Page 1

16.0 MATERIAL SAFETY DATA

TABLE OF CONTENTS

SECTION 1

PRODUCT IDENTIFICATION

Product Name: SOUNDSAFE®

Generic Name: Ultrasonic Couplant

Manufacturer: Sonotech, Inc.

774 Marine Dr., Bellingham, WA 98225

(360) 671-9121

NFPA Hazardous Materials

Identication System (est)

Health ...............................................................0

Flammability ....................................................0

Reactivity .........................................................0

SECTION 2

HAZARDOUS INGREDIENTS

This material does not contain any ingredients having

known health hazards in concentrations greater than 1%.

This material does not contain any known or suspected

carcinogens.

SECTION 3

PHYSICAL DATA (nominal)

Boiling Point: >220°F pH: 7.35 – 7.9

Freezing Point: <20°F Acoustic Imp.: 1.726x106

Vapor Pressure: N/A Vapor Density: N/A

Evaporation Rate: N/A Specic Gravity: >1.02

Solubility in Water: complete

Appearance and Odor: water white, opaque gel;

bland odor

SECTION 4

FIRE AND EXPLOSION HAZARD DATA

Flash Point: None

Upper Exposure Limit: None

Lower Exposure Limit: None

Special Fire Fighting Procedures: N/A

Extinguishing media: N/A

Unusual Fire and Explosion Hazards: None

SECTION 5 – REACTIVITY DATA

Stability: Stable

Conditions to Avoid: None

Incompatibility (Materials to Avoid): None known

Hazardous Polymerization: Will not occur

Hazardous Decomposition

or Byproducts: None known

SECTION 6

HEALTH HAZARD AND FIRST AID DATA

Routes of Entry: 1

Skin: not likely

Ingestion: not normally

Eyes: not normally

Inhalation: no

Effects of Overexposure:

Acute: May cause temporary eye

irritation

Chronic: none expected

First Aid Procedures:

Skin: Remove with water if

desired.

Eyes: Flush with water for 15

minutes.

Ingestion: For large quantities, induce

vomiting, call a physician.

Inhalation: N/A

SECTION 7

STORAGE AND HANDLING INFORMATION

Precautions to be taken in handling and storage:

Store between 20°F and 120°F.

Spills are slippery and should be cleaned up

immediately.

Steps to be taken in case material is released or spilled:

Pick up excess for disposal. Clean with water.

Waste disposal method: Dispose of in accordance with

federal, state, and local regulations.

SECTION 8

CONTROL MEASURES

Respiratory Protection: Not required

Ventilation: Not required

Protective Gloves: On individuals

demonstrating

sensitivity to

SOUNDSAFE®

Eye Protection: As required by

working conditions

Other Protective Equipment: Not required

SOUNDSAFE® contains only food grade and cosmetic

grade ingredients.

01.0 Introduction ............................................................................................ 04

02.0 Quick Start Guide .................................................................................. 05

2.1 Overview

2.2 Auto Probe Recognition

2.3 Selecting the Transducer Type

2.4 Probe Zero and Calibration

2.5 Zero Coating

2.6 Coating Calibration

2.7 Measure

03.0 Keyboard, Menu and Connector Reference ........................................... 17

3.1 Menu Key

3.2 Probe Menu

3.3 CAL Menu

3.4 DISP (Display) Menu

3.5 TUNE Menu

3.6 GT1 Menu

3.7 GT2 Menu

3.8 GT3 Menu

3.9 SETUP Menu

3.10 DATA Menu

3.11 UTIL (Utilities) Menu

3.12 XFER (Transfer) Menu

3.13 CLR (Clear) Key

3.14 MEAS (Measurement Mode) Key

3.15 OK Key

3.16 ESC Key

3.17 Arrow Keys

3.18 ENTER Key

3.19 MULTI MODE Key

3.20 ON/OFF Key

3.21 Top & Bottom End Caps

04.0 Principles Of Ultrasonic Measurement .................................................. 26

4.1 Time versus Thickness relationshi

4.2 Suitability of Materials

4.3 Range of Measurement and Accuracy

4.4 Coupulant

4.5 Temperature

4.6 Measurement Modes

05.0 Selecting The Measurement Mode ........................................................ 30

5.1 The Setup Library

5.3 Selecting the correct Mode and Transducer

5.3 Factory Setup Chart

– 104 –

– 1 –

– 1 –

Page 2

TABLE OF CONTENTS (continued)

06.0 Making measurements ........................................................................... 33

6.1 Auto Probe Recognition and Selecting the

Transducer Type

6.2 Probe Zero

6.3 Material Calibration

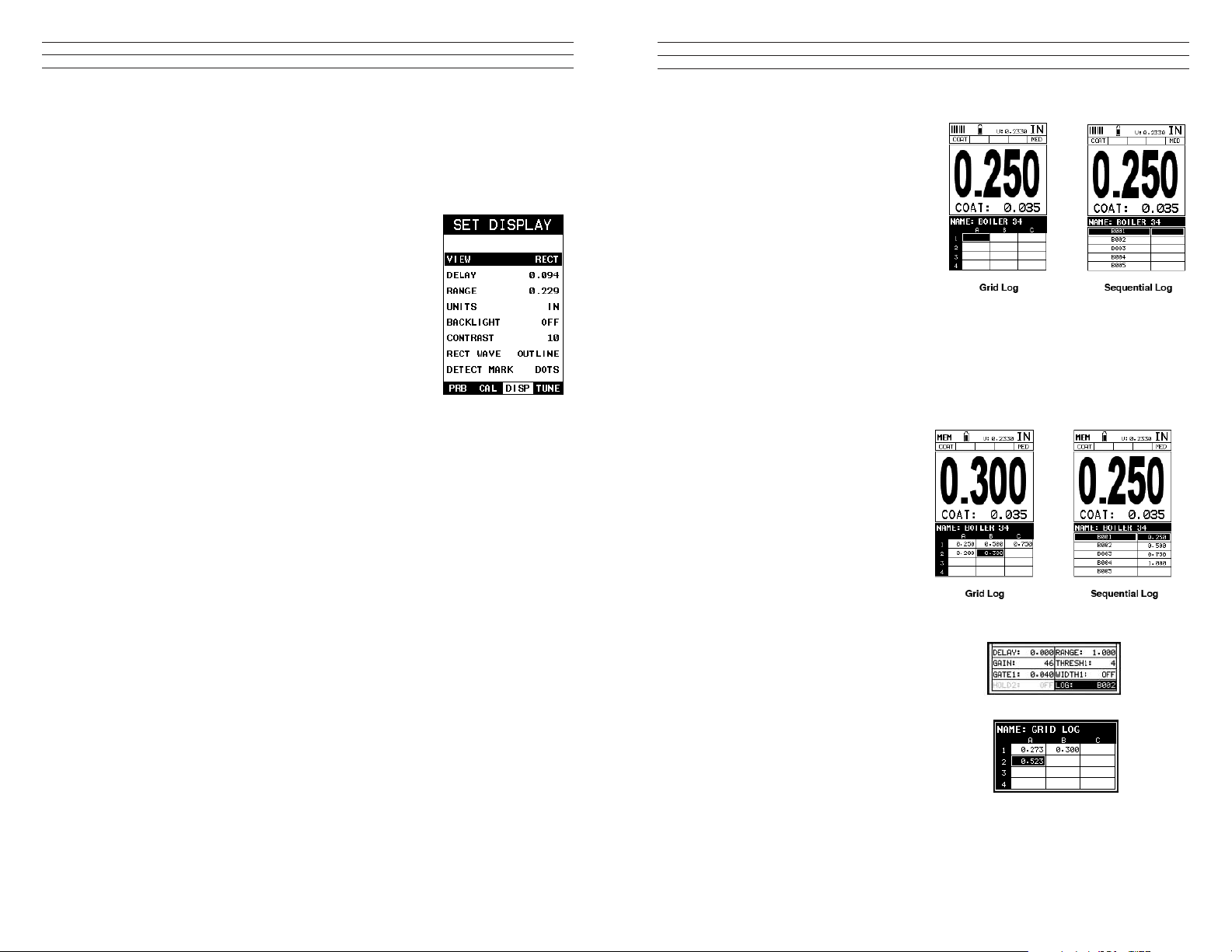

07.0 Using The Display Options .................................................................... 41

7.1 Display Views

7.2 Changing The Display Options

7.3 Adjusting The Display

7.4 Gain

7.5 Threshold

7.6 Understanding the features of the Gate

7.7 Gates

08.0 Thru-Paint Measurement Technique ..................................................... 60

8.1 Introduction to Thru-Paint Measurement

8.2 Using the Paint Mode

09.0 Pulse-Echo Coating And Coating Techniques ....................................... 63

9.1 Introduction to Pulse-Echo Coating Measurement (PECT)

9.2 Enabling Pulse-Echo Coating Mode (PECT) & Coating (CT)

9.3 Zero Coating

9.4 Coating Calibration (PECT)

9.5 Introduction to Coating Measurements (CT)

9.6 Two-Point Coating Calibration (CT)

10.0 Additional features of TI-CMXDLP ..................................................... 71

10.1 Auto Find

10.2 High Speed Scan Mode

10.3 Alarm Mode

10.4 Differential Mode

10.5 Brightness (color version only)

10.6 VIEW (color version only)

10.7 DIM (color version only)

10.8 Damping (color version only)

10.9 Introduction to Flaw Mode

10.10 Graphics Options (look & fee)

10.11 Polarity

10.12 Pulse Width

10.13 Pulse Voltage

10.14 Attunuator

15.0 APPENDIX B – SETUP LIBRARY

Num Name Comment 1 Gn/AGC Velocity

1 Enter Custom Name

2

3

4

5

6

– 2 –

– 103 –

Page 3

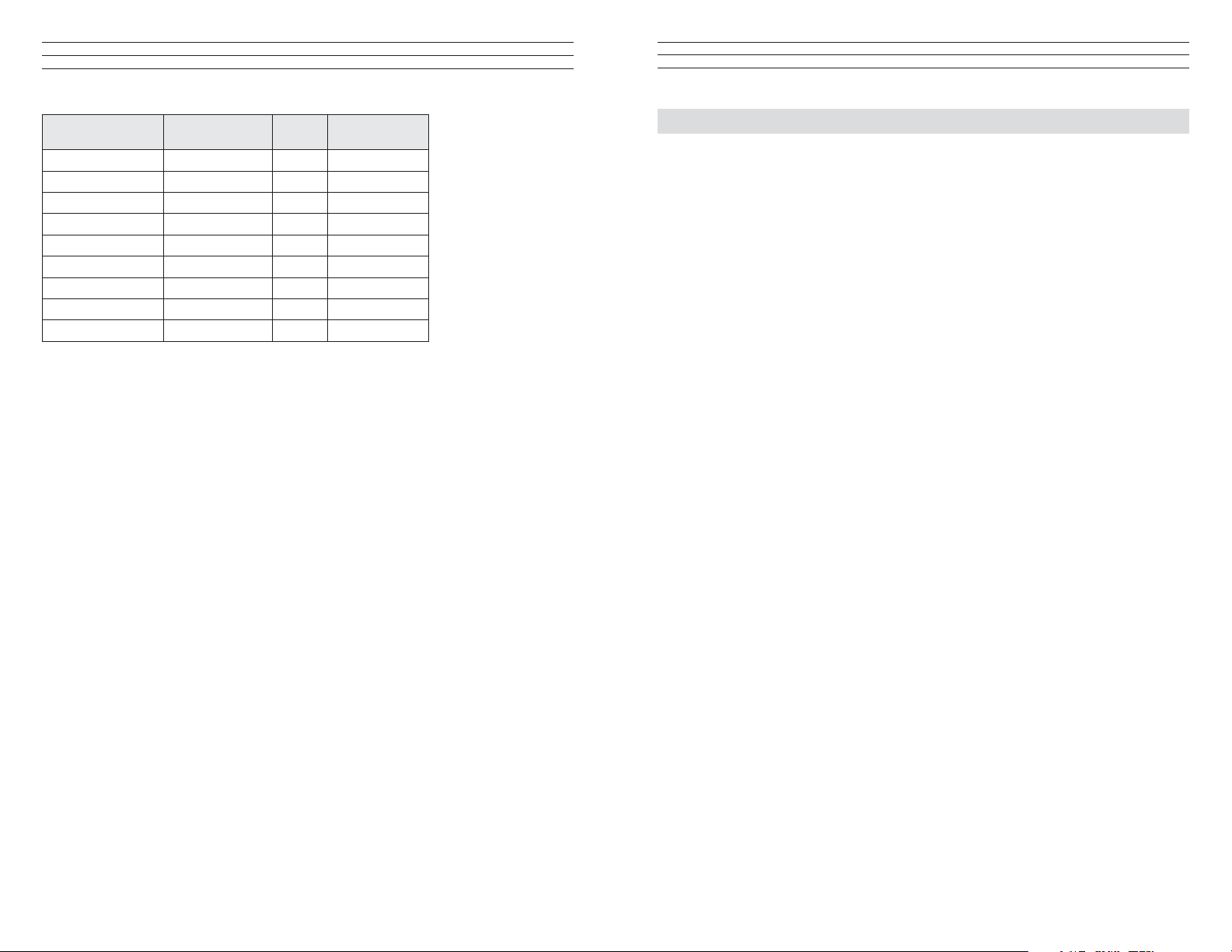

Material Sound Velocity

in/µs

Teon 0.0540 1372

Tin 0.1310 3327

Titanium 0.2400 6096

Tungsten 0.2040 5182

Uranium 0.1330 3378

Water 0.0580 1473

Zinc 0.1660 4216

Zirconium 0.1830 4648

Sound Velocity

m/s

TABLE OF CONTENTS (continued)

11.0 Data Storage: Set-up, edit and view les ............................................... 84

11.1 Introduction to Grid and Sequential File Formats

11.2 Creatinga a New Grid or Sequential Log (File)

11.3 Storing a Reading

11.4 Viewing Stored Readings and A&B Scans

11.5 Deleting Grids (Files)

11.6 Editing a Grid (File)

11.7 Changing the Active File - Open

11.8 Closing An Active File - Close

12.0 Set-Ups: create, store, edit and recall ..................................................... 96

12.1 Introduction to Setusp

12.2 Opening a Setup

12.3 Saving a Setup

12.4 Deleting a Saved Setup

12.5 Using the Default Setup

12.6 Selecting a Languate

13.0 Using The Utility Software .................................................................... 100

13.1 Computer System Requirements

13.2 Installing Datacomm

13.3 Using the XFER Menu (TI-CMXDLP)

14.0 APPENDIX A: Velocity Table ............................................................... 101

15.0 APPENDIX B: Setup Library ................................................................ 103

16.0 Material Safety Data .............................................................................. 104

17.0 Warranty ........................................................................... Inside Back Cover

– 102 –

– 3 –

Page 4

14.0 APPENDIX A – VELOCITY TABLE

1.0 Introduction

Material Sound Velocity

in/µs

Aluminum 0.2510 6375

Beryllium 0.5080 12903

Brass 0.1730 4394

Bronze 0.1390 3531

Cadmium 0.1090 2769

Columbium 0.1940 4928

Cooper 0.1830 4648

Glass (plate) 0.2270 5766

Glycerine 0.0760 1930

Gold 0.1280 3251

Onconel 0.2290 5817

Iron 0.2320 5893

Cast iron 0.1800 approx. 4572

Lead 0.0850 2159

Magnesium 0.2300 5842

Mercyry 0.0570 1448

Molybdenum 0.2460 6248

Monel 0.2110 5359

Nickel 0.2220 5639

Nylon 0.1060 approx 2692

Platinum 0.1560 3962

Plexiglas 0.1060 2692

Polystyrene 0.0920 2337

PVC 0.0940 2388

Quartz glass 0.2260 5740

Rubber vulcanized 0.0910 2311

Silver 0.1420 3607

Steel (1020) 0.2320 5893

Steel (4340) 0.2330 5918

Steel Stainless* 0.2230 5664

Sound Velocity

m/s

The Check•Line model TI-CMXDLP is an ultrasonic thickness gauge that measures

with extreme versatility. It has the ability to measure simultaneously measure coatings

and material thicknesses while maintaining the ability to locate pits, aws and defects

in the material. Based on the same operating principles as SONAR, the TI-CMXDLP is

capable of measuring the thickness of various materials with accuracy as high as ± 0.001

inches, or ± 0.01 millimeters. The principle advantage of ultrasonic measurement over

traditional methods is that ultrasonic measurements can be performed with access to

only one side of the material being measured.

