Page 1

Force Test Stands Series

TSF

MODELS TSFM500, TSFM500H, TSF & TSFH

User’s Guide

Page 2

Series TSF

Thanks!

Thank you for purchasing a Mark-10 Series TSF Force Measurement

Test Stand. We are confident that you will get many years of great service from this product.

Mark-10 test stands are ruggedly built for many years of service in laboratory and industrial environments.

This User’s Guide provides unpacking, setup, and operator instructions.

Dimensions and specifications are also provided for each model. For

additional information or answers to your quest ions, please contact us.

Our technical support and engineering teams will be eager to assist you.

Thank you again for your purchase and happy testing!

TABLE OF CONTENTS

LIST OF INCLUDED ITEMS...................................................... 2

UNPACKING AND SETTING UP.............................................. 2

User’s Guide

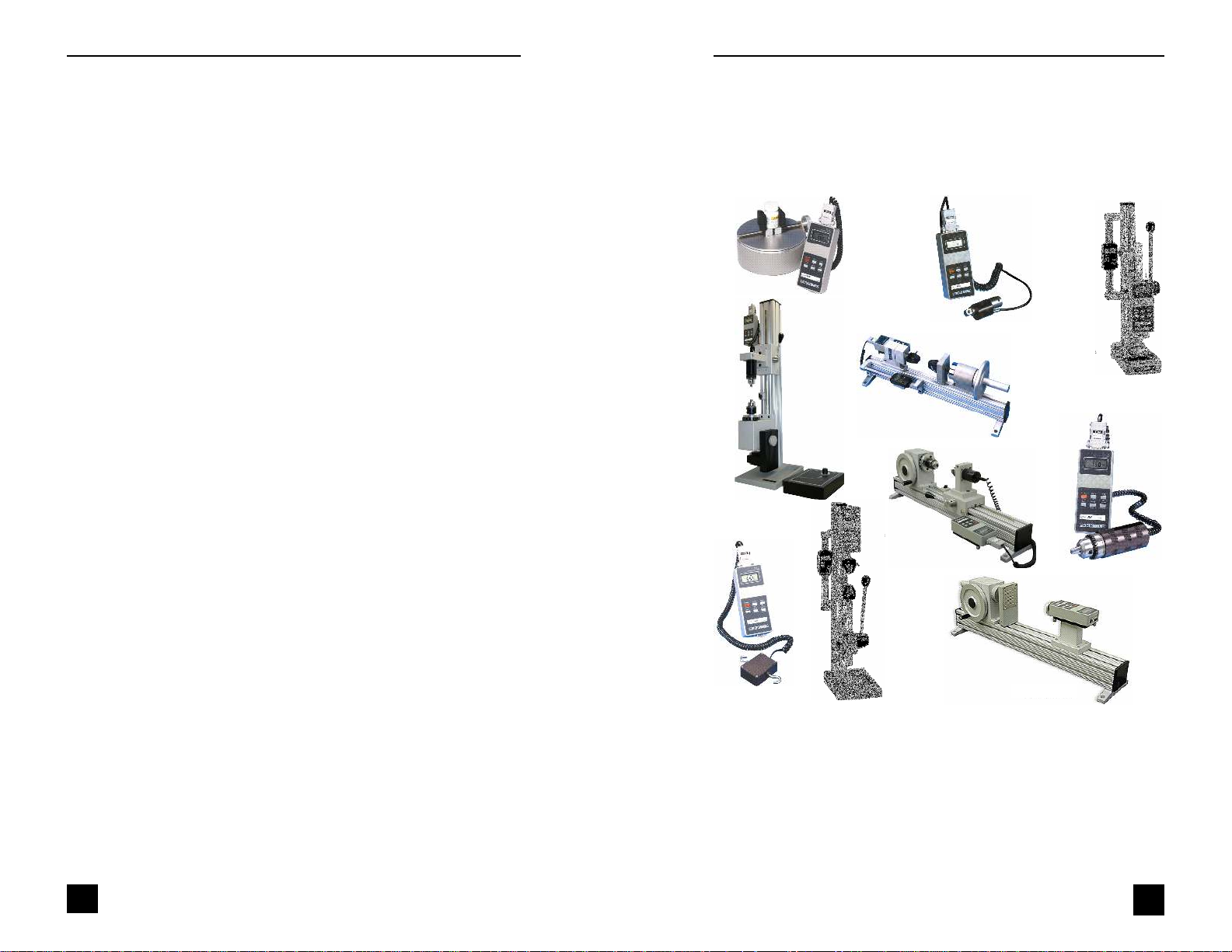

OTHER MARK-10 PRODUCTS

A full line of force and torque measurement products and re-

lated items – force gauges, torque gauges, force and torque

measurement test stands, sensors, grips, systems

MODELS TSFM500 & TSFM500H ........................................... 3

Safety Tips .......................................................................... 3

Setup ................................................................................... 3

Operation ............................................................................ 4

Specifications ...................................................................... 6

Dimensions ......................................................................... 7

MODELS TSF & TSFH ............................................................. 8

Operation ............................................................................ 8

Specifications ...................................................................... 8

Dimensions ......................................................................... 9

OTHER MARK-10 PRODUCTS............................................... 10

WARRANTY............................................................................. 10

1

WARRANTY

Mark-10 Corporation expressly warrants to its buyer for three (3) years from the

date of delivery that the goods sold are free from defects in workmanship and

materials. Mark-10 Corporation will, at its option, repair or replace or refund the

