Page 1

1

TABLE OF CONTENTS

01.0 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 02

02.0 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 02

03.0 Description of Gauge . . . . . . . . . . . . . . . . . . . . . . . . . . 03

04.0 Getting Started . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 05

4.1 Units of Measure

4. 2 Installing the Battery

4.3 Turning the Power On

4.4 Turning the Power Off

4. 5 Using the Built-in Calibration Disc

4.6 Using Couplant Fluid

05.0 Quick Start Instructions - Steel . . . . . . . . . . . . . . . . . . 07

06.0 Setup for Measuring Thickness

of Materials Other Than Steel . . . . . . . . . . . . . . . . . . . . 008

7.1 Acoustic Velocity Selection Table

7.2 Setup of Gauge When Acoustic Velocity is Unknown

7.3 Changing Modes

7.4 Thickness Measurement Methods

07.0 Taking Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . 13

8.1 Notes on Measurements

8.2 Preparing the Surface For Measurement

8.3 Measurement of Pipes or Cylindrical Objects

08.0 Trouble-Shooting Guide . . . . . . . . . . . . . . . . . . . . . . . . 15

09.0 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

TI-44N Operating Instruction GuideTI-44N Operating Instruction Guide

20

NOTES

Page 2

1.0 INTRODUCTION

The CHECK•LINE® TI-44N Thickness Gauge measures the wall thickness of metals,

glass, ceramics and many rigid plastics. This gauge uses the “pulse-echo“ principle

of ultrasonic testing where a short ultrasonic signal is transmitted from the probe.

The signal travels through the measurement sample until it is reflected back towards

the probe from the back side of the material. The elapsed time for this complete

cycle is measured and converted into an accurate thickness reading.

The gauge can be used to measure the extent of corrosion on the opposite, inaccessible side of the wall by using the “Subtractive Method.” When the thickness of the

original wall is known, subtracting the thickness reading obtained from the TI-44N

gauge will determine the extent of corrosion at the point of probe placement. If the

original wall thickness is not known, test readings should be made along a grid of

equally-spaced points to obtain a profile of thickness readings. The smallest thickness reading will locate the area of greatest corrosion.

The gauge is supplied from the factory set for an acoustic velocity of 5930 m/sec to

measure steel. The acoustic velocity is easily changed to accurately measure materials other than steel. Refer to section 6.3 Changing Acoustic Velocity and section

6.1 the Acoustic Velocity Selection Table. The TI-44N gauge measures thickness in

either Inch (factory default) or mm units. To change units of measure,refer

to section 4.1.

The TI-44N is supplied as a complete kit, including the gauge with wrist-strap,

probe and cable assembly, a 2-ounce bottle of coupling fluid (couplant) and a

AA battery — all supplied in a fitted, hard-plastic carrying case.

2.0 PRECAUTIONS

1. The probe surface is fabricated from acrylic resin and care should be taken to

insure that it is not scratched by sliding over rough surfaces. The probe should

be placed down for measurements and lifted vertically when complete. Do not

slide over rough surfaces.

2. Do not use this gauge where material temperatures exceed 140 °F (60 °C) as the

probe will be damaged. Use the CHECK•LINE Model TI-25H High Temperature

Thickness Gauge for these applications.

3. Keep the gauge free of dust (especially metal powders, carbon, etc.) as they will

damage the PC Board. Use a damp cloth to clean the gauge after use. DO NOT

USE CHEMICAL SOLVENTS OF ANY KIND.

TI-44N Operating Instruction Guide

2

ELECTROMATIC Equipment Co., Inc. (ELECTROMATIC) warrants to the

original purchaser that this product is of merchantable quality and confirms

in kind and quality with the descriptions and specifications thereof. Product

failure or malfunction arising out of any defect in workmanship or material in

the product existing at the time of delivery thereof which manifests itself

within one year from the sale of such product, shall be remedied by repair or

replacement of such product, at ELECTROMATIC’s option,except where unauthorized repair, disassembly, tampering, abuse or misapplication has taken

place, as determined by ELECTROMATIC. All returns for warranty or non-warranty repairs and/or replacement must be authorized by ELECTROMATIC, in

advance, with all repacking and shipping expenses to the address below to be

borne by the purchaser.