1.1 Disclaimer

Inherent in ultrasonic thickness measurement is the possibility that the instrument will

use the second rather than the rst echo from the back surface of the material being

measured. This may result in a thickness reading that is TWICE what it should be.

Responsibility for proper use of the instrument and recognition of this phenomenon

rest solely with the user of the instrument. Other errors may occur from measuring

coated materials where the coating is insufciently bonded to the material surface.

Irregular and inaccurate readings may result. Again, the user is responsible for

proper use and interpretation of the measurements acquired.

– 101 –

– 4 –

Page 5

13.0 USING THE UTILITY SOFTWARE

2.0 QUICK STARTUP GUIDE

13.1 Computer System Requirements

Datacomm will run on many different operating systems: Windows 98 (1st or

2nd edition), Windows NT 4.0 with Service Pack 5, Windows ME, Windows XP,

Windows2000 Professional, Windows 2000 Server, or Windows 2000 Advanced Server

operating systems running on Intel or AMD hardware. A Pentium 166MHz or faster

processor with at least 32 megabytes of physical RAM is required. You should have

40 megabytes of free disk space before attempting to install Datacomm. Datacomm

requires an available communications port in order to transfer data to and from the

TI-CMXDLP. Datacomm supports COM1, COM2, COM3, and COM4. USB to Serial

Converter. Some newer laptop computers do not have standard serial ports. In this case

it is possible to use a USB to Serial converter. If a serial to USB cable is needed, contact

Electromatic.

13.2 Installing Datacomm

Datacomm comes on a CD-ROM with an automatic installer program. Place the CD

in your computer’s CD tray and close the door. Open the CD-ROM by double clicking

on the My Computer ICON, then double click on the CD. Finally, double click on the

SETUP icon to begin the installation. Refer to the help section in Datacomm software

for the complete operating manual,setup, and operation.

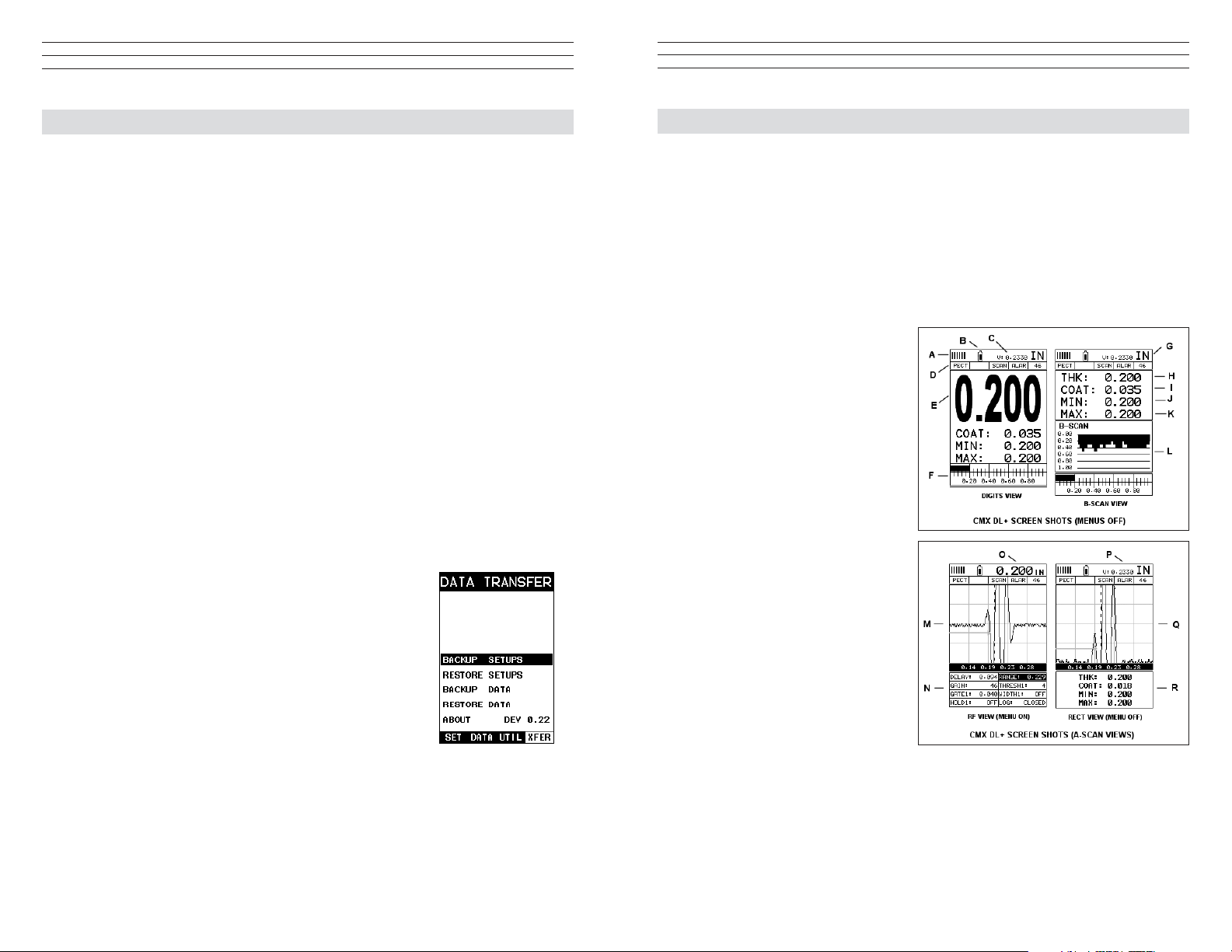

13.3 Using the XFER menu (TI-CMXDLP)

The XFER menu of the TI-CMXDLP will be used in

conjunction with the Datacomm PC software. The steps

below outline the procedure for accessing the XFER menu

and basic operation as follows:

1. Press the MENU key once to activate the menu items

tab. Press the MENU key multiple times to tab right,

and the ESC key multiple times to tab left,until

the XFER menu is highlighted and displaying the

submenu items.

2. Use the UP and DOWN arrow keys to scroll

through the sub menu items until the desire option is

highlighted.

3. Press the ENTER key to activate the option selected.

4. Once the Backup or Restore function has been

completed, press the MEAS key once to return to the

menu items, or twice to return to the measurement

mode.

Turn the TI-CMXDLP on and off using the switch located on the bottom right corner of

the keypad. When TI-CMXDLP is initially turned on, a ash logo and blinking lights

will be displayed, followed by the identity of the transducer (probe) currently plugged

into the gauge. The TI-CMXDLP is equipped with an “Auto Probe Recognition”

feature that attempts to identify special transducers. If the TI-CMXDLP doesn’t nd a

transducer equipped with this feature, the user will be see a list of transducers and will

need to select a specic transducer type. The following sections outline each scenario.

NOTE: This section is primarily written as a basic startup guide only.

2.1 TI-CMXDLP Overview

The TI-CMXDLP has great features

and tools that will be a benet for the

variety of applications you face on

a continual basis. Let’s have a brief

look at the screens you’ll be looking

at most often:

A. Repeatability/Stability

Indicator: This is used in

conjunction with the digital

thickness values displayed.

When all the vertical bars are

fully illuminated and the last digit

on the digital thickness value is

stable, the TI-CMXDLP is

reliably measuring the same

value 3 to 200 times per second,

depending on which

measurement mode and features

are enabled.

B. Battery Icon: Indicates amount

o f battery life remaining.

C. Velocity: The material velocity

value the TI-CMXDLP is

currently using or calibrated for. It can be set to display in English or Metric units.

D. Feature Status Bar: Indicates the features currently enabled and in use

in the following order:

1. Measurement Mode 3. High-Speed Scan Mode 5. Gain Setting

2. Differential Mode 4. Alarm Mode

– 100 –

– 5 –

Page 6

E. Digital Material Thickness Value: Extra large font size for viewing ease.

F. Scan Bar: Another view of material thickness in a deection style horizontal bar.

This visual tool enables the user the ability to see thickness changes during high

speed scans from aws and pits.

G. Units: The current measurement units being used (English, Metric)

H. Digital Material Thickness Value: Smaller font size when the B-Scan display

view is enabled.

I. Coating Thickness Value: Displays the actual thickness of any coating adhered

to a metallic material surface (PECT Mode), or a coating adhered to anon-metallic

surface (CT Mode).

J. Minimum Material Thickness: Part of the Alarm feature. Displays the minimum

thickness value found during a scan.

K. Maximum Material Thickness: Part of the Alarm feature. Displays the maximum

thickness value found during a scan.

L. B-Scan Display: Cross section view of the material. Provides a graphical view

of the opposite/blind surface (i.e. inside pipe wall surface), to give some idea of the

condition, or integrity of the material being tested.

M. RF A-Scan Display: The actual sound wave reection returned from the detection

of the opposite surface of the material being measured. In this view, the entire

sine wave is displayed, showing both the positive and negative half cycles from the

detection/reection. This view is commonly used to “see the big picture” and make

ne adjustments to the scope settings, prior to selecting another view option.

N. Hot Menu items: Items in this menu section are the most commonly adjusted

features. They can be displayed and scrolled by pressing the MEAS key at anytime.

The ESC key is used in conjunction with MEAS key to reverse the direction

scrolled.

O. Reference Note: When the “hot menu” items are displayed/activated, the base

material thickness value shown at reference point “O”. However, when the “hot

menu” items have been deactivated, the current base material velocity value is

displayed, as shown in reference point “P”. When the “hot menus” are deactivated,

the entire “hot menu” section becomes a multiple measurement display area,

allowing the user to simultaneously view: base material, coating,and base material

minimum/maximum thickness values dynamically, as shown in reference point “R”

P. Reference Note: Please refer to “O”, for a detailed explanation.

Q. RECT A-Scan Display: The actual sound wave reection that is returned from the

detection of the opposite surface of the material being measured. In this view, only

half of the sine wave is being displayed (positive or negative). This view is comonly

used as a “aw detection” mode, once the user made all the necessary adjustments

using the RF mode (refer to M).

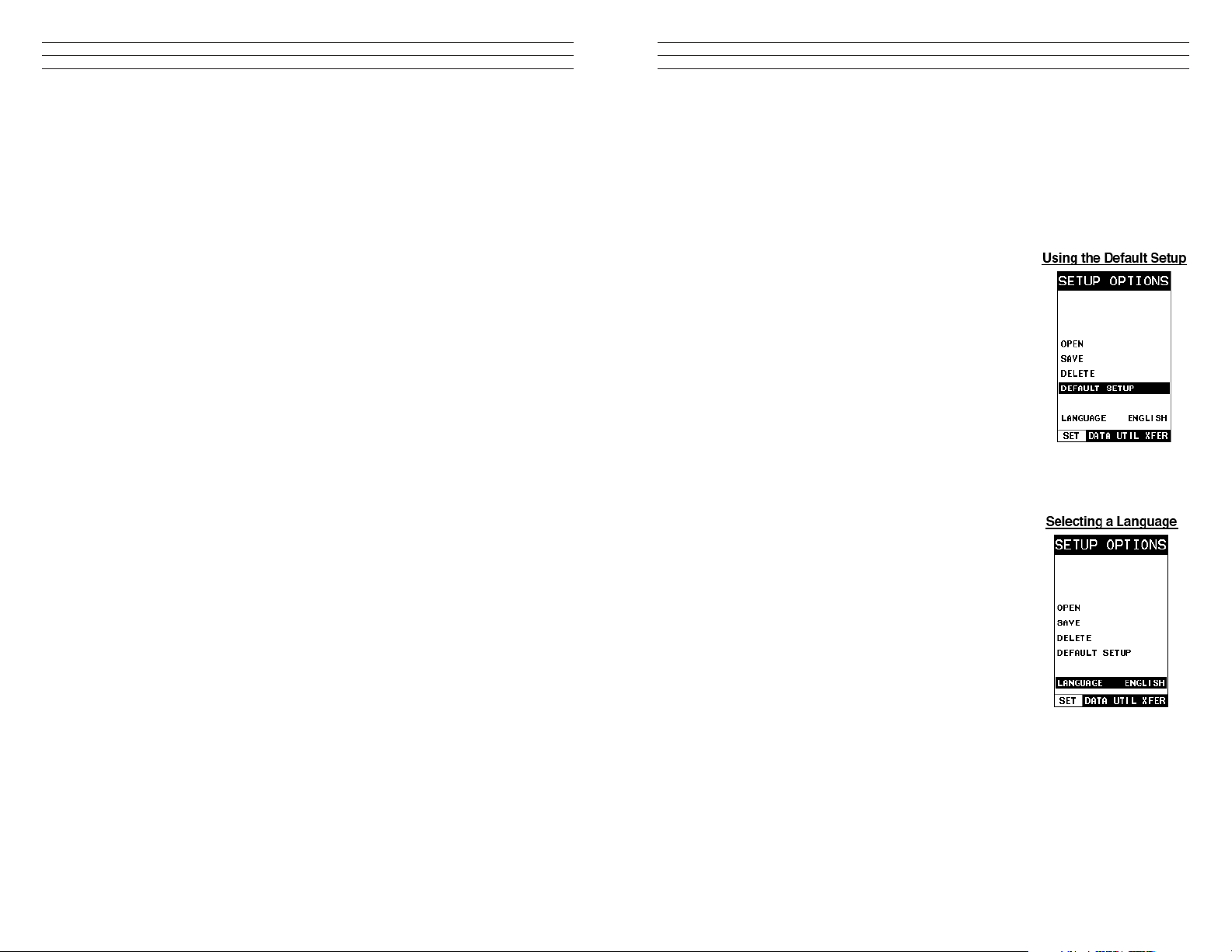

12.5 Using the Default Setup

The default setup feature was added to the TI-CMXDLP to use, as a last resort, if

there are no setups stored in the gauge –factory or otherwise. The only time this might

possibly occur is if the setup le in the TI-CMXDLP was somehow corrupted, and

the user does not have access to a computer to re-load the factory setups back into the

TI-CMXDLP. This gives the user the ability to load and modify a basic setup as follows:

NOTE: The default le contains no probe zero data.

