist you.

Before use, each person who is to use a Series TT05 digital torque tester should be fully trained in

appropriate operation and safety procedures.

TABLE OF CONTENTS

OVERVIEW .........................................................2

POWER ...............................................................3

SETUP ................................................................4

HOME SCREEN AND CONTROLS ...................4

OPERATING MODES .........................................6

CHANGING THE UNITS .....................................6

DIGITAL FILTERS ..............................................6

SET POINTS .......................................................7

DATA MEMORY AND STATISTICS ..................8

COMMUNICATIONS AND OUTPUTS .............10

BREAK DETECTION ........................................13

FIRST / SECOND PEAK ..................................14

CALIBRATION .................................................16

PASSWORDS ...................................................19

OTHER SETTINGS ...........................................21

SPECIFICATIONS ............................................23

1

Page 3

Series TT05 Digital Torque Testers User’s Guide

1 OVERVIEW

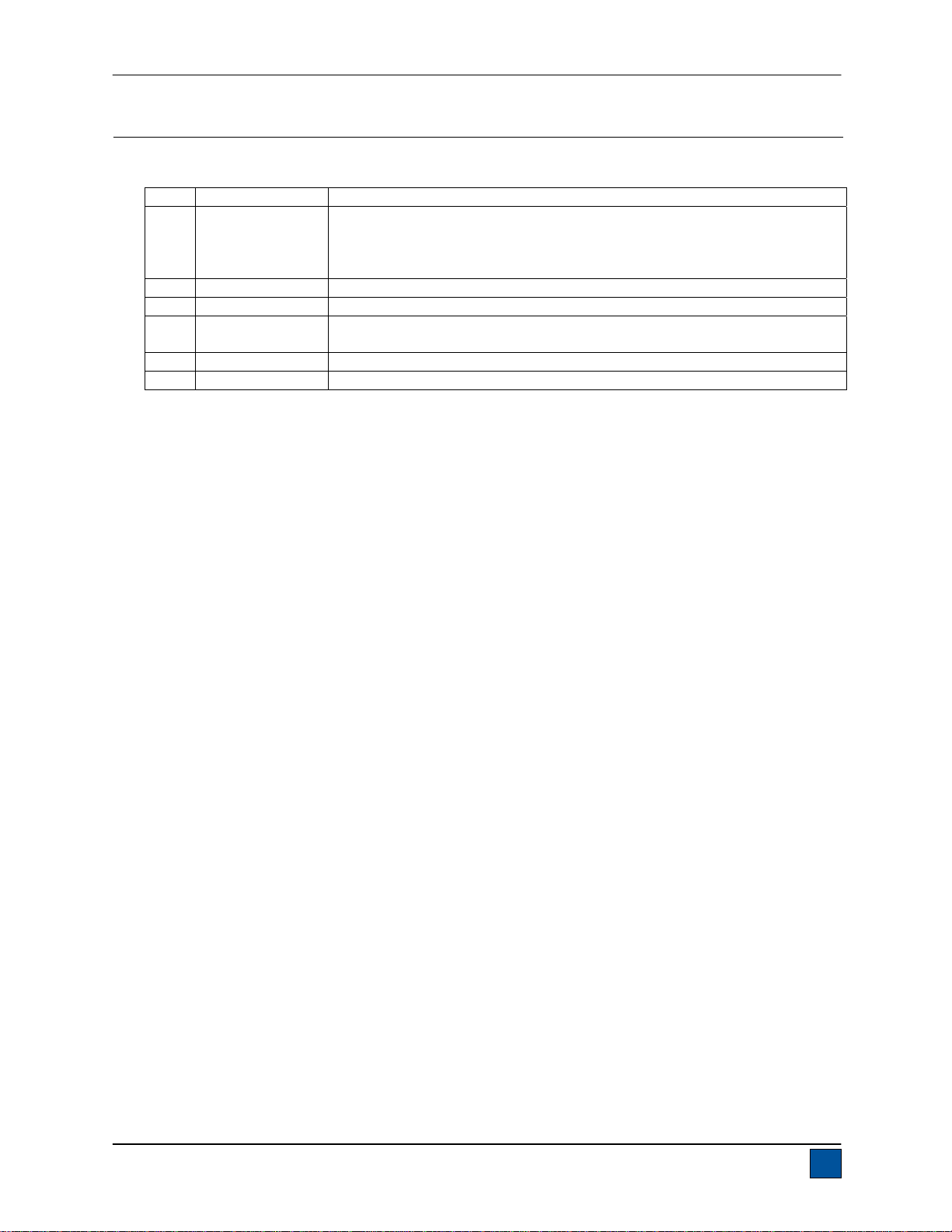

1.1 List of included items

Qty. Part No. Description

1 MTT05-12 /

MTT05-25 /

MTT05-50 /

MTT05-100

1 08-1026 Battery (inside the instrument)

1 09-1165 USB cable

1 - Resource CD (USB driver, user’s guides, MESURTM Lite software,

1 - Certificate of calibration (optional)

1 CT002 Carrying case (optional)

1.2 Safety / Proper Usage

Series TT05 digital torque tester

TM

MESUR

gauge DEMO software, User’s Guide)

Caution!

Note the torque tester’s capacity before use and ensure that the capacity is not exceeded.

Producing a torque greater than 150% of the tester’s capacity can damage the internal sensor. An

overload can occur whether the tester is powered on or off.

The tester is designed for various torque testing applications. Items that should not be used with the

tester include potentially flammable substances or products, items that can shatter in an unsafe manner,

and any other components that can present an exceedingly hazardous situation when acted upon by a

load.

The following safety checks and procedures should be performed before and during operation:

1. Never operate the tester if there is any visible damage to the AC adapter or the tester itself.

2. Ensure that the tester is kept away from water or any other electrically conductive liquids at all

times.

3. The tester should be serviced by a trained technician only. AC power must be disconnected and

the tester must be powered off before the housing is opened.

4. Always consider the characteristics of the sample being tested before initiating a test. A risk

assessment should be carried out beforehand to ensure that all safety measures have been

addressed and implemented.

5. Wear eye and face protection when testing, especially when testing brittle samples that have the

potential to shatter under force. Be aware of the dangers posed by potential energy that can

accumulate in the sample during testing. Extra bodily protection should be worn if a destructive

failure of a test sample is possible.