THE FOREGOING WARRANTY IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING BUT NOT

LIMITED TO, THE WARRANTY OF MERCHANTABILITY AND FITNESS FOR

ANY PARTICULAR PURPOSE OR APPLICATION. ELECTROMATIC SHALL

NOT BE RESPONSIBLE NOR LIABLE FOR ANY CONSEQUENTIAL DAMAGE,

OF ANY KIND OR NATURE, RESULTING FROM THE USE OF SUPPLIED

EQUIPMENT, WHETHER SUCH DAMAGE OCCURS OR IS DISCOVERED

BEFORE, UPON OR AFTER REPLACEMENT OR REPAIR, AND WHETHER OR

NOT SUCH DAMAGE IS CAUSED BY MANUFACTURER’S OR SUPPLIER’S

NEGLIGENCE WITHIN ONE YEAR FROM INVOICE DATE.

Some State jurisdictions or States do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation may not apply

to you. The duration of any implied warranty, including, without limitation,

fitness for any particular purpose and merchantability with respect to this

product, is limited to the duration of the foregoing warranty. Some states do

not allow limitations on how long an implied warranty lasts but, not withstanding, this warranty, in the absence of such limitations, shall extend for

one year from the date of invoice.

ELECTROMACTIC Equipment Co., Inc.

600 Oakland Ave. Cedarhurst, NY 11516—USA

Tel: 1-800-645-4330/ Tel: 516-295-4300/ Fax: 516-295-4399

Every precaution has been taken in the preparation of this manual. Electromatic Equipment Co., Inc.,

assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting

from the use of information contained herein. Any brand or product names mentioned herein are used

for identification purposes only, and are trademarks or registered trademarks of their respective holders.