Therefore, a zero must be performed after loading. Also,

the default setup can be loaded when using the aw mode

feature, to eliminate the probe zero delay value, and start

at the initial pulse or zero.

1. Press the MENU key once to activate the menu items

tab. Press the MENU key multiple times to tab right

and the ESC key multiple times to tab left until the

SETUP menu is highlighted and displaying the

submenu items.

2. Use the UP and DOWN arrow keys to scroll through

the sub menu items until DEFAULT SETUP is

highlighted.

12.6 Selecting a Language

The TI-CMXDLP is equipped with a language option.

Currently, the only languages supported are English,

Spanish, and German.

1. Press the MENU key once to activate the menu items

tab. Press the MENU key multiple times to tab right

and the ESC key multiple times to tab left until the

SETUP menu is highlighted and displaying the

submenu items.

2. Use the UP and DOWN arrow keys to scroll through

the sub menu items until LANGUAGE is highlighted.

3. Press the LEFT and RIGHT arrow keys to toggle the

language options.

4. Once the desired language is displayed, press the

MEAS key to return to the measurement screen.

– 6 –

– 99 –

Page 7

7. Press the OK key to return to the Save Setup

Parameters List Box.

8. If both parameters will be edited, repeat steps 4 – 7.

9. Use the UP and DOWN arrow keys to scroll to and

highlight SAVE SETUP.

10. Press the ENTER key to activate the Setup List

Box.11) Use the UP and DOWN arrow keys to scroll

through the setups until the target location to save the

Setup is highlighted.

12. Press the OK key to activate the conrmation screen.

13. Press the OK key to save the Setup, or ESC to cancel

saving the Setup.

14. Finally, press the MEAS key to return to the

measurement screen.

NOTE: The Name and Comments of the Setup can

be edited at any time by simply repeating the Save Setup routine described above.

Therefore, the Save Setup function can also be considered an Edit Function.

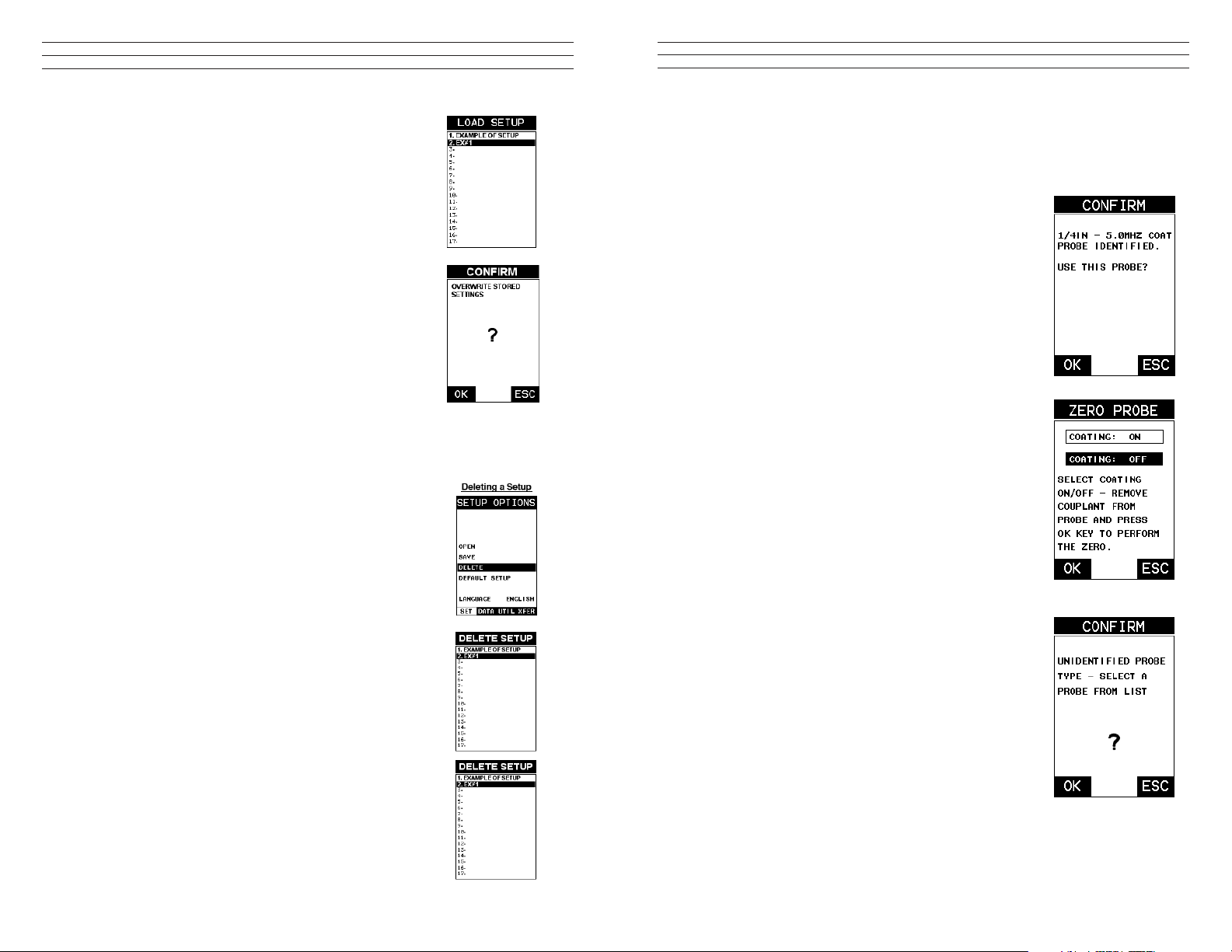

12.4 Deleting a Saved Setup

This option allows a user to delete setup les that were

previously saved and no longer needed. It’s a simple

feature to allow the user to do a bit of “house cleaning”.

1. Press the MENU key once to activate the menu items

tab. Press the MENU key multiple times to tab right

and the ESC key multiple times to tab left until the

SETUP menu is highlighted and displaying the

submenu items.

2. Use the UP and DOWN arrow keys to scroll through

the sub menu items until DELETE is highlighted.

3. Press the ENTER key to display the Setups List.

4. Press the UP and DOWN arrow keys to scroll to the

Setup Name.

5. When the Setup Name is highlighted, press the

ENTER key to display the conrmation screen.

6. Press the OK key to delete the Setup File.

7. Finally, press the MEAS key to return to the

measurement screen.

2.2 Auto Probe Recognition

When the TI-CMXDLP is initially powered up, the gauge will automatically check to

see if the transducer plugged into the gauge can be recognized. The steps that follow

assume the TI-CMXDLP recognized the probe type:

1. Press the OK key once to use the identied probe,

or ESC to display a list of optional transducers.

NOTE: If the TI-CMXDLP recognizes a specic transducer,

the user should always select OK to use the identied probe.

The only time an alternative probe should be selected from a

list is if the user switched probes following initial power up

and recognition

2. Assuming the TI-CMXDLP recognized the probe and

the OK key was pressed, the TI-CMXDLP will advance

to a Zero Probe menu. If the transducer was identied

as a special transducer capable of measuring coating

thickness, a menu will be displayed giving the user the

ability to toggle the coating thickness display on/off as

follows:

3. Press the UP and DOWN arrow keys to toggle the

coating option on/off.

4. Wipe all couplant from the transducer face and advance

to the Probe Zero & Calibration section.

2.3 Selecting the Transducer Type

If the TI-CMXDLP does not identify a specic transducer

type on initial power up, the user will be required to select

a type from a predened list of types by diameter and

frequency. By selecting a transducer type from a predened

list, the TI-CMXDLP can recall specic properties about the

transducer.

NOTE: Once the transducer has been selected, the

TI-CMXDLP will store and recall this transducer type every

time the TI-CMXDLP is powered on/off. The type will only

change if the user physically selects another transducer type

from the list, or selects a previously saved setup. However,

the TI-CMXDLP will continue to take you through these

steps each time the gauge is powered up. You’ll notice that

the probe type previously selected will be highlighted every

time the probe type screen is displayed. Use the following

steps to select your transducer type:

– 98 –

– 7 –

Page 8

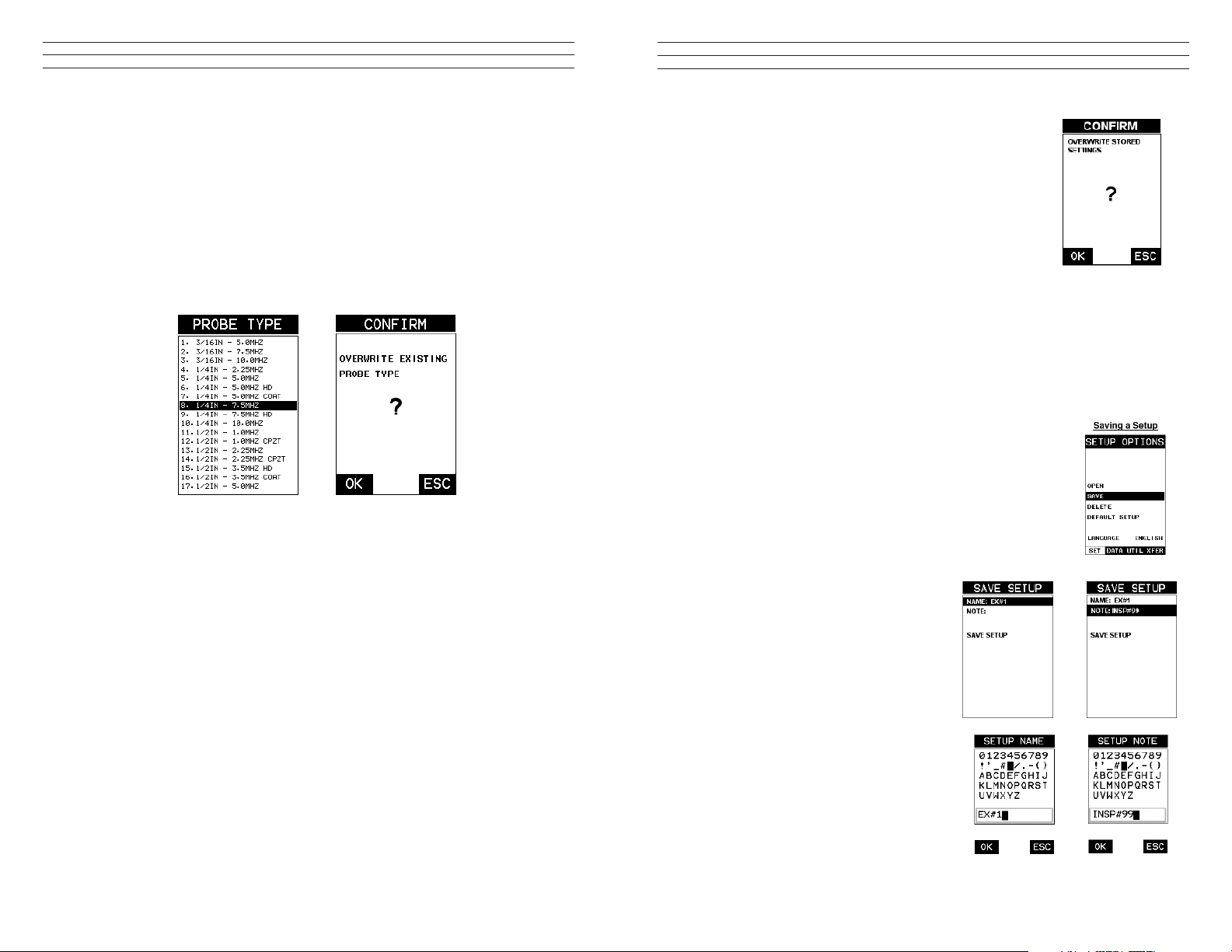

1. Press the OK or ESC keys to display the factory list of transducer types

(by diameter and frequency).

2. Press the UP and DOWN arrow keys to scroll through the transducer list until the

appropriate type is highlighted.

3. Press the ENTER key to select the transducer type and display overwrite existing

probe screen.

4. Press the OK key to overwrite the existing probe type with the newly selected probe

type. The zero probe screen will be displayed. Proceed to the zero probe section that

follows.

2.4 Probe Zero & Calibration

The next steps are to perform a probe zero and calibrate the TI-CMXDLP to the material

and transducer being used. If the sound velocity is unknown, the TI-CMXDLP can be

calibrated to a known thickness sample. This demo will briey explain both of the set

techniques. The TI-CMXDLP is equipped with two zero options:

1. Off Block Zero (Automatic Probe Zero): When this feature is enabled the

TI-CMXDLP will do an electronic zero automatically, eliminating the need for a

zero disk or block.

2. On Block Zero (Manual Probe Zero): When this feature is enabled the transducer

must be placed on the Probe Zero Disk (battery cover located on the top of the unit.

NOTE: Transducers of the same type will have very slight mechanical and electrical

variations. If it’s discovered that the linearity is off following an initial auto probe

zero and extreme accuracy is required, a manual zero should be performed followed

by an auto zero. This will adjust and eliminate any error. This is only required if

it’s discovered the transducer is non-linear following an initial auto probe zero. The

procedures are outlined as follows:

4. Use the UP and DOWN arrow keys to scroll through

the setups until the target setup is highlighted.

5. Press the ENTER key to activate the conrmation

screen.