6. In certain applications, such as the testing of brittle samples that can shatter, or other applications

that could lead to a hazardous situation, it is strongly recommended that a machine guarding

system be employed to protect the operator and others in the vicinity from shards or debris.

7. When the tester is not in use, ensure that the power is turned off.

2

Page 4

Series TT05 Digital Torque Testers User’s Guide

2 POWER

The TT05 is powered either by an 8.4V NiMH rechargeable battery or by an AC adapter. Since these

batteries are subject to self discharge, it may be necessary to recharge the unit after a prolonged period

of storage. Plug the accompanying charger into the AC outlet and insert the charger plug into the

receptacle on the tester (refer to the illustration below). The battery will fully charge in approximately 8

hours.

USB connector

Serial connector

Power input jack

Caution!

Do not use chargers or batteries other than supplied or instrument damage may occur.

If the AC adapter is plugged in, an icon appears in the lower left corner of the display, as follows:

If the AC adapter is not plugged in, battery power drainage is denoted in a five-step process:

1. When battery life is greater than 75%, the following indicator is present:

2. When battery life is between 50% and 75%, the following indicator is present:

3. When battery life is between 25% and 50%, the following indicator is present:

4. When battery life is less than 25%, the following indicator is present:

5. When battery life drops to approximately 2%, the indicator from step 4 will be flashing.

Several minutes after (timing depends on usage and whether the backlight is turned on or

off), a message will appear, “BATTERY VOLTAGE TOO LOW. POWERING OFF”. A 4-tone

audio indicator will sound and the tester will power off.

The tester can be configured to automatically power off following a period of inactivity. Refer to the Other

Settings section for details. If battery replacement is necessary, the battery may be accessed by

removing the cover attached to the underside of the base.

3 SETUP

The matrix of threaded holes in the loading table allows for the mounting of specialized fixtures, as

required for the application. When designing and mounting the fixture, ensure that the axis of torque

aligns with the center of the loading table. Side loading or off-center loading may produce erroneous

readings, and can damage the instrument. The tester can be mounted to a bench via four threaded holes

located on the underside of the base.

3

Page 5

Series TT05 Digital Torque Testers User’s Guide

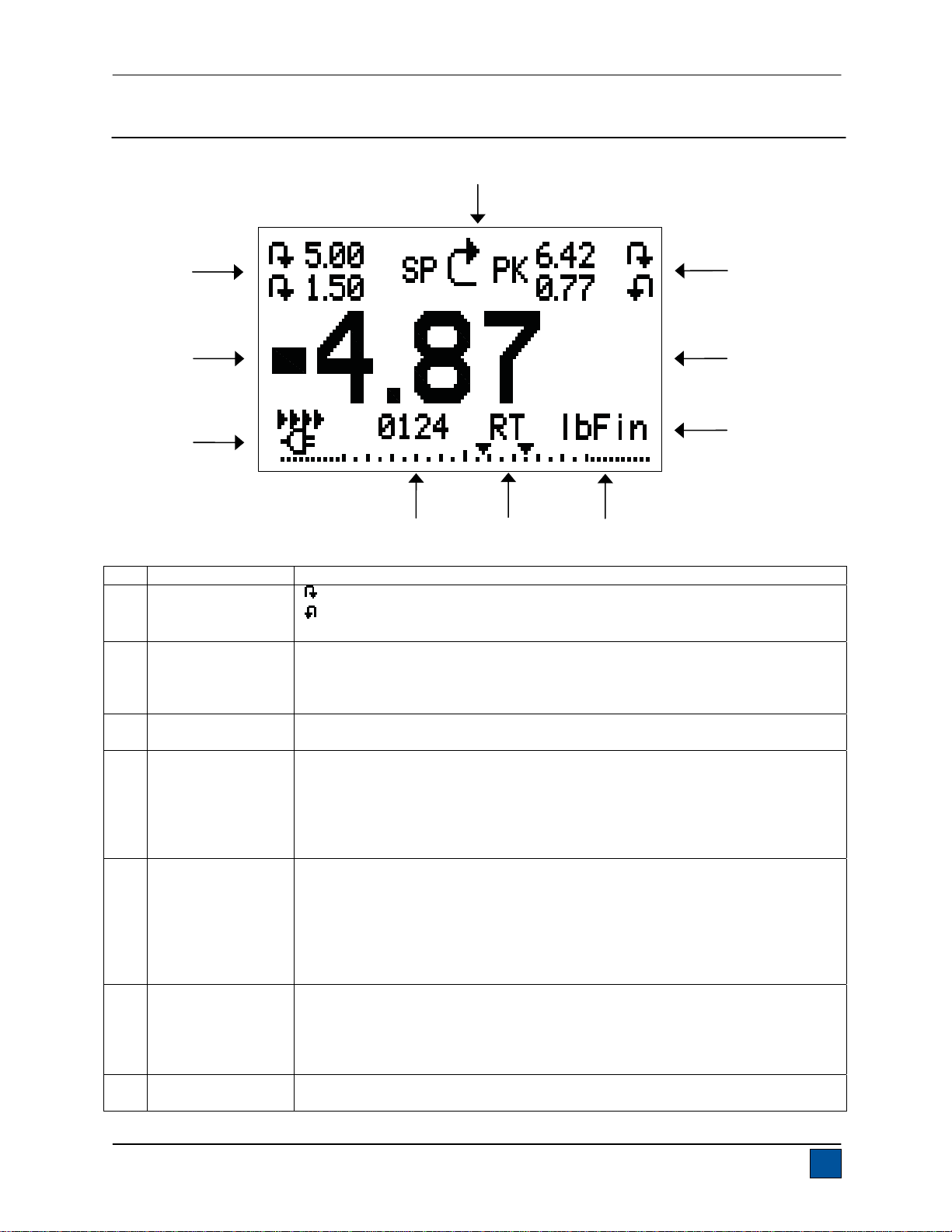

4 HOME SCREEN AND CONTROLS

4.1 Home Screen

10

No. Name Description

1 Measurement

2 Peaks

3 Primary reading

4 Units

5 Load bar

6 Mode

7 Number of stored

9

8

direction

indicator

data points

7

– indicates clockwise direction

– indicates counter-clockwise direction

These indicators are used throughout the display and menu.

The maximum measured clockwise and counter-clockwise readings, or

maximum measured 1

selected (see 1

pressing ZERO or by powering the tester off and on.