WARRANTY

TI-44N Operating Instruction Guide

19

Page 3

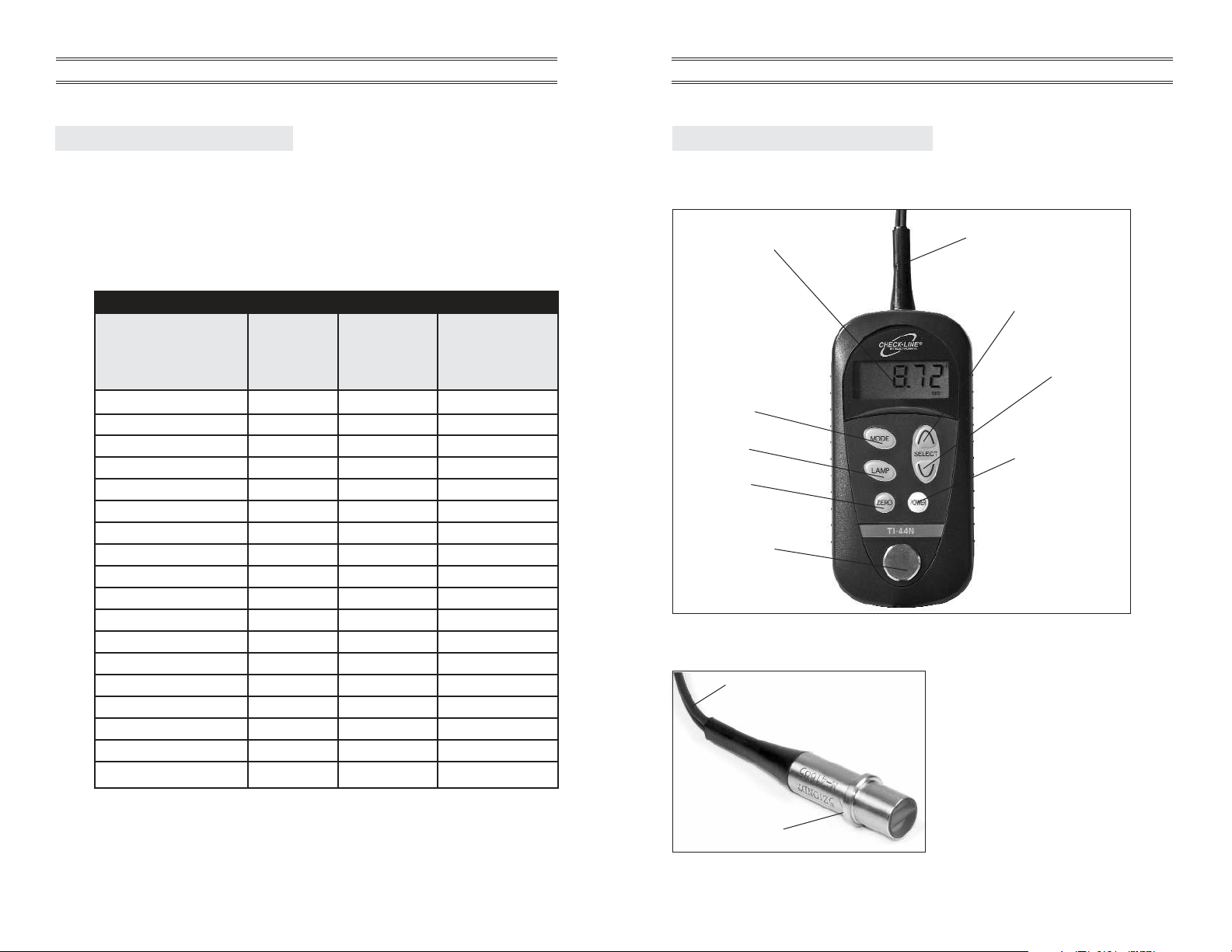

Mode Selector

Back Light

On/Off

Probe Zero

Test Plate for

Zero Adjustment

Equivalent to 0.197"

(5.00 mm) steel

On/Off Switch

Hard-wired cable and probe

LCD Display

Increase Sonic

Velocity

or Thickness

Adjustment

Decrease Sonic

Velocity or

Thickness

Adjustment

Probe

3.0 DESCRIPTION OF GAUGE

3.1 Gauge

3.2 Probe Assembly

Probe Cable: Do not bend sharply.

Do not bring into contact with high

temperature objects (> 60 °C)

TI-44N Operating Instruction Guide

3

APPENDIX

The TI-44N Thickness Gauge is supplied from the factory set for an acoustic

velocity of 5930 m/sec for the measurement of steel. To measure the thickness of

any other material, the acoustic velocity must be changed. When checking the

built-in calibration sample, the gauge will display the “Equivalent Value” listed in

the Table in section 6.1, instead of 0.197" (or 5.0 mm)

ACOUSTIC VELOCITY SELECTION TABLE

Material Acoustic Equivalent Equivalent

Type Velocity Value Value Of

(meters/sec) Of Calibration Calibration Disc

Disc (Inch) Disc (mm)

Aluminum 6260 .208 5.3

Acrylic (Plexiglass) 2700 .090 2.3

Cast Iron 4400-5000 .148 - .168 3.8 - 4.3

Ceramics 10000 .332 8.4

Copper 4700 .156 3.9

Duralumin (17S) 6320 .211 5.3

Ebonite 2500 .083 2.1

Glass 5570 .185 4.7

Nickel 6040 .201 5.1

Polyethylene (Soft) 1900 .063 1.6

Polyvinyl Chloride (PVC) 2300-2500 .077-.083 1.9 - 2.1

Quartz (X cut) 5720 .191 4.9

Stainless Steel (SUS304) 5790 .193 4.9

Stainless Steel (SUS403) 6100 .205 5.2

Stainless Steel (SUS410) 7390 .246 6.2

Steel 5930 .197 5.0

Tin 3320 .110 2.8

Zinc (Zn) 4170 .139 3.5

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆ Denotes one of the 10 preset values in Mode C.