6. Press the OK key to load the setup from memory.

7. Press the MEAS key to return to the measure screen.1

12.3 Saving a Setup

Once the TI-CMXDLP parameters and features have be adjusted for an application,

the user may elect to save these setting to a specic setup location for future use. This

can potentially save time and reduce error between users. It is sometimes necessary to

rename a previously saved setup, or add additional comments about a particular setup.

The setup name may have been entered incorrectly, or the user needs to use the setup for

a completely different project. An inspector’s name or other comments about the project

may also be required for additional documentation purposes. The following procedures

outline the necessary steps for saving and editing a setup:

1. Press the MENU key once to activate the menu items tab.

Press the MENU key multiple times to tab right and the

ESC key multiple times to tab left until the SETUP menu

is highlighted and displaying the submenu items.

2. Use the UP and DOWN arrow keys to scroll through the

sub menu items until SAVE is highlighted.

3. Press the ENTER key to display the

Save Setup Parameters List Box.

4. Press the UP and DOWN arrow keys to

scroll the Name and Note parameters.

5. When the parameter to edit is

highlighted, press the ENTER key to

activate the Alpha Edit Box.

6. Use the UP, DOWN, LEFT, and

RIGHT arrow keys to scroll through

the characters, the ENTER key to

select characters, and the CLR key to

backspace through the characters, until

the Name or Note elds have been

edited.

– 8 –

– 97 –

Page 9

12.0 SETUPS – CREATE, STORE, EDIT, & RECALL

12.1 Introduction to Setups

Often times, users are faced with a variety of tasks and applications that are sometimes

similar, but often times very different. With a standard thickness gauge,the user would

have to recalibrate for each individual application respectively. With all the features of

the TI-CMXDLP, the number of potential applications also increases based on ability

alone. This is primarily in reference to the addition of those very difcult applications,

where a standard thickness gauge would not be feasible, or capable of accomplishing

the tasks. The increased number of features and parameters also adds to the overall

setup time, or amount of time to set up marginal applications with perfection and

understanding. Because of the additional time involved, the TI-CMXDLP has been

equipped with the ability to save these setups to memory and be recalled at any time.

The TI-CMXDLP can store up to 64 custom setups. These setups can be bidirectionally

transferred to and from a PC. Therefore, the user can save as many setups as necessary

for all their individual applications requirements. This saves a great deal of time and

knowledge for future inspections of the same job or project. This feature also eliminates

error between two or more users during the setup and calibration process.

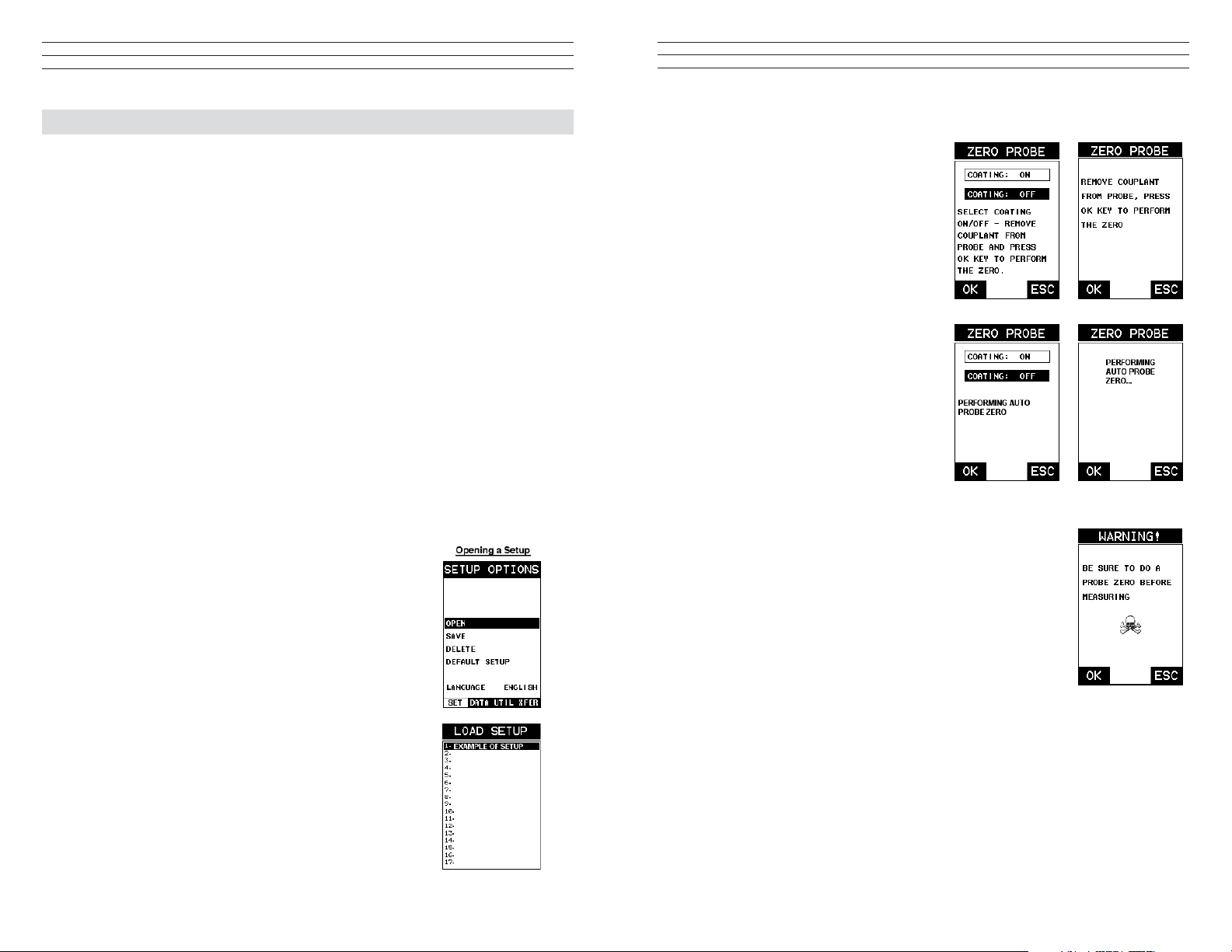

12.2 Opening a Setup

The TI-CMXDLP is loaded with a number of setups from the factory. These setups

can be opened, edited, and saved to any one of 64 setup locations. If a factory setup

is written over, the user can simply reload the default factory setups at anytime using

the utility software included with the TI-CMXDLP. The

factory setups are general setups Only. However, they

may serve as an excellent starting point, requiring only

minor adjustments to work for custom applications. It

is recommended that user customized setups be saved

to an empty location, and save the factory setups for

the purpose of a general starting point. The following

procedures outline how to open factory and custom

setups:

1. Press the MENU key once to activate the menu

items tab. Press the MENU key multiple times to tab

right and the ESC key multiple times to tab left until

the SETUP menu is highlighted and displaying the

submenu items.

2. Use the UP and DOWN arrow keys to scroll through

the sub menu items until OPEN is highlighted.

3. Press the ENTER key to display the Setup List Box.

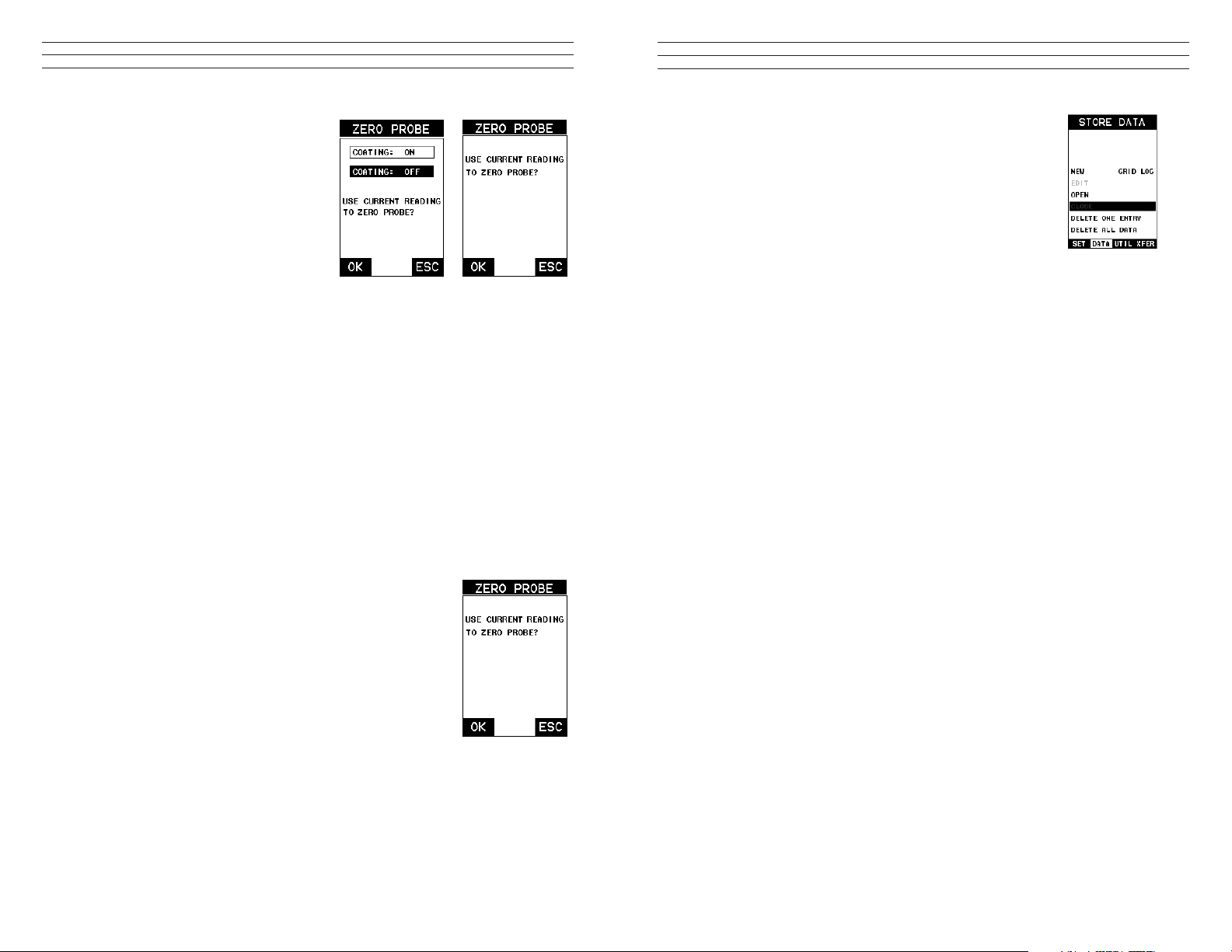

Performing An Auto Zero (Off Block)

1. Be sure all couplant has been removed

from the face of the transducer.

2. Press the OK key to perform the

automatic probe zero, or ESC key

to cancel the zero operation.

3. The screens illustrated will be

briey displayed followed by the

main measurement screen. The

TI-CMXDLP is ready to be calibrated.

Performing a Manual Probe Zero (On Block)

NOTE: When the zero probe option is set to manual, the Probe

Zero Disk (battery cap) located on the top of the gauge, will be

used as a zero standard and the warning screen illustrated above

will be displayed.

1. Press the OK or ESC keys to enter the main measurement

screen and begin the manual zero process.

2. Apply a drop of couplant on the transducer and place the

transducer in steady contact with the Probe Zero Disk, and

obtain a steady reading.

3. Press the MENU key once to activate the menu items tab. Press the MENU key

multiple times to tab right and the ESC key multiple times to tab left until the

PRB menu is highlighted and displaying the submenu items.

4. Press the UP and DOWN arrow keys to scroll through the sub menu items until

ZERO PROBE is highlighted.

–96 –

– 9 –

Page 10

5. Press the ENTER key to display the

conrmation screen.

6. If a coating transducer was identied

use the UP and DOWN arrow keys to

toggle coating on/off.

7. Press the OK key to complete the

probe zero function, or ESC key to

cancel the Probe Zero function.

8. Remove the transducer from the Probe

Zero Disk, and proceed to the calibration section.

NOTE: The value that is displayed will change depending on the current velocity setting

in the TI-CMXDLP. Disregard the number that is displayed. It is not important. What is

important is accurately performing the steps outlined above to insure reliability of the

probe zero calculation.

One Point Material Calibration

For the purposes of this quick start section, we’ll only be covering the most common

one point calibration option to determine the sound velocity of the test material. It

would be very handy to carry a set of mechanical calipers to use in conjunction with the

TI-CMXDLP for calibration in the eld.

Using a Known Thickness

NOTE: Be sure that the probe zero procedure has been performed prior to performing

this calibration procedure.

1. Physically measure an exact sample of the material or a

location directly on the material to be measured using a set

of calipers or a digital micrometer.

2. Apply a drop of couplant on the transducer and place the

transducer in steady contact with the sample or actual

test material. Be sure that the reading is stable and the

repeatability indicator, in the top left corner of the display, is

fully lit and stable. Press the MENU key once to activate the

menu items tab. Press the MENU key multiple times to tab

right and the ESC key multiple times to tab left until the CAL menu is highlighted

and displaying the submenu items.

3. Use the UP and DOWN arrow keys to scroll through the sub menu items until

MATL 1PT is highlighted.

2. Use the UP and DOWN arrow keys to scroll through

the sub menu items until CLOSE is highlighted.

3. Press the ENTER key to close the active le.

NOTE: Following the keypress, the CLOSE text will

be grayed out indicating the le has been close and is no

longer active.

– 10 –

– 95 –

Page 11

11.7 Changing the Active File - Open

The user may have transferred grid/

seq templates from a PC to the

TI-CMXDLP, or setup grids/seq using

the TI-CMXDLP at an earlier time.

The name of the currently active le is

always displayed at the top of the Grid/

Seq Box in measurement mode (refer to

photo below). It’s not only important to

recognize what le is currently active,

but also be able to change the active le

at any time. The following procedures

outline this process:

1. Press the MENU key once to activate the menu

items tab. Press the MENU key multiple times

to tab right and the ESC key multiple times to

tab left until the DATA menu is highlighted and

displaying the submenu items.

2. Use the UP and DOWN arrow keys to scroll through

the sub menu items until OPEN is highlighted.

3. Press the ENTER key to display the Grid/Seq List

Box.

4. Use the UP and DOWN arrow keys to scroll through

the grids until the target grid is highlighted.

5. Press the ENTER key to activate the conrmation

screen.