purchase price of goods found to be defective. This remedy shall be the buyer’s

sole and exclusive remedy. Any modification, abuse, exposure to corrosive environment or use other than intended will void this warranty. This warranty is in lieu

of all other warranties, including implied warranties of merchantability and fitness

for an intended purpose. In no event shall Mark-10 Corporation be liable for any

incidental and consequential damages in connection with goods sold or any part

thereof.

10

Page 3

Series TSF

DIMENSIONS

IN [MM]

TSF

]

0

0

8

[

5

.

1

3

TSF / TSFH

)

]

)

4

G

G

]

7

M

3

B

3

(

/

[

4

G

3

7

X

[

.

E

A

4

1

M

4.35 [110]

(

5

.

X

3

1

A

M

0.500 [12.7]

TYP

2.800 [71.1]

5/16-18 UNC-2B

X0.600 DEEP

X4

7.300 [185.4]

BASE PLATE

BOTTOM VIEW

]

5

.

0

9

1

[

0

0

5

.

7

#10-32 UNF-2B

X 0.360 DEEP

X25

0.500 [12.7]

TYP

User’s Guide

LIST OF INCLUDED ITEMS

Item

Force measurement test stand 1 1

User’s guide (this booklet) 1 1

Base 1 Mounting leg - 2

Column cap 1 2

5/16-18 x 1” screw for base installation 4 1/4-20 x 3/4” screw for top cap installation 2 4

Thumb screw for gauge mounting 4 4

Mounting hole drill template 1 Attachment kit – includes three hooks (small, me-

dium, and large), 2” and 3” diameter compression

plates, and two couplers (#10-32 and 5/16-18)

Tool kit

Quantity

TSF /

TSFM500

1 1

1 1

TSFH /

TSFM500H

TSFH

9

10.0 [254]

7.9 [201]

5.00 [127.0]

6.0 [152]

MOUNTING PLATE

TOP VIEW

0.50 [12.7]

TYP

2.80 [71.1]

2.30 [58.4]

9.4 [239]

#10-32 UNF-2B

X 0.36 DEEP

X25

0.50 [12.7]

TYP

2.300 [58.4]

MOUNTING PLATE

TOP VIEW

IN [MM]

Control unit with power cord (TSFM500 and

TSFM500H, only)

1 1

UNPACKING AND SETTING UP

1. Carefully unpack the test stand from the box and inspect for any

damage. Check the contents to ensure that you have received a

test stand complete with all accessories – see the list of included

items above.

2. Remove the foam from the middle portion of the test stand column

and remove the plywood caps by unscrewing the pair of screws at

each end. For models TSF and TSFM500, install the base with four

5/16-18 x 1” screws and the top cap with two 1/4-20 x 3/4” screws.

For models TSFH and TSFM500H, install the two column caps with

two 1/4-20 x 3/4” screws each. Store all packaging materials for

possible future use.