TI-44N Operating Instruction Guide

18

Page 4

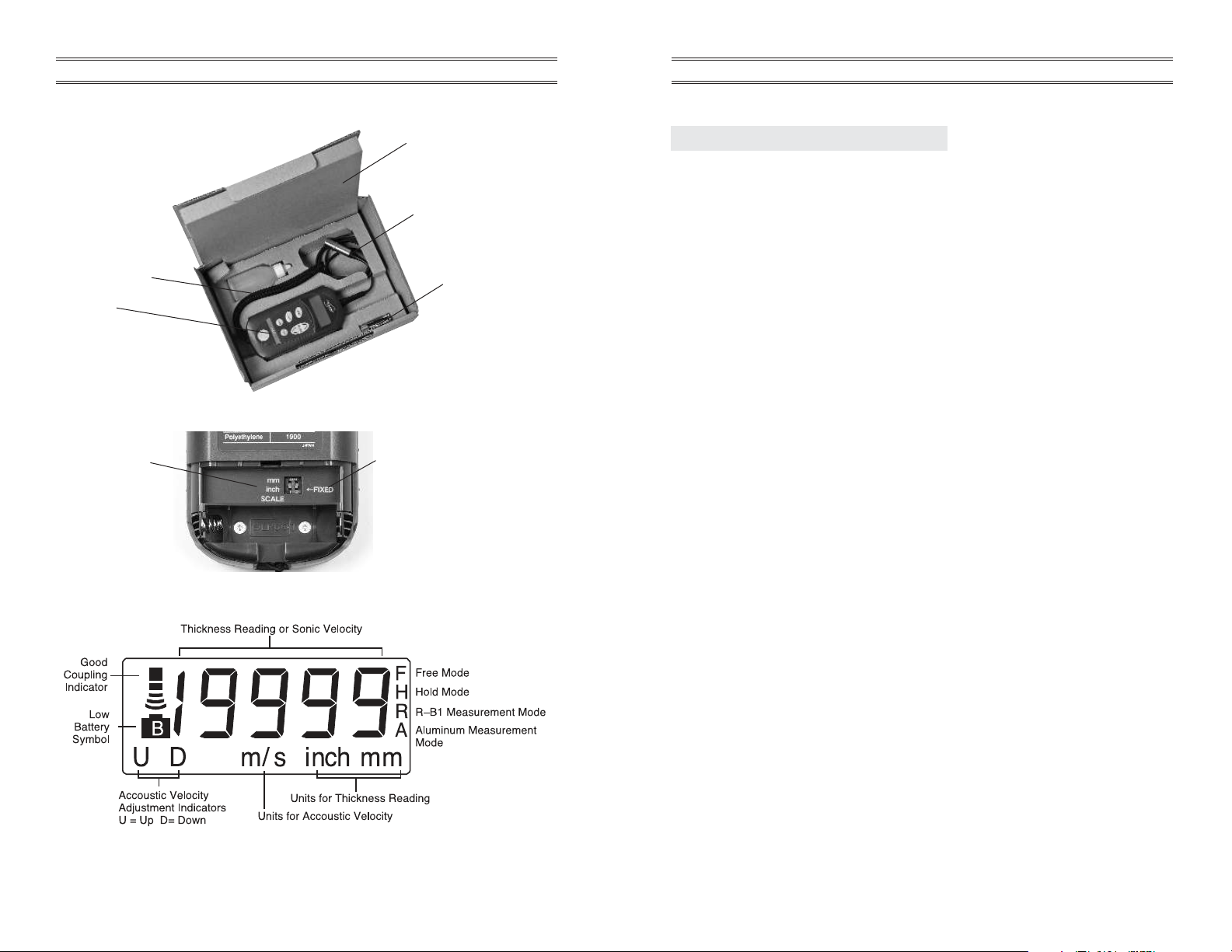

3.3. Complete Kit

3.4 Battery Compartment

3.5 LCD Display

Units of Measure

Selector Switch

Gauge

Coupling Fluid

Operating Instructions

Probe/Cable Assembly

Battery

Probe selection switch

set on FIXED

Bottom of gauge

Use AA-type alkaline battery

TI-44N Operating Instruction Guide

4

9.0 SPECIFICATIONS

Range (steel) Flat plate 1.00 to 199.99

mm

Pipe 30 in. diameter and 1.50 in. thickness or more

Accuracy

(mm)

±0.02

Errors

(mm)

1.00 to 99.9 ±0.05

100.00 to 199.99 ±2% / rdg

Probe (standard) 5Z10NDT-Ma

Probe Cable HF coaxial cable: 1.5 D-QEVX2C, 1.0m

Object Material Iron, steel, aluminum, any other metal, hard plastics,

glass and ceramics

Sonic Velocity 1,000 – 12,000 m/s

Adjustable Range (10 predefined sonic velocities stored in gauge)

Display Digital LCD display with backlight

Display Resolution 0.01

mm

(1.00mmto 199.9mm)

Display Frequency Approx. 3 times / sec

Digits 4-1/2 (max 19999) the upper digit displays 1 only

Start-up Time Approx 2 Sec.