6. Press the OK key to load the le from memory.

7. Press the MEAS key to return to the measure screen.

11.8 Closing an active File - Close

A user might not have a current requirement to store

measurements, but a le is currently open or active and

needs to be closed. The following procedures outline how

to close an open or active le :

1. Press the MENU key once to activate the menu items

tab. Press the MENU key multiple times to tab right

and the ESC key multiple times to tab left until

the DATA menu is highlighted and displaying the

submenu items.

2.5 Zero Coating

In order to account for very slight electronic differences in transducers of the same type,

frequency, and diameter, the TI-CMXDLP has been equipped with a “zero coating”

feature. This enables the TI-CMXDLP to obtain very accurate readings on coatings,

eliminating potential errors incurred from slight differences in the manufacturing

processes. The procedure is outlined below:

Performing A Coating Zero

1. Press the MULTI MODE key once to activate the

measurement mode options.

2. Use the UP and DOWN arrow keys to scroll through

the sub menu items until Coating Only (CT) mode is

highlighted.

3. Press the ENTER key to select the measurement mode

and return to the measurement screen.

4. Apply a drop of couplant on the transducer and place the

transducer in steady contact with the Probe Zero Disk

(battery cover) and obtain a steady reading.

NOTE: The coating measurement displayed will potentially

be a value greater or less than 0.

5. Press the MENU key once to activate the menu items tab.

Press the MENU key multiple times to tab right and the

ESC key multiple times to tab left until the PRB menu is

highlighted and displaying the submenu items.

6. Use the UP and DOWN arrow keys to scroll through the

sub menu items until ZERO COATING is highlighted.

7. Press the ENTER key to display the conrmation screen.

8. Press the OK key to zero the coating and return to the

PRB menu, or ESC to cancel the coating zero process.

9. Press the MULTI MODE key once to activate the

measurement mode options.

10. Use the UP and DOWN arrow keys to scroll through the

sub menu items until Coating On (PECT) is highlighted

11. Press the ENTER key to select the measurement mode

and return to the measurement screen, and begin taking

readings.

–94 –

– 11 –

Page 12

2.6 Coating Calibration

The TI-CMXDLP has been preset to a default coating velocity of 0.0850 in/sec

(2159m/sec). This will be very close to the most common coating material velocities

used in the eld. If the velocity of the coating is known, and different than the above

default setting, the user can simply enter the coating velocity into the TI-CMXDLP.

However, if the velocity is unknown, the TI-CMXDLP can also be calibrated to a

specic coating sample/type using the 1pt calibration option in PECT (pulse-echo

coating)mode, or a two point calibration is CT (coating only) mode. For the purpose

of this quick start section only the 1pt option PECT (pulse-echo coating) mode will

be covered. Refer to the calibration section of the manual for a complete explanation

on the coating calibration options. The following steps below outline the necessary

steps to either set the velocity of the coating, or perform a one point calibration to

calculate the coating velocity:

Known Coating Velocity

If the coating velocity is known, the user may wish to

simply enter the velocity number into the TI-CMXDLP,

rather than have the TI-CMXDLP calculate the velocity

value using a known thickness on a coating sample. The

steps for entering the velocity are outlined below:

1. Press the MENU key once to activate the menu items

tab. Press the MENU key multiple times to tab right and

the ESC key multiple times to tab left until the CAL

menu is highlighted and displaying the submenu items.

2. Use the UP and DOWN arrow keys to scroll through

the sub menu items until COATING VEL is highlighted.

3. Press the ENTER key to display the Digits Edit Box.

4. Press the UP and DOWN arrow keys to scroll the

highlighted value.

5. Press the LEFT and RIGHT arrow keys to scroll the

digit locations.

6. Repeat steps 4 & 5 until the velocity number is correctly

displayed.

7. Press the OK key to set the coating velocity and return

to the menu screen,or ESC to cancel entering the

coating velocity.

8. Finally, press the MEAS key to return to the

measurement screen and begin taking readings.

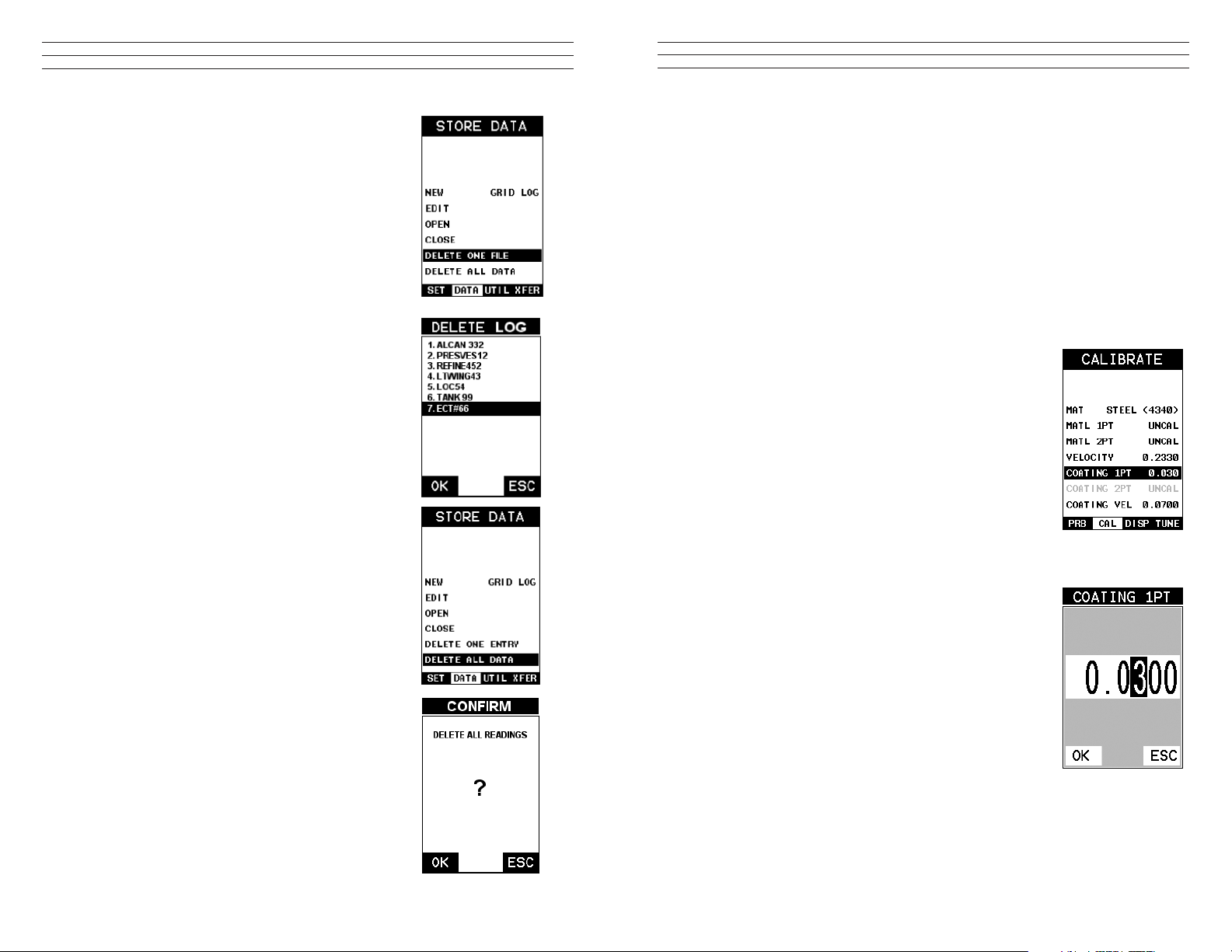

4. Press the OK key to delete All Files from memory, or the ESC key to abort.

5. Press the MEAS key to return to the measurement screen.

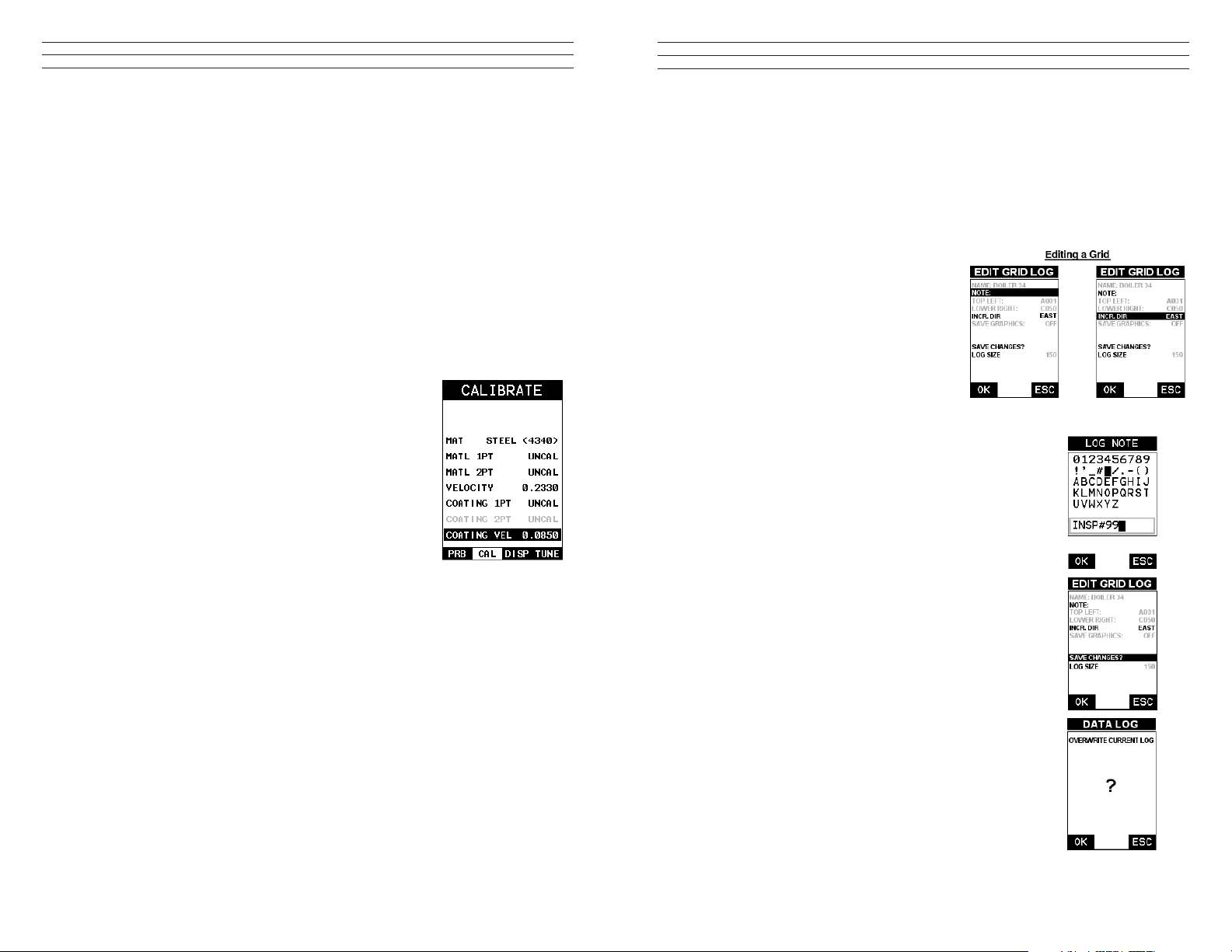

11.6 Editing a Grid (File)

Once a grid has been created and saved to memory, the user can edit the Comments or

Increment Direction at a later time. The following procedures outline this process

1. Press the MENU key once to activate

the menu items tab. Press the MENU

key multiple times to tab right and the

ESC key multiple times to tab left until

the DATA menu is highlighted and

displaying the submenu items.

2. Use the UP and DOWN arrow keys to

scroll through the sub menu items until

EDIT is highlighted.

3. Press the ENTER key to display the Edit List Box.

4. Use the UP and DOWN arrow keys to scroll through

the Edit options until NOTE or INCR. DIR is

highlighted.

NOTE: If editing the INCR. DIR, simply use the LEFT

or RIGHT arrow keys to scroll NONE, NORTH, EAST,

SOUTH, WEST for a Grid, or INC, DEC for a SeqLog.

Proceed to step 10.

5. Press the ENTER key to activate the Alpha Edit box –

Only used when editing the NOTE.

6. Use the UP, DOWN, LEFT, & RIGHT arrow keys to

highlight the appropriate alpha characters.

7. Press the ENTER key to select a character and

advance to the next eld of the Comments.

8. Use the CLR key to backspace if necessary.

9. Repeat steps 6 - 8 until the Comments are completed

10. Press the UP or DOWN arrow key to highlight

SAVE CHANGES, and the OK key to activate the

conrmation screen.

11. Press the OK key to save the changes or the ESC key

to cancel editing the le parameters.

12. Press the MEAS key to return to the measurement screen.

– 12 –

– 93 –

Page 13

4. The user may opt to clear a specic reading

and save a new one at anytime. Press the CLR

key in the appropriate cell location to clear the

reading,take a new measurement, and press the

ENTER key to save the new reading.

5. Abort the Grid/Seq Log View Box by pressing

the MEAS key at any time.

11.5 Deleting Grids (Files)

Deleting One File

1. Press the MENU key once to activate the menu

items tab. Press the MENU key multiple times

to tab right and the ESC key multiple times to

tab left until the DATA menu is highlighted and

displaying the submenu items.

2. Use the UP and DOWN arrow keys to scroll

through the sub menu items until DELETE ONE

FILE is highlighted.

3. Press the ENTER key to display the File List

Box.

4. Use the UP and DOWN arrow keys to scroll

through the stored Files until the target File to

delete is highlighted.

5. Press the OK key to delete the File.

6. Press the MEAS key to return to the

measurement screen.

Deleting All Data

1. Press the MENU key once to activate the menu

items tab. Press the MENU key multiple times

to tab right and the ESC key multiple times to

tab left until the DATA menu is highlighted and

displaying the submenu items.

2. Use the UP and DOWN arrow keys to scroll

through the sub menu items until DELETE ALL

DATA is highlighted.

3. Press the ENTER key to activate the

conrmation screen.

Known Coating Thickness

When the exact velocity of a coating is unknown, the user has the option of performing

a one point calibration on a sample of the coating with a known thickness to determine

the sound velocity. It would be very handy to carry a set of mechanical calipers to use in

conjunction with the TI-CMXDLP for calibration in the eld:

1. Physically measure a location on a coating sample using a set of calipers or a digital

micrometer.

IMPORTANT NOTE: In PECT (pulse-echo coating) mode, the coating sample must be

coupled to metal in order to calibrate successfully. Simply place a drop of couplant on

a piece of metal, lay the coating sample over the couplant on the metal and proceed to

step 2.