The current displayed load reading. See Operating Modes section for

details.

The current measurement unit. Abbreviations are as follows:

ozFin – Ounce-inch

lbFin – Pound-inch

lbFft – Pound-foot

Ncm – Newton-centimeter

Nm – Newton-meter

Analog indicator to identify when an overload condition is imminent. The bar

increases either to the right or left from the midpoint of the graph. Increasing

to the right indicates clockwise load, increasing to the left indicates counterclockwise load. If set points are enabled, triangular markers are displayed for

visual convenience. This indicator reflects the actual load, which may not

correspond to the primary reading (depends on operating mode). The ZERO

key does not reset the load bar. See Operating Modes section for details.

The current measurement mode. Abbreviations are as follows:

RT – Real Time

PCW – Peak Clockwise

PCCW – Peak Counter-clockwise

See Operating Modes section for details about each of these modes

The number of stored data points in memory, up to 1000. Displayed only if

Memory Storage is enabled for the DATA key.

st

/ 2nd Peak section for details). These readings are reset by

1

2

3

4

6

st

and 2nd peaks, when 1st / 2nd Peak Mode has been

5

4

Page 6

Series TT05 Digital Torque Testers User’s Guide

8 Battery / AC

adapter indicator

9 High / low limit

indicators

Either the AC adapter icon or battery power icon will be shown, depending on

power conditions. Refer to the Power section for details.

Correspond to the programmed set points. Indicator definitions are as follows:

– the primary reading is greater than the upper load limit

– the primary reading is between the load limits

– the primary reading is less than the lower load limit

10 Set points

The programmed load limit values. Typically used for pass/fail type testing.

One, two, or no indicators may be present, depending on the configuration

shown in the Set Points menu item.

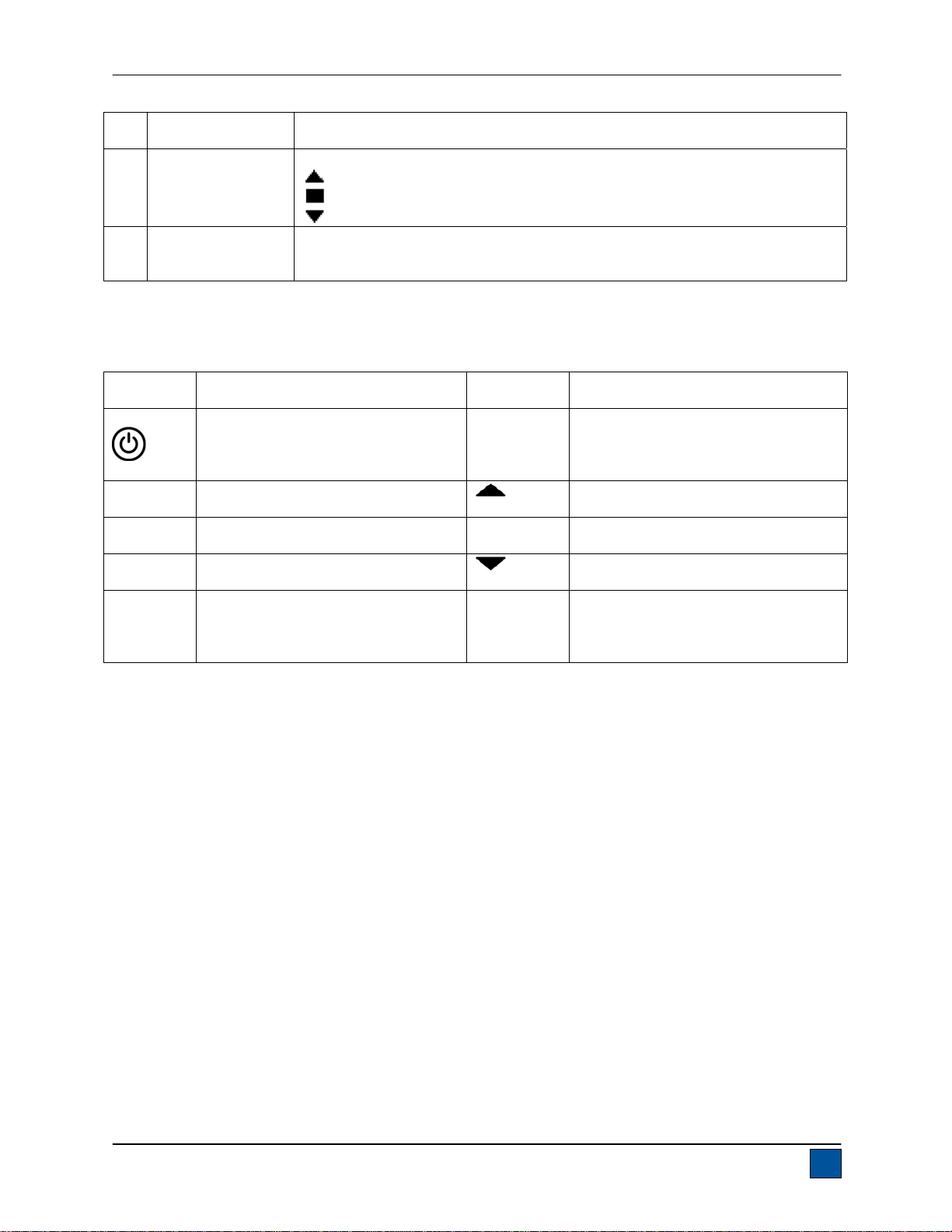

4.2 Controls

Primary

Label Primary Function

Powers the tester on and off. Press

briefly to power on, press and hold

to power off. Active only when the

Secondary

Label Secondary Function

ENTER

Various uses, as described in the

following sections.

home screen is displayed.

ZERO

MENU

Zeroes the primary reading and

peaks.

Accesses the main menu.

(UP)

ESCAPE

Navigates up through the menu and

sub-menus.

Reverts one step backwards through

the menu hierarchy.

MODE

DATA

Toggles between measurement

modes.

Stores a value to memory and/or

transmits the current reading to an

external device, depending on

configuration.

(DOWN)

DIRECTION

Navigates down through the menu

and sub-menus.

Toggles between clockwise and

counter-clockwise directions while

configuring set points and other menu

functions.

Note: Measurement units are configured through the menu. Refer to the Changing The Units section for

details.

