Page 1

-1-

1.0 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 02

1.1 Complete Kit

2.0 Overview of Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 03

3.0 Removing/Replacing Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 03

4.0 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 04

4.1 Setting Decimal Point

4.2 Setting the Low Alarm Limit

4.3 Setting the High Alarm Limit

4.4 Enabling & Disabling Electronic Damping

5.0 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 06

6.0 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 07

6.1 Zero Adjustment

6.2 Gain Adjustment

6.3 Checking the Calibration

7.0 Analog Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7.1 Changing Analog Output Type

7.2 Zero and Gain Adjustments

8.0 Technical Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8.1 TD-1-TE Specifications

8.2 Pin Assignments

8.3 On-Line Sensor Specifications

9.0 Warranty

TABLE OF CONTENTS

-16-

8.3 Online Sensor Specifications

Series TS (Models TS1,TSP ,TSH, TSL,TSF,TSB1, TSB2)

Calibration: According to Electromatic factory procedure

Accuracy: For 10% to 100% of range: ± 1 % full scale

Remainder of

range and other

calibration material 3% full scale or better

Overload protection 100% of range

Measuring principle Strain gauge bridge

Measuring roller

deflection 0.5 mm, max.

Signal processing Analog

Output signal: 0 - 1 V DC (standard)

Damping (fg) Standard: 30 Hz (other values on request)

Temperature

coefficient: Gain: less than ± 0.01% full scale / °C

Temperature range 10 – 45 °C

Air humidity 85% RH, max.

Power supply Standard: 12 to 18 VDC (21 mA) (regulated)

Page 2

-2-

1.0 INTRODUCTION

Photo of complete kit if available

The TD-1-TE Tension Indicator accurately displays tension values calibrated

in any unit of measure on a bright LED display, designed for flush panel

mounting.

1.1 Complete Kit

• TD-1-TE

• Sensor (as ordered)

• Sensor connecting cable (standard length or as ordered)