Power Supply 1 AA-type alkaline battery, 1.5 V

Operating Time >30 hours continuous operation

Usage: 2 sec. measurement followed by 10 sec

standby

Test Panel for 5.00 mm thickness for steel (sonic velocity 5930 m/s)

Zero Adjustment come standard with gauge

Weight Meter: approx 150 g. Probe: Approx. 50 g

Dimensions 69 (W), 144 (L), 30 (H) mm

Operating Temperature -5 °C to 55 °C

Storage Temperature -10 °C to 55 °C

Warranty Meter: 1 year. Probe: 90 days

TI-44N Operating Instruction Guide

17

Page 5

4.0 GETTING STARTED

4.1 Setting Units Of Measure

Remove the Battery Cover on the back side of the gauge

by pressing it down with your thumb and sliding it in the

direction indicated by the arrow. The Units Selector Switch

is located in the Battery Compartment. Slide the switch to

either the Inch (up) or mm (down) position as desired.

Inch is the factory default unit of measure .

4.2 Installing The Battery

Remove the Battery Cover on the back side of the gauge by pressing it down

with your thumb and sliding it in the direction indicated by the arrow. Place

one (1) AA-size battery (1.5 Volt) into the battery compartment in the

orientation shown on the sketch. Replace the Battery Cover.

AA Battery

mm

Inch

+

–

Correct Battery Orientation

Battery

Compartment

TI-44N Operating Instruction Guide

5

Description of Problem Possible Cause Action To Be Taken

Fluxuating readings Defective probe Return to manufacturer

Fluxuating readings while Aluminum measurement Switch to aluminum mode

measuring aluminum is being taken in standand

mode

No reading or wildly Measurment is being taken Switch to R to B1mode

fluxuating reading while in S to B1mode

measuring resin

Flashing coupling signal Probe or meter failure or Return to manufacturer for

and/or reading is displayed deterioratioin service

while the measurement is

in standby

Sonic velocity reading • Effect of external noise • Change use location

cannot be modified (fixed

to 5930 m/s) • Meter failure • Return to manufacturer for

service

Measurement of Test • Accoustic Velocity not • Change velocity to 5930

Plate does not show set to 5930 (steel) 5930 µs.

0.197”

(5.00mm)

(Refer to section 5.0)

TI-44N Operating Instruction Guide

16

Page 6

4.3 Turning The Power ON

Turn on the power by pressing the POW key. The current acoustic velocity

setting will be momentarily displayed prior to entering the Measurement

Mode (Mode H). The display should then read 0.000 inch (or 0.00 mm).

If the Good Coupling Indicator is flashing on and off, the red transmit

connector of the probe is not connected properly.

4.4 Turning The Power OFF

The Power will turn off automatically after three (3) minutes of non-use.

To manually turn off the power, press & hold the POW key for 3 sec.,

then release.

4.5 Zero Adjustment

This operation adjusts the zero point of the probe. Zero adjustment data is stored in

the instrument. It is recommended that the zero

adjustment data be refreshed once a day, preferably

before starting the day’s work.

1 . Apply couplant on the test plate surface and

place the probe on it.

2 . Make sure the probe is in good contact with

the test plate surface and press the ZERO

switch.

3 . The zero adjustment procedure takes place and the display reads 0.197" or

5.00 mm when the process has been successfully completed.

NOTE: When the sonic velocity is set to a value other than 5390 m/s, the

display reads 0.197" or 5.00 momemtarily when the ZERO switch

is pressed. Zero adjustment is nonetheless proceeding correctly.

If the material to be tested is signifcantly larger or smaller than

0.197" or 5.00mm, and the ZERO switch is pressed, the display

will read --- -and the zero adjustment process becomes invalid. In

this case, the zero adjustment should be made on a sample of known

thickness of the test material itself.

4.6 Using Couplant Fluid

Apply couplant fluid to the mesuring surfacae before measurement. The

couplant eliminates air between the probe and test surface, promoting the

transmission of the ultrasonic pulse.

NOTE: Never use organic solvents, including thinners and alcohols.

The surface must be cleaned of couplant after measurement.