4.3 Menu navigation basics

Most of the tester’s various functions and parameters are configured through the main menu. To access

the menu press MENU. Use the UP and DOWN keys to scroll through the items. The current selection is

denoted with clear text over a dark background. Press ENTER to select a menu item, then use UP and

DOWN again to scroll through the sub-menus. Press ENTER again to select the sub-menu item.

For parameters that may be either selected or deselected, press ENTER to toggle between selecting and

deselecting. An asterisk (*) to the left of the parameter label is used to indicate when the parameter has

been selected.

For parameters requiring the input of a numerical value, use the UP and DOWN keys to increment or

decrement the value. Press and hold either key to auto-increment at a gradually increasing rate. When

the desired value has been reached, press ENTER to save the change and revert back to the sub-menu

item, or press ESCAPE to revert back to the sub-menu item without saving. Press ESCAPE to revert one

step back in the menu hierarchy until back into normal operating mode.

Refer to the following sections for details about setting up particular functions and parameters.

5

Page 7

Series TT05 Digital Torque Testers User’s Guide

5 OPERATING MODES

Caution!

In any operating mode, if the capacity of the instrument has been exceeded by more than 110%,

the display will show “OVER” to indicate an overload. A continuous audible tone will be sounded

(if beeps are enabled) until the MENU key has been pressed or the load has been reduced to a

safe level.

Three operating modes are possible with the TT05 torque tester. To cycle between the modes, press

MODE while in the home screen.

5.1 Real time (RT)

The primary reading corresponds to the live measured reading.

5.2 Peak Clockwise (PCW)

The primary reading corresponds to the peak clockwise reading observed. If the actual load decreases

from the peak value, the peak will still be retained in the primary reading area of the display. Pressing

ZERO will reset the value.

5.3 Peak Counter-clockwise (PCCW)

Same as above, but for counter-clockwise readings.

6 CHANGING THE UNITS

The TT05 can display five different measurement units. To change the unit, select Units from the menu.

The display will list the available units, as follows:

UNITS

ozFin

* lbFin

lbFft

Ncm

Nm

The tester will always power on with the unit selected in this sub-menu.

7 DIGITAL FILTERS

Digital filters are provided to help smooth out the readings in situations where there is mechanical

interference in the work area or test sample. These filters utilize the moving average technique in which

consecutive readings are pushed through a buffer and the displayed reading is the average of the buffer

contents. By varying the length of the buffer, a variable smoothing effect can be achieved. The selection

of 1 will disable the filter since the average of a single value is the value itself.

To access digital filter settings, select Filters from the menu. The display will appear as follows:

6

Page 8

Series TT05 Digital Torque Testers User’s Guide

DIGITAL FILTERS

(1 = Fastest)

Current Reading

8

Displayed Reading

1024

Two filters are available:

Current Reading – Applies to the peak capture rate of the instrument.

Displayed Reading – Applies to the primary reading on the display.

Available settings: 1,2,4,8,16,32,64,128,256,512,1024. It is recommended to keep the current reading

filter at its lowest value for best performance, and the displayed reading filter at its highest value for best

stability.

8 SET POINTS

8.1 General Information

Set points are useful for tolerance checking (pass/fail)

and triggering an external device in process control

applications. Two limits, high and low, are programmed

in the tester, and the primary reading is compared to

these limits. The results of the comparisons are indicated

via on-screen indicators as well as through the three

outputs provided on the 15-pin connector, thus providing

“under”, “in range”, and “over” signaling. These outputs

can be connected to indicators, buzzers, or relays as

required for the application. On-screen indicators are

described in the next sub-section.

8.2 Configuration

To configure set points, select Set Points from the menu. The screen will appear as follows:

SET POINTS

Upper Disabled

* Upper Enabled

5.00

Lower Disabled

* Lower Enabled

3.50

Either one, two, or none of the set points may be enabled. To toggle between the clockwise and counterclockwise directions, press the DIRECTION key.

If two set points have been enabled, they are displayed in the upper left corner of the display. If only one

set point has been enabled, the word “OFF” will appear in place of the value. If no set points have been

enabled, the upper left corner of the display will be blank.

7

Page 9

Series TT05 Digital Torque Testers User’s Guide

8.3 Set Point Indicators

When set points are enabled, the following indicators are shown to the left of the primary reading:

– the displayed value is greater than the upper load

limit (NO GO HIGH)

– the displayed value is between the limits (GO)

– the displayed value is less than the lower load

limit (NO GO LOW)

Note: Set point indicators reference the displayed reading, not necessarily the current live load.

9 DATA MEMORY AND STATISTICS

Series TT05 testers have storage capacity of 1,000 data points. Readings may be stored, viewed, and

output to an external device. Individual, or all, data points may be deleted. Statistics are calculated for the

data presently in memory.

Individual data points may be saved to memory by pressing the DATA key, or automatically via the Break

Detection function, whichever is enabled. Refer to the Communications section for details. Once data

storage has been enabled, the data record number 0000 will appear below the primary reading in the

home screen. The record number will increment each time DATA is pressed or the automatic data

storage function is activated. When memory is full the message “MEMORY FULL” will be flashed at the

bottom of the display and a double audio tone will be sounded.

To view, edit, and output stored readings and statistics, select Memory from the menu. The screen

appears as follows:

MEMORY

View Data

View Statistics

Output Data

Output Statistics

Output Data & Stats

Clear All Data

9.1 View Data

All the saved data points may be viewed. The record number is displayed, along with the corresponding

value and presently set unit of measurement. Any readings may be deleted individually. To do so, scroll

to the desired reading and press DELETE. The letter “D” will appear to the left of the record number,

indicating that the gauge is in Delete mode, as follows:

0001 2.458 lbFin

0002 2.224 lbFin

0003 2.446 lbFin

0004 1.890 lbFin

D 0005 2.098 lbFin

0006 1.998 lbFin

0007 2.042 lbFin

8

Page 10

Series TT05 Digital Torque Testers User’s Guide

Press ENTER to delete the value. To exit Delete mode, press DELETE again. Any number of readings

may be individually deleted, however, all readings may also be cleared simultaneously. Refer to the Clear

All Data sub-section for details.

9.2 Statistics

Statistical calculations are performed for the saved values. Calculations include number of readings,

minimum, maximum, mean, and standard deviation.

9.3 Output Data

Press ENTER to output data to an external device. The display will show, “SENDING DATA…”, then

“DATA SENT”. If there was a problem with communication, the display will show, “DATA NOT SENT”.

