Page 1

TSN (Cam-Over Wrench) Operating Instructions

Rev 2.0 (March 20, 2008)

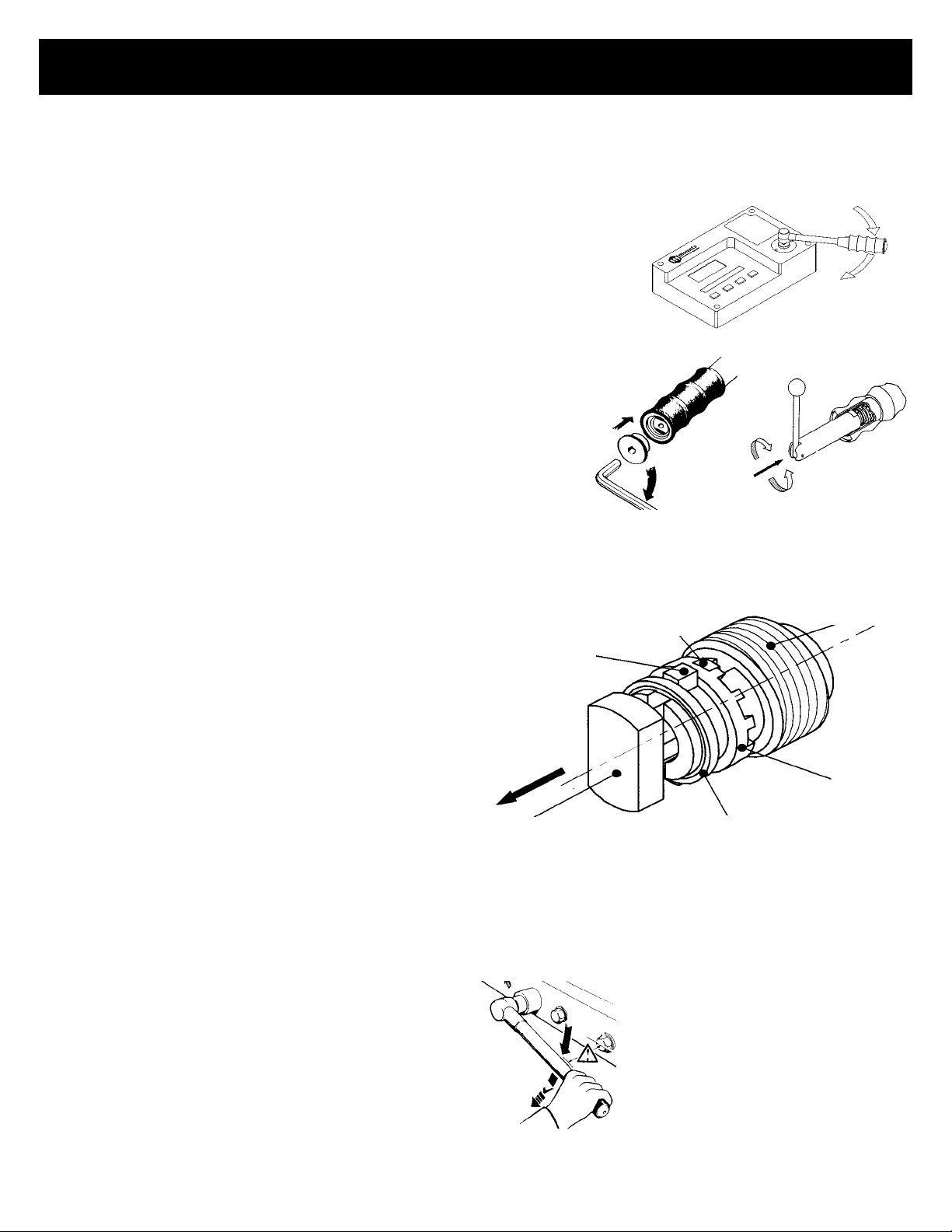

Calibrating Torque Wrenches

To calibrate torque wrenches either use a torque analyzer or torque transducer within the range of the torque wrench. For

cam-over torque wrenches calibrate torque in “Peak” mode with an analyzer or transducer. Make sure you apply the torque

slowly and smoothly.

