Page 1

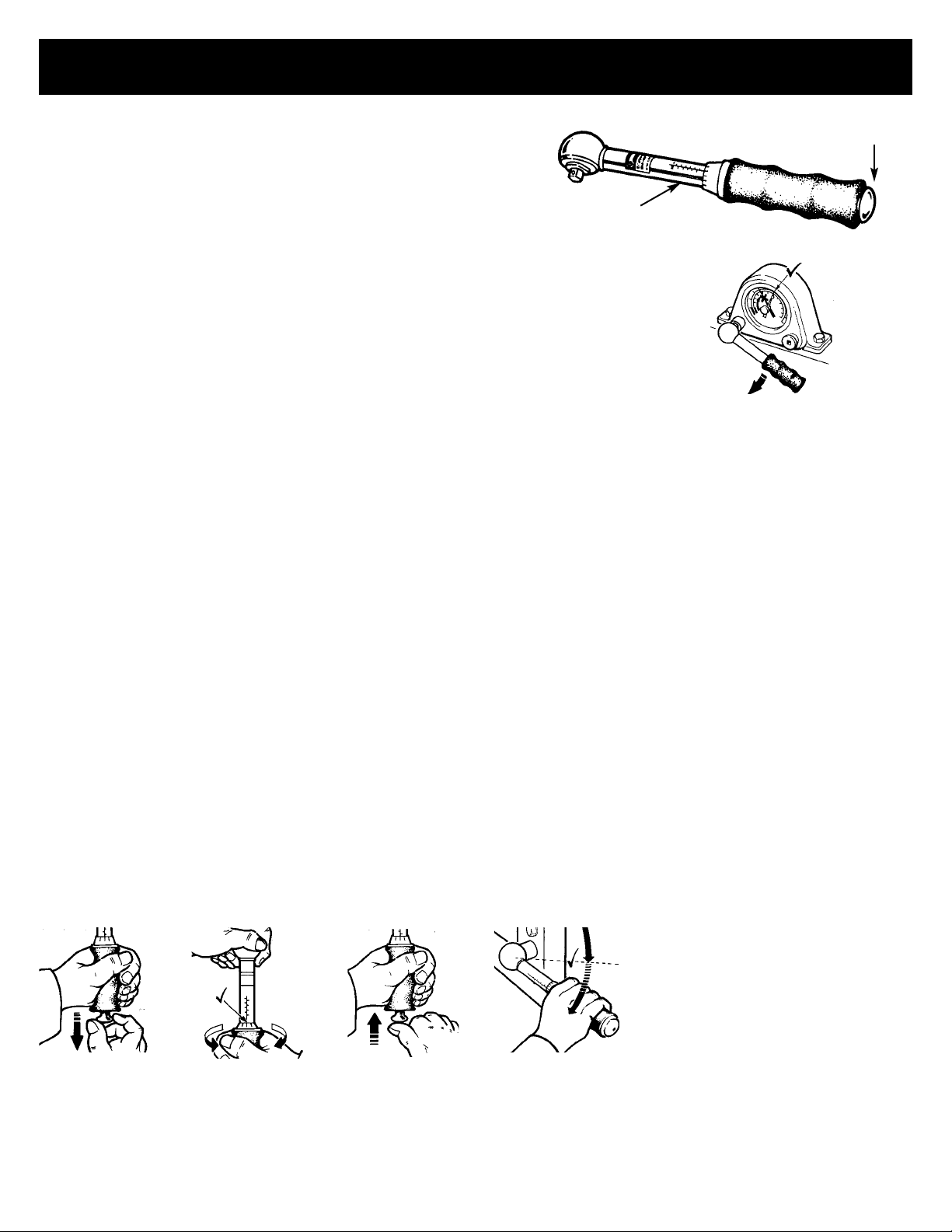

TSC (Cam-Over Wrench) Operating Instructions

Rev 1.0

Calibrating Torque Wrenches

To calibrate torque wrenches either use a torque analyzer or torque

transducer within the range of the torque wrench. For cam-over torque

wrenches calibrate torque in “Peak” mode with an analyzer or

transducer. Make sure to apply the torque slowly and smoothly.

Scale

1. Select a torque analyzer or transducer that covers the torque range

of the TSC wrench. Connect wrench to the torque analyzer or transducer.