2. Place the stand on a firm, flat and level working surface free from

vibration to ensure accurate readings. It is recommended that the

test stand can be secured to a work bench – see your model’s

“Operation” section for further details.

2

Page 4

Series TSF

User’s Guide

TSFM500 / TSFM500H

SAFETY TIPS

•

Wear eye and face protection when testing. Although the test stand

has relatively slow moving mechanisms, be aware of the dangers

posed by potential energies that can accumulate in the sample

during testing.

•

Keep away from the moving parts of the test stand.

•

Never operate the test stand if there is any visible damage to the

power cord or the control unit. The test stand is powered by

110/220 volts that are present in both the po wer cord and the control unit. Any contact with this high voltage can cause serious injury

or even death.

•

Ensure that the control unit be kept away from water or any other

electrically conductive liquids at all times.

•

Make sure the electrical outlet powering the test stand has local

earth ground (3-hole outlet).

•

Do not remove the cover of the control unit or motor drive unless

instructed to do so by a Mark-10 representative. Always disc onnect

power before removing the cover. Use Mark-10 replacement parts,

only, if any repairs are needed.

SETUP

Place the stand on a clean, flat and level work area that meets the criteria outlined in the work area safety instructions. For accurate readings,

the area should be free of vibrations.

If desired, the stand can be mounted to the work area with two 5/16

screws. Included is a mounting hole drill template for quick setup. Before the stand can be mounted, the belt cover surrounding the fine adjustment knob on the right hand side of the stand has to be removed.

Using a flat screwdriver, loosen the four captive screws and slide off the

cover.

After the two 5/16 screws holding the stand are tight, place the belt

cover back into place. While making sure that there is no contact with

the fine adjustment knob, tighten the screws in the four corners.

TSF / TSFH

OPERATION

1. Mount the test stand to a firm, flat, and level working surface for

maximum safety and accuracy using four 5/16 screws (not included). Use the included mounting hole drill template to accurately

drill the holes. Testing can take place without securing the test stand

in such a manner, however, it is strongly recommended that the

stand be secured, especially for large forces.

2. Install a force gauge onto the gauge plate with four thumb screws.

All Mark-10 force gauges mount directly to the stand without adapters.

3. Install any required attachments, including grips, adapters, and

other materials necessary for your test sample. Make sure these

items are set up in a secure and safe manner.

4. Begin the test by turning the hand wheel clockwise for compression

or counter-clockwise for tension.

The gauge bracket’s height can be adjusted along the column. Loosen

the four screws that secure the bracket to the column, adjust to the

desired height, and retighten the screws.

Note: To maintain smooth operation of the test stand, avoid overloads

and repetitive shock loads.

Optional Equipment

Digital Travel Display Kit

This travel indicator has a 5-digit display (0.0005” [0.01 mm] resolution)

and a computer interface for automated data collection. I f purchased at

the same time as the test stand, no setup is needed. Otherwise, it may

be easily installed by the user.

SPECIFICATIONS

Load capacity 1000 lb [4500 N]

Maximum travel 4” [102 mm]

Travel rate 0.013” [0.34 mm]/rev

Weight (test stand only) TSF: 33 lb [14.5 kg], TSFH: 27 lb [12.3 kg]

3

8

Page 5

Series TSF

User’s Guide

TSFM500 / TSFM500H

DIMENSIONS

TSFM500

L

A

Y

T

I

A

L

G

I

P

D

S

I

L

D

A

L

N

E

O

I

V

T

A

P

R

T

O

]

0

0

8

[

5

.

1

3

TSFM500H

MOUNTING PLATE

TOP VIEW

10.0 [254]

7.9 [201]

0.50 [12.7]

2.80 [71.1]

2.30 [58.4]

TYP

TSFM500 / TSFM500H

5/16-18 UNC-2B

X 0.600 [15.2] DEEP

X4

]

5

.

0

9

1

[

0

5

.

7

)

]

)

4

G

G

]

7

M

3

B

3

(

/

[

4

G

3

5

X

[

.

E

A

4

1

M

(

5

.