TI-44N Operating Instruction Guide

6

8.0 TROUBLE-SHOOTING GUIDE

Description of Problem Possible Cause Action To Be Taken

Gauge will not power Battery voltage may be Replace with new AA

up too low battery

Gauge will not power • New battery may be • Check battery voltage

up even though battery too weak (should be ≈1.5 Volt)

has been replaced

• Back-up battery (lithium) • Return gauge for a new

could be too weak lithium battery

Good Coupling

• Probe or cable could be • Clean probe & surface

Indicator flashes on/off defective and retry measurement

• Foreign substance may • Return to manufacturer

be trapped between for inspection/repair

probe and sample

Good Coupling

• Insufficient couplant fluid • Add more couplant

Indicator not shown

• Paint or coating is too • Grind off paint and/or

thick or voids and/or corrosion

corrosion lies under paint

“......” is displayed Probe could be degraded Return to manufacturer

when ZERO key is or defective for inspection or repair

pressed

Displayed thickness Acrylic probe face is Carefully sand face of

value is unstable deteriorated probe using #500 paper

Can’t obtain measure- Pipe diameter (OD) may Consult factory

ment on small dia. pipe be less than 1”

(25 mm)

Couping indicator does • Insufficient amount of • Apply additional couplant

not appear while measure- couplant

ment is being taken • Test material surface is • Grind/polish measuring

too rough surface to 50-100-s

smoothness

• Test material bottom • Change measurement

surface is too rough point

• Too much ultrasonic • Change measurement

attenuation due to point

material composition

• Test material thickness is • Change measurement

outside the proper point

measuring range

Fluxuating readings Defective probe Return to manufacturer

TI-44N Operating Instruction Guide

15

Page 7

5.0 QUICK STA RT INSTRUCTIONS - STEEL THICKNESS

These Quick Start procedures are intended for those applications where the thickness

of steel is to be measured.

If a material other than steel will be measured, the acoustic velocity must be adjusted

to the appropriate value. In this case refer to Changing Acoustic Velocity Settings in

section 6.3

1. Turn the power on by pressing the POW key.

2. Check the calibration by placing a drop of coupling on the built-in calibration

disc on the front face of the gauge.

3. Grasp the probe and place it on the calibration disc.

4. The display should show a reading of 0.197 Inch ±0.001"

or 5.00 mm ±0.01 mm,along with the Good Coupling

Indicator located in the upper left side of the LCD display.

The indicator will remain on the display while the probe is in contact with the

sample.

5. If the gauge shows any other value press the

ZERO key while the probe remains

in contact with the calibration disc. The reading should then be adjusted to read

correctly. The gauge is now ready to perform thickness readings on steel

samples.

6. Place a small amount of coupling fluid on the steel surface to be measured and

proceed as indicated in step 3 above.

7. The gauge will display the thickness of the steel wall along with the Good

Coupling Indicator. The Indicator will remain on the display while the probe is

in contact with the sample. If the Indicator is not displayed, then the

measurement was not successful and should be repeated.

Good Coupling

Indicator

NOTES

a. When the probe is removed from the sample after a measurement, the last reading

will be stored.

b. The gauge will power off automatically after 3 minutes of non-use. To manually

turn off the power, press and hold the POW key for 3 or more seconds and then

release.

c. Refer to Trouble-shooting Guide if any problems occur.

TI-44N Operating Instruction Guide

7

7.1 Notes On Measurements

1. The following surface conditions can prevent accurate measurements.

(Refer to section 7.2 Preparing The Surface For Measurement.)

• More than 0.012" (12 mils or 300 microns) of paint or other coating

• Flaking or loosely adhered coatings

• Rough or heavily-pitted surface

2 . If the Good Coupling Indicator is not shown on the display when the

probe is in contact with the sample or if it flashes on and off, the

following possibilities could exist:

• Some foreign substance (other than coupling fluid) could be present

between the probe and the sample (i.e. dust, sand, dirt, etc.)

• Extent of corrosion is too heavy

• A problem exists in the receiving (green) side of the cable or connector

3. If two materials are press-fitted or laminated together, the gauge will only

read the thickness of the sample that the probe contacts.

4. Pipes with outer diameters less than 1 Inch (25 mm) cannot be measured.

Specify Model TI-25.

5. Measurement of materials at or above 140 °F (60 °C) will damage the probe

and should be avoided.

