Page 1

-1-

TABLE OF CONTENTS

01.0 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 02

1.1 Upacking

1.2 Optional Accessories

2.0 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

03

2.1 First Installation

2.2 Internal Sensor Calibration

2.3 ZERO Adjustment

2.4 GAIN Adjustment

2.5 Checking The Adjustment

3.0 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

07

4.0 Pin Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

07

5.0 Appendix: Available Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

08

5.1 TE Models

52. TP Mocels

5.3 TE-24 Models

5.4 TE-22 Models

5.5 TF Models

5.6 TERX Models

5.7 BTMS Models

6.0 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

-12-

6.0 WARRANTY

ELECTROMATIC Equipment Co., Inc. (ELECTROMATIC) warrants to theoriginal

purchaser that this product is of merchantable quality and confirms in kind and quality

with the descriptions and specifications thereof. Product failure or malfunction arising

out of any defect in workmanship or material in the product existing at the time of

delivery thereof which manifests itself within one year from the sale of such product,

shall be remedied by repair or replacement of such product, at ELECTROMATIC’s

option, except where unauthorized repair, disassembly, tampering, abuse or misapplication has taken place, as determined by ELECTROMATIC. All returns for warranty

or non-warranty repairs and/or replacement must be authorized by ELECTROMATIC,

in advance, with all repacking and shipping expenses to the address below to be borne

by the purchaser.

THE FOREGOING WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO, THE

WARRANTY OF MERCHANTABILITY AND FITNESS FOR ANY PARTICULAR

PURPOSE OR APPLICATION. ELECTROMATIC SHALL NOT BE RESPONSIBLE

NOR LIABLE FOR ANY CONSEQUENTIAL DAMAGE, OF ANY KIND OR

NATURE, RESULTING FROM THE USE OF SUPPLIED EQUIPMENT, WHETHER

SUCH DAMAGE OCCURS OR IS DISCOVERED BEFORE, UPON OR AFTER

REPLACEMENT OR REPAIR, AND WHETHER OR NOT SUCH DAMAGE IS

CAUSED BY MANUFACTURER’S OR SUPPLIER’S NEGLIGENCE WITHIN

ONE YEAR FROM INVOICE DATE.

Some State jurisdictions or States do not allow the exclusion or limitation of incidental

or consequential damages, so the above limitation may not apply to you. The duration

of any implied warranty, including, without limitation, fitness for any particular

purpose and merchantability with respect to this product, is limited to the duration of

the foregoing warranty. Some states do not allow limitations on how long an implied

warranty lasts but, not withstanding, this warranty, in the absence of such limitations,

shall extend for one year from the date of invoice.

ELECTROMATIC Equipment Co., Inc.

600 Oakland Ave. Cedarhurst, NY 11516—USA

Tel: 1-800-645-4330/ Tel: 516-295-4300/ Fax: 516-295-4399

Every precaution has been taken in the preparation of this manual. Electromatic Equipment Co., Inc., assumes

no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of

information contained herein. Any brand or product names mentioned herein are used for identification purposes only, and are trademarks or registered trademarks of their respective holders.

Page 2

-2-

1.0 INTRODUCTION

These Operating Instructions refer to Model TE sensor; they are also applicable to the

following models:

TP, TE-24, TE-22, TF, TERX, BTMS

1.1 Unpacking

When the sensor is delivered without a display and data analysis unit:

1 Diode connector, 8-pin

1 Operating Instructions

Unpack the instrument and inspect it for any shipping damage. Notices of defect

must be filed immediately, at the latest within 10 days on receipt of the goods.