X

3

1

A

M

#10-32 UNF-2B

4.35 [110]

9.4 [239]

X 0.36 DEEP

X25

0.50 [12.7]

TYP

3.26 [82.8]

0.500 [12.7]

TYP

2.800 [71.1]

2.300 [58.4]

2.76 [70.1]

7.30 [185.4]

BASE PLATE

BOTTOM VIEW

MOUNTING PLATE

TOP VIEW

#10-32 UNF-2B

X 0.360 DEEP

X25

0.500 [12.7]

TYP

IN [MM]

IN [MM]

With the base removed, the test stand can be easily integrated into

large systems such as production lines. In general, the stand can be

mounted on any angle (upside down, for example), although extra care

should be taken during installation and operat ion.

After the stand is in a stable and secure position, insta ll a force gauge

with four thumb screws (provided). All Mark-10 gauges mount directly

without adapters.

Plug the control unit cable into the 9-pin male connector located above

the motor in the rear of the stand.

Plug the power cord into the remote console and the other end into a

wall outlet.

Turn on the power with the switch located on the control unit beside the

power cord.

The test stand is now ready for operation.

OPERATION

1. Mount the test stand to a firm, flat, and level working surface for

maximum safety and accuracy using four 5/16 screws (not included). Use the included mounting hole drill template to accurately

drill the holes. Testing can take place without securing the test stand

in such a manner, however, it is strongly recommended that the

stand be secured.

2. Install a force gauge onto the gauge plate with four thumb screws.

All Mark-10 force gauges mount directly to the stand without adapters.

3. Install any required attachments, including grips, adapters, and

other materials necessary for your test sample. Make sure these

items are set up in a secure and safe manner.

4. Power on the control unit (further instructions to follow). For fine

adjustment or otherwise manual testing, turn the kno b on the right

hand side of the stand clockwise for compression, counterclockwise

for tension.

7

5.00 [127.0]

6.0 [152]

4

Page 6

Series TSF

User’s Guide

TSFM500 / TSFM500H

The gauge bracket’s height can be adjusted along the column. Loosen

the four screws that secure the bracket to the column, adjust to the

desired height, and retighten the screws.

Note: To maintain smooth operation of the test stand, avoid overloads

and repetitive shock loads.

Optional Equipment

Digital Travel Display Kit

This travel indicator has a 5-digit display (0.0005” [0.01 mm] resolution)

and a computer interface for automated data collection. If purchased at

the same time as the test stand, no setup is needed. Otherwise, it may

be easily installed by the user.

Limit Switches

Adjust the switches’ vertical positions by loosening and re-t ightening

the wing screws. A limit condition is indicated by an amber light on the

front surface of each sensor.

Upper limit switch – while a limit condition exists, the slider will not

move up

Lower limit switch – while a limit condition exists, the slider will not

move down

Using the Control Unit

UP

Press and hold for tension, release button to stop motion. Located on

the face of the Control Unit.

DOWN

Press and hold for compression, release button to stop motion. Located

on the face of the Control Unit.

SPEED CONTROL DIAL

Adjust speed by turning the dial 0.2 – 5.5 in/min [5 – 140 mm/min]. Located on the face of the Control Unit.

POWER SWITCH

Use this switch, in the left rear of the Control Unit, to turn on and turn

off power to the test stand. Power is indicated by an amber light on the

face of the Control Unit.

TSFM500 / TSFM500H

POWER PLUG RECEPTACLE

Located in the left rear of the Control Unit. Plug the power cord in here.

CONTROL CABLE

Plug this cable into the lower male connector on the test stand, adjacent to the motor.

SPECIFICATIONS

Load capacity 500 lbF [2.2 kN]

Speed range 0.2 - 5.5 in/min [5 - 140 mm/min]

Maximum travel 4” [102 mm]

Speed variation with load ±0% (Stepper motor driven)

Speed accuracy ±5% of setting

Power Universal input, 80 - 240 VAC, 50/60 Hz

Fuse type 1.2A, 250V, 3AG SLO BLO

Weight (test stand only)

Control unit weight 2.7 lb [1.2 kg]

TSFM500: 36 lb [16.3 kg]

TSFM500H: 30 lb [13.6 kg]

5

6

Loading...

Loading...