7.2 Preparing The Surface For Measurement

The TI-44N Gauge can be used to measure thickness over existing paint or

coatings as long as the coating is in good condition, is well adhered to the

surface and does not exceed 0.012" (12 mils or 300 microns) in thickness.

Please note that the paint or coating thickness will be included in the overall

wall thickness measurement.

If the surface to be measured is rusty, heavily pitted or corroded, it will have

to be prepared using a wire brush, grinder, file or sandpaper. Additionally, if

the surface is still rough after preparation, use of a more viscous couplant

fluid (i.e. water-based K-Y Jelly) will help obtain a good acoustic coupling.

K-Y Jelly is also a good choice when measuring on vertical surfaces or on

the underside as it will help adhere the probe to the measurement surface

while also acting as a coupling agent.

TI-44N Operating Instruction Guide

14

Page 8

6.0 SETUP FOR MEASURING THICKNESS OF MATERIALS

OTHER THAN STEEL

The TI-44N Thickness Gauge is supplied from the factory set for an acoustic velocity

of 5930 m/sec for the measurement of Steel. To measure the thickness of any other

material, the acoustic velocity must be changed. When checking the built-in calibration disc, the gauge should display the “Equivalent Value” listed in the Table in section 6.1, instead of 0.197" or 5.0 mm for steel.

To determine the proper acoustic velocity for measurement of the non-steel material,

refer to the Acoustic Velocity Selection Table in section 6.1. After determining the

proper acoustic velocity, the gauge must be changed to this new value as described

in section 6.3 Changing The Acoustic Velocity Settings.

If you do not know the type of material to be measured or the material type is not

listed in the Acoustic Velocity Selection Table, refer to section 6.2, Setup Of Gauge

When Acoustic Velocity is Unknown

TI-44N Operating Instruction Guide

8

7.0 TAKING MEASUREMENTS

After setting the gauge for the correct acoustic velocity for the material to be measured or retaining the factory preset value of 5930 m/sec for measurement of steel, the

gauge is ready to take measurements.

A coupling fluid must be used between the probe and the sample to obtain measurements. Atwo (2) ounce bottle is supplied with the gauge. We highly suggest using

this water soluble couplant. Long-term use of petroleum-based couplants (grease,

oil, etc.), salt water or chemical solvents will eventually damage the probe.

Additional bottles of coupling fluid are available from the gauge supplier.

1. Turn the power on by pressing the

POW key.

2. Place a small amount of coupling fluid on the calibration disc located on the

face of the instrument.

3. Grasp the probe by the holding the spring-loaded centering shell and place it on

the calibration disc. Press the shell down until it contacts the surface.

4 . Confirm that the calibration disc measures 0.197" (± 0.001") or

5.0 mm (± 0.01mm) or the “Equivalent Value” as found in the Acoustic Velocity

Selection Table for non-steel materials.

5. Place a small amount of coupling fluid on the surface to be measured, press

probe onto the surface and proceed as indicated in step 3 above.

The gauge will display the thickness of the material or wall along with the Good

Coupling Indicator. The Indicator will remain on the display while the probe is in

contact with the sample.

If the Good Coupling Indicator is not displayed, then the measurement was not

successful and should be repeated. If this problem persists then the surface may

not be in acceptable condition for measurement. Refer to Preparing The Surface

For Measurement, section 7.2.

Good Coupling

Indicator

TI-44N Operating Instruction Guide

13

Page 9

6.1 Acoustic Velocity Selection Table

ACOUSTIC VELOCITY SELECTION TABLE

Material Acoustic Equivalent Equivalent

Type Velocity Value Value Of

(meters/sec) Of Calibration Calibration Disc

Disc (Inch) Disc (mm)

Aluminum 6260 .208 5.3

Acrylic (Plexiglass) 2700 .090 2.3

Cast Iron 4400-5000 .148 - .168 3.8 - 4.3

Ceramics 10000 .332 8.4

Copper 4700 .156 3.9

Duralumin (17S) 6320 .211 5.3

Ebonite 2500 .083 2.1

Glass 5570 .185 4.7

Nickel 6040 .201 5.1

Polyethylene (Soft) 1900 .063 1.6

Polyvinyl Chloride (PVC) 2300-2500 .077-.083 1.9 - 2.1

Quartz (X cut) 5720 .191 4.9

Stainless Steel (SUS304) 5790 .193 4.9

Stainless Steel (SUS403) 6100 .205 5.2

Stainless Steel (SUS410) 7390 .246 6.2

Steel 5930 .197 5.0

Tin 3320 .110 2.8

Zinc (Zn) 4170 .139 3.5

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆

◆ Denotes one of the 10 preset values in Mode C.