1.2 Optional Accessories

Option DC: Analog output 0 - 10 V DC

Option MA: Analog output 4 - 20 mA

-11-

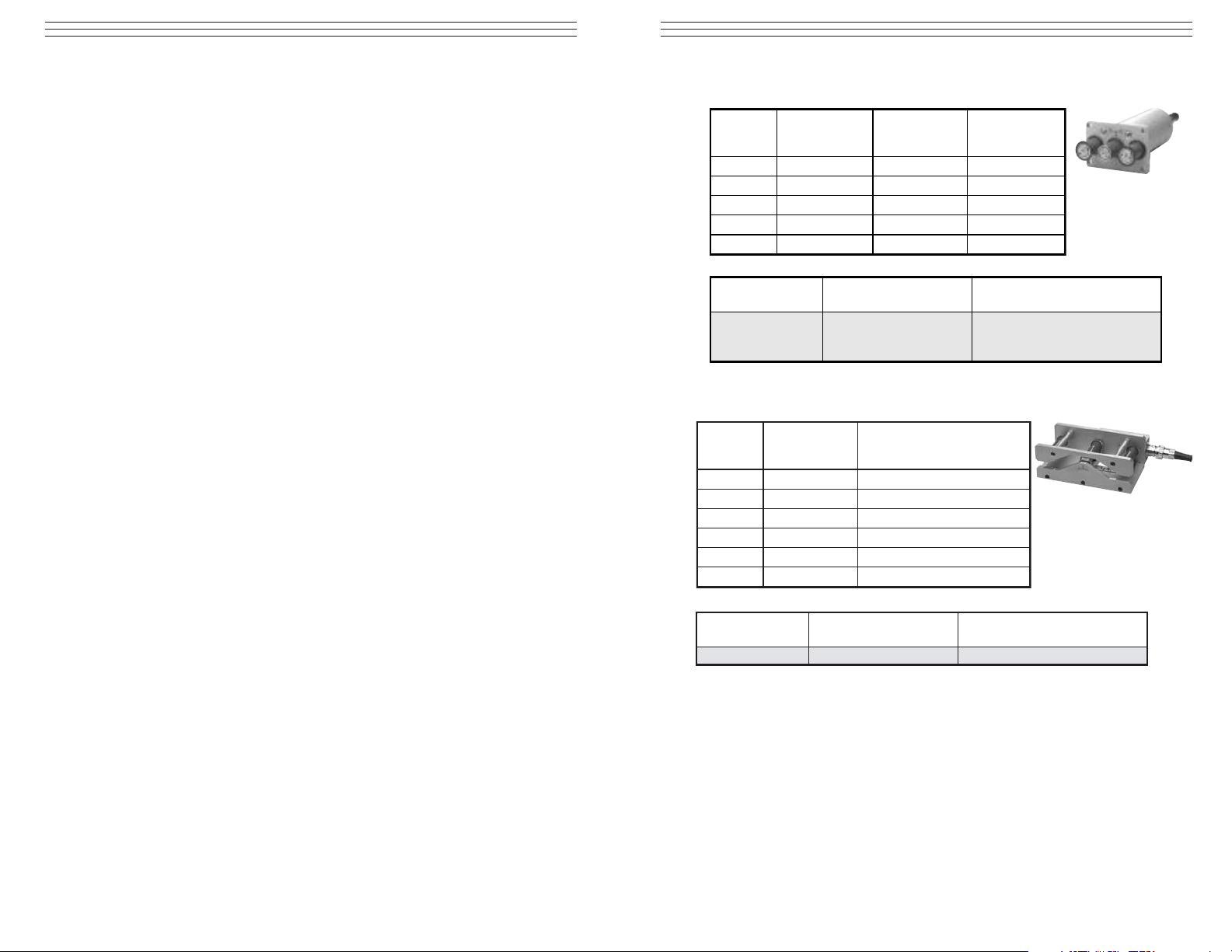

5.7 BTMS Models

5.6 TERX Models

Model

TERX-100

TERX-200

TERX-500

TERX-1000

TERX-2000

TERX guide rollers:

Guide Rollers

Ten s ion Ran g es

0 - 1000 60 7, 10, 15, 20

0 - 2000 120 7, 10, 15, 20

Standard

Model

BTMS-1000

BTMS-2000

BTMS-5000

BTMS-10K

BTMS-20K

BTMS-50K

BTMS guide rollers:

Guide Rollers

Tension Ranges

cN

0 - 1000 30, 36, 41, 50, 100

0 - 2000 30, 36, 41, 50, 100

0 - 5000 10, 15, 20, 30, 36, 41, 50, 100

0 - 10 daN 10, 15, 20, 30, 36, 41, 50, 100

0 - 20 daN 10, 15, 20, 30, 36, 41, 50, 100

0 - 50 daN 10, 15, 20, 30, 36, 41, 50, 100

Standard

*

cN

0 - 100 60 7, 10, 15, 20

0 - 200 60 7, 10, 15, 20

0 - 500 60 7, 10, 15, 20

Measuring

Head Width mm

Line Speed

m/min max.