2. Apply a drop of couplant on the transducer and place the

transducer in steady contact with the coating (on metal)

sample or actual test material. Be sure that the reading is

stable and the repeatability indicator, in the top left corner

of the display, is fully lit and stable. Press the MENU

key once to activate the menu items tab. Press the MENU

key multiple times to tab right and the ESC key multiple

times to tab left until the CAL menu is highlighted and

displaying the submenu items.

3. Use the UP and DOWN arrow keys to scroll through the

sub menu items until COATING 1PT is highlighted.

4. Press the ENTER key to display the Digits Edit Box.

5. Press the UP and DOWN arrow keys to scroll the

highlighted value.

6. Press the LEFT and RIGHT arrow keys to scroll the digit

locations.

7. Repeat steps 5 & 6 until the known thickness value is

correctly displayed.

8. Press the OK key to calculate the coating velocity and

return to the menu screen, or ESC to cancel the one point

calibration.

9. Finally, press the MEAS key to return to the measurement

screen and begin taking readings.

NOTE: CHECK YOUR CALIBRATION! Place the transducer back on the calibration

point. The coating thickness reading should now match the known coating thickness

sample. If the thickness is not correct, repeat the steps above.

– 92 –

– 13 –

Page 14

2.7 Measure

The TI-CMXDLP is now ready to measure. There are four different measurement view

options, each with a specic purpose – Digits, RF, RECT, & B-Scan. The below outline

how to toggle between the different view mode options:

Selecting the Measurement View Option

1. Press the MENU key once to activate the menu items

tab. Press the MENU key multiple times to tab right and

the ESC key multiple times to tab left until the DISP

menu is highlighted and displaying the submenu items.

2. Use the UP and DOWN arrow keys to scroll through the

sub menu items until VIEW is highlighted.

3. Use the LEFT and RIGHT arrow keys to scroll the view

options.

4. Once the view is displayed, press the MEAS key to

return to measurement mode.

DIGITS: Displays the digital thickness value using a large font size. This view is useful

when the TI-CMXDLP is being used as a basic thickness gauge.

RF: Displays the actual waveform signal, much like an oscilloscope, from the reection

of the opposite surface, pit, aw, crack or void. This view shows both the positive and

negative peaks, and is often used to ne tune the scope settings, prior to inspection

RECT: Displays a half waveform signal, either positive or negative, from the reection

of the opposite surface, pit, aw, crack or void. The user can select the polarity or

“phase” displayed. This is typically determined by rst using RF view to select the most

optimal polarity “phase”, to ne tune the scopes settings. The RECT view is commonly

used as the primary “aw detection” view.

BSCAN: The Time Based B-Scan provides the user with a cross sectional view of the

material being tested. This mode is useful when there is concern regarding the prole of

the blind surface. This can also be a useful view when scanning for pits and aws.

Once the view has been selected according to the application requirements, the Delay

and Range of the screen will potentially need to be adjusted, if the view has been set to

RF or RECT. Alternatively, if BSCAN was selected, the B-Start and B-Depth settings

will need to be adjusted. These settings serve the same purpose,with only differences

in terminology. The Delay the same as B-Start, and the Range is the same as B-Depth.

Therefore, these items will be grouped together for the duration of this manual, as

follows: Delay (B-Start) and Range (B-Depth). Use the following steps to adjust these

settings directly from the measurement screen as follows:

NOTE: The Delay (B-Start) and Range (B-Depth) are also used to adjust the parameters

of Scan Bar.

1. Press the UP, DOWN, LEFT,

and RIGHT arrow keys to scroll

the target cell cursor to the desired

storage location.

2. Press the ENTER key to save the

current reading in the highlighted

cell location. It’s as simple as that!

3. Press the MEAS key to hide the

GRID/SEQ View Box, or ENTER

to display it as necessary.

Note: Once the le is open, it will remain open until it’s closed or another le is opened

by the user. If the gauge is powered off, the TI-CMXDLP will automatically open

the le when powered on. Simply press the ENTER key to display the le from the

measurement screen.

11.4 Viewing stored readings & A/B Scans

It is sometimes necessary to

go back and view the stored

readings and B-Scans using the

TI-CMXDLP without a PC. The

following procedures outline this

process:

1. Press the MEAS key once to

activate measure menu items. Press

the MEAS key multiple times

to move right and the ESC key

multiple times to move left until the

LOG cell is highlighted.

2. Press the ENTER key to display

the Grid Log Box.

3. Press the UP, DOWN, LEFT, and

RIGHT arrow keys to scroll the stored

readings and corresponding display

view. Notice as the cursor is moved to a

different cell, the display will be updated

with the display view saved with the

reading. Readings stored in memory

are indicated by displaying a MEM in

the top left corner of the measurement

screen.

– 14 –

– 91 –

Page 15

3. Continue on to the next section “Saving a Grid or Seq File”.

Saving a Grid

Once all the parameters are set, the user

has the option of saving or canceling

the new grid.

4. Use the UP and DOWN arrow

keys to scroll through the new Grid

or Seq List Items until CREATE

GRID or LOG? is highlighted.

5. Press the ENTER key to accept

the grid or seq log parameters and

activate the conrmation screen

6. Press the OK key to save the New

Grid or Seq Log, or the ESC key

to cancel the New Grid or Seq Log

setup and return to the DATA menu.

7. Press the MEAS key to return to

the measurement screen and begin

storing readings.

11.3 Storing a reading

Now that a grid or sequential log has been created, it’s time to make some measurements

and store the readings. The following procedures outline this process: Storing a Reading

NOTE: Once the gird or sequential log has been created it will automatically be

displayed following the create conrmation screen. It is located at the bottom of the

measurement screen, and can be left open for the duration of the inspection process.

This section assumes the grid or sequential log was just created. Refer to the section on

“opening a grid or seq log” if the le was created at another time.

Key Feature: When the TI-CMXDLP is displaying a “grid log”, pressing the OK key

will initiate an advance to row number option. Use the Left, Right, UP, and DOWN

arrow keys to enter the row number. Once the row number is correctly displayed, press

the OK key to advance directly to that row number in the grid log.

Key Feature: When the TI-CMXDLP is displaying a “grid log”, pressing the ESC key

multiple times, will toggle through the display options: Digits, RF, RECT,and B-SCAN

views.

Adjusting Delay (B-START & Range (B-DEPTH)

1. Press the MEAS key once to activate the measure menu

items. Press the MEAS key multiple times to move right

and the ESC key multiple times to move left, until the

either the DELAY (START) or RANGE (DEPTH) cell is

highlighted.

2. Use the UP, DOWN, LEFT, or RIGHT arrow keys

to scroll the DELAY(START) and RANGE (DEPTH)

values.

3. Repeat steps 1 & 2 until the range is correctly being

displayed. Alternatively, the DELAY (START) and

RANGE (DEPTH) values can be changed using the Digit

Edit Box as follows:

4. Press the MEAS key once to activate measure menu

items. Press the MEAS key multiple times to move right

and the ESC key multiple times to move left, until the

either the DELAY (START) or RANGE (DEPTH) cell is

highlighted.

1. Press the ENTER key to display the digits edit box.

2. Press the UP and DOWN arrow keys to scroll the

highlighted value.

3. Press the LEFT and RIGHT arrow keys to scroll the digit

locations.

4. Repeat steps 3 & 4 until the DELAY (START) or

RANGE (DEPTH) value is correctly displayed.

5. Press the OK key to set the DELAY (START) and

WIDTH (DEPTH) value and return to the measure

screen, or ESC to cancel entering the DELAY(START)

or WIDTH (DEPTH) value.

6. Finally, press the MEAS key to return to the

measurement screen and begin taking readings.

NOTE: The DELAY (START) & WIDTH (DEPTH) can

also be adjusted from the tabbed menu item DISP. However,

using the hot menu keys is the easiest method.

– 90 –

– 15 –

Page 16

In the upper left corner of each of the display photos above, is the repeatability indicator.

The repeatability indicator is represented by six vertical bars and represents how

repeatable the measurements are. In regular measurement mode,the TI-CMXDLP makes

8 measurements a second. In scan mode, the TI-CMXDLP makes 200 measurements a

second. If the coating mode option is activated, the TI-CMXDLP makes 3 measurements

a second in regular measurement mode and 65 measurements a second in scan mode.

When the TI-CMXDLP is idle, only the left vertical bar will be displayed. However,

when the TI-CMXDLP is making a measurement,four or ve of the bars should

be displayed on the repeatability indicator. If fewer than four bars are showing, the

TI-CMXDLP is having difculty achieving a stable measurement and the thickness

value displayed is potentially unstable.

4. Press the OK key to select the coordinate or end ID and return to the Grid or Seq

List Items screen, or ESC to cancel the selection and return to the Grid or Seq List

Items menu.

NOTE: If there is not enough memory available to create the grid or sequential log, an

error message box “NOT ENOUGH MEMORY“ will be displayed. Press the OK or

ESC key to return to the Grid or Seq List Items menu. It may be necessary to free some

memory in the TI-CMXDLP at this time. Refer to section 11.5 for more information on

Deleting a File.

Selecting the Auto Increment Direction

The Auto Increment feature gives the user

the ability to specify which direction to

advance the cursor after storing a reading.

5. Use the UP and DOWN arrow keys

to scroll through the new Grid or

Seq List Items until INCR. DIR or

DIRECTION is highlighted.

6. Use the LEFT & RIGHT arrow keys to

toggle the Increment direction NONE,

NORTH, EAST, SOUTH, or WEST for

a grid, or INC, DEC for a sequential

log.

7. When the correct Increment direction is displayed, continue on to the next section

“Graphics”.

Saving Graphics

The TI-CMXDLP provides the user with the ability to save a snapshot of the display

screen and all the current settings of the TI-CMXDLP with every reading, or just save

the reading only. Saving the graphics might be advantageous to the user when the A/BScan views will be used to graphically save a picture of the scanned areas for reporting

purposes. It might also come in handy when user requires backup of all the current

TI-CMXDLP parameters for each reading. However, if neither of these requirements are

necessary, this option should be disabled

in order make more efcient use to the

TI-CMXDLP storage capacity.

1. Use the UP and DOWN arrow keys

to scroll through the new Grid or Seq

List Items until SAVE GRAPHICS

is highlighted.

2. Use the LEFT & RIGHT arrow keys

to toggle the Increment direction to

YES or NO.

– 16 –

– 89 –

Page 17

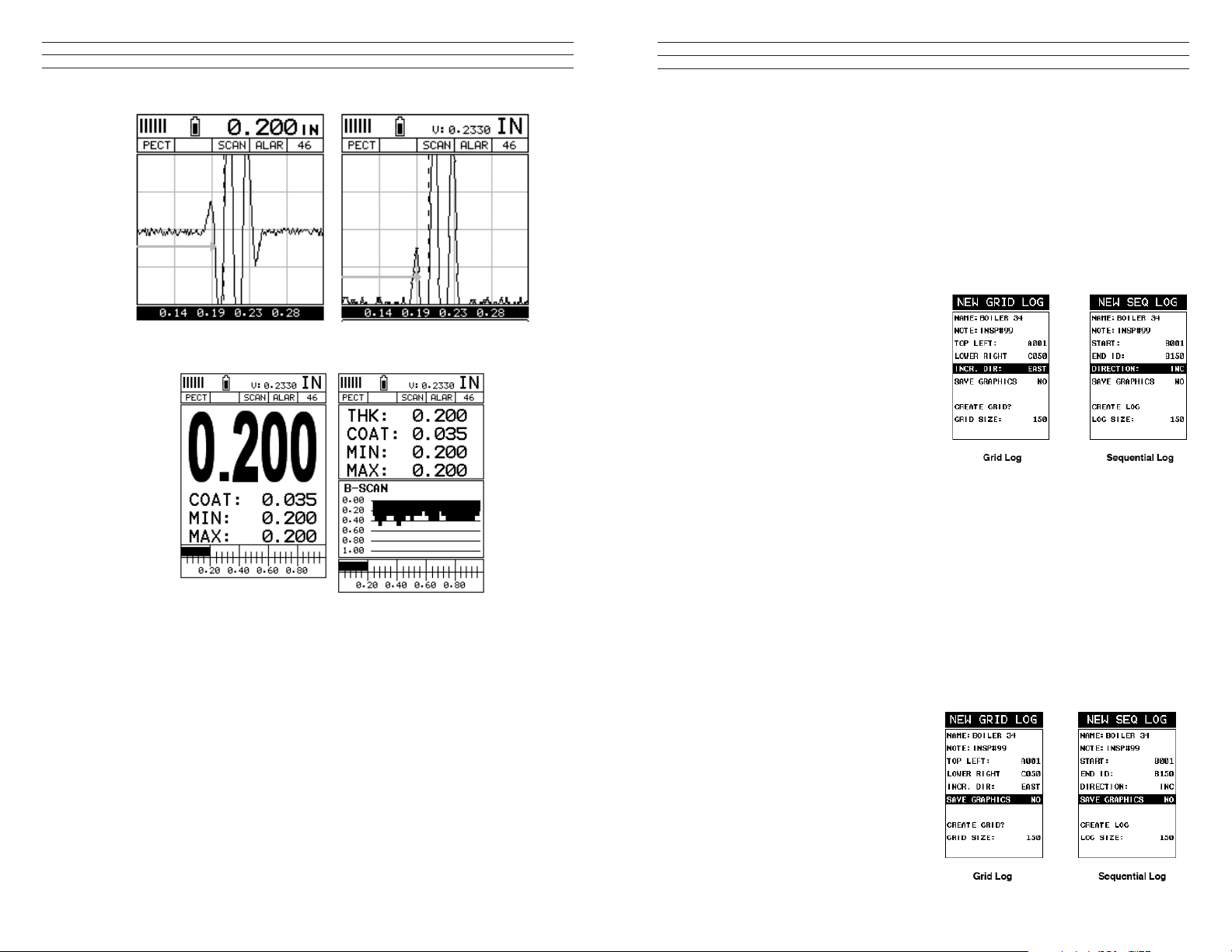

Setting the Top Left(Grid) or Start ID(Seq)

1. Use the UP and DOWN arrow keys to

scroll through the new Grid or Seq List

Items until TOP LEFT or START ID is

highlighted.

2. Press the ENTER key to activate the

Coordinate or Start ID Edit Box.

3. GRID LOG: Use the LEFT, & RIGHT

arrow keys to scroll the Columns, and

the UP, DOWN arrow keys to scroll the

Rows.

SEQ LOG: Use the UP, DOWN, LEFT,

& RIGHT arrow keys to highlight the

appropriate alpha characters. Press the

ENTER key to select a character and

advance to the next character eld, in

conjunction with using the CLR key to

backspace if necessary.