Saved data can be downloaded by some Mark-10 data collection programs. Refer to their respective

user’s guides for details.

9.4 Output Statistics

Press ENTER to output statistics to an external device. The display will show, “SENDING STATS…”, then

“STATS SENT”. If there was a problem with communication, the display will show, “STATS NOT SENT”.

9.5 Output Data & Stats

Press ENTER to output data and statistics to an external device. The display will show, “SENDING

DATA”, then “SENDING STATS…”, then “DATA SENT”, then “STATS SENT”. If there was a problem with

communication, the display will show, “DATA NOT SENT” and/or “STATS NOT SENT”.

9.6 Clear All Data

Press ENTER to clear all data from the memory. A prompt will be shown, “CLEAR ALL DATA?”. Select

Yes to clear all the data, or No to return to the sub-menu.

For output of data and/or statistics, RS-232 or USB output must be enabled. Data formatting is

<CR><LF> following each value. Units can be either included or excluded. Output of data via the Mitutoyo

output is possible, however, output of statistics is not. Refer to the Communications section for details.

Note: Data is not retained while the tester is powered off. However, the tester protects against accidental

or automatic power-off. If manually powering the instrument off, or if the inactivity time limit for the

Automatic Shutoff function has been reached, the following warning message will appear:

*** WARNING ***

DATA IN MEMORY

WILL BE LOST

CANCEL

POWER OFF

If no option is selected, this screen will be displayed indefinitely, or until battery power has been depleted.

9

Page 11

Series TT05 Digital Torque Testers User’s Guide

10 COMMUNICATIONS & OUTPUTS

Communication with the TT05 tester is achieved through the micro USB or 15-pin serial ports located in

the rear of the housing, as shown in the illustration in the Power section. Communication is possible only

when the tester is in the main operating screen (i.e. not in a menu or configuration area).

10.1 Installing the USB driver

Caution!

It is recommended that the USB driver be installed before physically connecting the tester to the

PC with a USB cable.

For installation instructions, refer to the Mark-10 USB Driver user’s guide, supplied on the Resource CD

or downloadable from www.mark-10.com.

10.2 Serial / USB

To set up RS-232 and USB communication, select Serial/USB Settings from the menu. The screen

appears as follows:

SERIAL/USB SETTINGS

* RS232 Selected

USB Selected

+ Baud Rate

+ Data Format

Select either RS-232 or USB input (output is always simultaneous through both the USB and RS-232

ports). Communication settings are permanently set to the following:

Data Bits: 8

Stop Bits: 1

Parity: None

Other settings are configured as follows:

10.2.1 Baud Rate

Select the baud rate as required for the application. It must be set to the same value as the receiving

device.

10.2.2 Data Format

Select the desired data format. The screen appears as follows:

DATA FORMAT

* Numeric + Units

Numeric Only

Invert Polarity

Omit Polarity

10

Page 12

Series TT05 Digital Torque Testers User’s Guide

Selection Description

Numeric + Units Output format includes the value and unit of measure. Clockwise values have

positive polarity, counter-clockwise values have negative polarity.

Numeric Only Output format includes the value only. Polarity same as above.

Invert Polarity Clockwise values have negative polarity, counter-clockwise values have positive

polarity. May be selected in addition to the Numeric + Units / Numeric Only

selection.

Omit Polarity Both directions are formatted with positive polarity. May be selected in addition to

the Numeric + Units / Numeric Only selection.

10.2.3 Data Communication

Individual data points may be transmitted by pressing DATA. Series TT05 testers will also respond to the

following ASCII commands:

? Request the displayed reading

MEM Transmit all stored readings

STA Transmit statistics

All commands must be terminated with a Carriage Return character or with a Carriage Return/Line Feed

combination. The tester’s responses are always terminated with a Carriage Return/Line Feed.

Any detected errors are reported back by means of error code *10 (illegal command).

10.3 Mitutoyo BCD settings

This output is useful for connection to data collectors, printers, multiplexers, or any other device capable

of accepting Mitutoyo BCD data. Individual data points may be transmitted by pressing DATA or by

requesting it from the Mitutoyo communication device (if available). Automatic output of individual data

points is also possible. Refer to the Break Detection sub-section for details. To enable Mitutoyo output,

select the desired format – either with polarity or without polarity. The screen appears as follows:

MITUTOYO BCD

* Disabled

Ena w/o Polarity

Ena w/Polarity

10.4 Analog Output

This output can be used for chart recorders, oscilloscopes, data acquisition systems, or any other

compatible devices with analog inputs. The output produces ±1 volt at full scale of the instrument. The

polarity of the signal is positive for clockwise and negative for counter-clockwise.

10.5 DATA Key Settings

To configure the functions of the DATA key, select DATA Key from the menu. The display will appear as

follows:

DATA KEY

* RS232/USB Output

Mitutoyo Output

Memory Storage

11

Page 13

Series TT05 Digital Torque Testers User’s Guide

1

1

1

1

RS232/USB Output

Mitutoyo Output

Memory Storage

Outputs data via the serial and USB ports

Outputs data via Mitutoyo (Digimatic) through the serial port

Stores a reading to memory (refer to the Memory section for details)

Any combination of the above functions may be selected.

10.6 I/O Connector Pin Diagram (female)

Pin No. Description Input / Output

1 Signal Ground --2 Counter-clockwise Overload Output

3 RS-232 Receive Input

4 RS-232 Transmit Output

5 +12V DC Output

6 Analog Output Output

7 Clockwise Overload Output

81 Mitutoyo Clock

Output Bit 2

91 Mitutoyo Data

Output Bit 0

101 Mitutoyo Request

112 Set Point Pin 12 Output2

122 Set Point Pin 22 Output2

132 Set Point Pin 32 Output2

14 Do not connect --151 Mitutoyo Ready

Input Bit 3

Output Bit 1

1

1

1

1

Output

Output

Input

Output

Notes:

1. Mitutoyo and general purpose outputs cannot be activated simultaneously.

2. The set point output assignments depend on several factors described in the table below. Output

functions always reference the primary reading on the display, regardless of the current mode.