1000

Roller Widths

Line Speed

m/min max.

1000 Hardcoated aluminium

Roller Widths

Roller Material

Hardcoated aluminium

(Exception: 7 mm rollers

are made of nickel-plated steel)

Roller Material

Page 3

-3-

2.0 OPERATION

2.1 First Installation

1. Install the sensor at the desired measuring location.

2. Connect the sensor with the supplied or existing display unit. The pin

assignment of the 8-pin connector located on the rear side of the sensor is

described in section 4.0.

3. If the material path is other than vertical or if the process material deviates

significantly from the factory calibration material, you have to carry out

zero and gain adjustment, as described in

section 2.3 adn 2.4, before

first installation.

3. Wait approx.10 minutes for the sensor to warm up.

4. Thread the process material through the measuring

rollers, following the thread acquisition symbol on

the front of the sensor.

2.2 Internal Sensor Calibration

General Notes:

If the sensor was delivered together with a display unit, ZERO and GAIN

adjustment should only be performed on the supplied display unit.

All tension meters are calibrated with standard materials—such as polyamidemonofilament (PA)—according to the factory procedure; the material path is

vertical (Model BTMS horizontal).

Any difference in process material size and rigidity from the standard material

may cause a deviation of the accuracy.

In 95% of all industrial applications the factory calibration has been proven

to provide the best results and is used for comparative purposes.

If required, you can operate the sensors with a material path other than

vertical.

If the process material differ significantly in size, rigidity and shape we recommend special calibration using customer material. In the case of a material path

other than vertical or special calibration using customer material you have to

carry out static zero and gain adjustment once again as described i

n Chapters

3.2.1 and 3.2.2.

The device must not be operated in explosion hazard areas and must not come

into contact with aggressive substances.

To avoid damage, do not move the center roller by hand.

Tensions that exceed the tension range of the device by more than 100%

may cause a permanent deformation of the measuring spring and must be

avoided under any circumstances.