4. Press the OK key to select the coordinate

or start ID and return to the Grid or Seq

List Items screen, or ESC to cancel the

selection and return to the Grid or Seq

List Items menu.

Setting the Bottom Right (Grid) or END ID (Seq)

1. Use the UP and DOWN arrow keys to

scroll through the new Grid or Seq List

Items until LOWER RIGHT or END ID

is highlighted.

2. Press the ENTER key to activate the

Coordinate or End ID Edit Box.Grid Log

Sequential Log

3. GRID LOG: Use the LEFT, & RIGHT

arrow keys to scroll the Columns,and

the UP, DOWN arrow keys to scroll the

Rows. SEQ LOG: Use the UP, DOWN,

LEFT, RIGHT arrow keys to highlight

the appropriate alpha characters. Press

the ENTER key to select a character and

advance to the next character eld, in

conjunction with using the CLR key to backspace if necessary.

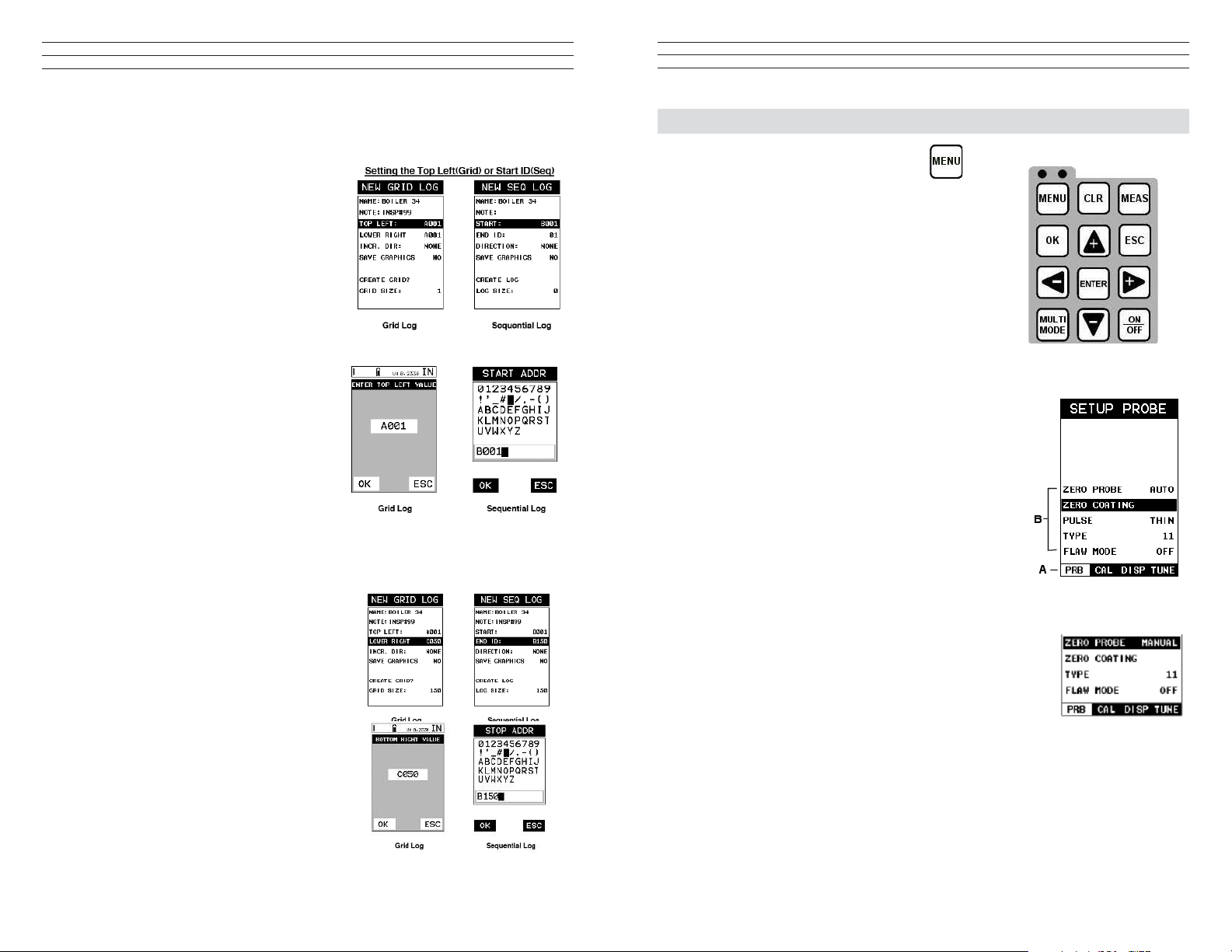

3.0 Keyboard, Menu & Connector Reference

3.1 Menu Key (Operation * Sub Menus)

The Menu key activates the primary menu structure

containing 8 menu tab groups. These tab groups then

contain sub menu items, or functions. The sub menu

items have been organized in tab groups according

to how closely they are related to the individual tab

group names. Let’s rst get familiar with how to move

around in these tabs before continuing on to the sub

menu functions. This procedure is outlined below:

Activating and Getting Around in the Menus Items

1. Press the MENU key once to activate the menu items

tab. Press the MENU key multiple times to tab right,

and the ESC key multiple times to tab left until the

desired tab group is highlighted and displaying the

submenu items. The tab groups are illustrated above

(A).

2. Use the UP and DOWN arrow keys to scroll

through the sub menu items until the desired

function is highlighted. The sub menu items are

illustrated in the diagram above (B).

3. Depending on which function is highlighted, use

the LEFT, RIGHT, and Enter keys to scroll the

options or activate the Digit Edit and List Box options.

3.2 Probe – Menu

ZERO PROBE: The TI-CMXDLP is zeroed in much the

same way that a mechanical micrometer is zeroed. If the

TI-CMXDLP is not zeroed correctly, all of the measurements

made using the TI-CMXDLP may be in error by some xed

value. The TI-CMXDLP is equipped with an optional automatic or manual zero feature.

Refer to section 6.2, for an explanation of this important procedure.

ZERO COATING: In order to account for very slight electronic differences in

transducers of the same type, frequency, and diameter, the TI-CMXDLP has been

equipped with a “zero coating” feature. This enables the TI-CMXDLP to obtain

very accurate readings on coatings, eliminating potential errors incurred from slight

differences in the manufacturing processes. Refer to section 6.2.

– 88 –

– 17 –

Page 18

TYPE: Enables the user to select the type of transducer being used from a chart of

transducer types. This provides increased linearity between transducers. Refer to section

6.1 for a further explanation.

FLAW MODE: Activates the aw detection mode and view. This feature is for use with

single element angle beam transducers and used as a general prove-up aw inspection

mode. Refer to section 10.9.

3.3 CAL – Menu

M AT: Select the material velocity from a chart of basic

material types when a known sample thickness, or material

velocity cannot be obtained. Refer to section 6.3.

MATL 1PT: Performs a single point calibration. This option

allows the user to automatically calculate the velocity by

entering a known sample thickness. Refer to

section 6.3.

MATL 2PT: Performs a two-point calibration. This option allows the user to

automatically calculate the velocity by entering a second known sample thickness. Refer

to section 6.3.

VELOCITY: Function to calibrate the TI-CMXDLP by setting the velocity to a known

material velocity. Refer to section 6.3.

COATING 1PT: Performs a single point coating calibration. This option allows the user

to automatically calculate the velocity by measuring a known coating sample thickness.

Refer to

s

COATING 2PT: Performs a two-point coating calibration. This option allows the user

to automatically calculate the velocity by entering a second known coating sample

thickness. Refer to section 9.6.

COATING VEL: Function to calibrate the TI-CMXDLP to a specic coating material

by entering a coating velocity. Refer to section 2.6 or section 9.3.

3.4 DISP (display) MENU

VIEW: Selectable BSCAN (cross section), and

DIGITS (large digits) views. Refer to section 7.1.

DELAY (B-START): Provides the user the ability

to change the start position of the B-SCAN view.

Refer to section 7.3 for further info.

RANGE (B-DEPTH): Provides the user the

ability to change the overall depth of the viewable

measurement area. It functions a lot like a zoom on

a camera. Refer to section 7.3.

Creating a Note Grid/Seq Log Note:

Can contain a combination of up to 20

numeric, alpha, or special characters

listed in the rst section of this chapter.

Grid Log Sequential Log

1. Assuming the Grid or Seq List

Items are displayed, use the UP

and DOWN arrow keys to scroll

through the new Grid or Seq List

Items until NOTE is highlighted.

2. Press the ENTER key to activate

the Alpha Edit Box.

3. Use the UP, DOWN, LEFT, & RIGHT

arrow keys to highlight the appropriate

alpha characters.

4. Press the ENTER key to select a

character and advance to the next eld of

the Grid or Seq Note.

5. Use the CLR key to backspace if

necessary.

6. Repeat steps 3 through 5 until the Grid or

Seq Note is completed.

7. Press the OK key to save the Grid or Seq Note and return to the Grid or Seq List

Items menu, or ESC to cancel entering the Grid or Seq Note.

Setting the Coordinates or Start & Stop ID’s

Grid: A grid is dened by using coordinates to dene the Top Left and the Bottom

Right corners of the grid. Alpha coordinates are horizontal across the top, and numeric

coordinates are vertical down the side. Therefore, to dene the top left corner of the

grid, there will be an (X,Y) coordinate. Where X is an alpha column location across the

top and Y is a numeric row location down the side. Use the same logic when choosing

the lower right corner. An individual grid can be up to 999 rows and 52 columns.

Sequential: The sequential le format can be viewed as a le as a single column of up

to 512 possible rows (readings), and a column of corresponding identiers associated

with each individual reading. The identier can be a combination of up to 10 numeric,

alpha, or special characters listed above,while the le name can consist of a combination

of up to 20 of the same character set. Note: The identier cannot start or end with a

special character. Once a start and end ID are entered into the TI-CMXDLP and the

log created, the TI-CMXDLP will automatically generate all the identiers within that

range.

– 18 –

– 87 –

Page 19

Creating a Name

Grid/Seq Log Name : Can contain

a combination of up to 20 numeric,

alpha,or special characters listed in the

rst section of this chapter. Grid Log

Sequential Log

1. Press the MENU key once to

activate the menu items tab. Press

the MENU key multiple times to

tab right, and the ESC key multiple

times to tab left, until the DATA

menu is highlighted and displaying

the submenu items.

2. Use the UP and DOWN arrow keys

to scroll through the sub menu items

until NEW is highlighted.

3. Press the LEFT & RIGHT arrow

keys to toggle the data formats –

GRIGLOG & SEQ LOG.

4. Press the ENTER key to display the

new Grid or Seq Edit Box.

5. Use the UP and DOWN arrow keys to

scroll through the new Grid or Seq List

Items until NAME is highlighted.

6. Press the ENTER key to activate the Alpha

Edit Box.

7. Use the UP, DOWN, LEFT, & RIGHT

arrow keys to highlight the appropriate

alpha characters.

8. Press the ENTER key to select a character

and advance to the next eld of the Grid or

Seq Name

9. Use the CLR key to backspace if necessary.

10. Repeat steps 6 thru 9 until the Grid or Seq Name (File Name) is completed.

11. Press the OK key to save the Grid or Seq Name and return to the Grid or Seq List

Items menu, or ESC to cancel entering the Grid or Seq Name (File Name).

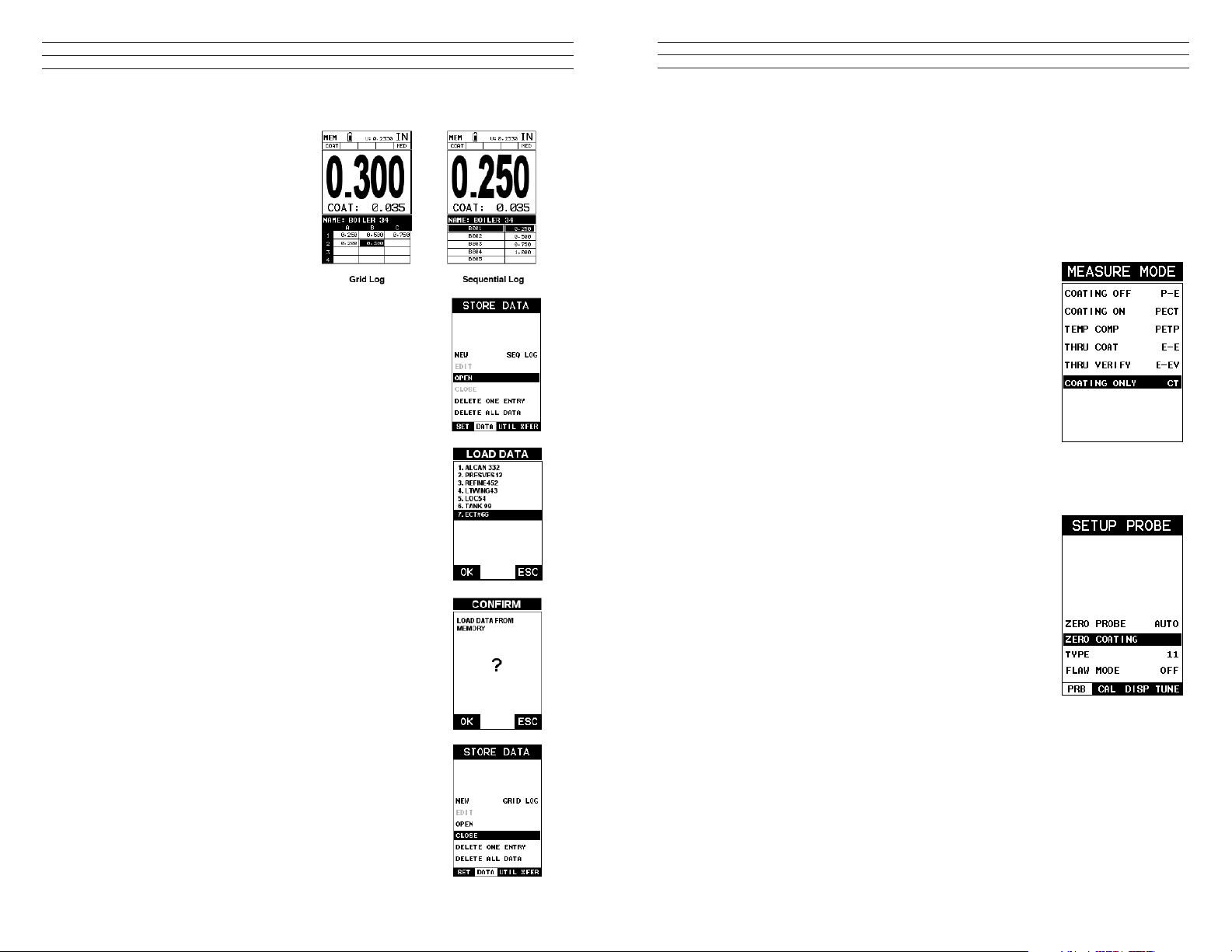

Grid Log

Grid Log

Sequential

Log

Sequential

Log

B-SCAN SPEED: (color version only) – Controls the speed of the time based B-Scan

with an arbitrary scale of 0-10, with 10 being the fastest scrolling speed. Default speed

set at 6. Refer to section 7.3.