• Operating instructions

-15-

8.0 TECHNICAL INFORMATION

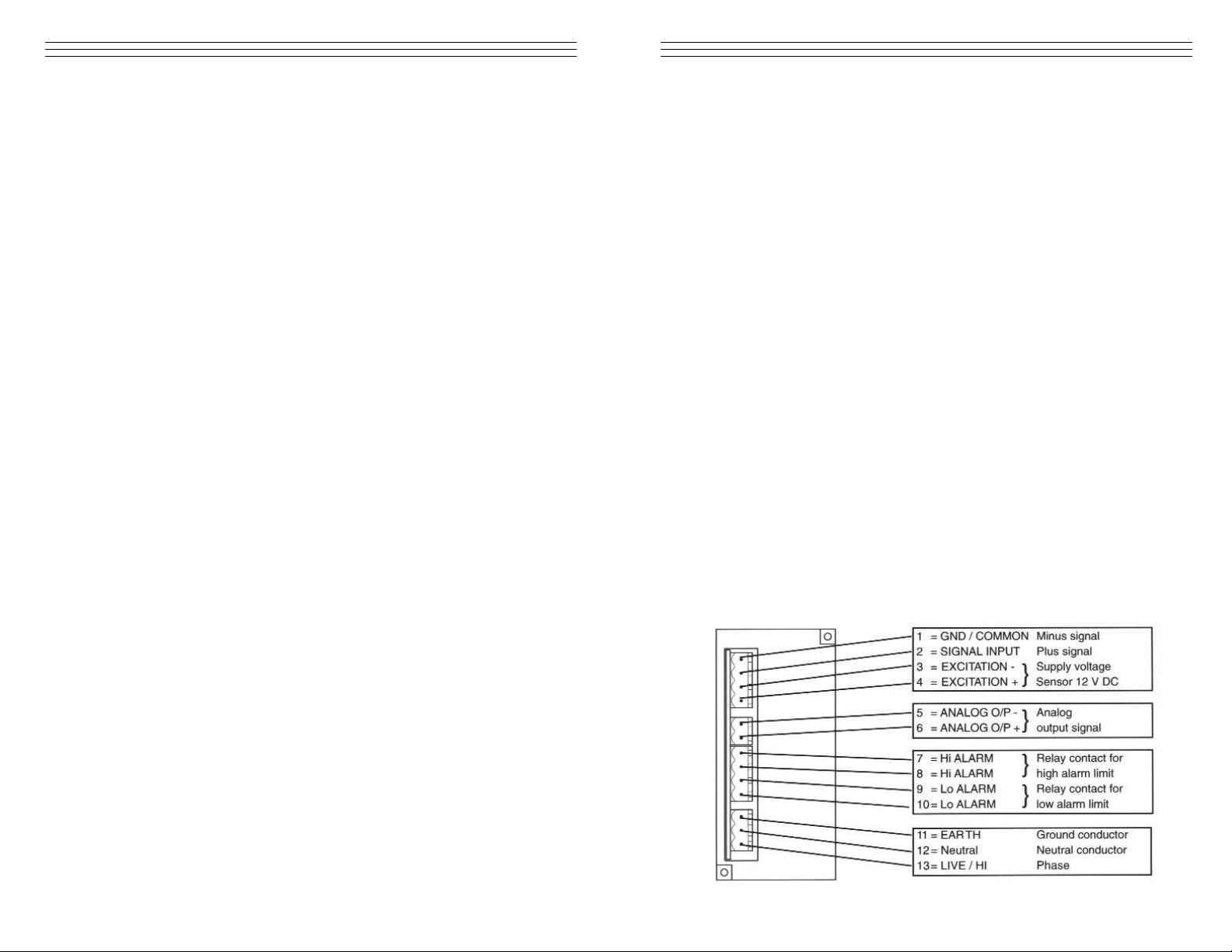

8.2 Pin assignments of connectors

8.1 TD-1-TE Specifications

Digital display 3.5-digit, 7 segment display, height 14.4mm

(with tension range setting

Tension units cN or daN (depending on sensor)

Damping (fg) 1 Hz or 40 Hz (selectable)

Output signal 0–10 VDC / R

LEAD

≥ 1K Ohm

Output voltage +12 VDC (115 V A C)

(sensor)

Power supply 115 V A C

Current Consumption 0.35 A (0.7A)

Relay output 1A / 230 VAC / 30 VDC break contact

Temperature range 1-–45 °C

Air humidity 85% RH, max

Housing Plastic

Dimensions 96 (L) x 48 (W) x 103 (H) mm

Panel cutout 96 (W) x 48 (H) mm

Weight (approx.) 400 g (net) 1000 g (gross)

Page 3

-3-

2.0 OVERVIEW OF THE TD-1-TE IND ICAT OR

3.0 REMOVING AND MOUNTING THE FRONT COVER

01 = Digital display

02 = Light emitting diode for low

alarm limit

03 = Light emitting diode for high

alarm limit

04 = Decimal point jumper no jumper

set of decimal point XXXX

05 = Pushbutton for low alarm limit

06 = Potentiometer for low alarm

limit

07 = ZERO potentiometer

08 = GAIN potentiometer

09 = Potentiometer for high alarm

limit

10 = Pushbutton for high alarm limit

Removing: Remove the two screws

Insert a screwdriver with a point width

of 4mm in the slot at the bottom of the

housing and carefully push the front

cover away from the panel in the

direction of the arrow.

Mounting: Carefully push the front

cover onto the housing in the opposite

direction of the arrow.

2. Hang a weight that corresponds to 10% of the tension range (pay attention

to the correct unit of measure) from the measured material, vertically, as

shown in the figure on page 12. (Always use a fresh portion of the

material to be measured.)