-10-

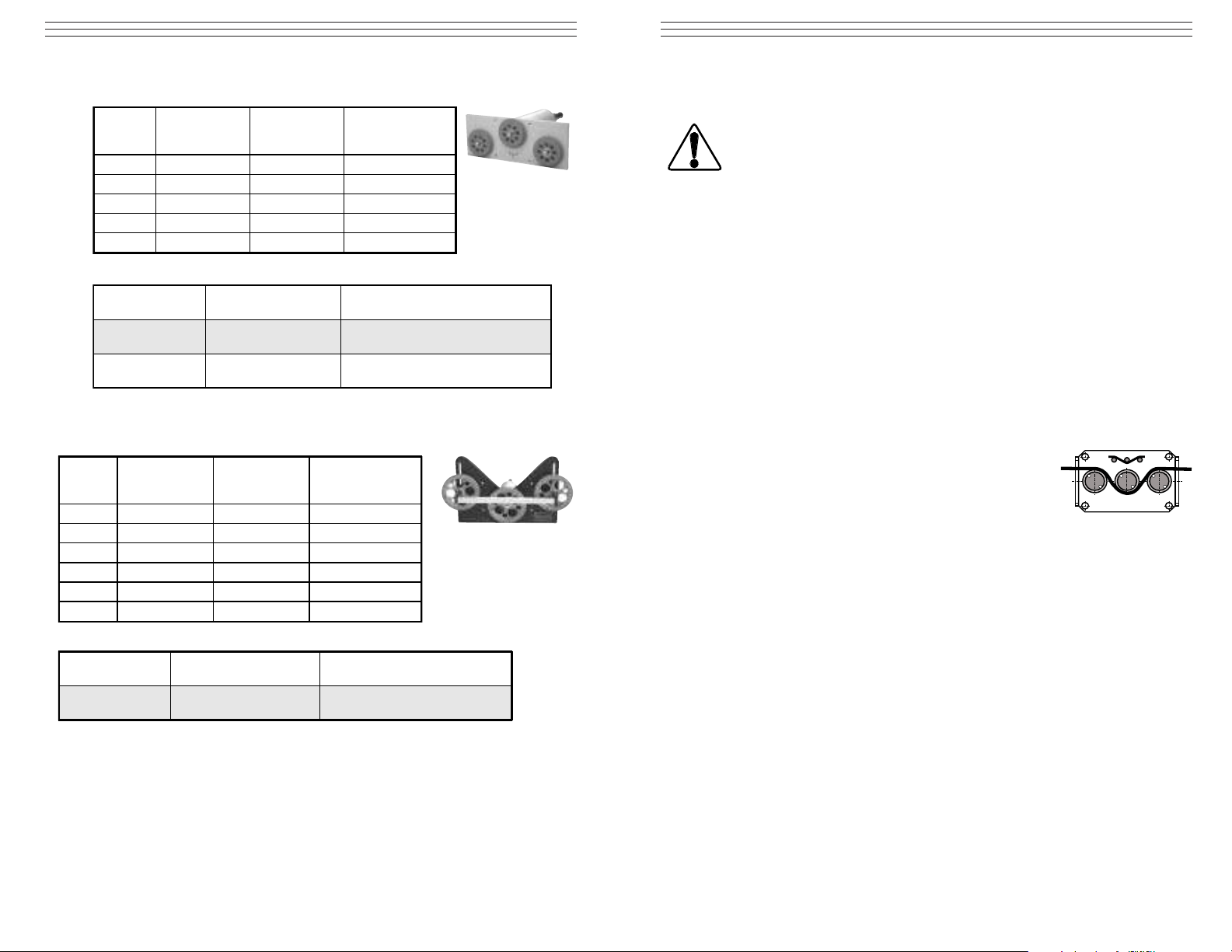

5.4 TE-22 Models

5.5 TF Models

Model

TE-22-50

TE-22-100

TE-22-200

TE-22-500

TE-22-1000

TSL guide rollers:

V-g ro ove d

Standard

Option

Model

TF-100

TF-200

TF-500

TF-1000

TF-2000

TF-5000

TSF guide rollers:

Tensi on Ra ng es

0 - 100 270 PA: 0.30 mm Ø

0 - 200 270 PA: 0.50 mm Ø

0 - 500 270 PA: 0.80 mm Ø

V-g ro ove d

Standard

Tension Ranges

cN

0 - 50 150 PA: 0.12 mm Ø

0 - 120 150 PA: 0.12 mm Ø

0 - 200 150 PA: 0.12 mm Ø

0 - 400 150 PA: 0.20 mm Ø

0 - 1000 15 PA: 0.30 mm Ø

T

cN

0 - 120 270 PA: 0.12 mm Ø

0 - 200 270 PA: 0.12 mm Ø

0 - 400 270 PA: 0.20 mm Ø

Head Width mm

Line Speed

m/min max.

*

Measuring

Head Width mm

Line Speed

m/min max.

4000

4000

*

Measuring

5000

**

FACTORY

Calibration Material

Hardcoated aluminium

(Same dimension as standard roller)

**

FACTORY

Calibration Material

Roller Material

Hardcoated aluminium

(Nr. R12045)

Roller Material

(Nr. R12021)

Plastic (PVC reed)

WARNING

Page 4

-4-

2.3 ZERO Adjustment

1. Install the sensor at the measruing locations in the desired measuring position,

using the provided mounting holes.

2. Remove the countersunk head screws (M2.5)

ZERO and GAIN on the rear side of the

sensor.

3 .Wait approx. 10 minutes for the measuring

head to warm up.

4. Thread the process material through the

measuring rollers, following the thread

acquisition symbol on the front of the sensor.

NOTE: Since zero and gain adjustments are always performed statically the

display values may differ under dynamic load.

5. Suspend a weight that corresponds to, for example, 10% of the tension range

from the measured material (see diagarm above).