UNITS: Toggle between English or Metric units. The readout will change from inches

to millimeters. BACKLIGHT: Selectable OFF, ON, AUTO, or INVERT backlight

option.

NOTE: Color version uses an AMOLED display, and ‘Brightness’ is substituted for

Backlight as the menu item label, with an arbitrary scale of 1 to 20, with the brightest

setting at 20. Refer to section 10.5.

CONTRAST: Adjustable display contrast for variable light conditions.

NOTE: This menu item is eliminated in the color version.

VIEW: (color version only) – Provides the user with 12 different color schemes to

select from. There are two schemes for each main color option. Refer to section 10.6.

DIM: (color version only) – Allows the user to conserve battery life by dimming the

display after idle for a specic amount of time – OFF, 30, 60, 90, 120 seconds. Once

dimmed, a single press of any key will restore the screen brightness. Refer to section

10.7.

RECT WAVE: This option provides the user an outlined or lled view option when the

display setting is in RECT (rectied) wave mode only. Refer to section 10.10.

DETECT MARK: Selectable graphics option for the point of detection on the

waveform: Line, Box, Dots, None. Offers the user a graphics preference on how they

prefer to view the detection on the waveform.

3.5 TUNE – Menu

MEASURE MODE: Toggles a variety of unique

measurement modes for different application

requirements: Coating Off (P -E), Coating On

(PECT), Temp Comp(PETP), Thru Coat (E-E),

Thru Verify (E-EV), Coating Only (CT). Refer to

section 4.6.

POLARITY: The TI-CMXDLP operates on a

zero crossing detection principle. This feature

toggles which stroke of the cycle the crossing detection uses, either positive or negative.

Refer to section 10.11.

PULSE: The TI-CMXDLP has an adjustable pulse width for both high penetration and

resolution applications. The pulse width refers to the duration of time the pulser ison.

The options are Spike, Thin, and Wide. Refer to section 10.12.

– 86 –

– 19 –

Page 20

PULSER VOLTAGE: This feature offers a 50 volt cut/boost to the pulser. The standard

setting is 150 volts. This enables the TI-CMXDLP to offer greater penetration for

difcult material types, or increased resolution on noisy materials. Refer to section 10.3.

DAMPING: (color version only) – Provides the user with multiple input impedances to

match the impedance of the transducer, and optimized overall transducer performance.

Refer to section 10.8.

ATTN: This feature is a 20dB attenuator, as well as a 20dB amplier. The primary

purpose is to is to offer further exibility to the TI-CMXDLP , by either cutting or

boosting signal strength. In instances where the 60 dB range is not enough, or too

much, this feature allows you to increase/decrease the amplier strength by a power

of 10 or(20dB). The standard setting is zero, which is an arbitrary value at a constant

attenuation. The attenuation value is added to the gain value. Therefore, if the attenuator

is increased to 20dB, this value is added to the value of the gain setting. Refer to section

10.4.

GAIN: The TI-CMXDLP has 100dB gain range from (-30 to 70 dB), used in

conjunction with the attenuator feature above. This feature is used to increase/decrease

the power or amplitude of the signal. This might easily be considered as similar to

turning the volume up or down on a stereo receiver. Refer to section 7.4.

AGC: This an automatic gain control used in E-E (echo-echo), and E-EV (echo-echo

verify). The TI-CMXDLP is equipped with an automatic gain control when operating

in -E(echo-echo), and E-EV (echo-echo verify) modes only. This feature automatically

increases/decreases the power or amplitude of the signal, to an optimal input to output

signal ratio. This might easily be considered as similar to turning the volume up or

down on a stereo receiver. Alternatively, the AGC can be manually controlled. The

TI-CMXDLP is equipped with manual override, using an arbitrary range of 1 to 20

clicks. The higher the number the better the dynamic gain range, and visa versa. Refer to

section 7.4.

Grid File Formats

Sequential Log Formats

3.6 GT1 – Menu

GATE1: Gates allow the user to view a specic

measurement range, or sections of the waveform, and

ignore others. The Gate1 feature adjusts the start of the

gate, according to time/distance. Gate 1 can be used

in all pulse-echo and echo-echo measurement modes.

Refer to section 7.6.

GATE1 WIDTH: This feature allows the user to set the overall width of the gate, in

terms of distance, from the starting value of Gate1. Refer to section 7.6 for further info.

THRESHOLD1: Enables the user to set the sensitivity level of Gate1. The amplitude

of the signal must reach or exceed the threshold level before a measurement is

detected. Refer to section 7.6.

– 20 –

IMPORTANT NOTE: For the duration of this chapter, all references to GRIDS and

SEQ LOGS should be considered synonymous with references to FILES.

11.2 CREATING A NEW GRID OR SEQUENTIAL LOG (FILE)

IMPORTANT NOTE: This entire section is a step by step guide to successfully create

a grid or sequential log. The instructions must be used in the sequential order specied,

as follows:

– 85 –

Page 21

11.0 DATA STORAGE – SETUP, EDIT, & VIEW FILES

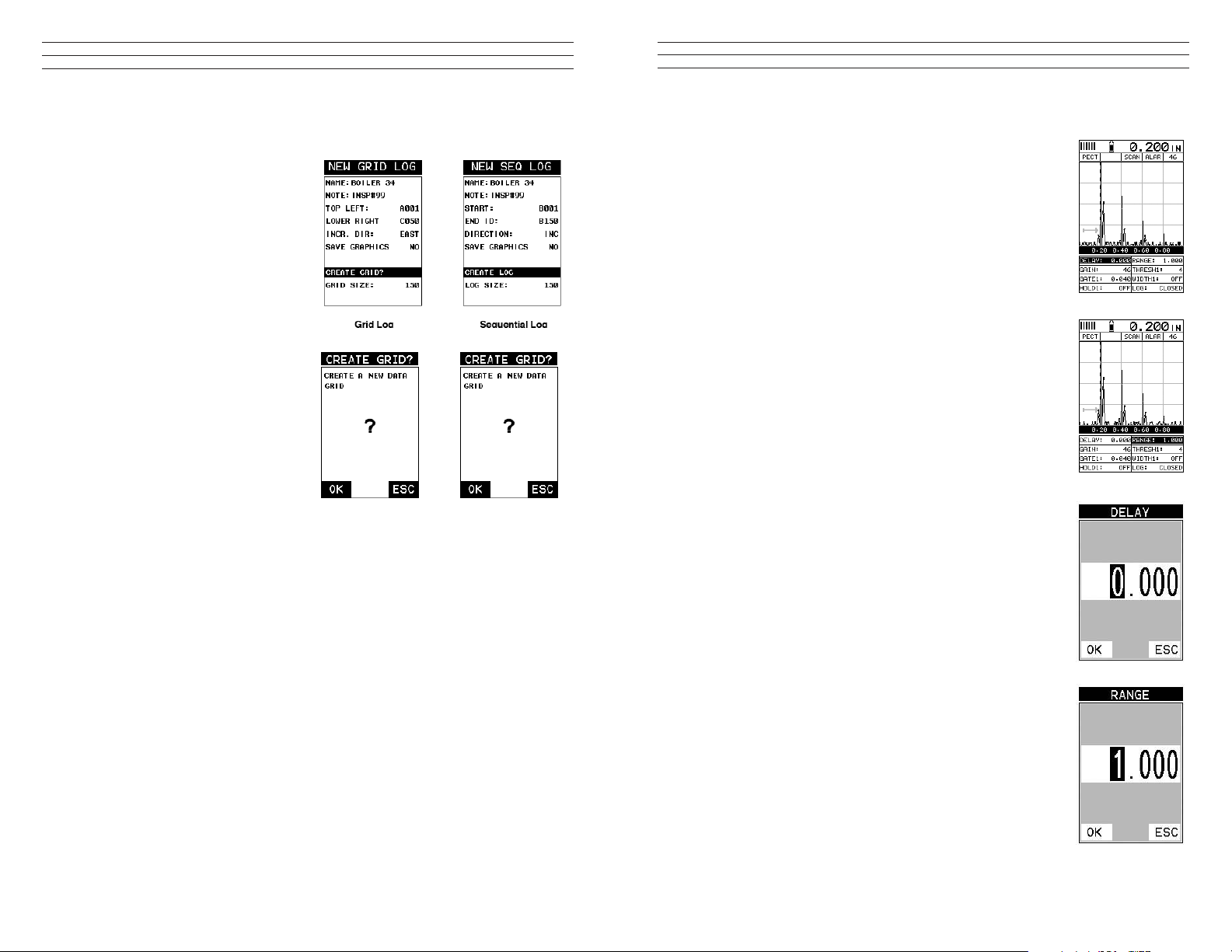

11.1 Introduction to Grid and Sequential file formats

The TI-CMXDLP is equipped with two data le format options, GRID LOG and SEQ

LOG. The GRID le format is very similar to a spreadsheet format found in popular

software programs like Excel. A GRID is simply a table of readings. A location in a

grid is specied by giving a row and column coordinate. The rows are numbered from

1 to 999 and the columns are labeled from A to ZZ (999 Rows & 52 Columns).The

sequential le format can be viewed as a le as a single column of up to 512 possible

rows (readings), and a column of corresponding identiers associated with each

individual reading. The identier can be a combination of up to 10 numeric,alpha, or

special characters listed above, while the le name can consist of a combination of up to

20 of the same character set.

NOTE: The identier cannot start or end with a special character. Once a start and

end ID are entered into the TI-CMXDLP and the log created, the TI-CMXDLP will

automatically generate all the identiers within that range.

The following character set listed below are all the allowable characters that will be

used for both le formats: GRID & SEQ LOG. Any combination of these character scan

be used for creating a Name and Note regardless of the selected format. The allowable

characters are as follows:

Numeric characters: 0 – 9 Alpha Characters: A – Z

Special Characters: ! ‘ _ # space / . – ( )

Multiple grids can be created and stored until the TI-CMXDLP’s memory is full. If the

user attempts to store a new le in the TI-CMXDLP and the size of the le exceeds the

capacity of memory, the TI-CMXDLP will respond with an error message indicating

that the memory is unable to store the new le.

The TI-CMXDLP can store a total of 16,000+ readings with a corresponding screen

shot of the DIGITS, RF, RECT, or B-SCAN views with every reading , as well as all the

TI-CMXDLP settings for every individual reading. If the graphics option is disabled,

not saving screen shots, the TI-CMXDLP can store a total of 210,000+ readings. The

screen shot stored with the reading will depend on what view the TI-CMXDLP was in at

the time it was saved. For example, if the view was in RECT, then a RECT will be saved

with the reading.

In the sections that follow, the procedures for creating, using, and editing GRID’s

and SEQ LOG’s have been combined together for the purpose of similarity in overall

functionality and structure. The illustrations below are snapshots of typical GRID and

SEQ LOG le formats:

3.7 GT2 – Menu

GATE2 WIDTH: This feature allows the user to set

the overall width of the gate, in terms of distance, from

the starting value of HoldOff2. Refer to section 7.6.

HOLDOFF 2: Provides the user with the ability to

delay the starting point of Gate2, a specic distance from the rst detection point found

inside of the boundaries of the Gate 1 settings. If no detection is found, the Gate1 width

value is used as a starting value for Gate2. Refer to section 7.6.

THRESHOLD2: Enables the user to set the sensitivity level of Gate2. The amplitude of

the signal must reach or exceed the threshold

3.8 GT3 – Menu

GATE3 WIDTH: This feature allows the user to set the

overall width of the gate, in terms of distance, from the

starting value of HoldOff3. Refer to section 7.6.

HOLDOFF 3: Provides the user with the ability to delay

the starting point of Gate3, a specic distance from the

rst detection point found inside of the boundaries of the

Gate 2 settings. If no detection is found, the Gate2 width

value is used as a starting value for Gate3. Refer to section 7.6.

THRESHOLD3: Enables the user to set the sensitivity level of Gate3. The amplitude

of the signal must reach or exceed the threshold level before a measurement is detected.

Refer to section 7.6.

3.9 SETUP – Menu

OPEN: Displays a list of factory and user dened setups

currently stored in memory. These setups can be recalled

and used at any time. Refer to section 12.2.

SAVE: Provides the user with the ability to save a custom

setup that has been modied or created by the user. Refer

to section 12.3.

DELETE: Provides the user with the ability to delete

specic setups previously save in memory. Refer to

section 12.4.

DEFAULT SETUP: Loads a basic default setup. Use only as a last resort when the

setups in the TI-CMXDLP have been corrupted and a computer is not accessible. Refer

to section 12.5.

LANGUAGE: Provides the user the ability to select different languages (section 12.6).

– 84 –

– 21 –

Page 22

3.10 DATA – Menu

NEW: Allows the user the ability to create a new alpha

numeric grid, or sequential log le with auto identiers.

It is equipped with custom parameters, rows, and

columns depending on the user’s application reporting

requirements. Refer to section 11.2.

EDIT: Gives the user the ability to change parameters of

grid or sequential le previously saved. Note: Pre-dened

coordinates cannot be changed once they have been created. Refer to section 11.6.

OPEN: This function provides the user with the ability to recall grids or sequential log

les that currently exist in memory, from a list of grids. Refer to section 11.7.

CLOSE: Provides the user the ability to close a currently opened grid or sequential log

le. Refer to section 11.8

DELETE ONE FILE: This function provides the user with the ability to delete one

individual grid or sequential log le from a list of multiple grids/les previously saved

in memory. Refer to section 11.5 for further info.

DELETE ALL DATA: This function provides the user with the ability to delete all les

currently stored in memory. Refer to section 11.5 .

3.11 UTIL (Utilities) – Menu

AUTO FIND: Automatically locates the detection point

if the measurement is out of the viewable display area.

Refer to section 10.1 for further info.

SCAN MODE: This function enables a hi speed scan

mode that increases the overall sample rate from 65 to

200 measurements per second, depending on the current

measurement mode used. Refer to section 10.2.

ALARM: Toggles alarm mode on, off, or audible . Refer to section 10.3.

ALARM HIGH: Gives the user the ability to set the HI limit parameter. If the