1. Select a torque analyzer or transducer that covers the torque range of the TSN

wrench. Connect wrench to the torque analyzer or transducer.

2. Apply torque clockwise slowly until wrench ‘slips’ and note reading.

3. Adjust wrench to required torque setting.

4. Test and repeat adjustment as necessary to obtain desired value.

5. Recalibrate torque wrench at prescribed intervals.

Adjusting Torque Setting

1. Remove end cap from wrench and insert special adjusting key.

2. The special Adjusting Key is an articulated design. When in use the two

halves are set at 90º, this allows downward force to be exerted on the

Sliding Lock while rotating the Adjusting Screw.

3. Turn clockwise to increase torque and counter clockwise to decrease

torque. Do not adjust torque above or below the recommended

torque ranges. Tighten end cap back on.

Adjusting

Key

Construction & Operation of M-TALD System

The TSN wrenches now feature the new M-TALD (Mechanical Torque Adjustment Locking Device) system. The M-TALD is an

easy to use locking device for adjusting the torque of the TSN. It's a positive, mechanical locking system that does not rely on

friction for movement, and does not require a secondary locking device. It's operated using a single key.

1. M-TALD comprises of three main parts: The Adjusting screw,

the spring-loaded Sliding Lock and the Castellated Lock

Ring. These are assembled into a single, self-contained unit

and held together by a retaining ring.

Sliding Lock Engaged

Location Lug

Adjusting Screw

2. The assembly is screwed into the wrench handle tube, with

the location lugs of the Lock Ring engaging with specially

formed grooves.

3. An inward force has to be exerted onto the Sliding Lock,

through the special adjusting key, while the Adjusting

Screw is being rotated.

4. As soon as the inward force is released, the spring-loaded

Sliding Lock engages with the teeth of the Lock Ring,

further rotation of the Adjusting Screw is not possible.

Sliding Lock

Retaining Ring

Castellated

Locking RIng

5. The Castellated Lock Ring has ten teeth, allowing the

Adjusting Screw to be set at increments of 36º. The

resolution of each increment varies with each model of

the tool and are, generally, as follows:

TSN 25 0.15 Nm

TSN 55 0.6 Nm

TSN 125 1.0 Nm

Applying Torque

1. Tighten nut or bolt by applying a steady even pull using

built in ratchet as necessary. Wrench should be kept at

90 degrees to axis of bolt during tightening. When

pre-set torque is reached, the wrench will ‘slip.’

2. The wrench will automatically reset itself for the next

application.

3. With its unique design, it’s impossible to over tighten

beyond the preset load.

Page 2

TSN (Cam-Over Wrench) Operating Instructions

Rev 2.0 (March 20, 2008)

TSN Maintenance Schedule

Expected Tool Life

With normal use – 100,000 operations

Initial Settling in Period

1500 operations, during which frequent calibration checks are recommended.

Period between Resetting of Torque

5000 operations (as recommended in BS EN 26789:1994). It is acknowledged that some TSN tools achieve 5000 operations

in a relatively short period of time. Under these circumstances the User may decide, with the benefit of their experience, to

increase the period between calibration checks.

Routine Maintenance

After 100,000 operations, strip, clean & re-grease the Spindle, Cam & Roller. Any worn components should be replaced.

Note: Any tool that is dismantled during its life must be re-lubricated in accordance with the Mountz recommendations. Do not

clean tools by immersing them in solvent, as this will destroy the internal lubrication and cause failure of the tool.