Torque Pin 11 Pin 12 Pin 13

Upper and Lower Set Points are Clockwise

Greater than or equal to upper set point On Off Off

Between upper and lower set points Off Off On

Less than or equal to lower set point Off On Off

Upper and Lower Set Points are Counter-clockwise

Greater than or equal to upper set point Off On Off

Between upper and lower set points Off Off On

Less than or equal to lower set point On Off Off

Upper Set Point is Clockwise, Lower Set Point is Counter-clockwise

Greater than or equal to upper set point, in clockwise Off On Off

Between upper and lower set points Off Off On

Greater than or equal to lower set point, in counter-clockwise On Off Off

Upper Set Point is Counter-clockwise, Lower Set Point is Clockwise

Greater than or equal to upper set point, in counter-clockwise Off On Off

Between upper and lower set points Off Off On

Greater than or equal to lower set point, in clockwise On Off Off

12

Page 14

Series TT05 Digital Torque Testers User’s Guide

11 BREAK DETECTION

11.1 Configuration

Three functions can be triggered automatically upon sample break or slip, defined as a programmable

percentage drop in load from the peak:

1. Transmit the peak reading

2. Save the peak value to memory

3. Zero the primary and peak readings

These automatic functions can help automate and expedite testing processes. If beeps are enabled, an

audible tone will sound when the output, storage, and zero functions have occurred. In order for break

detection to be active, the appropriate operating mode must be selected. See the Operating Modes

section for details. The display will appear as follows:

BREAK DETECTION

* Enabled

+ Break Settings

+ Auto Output

* Auto Storage

* Auto Zero

Any combination of the above functions may be selected.

Function Description

Enabled

Break Settings

Auto Output

Auto Storage

Auto Zero

11.2 Settings

The display will appear as follows:

BREAK DETECTION

SETTINGS

Threshold: 10 %

% Drop: 50 %

Auto Zero Delay

5 sec.

Threshold

% Drop

Auto Zero Delay

If enabled, BRK will appear as one of the operating modes.

Press ENTER to access the Break Detection Settings sub-menu.

See Section 11.2 for details.

Press ENTER to access the Auto Output Settings sub-menu.

See Section 11.3 for details.

Automatically stores the peak reading to memory. Press ENTER to enable.

Automatically zeroes the display following data transmission and/or storage.

Press ENTER to enable.

Sets the percentage of full scale at which break detection becomes active.

Provided to ignore peaks that can occur during sample handling.

Available settings: 5-90%, in 5% increments.

Sets the percentage of peak load at which the break is detected.

Available settings: 5-90%, in 5% increments.

Sets the time delay before the primary and peak readings are zeroed.

Available settings: 1-60 sec., in 1 sec. increments between 1-10 sec., in 5

sec. increments between 5-60 sec.

13

Page 15

Series TT05 Digital Torque Testers User’s Guide

11.3 Auto Output Settings

Select the output type. One or both output types may be enabled. The display will appear as follows:

AUTO OUTPUT

SETTINGS

RS232/USB Output

Mitutoyo Output

Note: The same auto save/output/zero functions are available in First / Second Peak mode. Refer to the

First / Second Peak section for details.

12 FIRST / SECOND PEAK

This function captures two consecutive peaks which can occur over the course of a test, such as with

tamper-evident breakaway band closures, torque tools, and other samples.

12.1 Configuration

Several functions can be triggered automatically upon second peak capture:

1. Transmit the first peak value

2. Transmit the second peak value

3. Save the first peak value to memory

4. Save the second peak value to memory

5. Zero the primary and peak values

These automatic functions can help automate and expedite testing processes. If beeps are enabled, an

audible tone will sound when the output, storage, and zero functions have occurred. In order for First /

Second Peak detection to be active, the appropriate operating mode must be selected. See the

Operating Modes section for details. The display will appear as follows:

FIRST/SECOND PEAK

* Enabled

+ Peak Settings

+ Auto Output

* Auto Store PK1

Auto Store PK2

* Auto Zero

Any combination of the above functions may be selected.

Function Description

Enabled

Peak Settings

Auto Output

Auto Store PK1

Auto Store PK2

Auto Zero

If enabled, 2PK will appear as one of the operating modes. In the main display,

the Peak values will reference the first and second peaks – first peak on top,

second peak below. Refer to the Home Screen & Control section for details.

Press ENTER to access. See Section 12.2 for details.

Press ENTER to access. See Section 12.3 for details.

Automatically stores the first peak value to memory.

Automatically stores the second peak value to memory.

Automatically zeroes the display following data transmission and/or storage.

14

Page 16

Series TT05 Digital Torque Testers User’s Guide

12.2 Settings

The display will appear as follows:

PEAK SETTINGS

Thresh. 1: 10 %

% Drop 1: 50 %

Thresh. 2: 10 %

% Drop 2: 50 %

Auto Zero Delay

5 sec.

Threshold 1

Sets the percentage of full scale at which the first/second peak detection

feature becomes active. This threshold is provided to ignore peaks that can

occur during sample handling. Available settings: 1-90%, in 1% increments

between 1-5%, and in 5% increments between 5-90%.

Percentage Drop 1

Identifies the first peak via detection of a specified percentage drop from

peak.

Threshold 2

Same as with Threshold 1, but refers to a percentage of full scale beyond

the first peak. For example, for a 50 lbFin capacity tester, if the first peak is

20 lbFin, and Threshold 2 is set to 15%, the threshold is equal to 27.5 lbFin.

Percentage Drop 2

Auto Zero Delay

Same as Percentage Drop 1, for the second peak.

Sets the time delay before the primary and peak readings are zeroed.

Available settings: 1-60 sec., in 1 sec. increments between 1-5 sec., and in

5 sec. increments between 5-60 sec.

Thresholds and percentage drops are illustrated below:

11.3 Auto Output Settings

Select the output type. Select RS-232/USB and/or Mitutoyo outputs, and select First and/or Second

peaks. The display will appear as follows:

AUTO OUTPUT

SETTINGS

RS232/USB Output

Mitutoyo Output

First Peak

Second Peak

15

Page 17

Series TT05 Digital Torque Testers User’s Guide

11 CALIBRATION

11.1 Initial Physical Setup

The TT05 should be mounted to a fixture rugged enough to withstand a load equal to the full capacity of

the instrument. A groove located in the side of table has a diameter of 6.666” [169.32 mm], and may be

used to accept a cable for calibration weights. This eliminates the need for a torque arm or torque wheel,

especially when using lb weights. Readily available lb weights may be used to easily achieve lbFin

calibration values. For example, for a calibration load of 50 lbFin, exactly 15 lb of weight is required.