6. Connect a voltmeter to pins 1 and 7 of the connector provided on the rear side

of the sensor. See section 4.0

When threading the process material through the rollers,

follow the material acquisition symbol on the front of the

sensor. If force is applied to the middle sensing roller in

the incorrect direction, damage could result.

W

-9-

5.2 TP Models

5.3 TE-24 Models

Mounting holes 4 x

Guide rollers 2x

Measuring

roller

Material path

symbol

Model

TP-50

TP-100

TP-200

TP-500

TP guide pins:

Tension Ranges

0 - 120 64 PA: 0.12 mm Ø

0 - 200 64 PA: 0.12 mm Ø

0 - 400 64 PA: 0.20 mm Ø

Guide Pins

Standard

*

cN

0 - 50 64 PA: 0.12 mm Ø

Measuring

Head Width mm

Line Speed

m/min max.

6000 Oxide ceramic 4 mm Ø (Nr. R12056)

**

FACTORY

Calibration Material

Pin Material

Weight

GAIN

ZERO

ARNING

Model

TE-24-1000

TE-24-2000

TE-24-5000

TE-24-10K

TE-24-20K

TE-24-50K

TE-24 guide rollers:

Tension Ranges

0 - 1000 150 PA: 0.30 mm Ø

0 - 2000 150 PA: 0.50 mm Ø

0 - 5000 150 PA: 0.80 mm Ø

0 - 10 daN 200 PA: 1.00 mm Ø

0 - 20 daN 200 PA: 1.50 mm Ø

0 - 50 daN 200

V-g ro ove d

Standard

U-grooved

Option R1

cN

*

Measuring

Head Width mm

Line Speed

max. m/min

4000

4000

**

FACTORY

Calibration Material

Steelrope 1.50 mm Ø

(7 x 7 x 0.20)

Roller Material

Hardened steel roller

(Nr. R10006)

Hardened steel roller

(Radius R5)

Page 5

-5-

7. Insert a screw driver (with a point width of up to 1.9 mm) into the now

accessible ZERO opening of the housing and adjust the potentiometer until

the connected voltmeter shows a measured voltage of, for example:

Sensor Model TS -200:

Weight 20 cN = Display 0.100 V for the TS standard version

or

Weight 20 cN = Display 1.00 V for the TS version with 10 V output signal.

2.4 GAIN Adjustment

Requirement: ZERO adjustment (section 2.3)t must be carried out first.

1. Thread the process material through the measuring rollers, following the

thread acquisition symbol on the front of the sensor.

2. Suspend a weight that corresponds to, for example, 95% of the tension range

from the measured material (see diagram on page 4).

3. Insert a screw driver (with a point width of up to 1,9 mm) into the now

accessible GAIN opening of the housing(see diagram on page 4) and adjust

the potentiometer until the connected voltmeter shows a measured voltage of,

for example:

Sensor Model TS-200:

Weight 190 cN = Display .950 V for the TS standard version

or

Weight 190 cN = Display 9.50 V for the TS version with 10 V output signal.

4. Check the adjustment with a fresh portion of the process material and repeat

the adjustments if required, following the direction in section 2.3 and 2.4.

5. Screw in the countersunk head screws

ZERO and GAIN on the rear side of the

sensor.

Do not tilt the screwdriver as this may damage the

potentiometer.

-8-

5.0 APPENDIX: AVAILABLE MODELS

In addition to the standard specifications listed below, the following custom modifications are also available:

■ Special tension ranges

■ Customized roller dimensions

■ Special calibration using customer supplied material

5.1 TE Models

Model

TE-50

TE-100

TE-200

TE-500

TE-1000

TE-2000 0 - 2000 124 PA: 0.50 mm Ø

TE-5000

TE-10K 0 - 10 daN 124 PA: 1.00 mm Ø

TE-20K

TE-50K

TE Guide Rollers

V-grooved

Option

Option

Option

Option

Option

Option

Option

Asymmetrical groove

U-grooved

Option

Tensi on

Ranges

cN

0 - 50 64 PA: 0.12 mm Ø

0 - 100 64 PA: 0.12 mm Ø

0 - 200 64 PA: 0.12 mm Ø

0 - 500 64 PA: 0.20 mm Ø

0 - 1000 64 PA: 0.30 mm Ø

0 - 5000 124 PA: 0.80 mm Ø

0 - 20 daN 224 PA: 1.50 mm Ø

0 - 50 daN 224

Standard

K

H

T

W

ST

B

CE

ASY

U

*Measuring

Head Width

mm

Line Speed

m/min max.