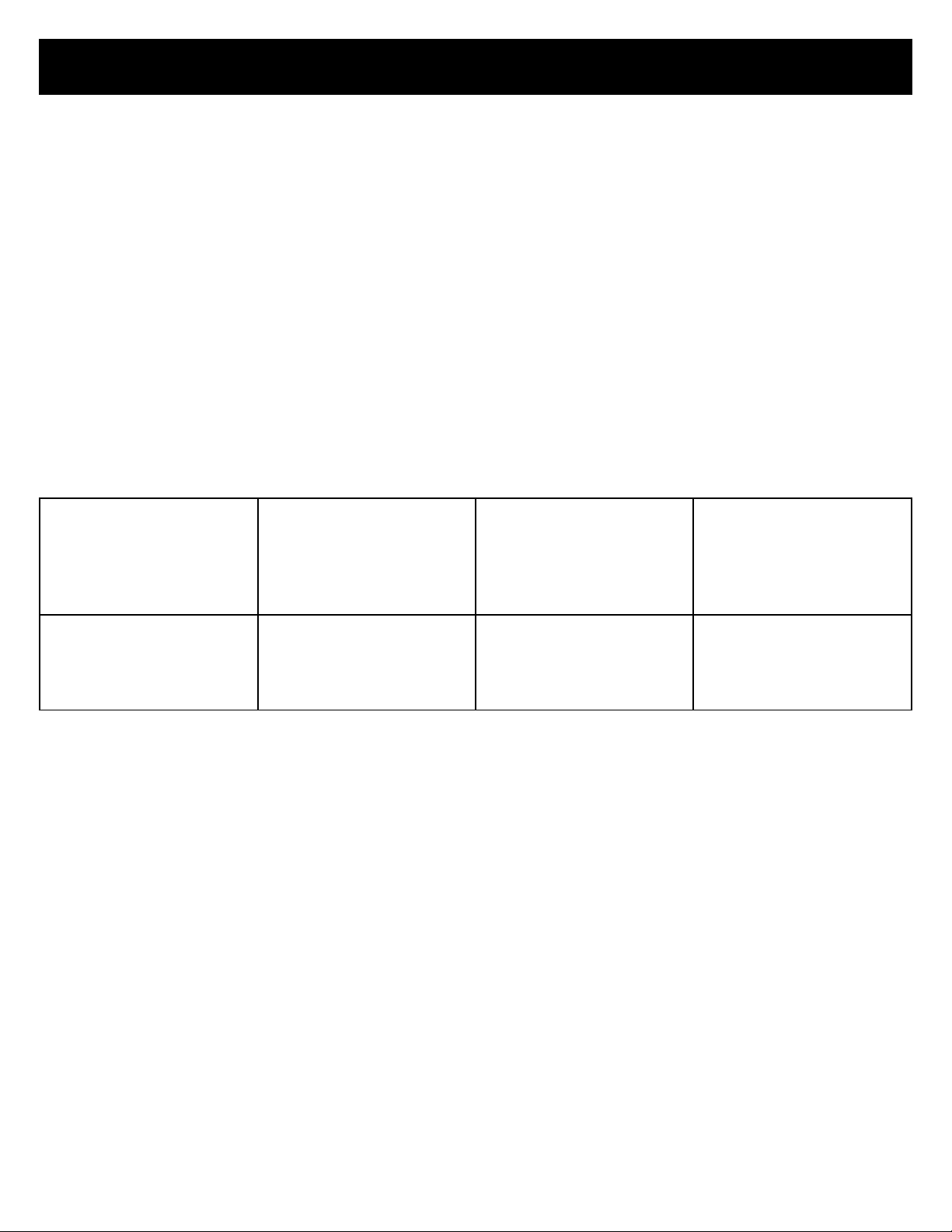

Tool Lubrication Chart for TSN

Gulf

Gulflex Moly

Temp Range

-1 to 120 C

or equivalent

General - except

Roller & Cam

Ratchet

TSN Cam/Spindle Replacement Procedure - Overview:

This procedure has been prepared in response to requests from authorized Mountz Distributors who wish to Service and

Replace components in the head assembly of TSN wrenches.