Suitable calibration equipment is required, and caution should be taken while handling such equipment.

11.2 Calibration Procedure

1. Select Calibration from the menu. The display will appear as follows:

CALIBRATION

ENTER # CAL POINTS

(1 TO 10)

CLOCKWISE:

5

COUNTER-CLOCKWISE:

5

The tester can be calibrated at up to 10 points in each direction. Enter the number of calibration

points for each direction. At least one point must be selected for each direction.

Note: To achieve the accuracy specification of ±0.3% of full scale, it is recommended to calibrate

the TT05 at 5 or more even increments in both the clockwise and counter-clockwise directions.

For example, Model MTT05-50 (with capacity of 50 lbFin) should be calibrated at 10, 20, 30, 40,

and 50 lbFin loads in each direction.

2. To escape the Calibration menu at any time, press ESCAPE. The display will appear as follows:

CALIBRATION

NOT COMPLETE

CANCEL

EXIT W/O SAVING

Selecting “CANCEL” will revert back to the Calibration setup. Selecting “EXIT W/O SAVING” will

return to the menu without saving changes.

3. After the number of calibration points has been entered, press ENTER. The display will appear as

follows:

CALIBRATION

OFFSET

Place tester

vertical

THEN PRESS ZERO

4. Place the TT05 in a fixture free from vibration, then press ZERO. The tester will calculate offsets,

and the display will appear as follows:

16

Page 18

Series TT05 Digital Torque Testers User’s Guide

CALIBRATION

OFFSET

Please wait…

CALIBRATION

CALIBRATION

OFFSET

Sen.Offset Adj.Passed

Ana.Offset Adj.Passed

Sen.Offset Adj.Failed

Ana.Offset Adj.Failed

If failed:

5. The following screen appears after the offsets have been calculated:

CALIBRATION

CLOCKWISE

Attach necessary

weight fixtures.

THEN PRESS ENTER

Attach weight fixtures (cable attachment, cable, hook, etc), as required. Do not yet attach any

weights or apply any calibration loads. Then press ENTER.

6. The display will appear as follows:

CALIBRATION

CLOCKWISE

Optionally exercise

load cell a few times.

THEN PRESS ENTER

Optionally exercise the internal sensor several times (at full scale, if possible), then press

ENTER.

7. After displaying “PLEASE WAIT…” the display will appear as follows:

CALIBRATION

ENSURE NO LOAD

THEN PRESS ZERO

OFFSET

8. The display will appear as follows:

17

Page 19

Series TT05 Digital Torque Testers User’s Guide

CALIBRATION

CLOCKWISE

GAIN ADJUST

APPLY FULL SCALE LOAD

50.000 LBFIN +/-20%

THEN PRESS ENTER

Apply torque equal to the full scale of the instrument, then press ENTER.

Remove the torque, leave the fixtures in place, then press ZERO.

9. The display will appear as follows:

CALIBRATION

CLOCKWISE

APPLY LOAD

1 OF 5

ENTER LOAD:

10.000 LBFIN

THEN PRESS ENTER

Use the UP and DOWN keys to adjust the torque value as required. The torque values default to

even increments, as indicated by the previously entered number of data points described in Step

1. Then press ENTER.

Repeat the above step for the number of data points selected.

10. After all the clockwise calibration points have been completed, the display will appear as follows:

CALIBRATION

CLOCKWISE COMPLETE

REVERSE DIRECTION

FOR CCW

Attach necessary

weight fixtures.

THEN PRESS ENTER

Press ENTER.

11. At the completion of the counter-clockwise calibration, the display will appear as follows:

CALIBRATION

COMPLETE

SAVE & EXIT

EXIT W/O SAVING

To save the calibration information, select “SAVE & EXIT”. To exit without saving the data select

“EXIT W/O SAVING”.

12. Any errors are reported by the following screens:

18

Page 20

Series TT05 Digital Torque Testers User’s Guide

CALIBRATION

Units must be kgFmm.

PLEASE TRY AGAIN

PRESS ENTER

Displayed at the start of calibration if a disallowed unit is selected.

LOAD NOT STABLE

PLEASE TRY AGAIN

Ensure that the load is not swinging, oscillating, or vibrating in any manner. Then try again.

CALIBRATION

CLOCKWISE

LOAD TOO LOW

PLEASE TRY AGAIN

The calibration load does not match the set value.

CALIBRATION

COUNTER-CLOCKWISE

LOAD TOO CLOSE

TO PREVIOUS

PLEASE TRY AGAIN

The entered calibration point is too close to the previous point.

12 PASSWORDS

Two separate passwords may be set to control access to the Calibration section and to the menu and

other keys. To access the passwords setup screen, select Passwords from the menu. The display will

appear as follows:

PASSWORDS

Calibration

Menu Key

Mode Key

Zero Key

Data Key

19

Page 21

Series TT05 Digital Torque Testers User’s Guide

12.1 Calibration Password

Select Calibration from the sub-menu. The display will appear as follows:

CALIBRATION PASSWORD

* Disabled

Enabled

Set Password

(0000 – 9999)

5000

To set the password, select Enabled, then Set Password. Use the UP and DOWN keys to increment and

decrement the value, from 0 to 9999. When the desired value has been selected, press ENTER, then

ESC to exit the sub-menu.

12.2 Menu Key Password

If enabled, a password must be provided every time the MENU key is selected. Select Menu Key from

the sub-menu. Follow the same procedure as described in the previous sub-section.

12.3 Locking Out Other Keys

Other keys may be locked out individually. Select any combination of keys (MODE, ZERO, DATA) by

pressing ENTER in the Passwords sub-menu. Pressing a locked key will prompt the message “KEY

PROTECTED” and then revert to the previous screen.

12.4 Password Prompts

If passwords have been enabled, the following will be displayed when pressing the MENU key or

accessing the Calibration section:

ENTER PASSWORD

(0000 – 9999)

5000

Use the UP and DOWN keys to select the correct password, then press ENTER to continue.

If the incorrect password has been entered, the display will appear as follows:

INCORRECT PASSWORD

Reset password

Request code:

XXXX

Press ENTER or ESC

To re-enter the password, press ESC to exit to the home screen. Then, access the desired function and

enter the password again when prompted.