2000 Hardcoated aluminium (Nr. R10008)

3500 Hardcoated aluminium

5000

1000 Plastic (POM) black

1000 Nickel-plated steel

1000 Hardened steel

1000

1000 Ceramic

1000

2000 Hardcoated aluminium

Calibration Material

Steel rope: 1.50 mm Ø

(for Model TE-100 and higher ranges)

Steel tempred, especially for measuring

(for Model TE-100 and higher ranges)

**FACTORY

(7 x 7 x 0.20)

Roller Material

Plasma-coated aluminium

Tyrecord

Hardcoated aluminium

WARNING

GAIN

ZERO

Page 6

-6-

2.5 Checking the Adjustment

For general information, refer to section 2.2.

Requirements:

1. The sensors must be installed at the measuring location. Connect the sensor

with the supplied or existing display unit.

NOTE: The pin assignment of the 8-pin connector located on the rear side of

the sensor is described in section 4.0. Wait approx. 10 minutes for the sensor to

warm up.

Checking procedure:

1. Thread the process material through the measuring rollers, following the

red marking on the front of the sensor.

2. Suspend a weight that corresponds to the tension to be measured (pay

attention to the correct unit of measure) from the measured material,

vertically, as shown above. (Always use a fresh portion of the material to

be measured.)

3. The tension value on the connected display unit should be equal to the value

of the suspended weight. If this procedure shows a deviation beyond the

allowable tolerance and a reliable operation is no longer allowed, the instrument has to be readjusted, following the directions in sections 2.3 and 2.4

When threading the process material through the rollers,

follow the material acquisition symbol on the front of the

sensor. If force is applied to the middle sensing roller in

the incorrect direction, damage could result.

W

-7-

3.0 SPECIFICATIONS

Calibration According to factory procedure Suitable for 95% of

applications. PA = Polyamide Monofilament. If the

material to be measured differs significantly from the

facctory calibration material in diameter, rigidity,

shape, etc., we recommend calibration using customer

material. For this purpose, a material sample of at least

5 m should be supplied. International unit for tension

force:1 cN = 1.02 g = 0.01 N 1 daN= 1.02 kg = 10 N

Accuracy For 10% to 100% of range: ±1% full scale

Remainder of range and

other calibration material ±3% full scale or better

Overload protection 100% of range

Measuring principle Strain gauge bridge

Measuring roller deflection 0.5 mm, max.

Natural frequency of

measuring spring Approx. 500 Hz, depending on tension range

Signal processing Analog

Temperature coefficient Zero point: less than ±0.05% full scale / °C

Output signal 0 - 1 V DC Impedance: > 5 kOhm (standard) Option

Option DC 0 - 10 V DC

Option MA 4 - 20 mA

Damping (f g) Standard: approx. 30 Hz (other values on request)

Temperature range 10 - 45 °C Air humidity: 85% RH, max.

Power supply Standard: 12 to 18 V DC (21mA) (regulated)

Housing Aluminium

4.0 PIN ASSIGNMENTS

Pin No. Signal Description

1 GND Ground - analog signal

2 Not assigned

3 Not assigned

4 Not assigned

5 +12 to 24 VDC Supply voltage

regulated

6 GND Ground - analog signal

7 0–1 VDC

8 Not assigned

ARNING

Guide rollers 2x

Mounting holes 4 x

Measuring

roller

Weight

Material path

symbol

1

6

Shield

5

7

Page 7

TENSION SENSORS

Operating Instructions

CHECK•LINE

®

BY ELECTROMATIC

ELECTROMATIC

E Q U I P M E N T C O., I N C.

600 Oakland Ave., Cedarhurst, NY 11516–U.S.A.

TEL: 516-295-4300 • FAX: 516-295-4399

CHECK•LINE

®

INSTRUMENTS

Loading...

Loading...