2. Using micrometer scale, set wrench to 20% full scale setting. Apply torque CW slowly

until wrench 'slips' and note reading from test device.

3. Repeat step 2 for 60% and 100% tool settings (other test points can be used if desired.)

4. If readings are not within the specification tolerance, then perform calibration adjustments

as described below.

5. Recalibrate torque wrench at prescribed intervals.

Note: Refer to ISO6789 International Standard for more information on hand tool testing

requirements.

Calibration Adjustments

1. Test tool through full range. Make scale adjustments, if required, as described in steps 2 - 5. If wrench is nonlinear, contact

Mountz for technical repair service.

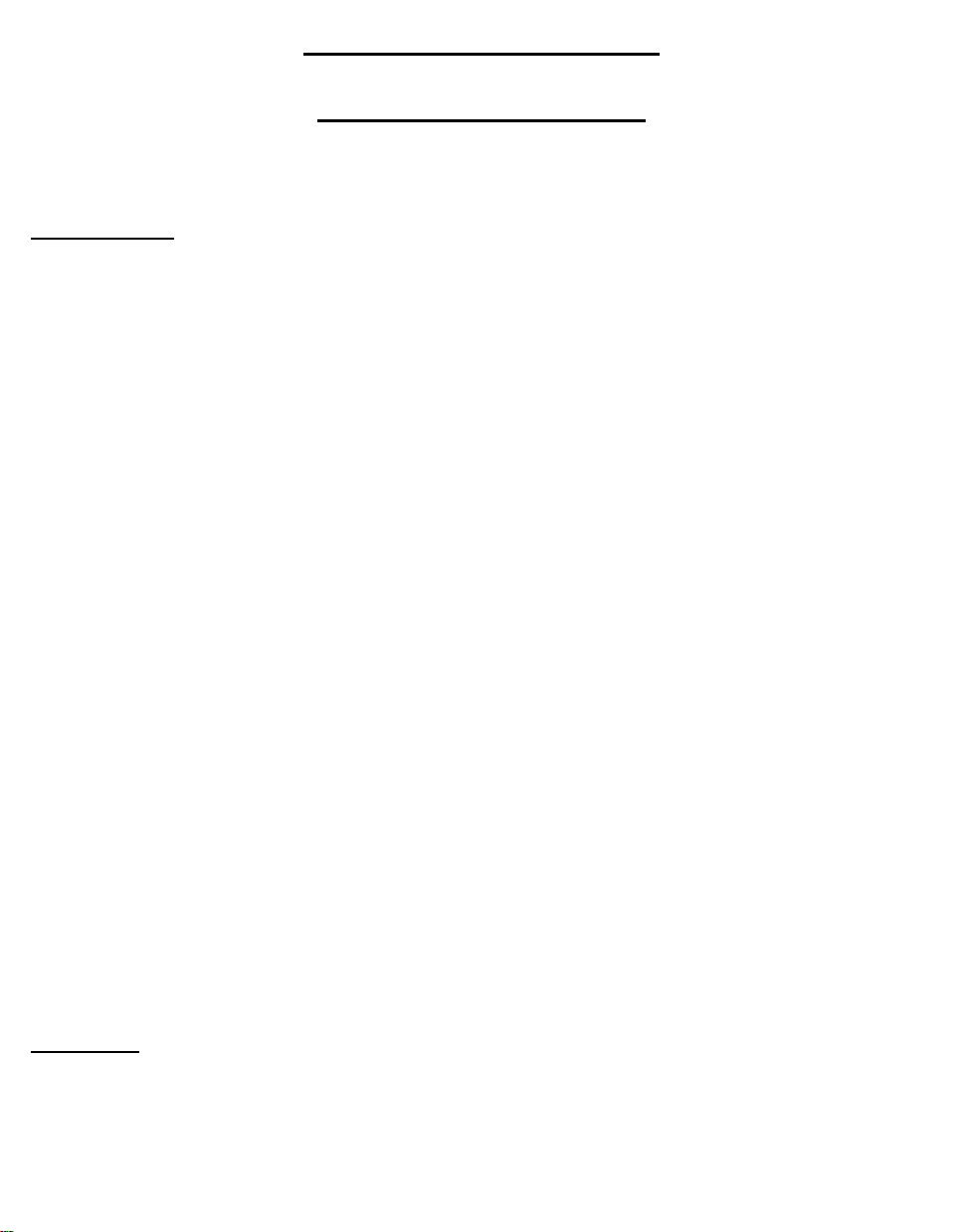

2. Adjust tool to 20% full scale setting. Remove set screw and locking knob at end of handle

3. Peel back rubber grip and loosen 3 set screws to remove handle adjusting sleeve.

4. Turn exposed torque adjustment screw CW to increase torque and CCW to decrease torque to proper setting. Test tool on

torque analyzer to ensure correct adjustment to 20% setting was made. Repeat as necessary.

5. Replace adjusting sleeve onto tool ensuring to align zero micrometer scale. Lock 3 set screws, replace locking knob and

tighten set screw. Replace rubber grip.

Torque Adjustment

Knob

Setting and Applying Torque

1. Set desired torque on the scale. Pull down on the "Adjustment Knob" and turn knob clockwise to increase torque and

counter clockwise to decrease torque on the scale. Align the desired torque value on the micrometer scale. Release

"Adjustment Knob."

2. Tighten nut or bolt by applying steady twists. Wrench should be kept at 90 degrees to axis of bolt during tightening.

When pre-set torque is reached, the wrench will 'slip.'

3. The wrench will automatically reset itself for the next application.

4. With its unique cam-over design, it's impossible to over tighten beyond the preset

load.

Page 2

TSC Wrenches - All Models

Re-calibration Procedure

Test Methods:

As adopted and stipulated by Mountz, and in accordance with ISO 6789 recommendations for

the testing of TSC Wrenches

1. Testing should be done at normal ambient temperature of 20ºC ± 5ºC after a period of

stabilisation and with the tool being maintained within this temperature band throughout the

test.

2. A good quality Electronic Torque Analyser should be used for testing with an accuracy of

±0.25% of reading ±1 LSD (Least Significant Digit).

3. The Transducer should be mounted with its axis in a vertical position.