TI-44N Operating Instruction Guide

9

6.5 Changing Modes

Flow of mode selection:

S to B1measurement method

Standard Thickness value

Measurement Ex.: 5.00 mm

F/ H appears on the extreme

right in Free / Hold mode,

respectively.

Aluminum Thickness value followed by A

Measurement Ex.: 5.00 mm_A

F/H appears on the extreme

right in Free/Hold mode,

respectively.

TI-44N provides two measurement modes depending

upon the nature of the test material (Standard and

Aluminum mode), which can be easily switched by

MODE switch operation:

Pressing and holding the MODE switch for longer than two seconds always

toggles back and forth between the Free and Hold modes.

Free mode is the correct choice for almost all applications. Select the Hold

mode when readings fluxuate and stable measurement cannot be obtaned.

TI-44N Operating Instruction Guide

12

Page 10

6.2 Setup Of Gauge When Acoustic Velocity Is Unknown

In applications where the type of material is not known or the material type

is not listed in the Acoustic Velocity Selection Table the following steps can

be performed to set the gauge to measure accurately.

1. Measure a sample of the material using a micrometer, caliper or similar

measuring device.

2. Turn the power on by pressing the POW key.

3. Place a small amount of couplant fluid on the sample and place the probe

on the sample.

4. After a thickness value is shown on the LCD display along with the Good

Coupling Indicator, remove the probe from the sample.

5. Use the

▲ and ▼ keys to increase or decrease the displayed value until

it equals the known thickness of the sample as measured in Step 1. When

the

▲ key is pressed the “UP” indicator will be show on the LCD display.

The “LOW” indicator will be shown for the ▼ key.

6. The acoustic velocity setting will be automatically adjusted to the correct

value for this material after Step 5 is completed.

7 . Change modes to either Mode C or Mode A to display the current acoustic

velocity, as described in section 6.4. Write this value down so it can be

re-entered without having to repeat the above procedures should you need

to change the acoustic velocity to another setting.

6.3 Changing Acoustic Velocity Settings

After determining the required acoustic velocity for the material to be

measured, the acoustic velocity must be adjusted by using either of the

following methods:

• Selecting one of the ten (10) preset values [Mode C, Coarse Adjustment]

• Adjusting the velocity to the desired setting [Mode A, Fine Adjusment]

METHODS FOR CHANGING ACOUSTIC VELOCITY SETTINGS

MODE Select one from Use ▲ or ▼ Last Setting ➔1900 ➔2700 ➔

C a list of 10 keys to index ➔ 4170 ➔ 4700 ➔ 5570 ➔ 5790

Preset Values thru selections ➔ 5930 ➔ 6260 ➔7390 ➔10000

MODE Fine Adjustment Use ▲ or ▼ Any acoustic value can be set

A to desired value keys to increase from 1000 to 12000 m/sec

or decrease value

TI-44N Operating Instruction Guide

10

6.4 Thickness Measurement Methods

(a) Standard mode vs. aluminum mode

The instrument is shipped with the standard sensitivity settings suitable

mainly for steel measurement. In addition to this, it provides an aluminum

measurement mode with lower sensitivity (approx. 10 dB less than the

standard mode).

High-sensitivity equipment will often pick up too much noise when

measuring materials with small ultrasonic attenuation (e.g. aluminum),

resulting in erroneous thickness values.

(b) S to B 1method

Thickness (D) is determined using the

time difference between the upper surface

reflection (S-echo) and the first bottom

surface reflection (B-echo). This method

is mainly used for steel measurement.

TI-44N Operating Instruction Guide

11

Page 11

ELECTROMATIC

E Q U I P M E N T C O., I N C.

600 Oakland Ave., Cedarhurst, NY 11516–U.S.A.

TEL: 516-295-4300 • FAX: 516-295-4399

CHECK•LINE

®

INSTRUMENTS

CHECK•LINE

®

BY ELECTROMATIC

TI-44N

Operating Instructions Guide

Loading...

Loading...