If the password has been misplaced, it can be reset. Press ENTER to generate a request code. The

request code must be supplied to Mark-10 or a distributor, who will then provide a corresponding

activation code. Enter the activation code to disable the password.

20

Page 22

Series TT05 Digital Torque Testers User’s Guide

13 OTHER SETTINGS

13.1 Automatic Shutoff

The tester may be configured to automatically power off following a period of inactivity while on battery

power. Inactivity is defined as the absence of any key presses or load changes of 100 counts or less. To

access these settings, select Automatic Shutoff from the menu. The display will appear as follows:

AUTOMATIC SHUTOFF

* Disabled

Enabled

Set Minutes

5

Select Disabled to disable automatic shutoff. Select Enabled to enable it. The length of time of inactivity

is programmed in minutes via the Set Minutes parameter. Available settings: 5-30, in 5 minute

increments.

Note: If the AC adapter is plugged in, the tester will ignore the Automatic Shutoff setting and remain

powered on until the POWER key is pressed.

13.2 Backlight

Several initial settings are available upon powering on the tester. To access these settings, select

Backlight from the menu. The display will appear as follows:

BACKLIGHT

Off

On

* Auto

Set Minutes

1

Select Off for the backlight to be off upon powering on the tester.

Select On for the backlight to be on upon powering on the tester.

Select Auto for the backlight to be on upon powering on the tester, but will shut off after a period of

inactivity (as defined in the Automatic Shutoff sub-section). The backlight will turn on again when activity

resumes. The length of time of inactivity is programmed in minutes via the Set Minutes parameter.

Available settings: 1-10, in 1 minute increments.

Note: If the AC adapter is plugged in, the tester will ignore these settings and keep the backlight on.

Selecting the On or Off setting in the Backlight menu will manually turn the backlight on or off.

21

Page 23

Series TT05 Digital Torque Testers User’s Guide

13.3 LCD Contrast

The contrast of the display may be adjusted. Select LCD Contrast from the menu. The screen will appear

as follows:

LCD CONTRAST

Set Contrast

10

Press ENTER to modify the contrast. Select a value from 0 to 25, with 25 producing the most contrast.

13.4 Beeps

Audible tones can be enabled for all key presses and alerts, such as overload, set point value reached,

etc. The Set Point alert can be configured to be either a momentary tone or a continuous tone (until the

load is restored to a value between the set points). To configure the functions for which audible tones will

apply, select Beeps from the menu. The screen will appear as follows:

BEEPS

Keys

* Alerts

Set Points

* Momentary

Continuous

13.5 Initial Settings

The default units and operating mode at power-on may be configured. To access this parameter, select

Initial Settings from the menu. The screen will display the available modes. An example is as follows:

INITIAL SETTINGS

Units

lbFin

Mode

Real Time

For available selections, refer to the Units and Home Screen And Controls sections.

13.6 Information / Welcome Screen

The following screen is displayed at power-up and can be accessed at any time by selecting Information:

Digital Torque Tester

Series TT05

Model No: MTT05-50

Serial No: 1234567

Version: 1.0

(c) Mark-10 Corp.

22

Page 24

Series TT05 Digital Torque Testers User’s Guide

14 SPECIFICATIONS

14.1 General

Accuracy: ±0.3% of full scale

Sampling rate: 7,000 Hz

Power:

Battery life: Backlight on:

Measurement units: ozFin, lbFin, lbFft, Nm, Ncm

Outputs:

Safe overload: 150% of full scale (display shows “OVER” at 110% and above)

Weight: 10.9 lb [4.9 kg]

Environmental requirements: 40 - 100°F, max. 96% humidity, non-condensating

Warranty: 3 years (see individual statement for further details)

14.2 Dimensions IN [MM]

AC or rechargeable battery. Low battery indicator appears when battery level is low, and tester

powers off automatically when power reaches critical stage.

up to 7 hours of continuous use /

USB / RS-232:

Mitutoyo (Digimatic):

Analog:

General purpose:

Set points:

Configurable up to 115,200 baud.

Serial BCD suitable for all Mitutoyo SPC-compatible devices.

±1 VCD, ±0.25% of full scale at capacity.

Three open drain outputs, one input.

Three open drain lines.

Backlight off:

up to 24 hours of continuous use

14.3 Capacity x Resolution

Model No. lbFin ozFin lbFft Ncm Nm

MTT05-12

MTT05-25

MTT05-50

MTT05-100

12 x 0.005 192 x 0.1 1 x 0.0005 135 x 0.1 1.35 x 0.001

25 x 0.01 400 x 0.2 2 x 0.001 290 x 0.2 2.9 x 0.002

50 x 0.02 800 x 0.5 4 x 0.002 570 x 0.5 5.7 x 0.005

100 x 0.05 1600 x 1 8 x 0.005 1150 x 0.5 11.5 x 0.005

23

Page 25

Series TT05 Digital Torque Testers User’s Guide

t

d

14.4 Factory Settings

Parameter Setting

Set points

Upper Disabled (defaults to 80% of full scale, clockwise, when enabled)

Lower Disabled (defaults to 40% of full scale, clockwise, when enabled)

Filters

Current 8

Displayed 1024

DATA Key Functions

RS-232/USB Output Enabled

Mitutoyo Output Disabled

Memory Storage Enabled

Backlight Auto

Minutes 1

Serial/USB

RS-232 Output Selected Disabled

USB Output Selected Enabled

Baud Rate 9,600

Data Format Numeric + units

Mitutoyo BCD Output Disabled

Break Detection

Automatic Output

RS-232/USB Output Disabled

Mitutoyo Output Disabled

Automatic Storage Disabled

Automatic Zero Disabled

Break Detection Settings

Trigger Threshold 10%

% Drop 50%

Auto Zero Delay 5 sec.

s

n

1

/2

Peak Disabled

Peak Settings

Threshold 1 10%

% Drop 1 50%

Threshold 2 10%

% Drop 2 50%

Auto Store Peak 1 Disabled

Auto Store Peak 2 Disabled

Auto Zero Disabled

Automatic Shutoff Enabled

Minutes 5

Beeps

Keys Enabled

Alerts Enabled

Set Points Momentary

LCD Contrast 10

Initial Mode Real Time

Units lbFin

Passwords All passwords disabled

24

Page 26

Series TT05 Digital Torque Testers User’s Guide

NOTES:

25

Loading...

Loading...