4. The Torque Analyser should have a “Peak Hold” facility, as it is impossible to read the

maximum torque achieved in “Track Mode”. (It should be remembered that it is impossible

to over-torque with TSC/P’s and similar cam-over mechanism wrenches unlike “Clicker”

wrenches that become solid levers after achieving the pre-set torque value).

5. Under test, the wrench should be operated without pauses to give a slow, consistent and

smooth action.

It should be realised that currently all Electronic Torque Analyser manufacturer’s quoted

accuracies refer to results obtained during Static testing. In practice most torque tool testing

is done Dynamically using Transducers - for which there are no dynamic Calibration

Standards at present.

It is also known that Electronic Torque Analysers with differing sampling/response rates will

provide differing torque readings for the same tool at the same setting!

Procedure:

1. Peel back the rubber hand grip from the end of the tool to reveal the three equally spaced

socket set screws located in the adjusting sleeve.

2. Ensure that the red lock knob is pulled fully out and engage the tool with the test device.

Page 3

3. Disregarding any scale or bezel markings, rotate the adjusting sleeve as required until the

test device displays a reading equal to the first setting on the wrench and at the same time

ensure the lock mechanism has engaged with one of the ten lock positions in the handle

tube. It should be possible to feel and hear this action, which will be confirmed by pushing in

the red knob to lock the tool. Ensure that the tool is operated as slowly as possible during

the test procedure.

4. If, to achieve the correct reading the zero position on the bezel is no longer in alignment with

the centre line of the main scale, unscrew the three socket set screws by two full turns each

and rotate the adjusting sleeve until the zero position is in alignment with the centre line of

the main scale. (A 1.5 mm A/F hex key is required for the screws).

5. Apply a minimal amount of Loctite 222 to the threads of each screw and carefully “nip up”

each of the screws evenly with sufficient torque to enable the tool to be adjusted.

6. Re-test the tool and if satisfactory readings are obtained throughout the range, fully tighten

the socket screws and release the rubber grip to its original position.

7. If, after several attempts, should it be found impossible to obtain satisfactory readings, it is

recommended that the tool be returned to the manufacturers for re-calibration.

Loading...

Loading...