Tools and Materials:

- Rear bearing removal tool - to suit model of TSN being serviced

- Rear bearing insertion mandrel - to suit model of TSN being serviced

- Normal Workshop tools

- Replacement parts as necessary

- Anti-scuffing paste - ROCOL ASP recommended

- Light machine oil

Silicon Grease

RS 555-083

Temp Range

-50 to + 200 C

“O” Rings Ratchet Roller & Cam

Shell Tonna 32

Lubricating Oil

Total

Drosera 68

Rocol ASP

Anti-Scuffing paste

Life Time Lubrication

Max Temp 450 C

Procedure

1. The external parts of the TSN should be cleaned. The dust cap at grip end of handle removed and the torque adjustment

mechanism slackened off just to the point where the square drive of the TSN can freely rotate in both directions. This

indicates that the roller is no longer in engagement with the cam. Do not slacken the adjustment screw further than this

point as the roller will become disengaged from the roller guide and may be difficult to relocate.

2. Remove the Spirolox retaining ring from the underside of the head assembly.

3. Gentle tapping of the head assembly against a wooden block (as per sketch) will eject the cam/spindle assembly complete

with cover plate and front bearing from the TSN head. This may also cause the spindle and pawls to be ejected from the

cam. If this occurs take care not to lose the pawls or pawl springs.

Page 3

TSN (Cam-Over Wrench) Operating Instructions

Rev 2.0 (March 20, 2008)

Procedure (continued)

4. Ensure the roller is below the surface of the main bearing housing and remove the rear main bearing using special

removal tool.

Note: It may not be necessary to replace the main bearings in every TSN unless there are signs of extreme wear, or the

cam will not rotate smoothly within the bearings.

5. With the cam/spindle assembly removed, check the condition of the roller guide and roller. It may be necessary to remove

the rear main bearing to carry out this check.

6. Degrease, clean and inspect all parts, replacing those which are worn or broken.

7. Replace rear main bearing in the head using special insertion mandrel ensuring that the roller is fully retracted so as not

to interfere with the bearing as it is inserted. Ensure that the rear main bearing sits squarely on the rear face of the housing.

8. Re-lubricate the rear main bearing with anti-scuffing paste.

9. Re-assemble spindle and pawls into the cam ensuring that the pawl springs are correctly positioned. Also ensure that the

pawls are located with their half rounded long edge resting in the spindle journals and that the pawls and spindle “ratchet”

when turned within the cam. The pawls and spindle should be lubricated with light machine oil.

10. Lubricate the cam faces and main bearing journals with anti-scuffing paste and insert the cam spindle assembly into the

head ensuring that the nylon thrust bearing is located on the spindle end and within the rear main bearing.

11. Insert the front main bearing into the head with the large chamfer outwards.

12. For TSN 55 and 125 Wrenches. Locate one or two ‘0’ rings on the front bearing chamfer and replace the cover plate and

Spirolox Ring.

For TSN 25 Wrenches Only. Replace the lip seal with the lip uppermost ensuring the seal is located squarely in the bore.

Tap fully home onto abutment washer using suitable tubular drift and replace the Spirolox Ring.

13. Progressively tighten the torque setting adjustment screw, operating the tool several times as torque increases.

The wrench is now ready for use. It is advisable to operate the wrench approximately 100 times at the upper end of its

designed capacity to ensure that new parts “settle in” properly before final calibration is carried out.

Testing & Servicing

In order to maintain accuracy, it is crucial that torque control measuring

equipment be calibrated regularly.

We recommend a general once a year calibration interval. However, it is

the user’s organization that must determine suitable intervals based upon

equipment performance, application, degree of usage and management

objectives.

For calibration, re-adjustment or repairs, please send the tool to one of

our 3 service locations.

Loading...

Loading...