3. Adjust the potentiometer (13)

using a screw-driver with a

point width of up to 2mm

until the display of the

voltmeter connected to the

Analog interface reads

0.1 volts

-14-

GAIN Adjustment Procedure

1. Perform a Zero adjustment.

2. Thread the process material through the measuring rollers.

When threading the process material through the rollers, follow the

material path symbol on the front of the sensor. If a force is applied

to the middle sensor roller in the incorrect direction, damage could

result.

NOTE: Since zero and gain adjustments are always performed

statically, the display values may differ under dynamic load.

3. Hang a weight that corresponds to 95% of the tension range (pay

attention to the correct unit of measure) from the measured material,

vertically as shown in the figure on page 12. (Always use a fresh

portion of the material to be measured.)

4. Adjust the potentiometer (14) using a screwdriver (with a point width

of up to 2mm) until the display of the voltmeter connected to the

Analog interface reads 9.5 volts.

Check the setting and repeat the procedure if necessary.

1

2

3

XXX.XX.XXX

WARNING

13

14

42

3

XX.XX

567

8

9

10

Screw

Screw

Page 4

-4-

4.0 SETUP

4.1 Setting the Decimal Point (Refer to the diagrams in Section 2.0)

The decimal point is factory-set to the supplied sensor. If the indicator

unit is supplied without a sensor or after changing to a sensor with a

different tension range, the decimal point jumper (4) must be set to the

sensor's tension range as follows:

1. Remove the front cover as described in Section 3.0.

2. Set the jumper for decimal point display to the desired position (4)

4.2 Setting the Low Alarm Limit (Refer to the diagrams in Section 2.0)

1. Remove the front cover as described in Section 3.0.

2. Connect the TD-1-TE to the power supply and switch on.

3. Press the pushbutton (5) and use a screwdriver with a point width of

2.5 mm to turn the potentiometer (6) to the desired low alarm limit.

Keep the pushbutton (5) depressed while adjusting the pot. At the

same time, the digital display (1) shows the set low alarm limit.

4.3 Setting the High Alarm Limit (Refer to the diagrams in Section 2.0)

1. Remove the front cover as described in Section 3.0.

2. Connect the TD-1-TE to the power supply and switch on.

3. Press the pushbutton (10) and use a screwdriver with a point width

of 2.5 mm to turn the potentiometer (9) to the desired high alarm

limit. Keep the pushbutton (10) depressed while adjusting the pot. At

the same time, the digital display (1) shows the set high alarm limit.

4. Then set the front cover back in place as described in Section 3.0.

4.4 Enabling and Disabling Electronic Damping (Refer to the diagrams

in Section 2.0)

1. The indicator unit is shipped from the factory with the damping

disabled. To enable damping follow this procedure

2. Make sure the TD-1-TE is switched off and all plug connections on

the rear side of the device are disconnected.

-13-

When power is switched on, a voltage of 115 V is applied to the PC

board which is not protected against accidental contact when

removed from the housing. For this reason, calibrating the analog

output may only be carried out by trained electricians whose qualification for such work has been certified in accordance with local

regulations.

2. Connect a voltmeter to the ANALOG interface.

3. Connect the power supply in accordance with the pin assignment of

Section 8.2.

4. Switch on the power to the TD-1-TE.

5. Allow approx. 10 minutes for thermal stabilization of the unit.

ZERO Adjustment Procedure

1. Thread the process material through the measuring rollers, following

the red marking on the front of the sensor.

When threading the process material through the rollers,

follow the material path symbol on the front of the sensor. If a force

is applied to the middle sensor roller in the incorrect direction, damage could result.

NOTE: Since zero and gain adjustments are always performed

statically, the display values may differ under dynamic load.

WARNING

WARNING

Mounting holes 4 x

Material path

symbol

Guide rollers 2x

Measuring

roller

Weight

Page 5

-5-

3. Remove the front cover as

described in Section 3.0

4. Loosen the retaining screw (11) at

the bottom of the housing.

5. Carefully slide out the PC board

from the indicator housing in the

direction of the arrow.

6. Carefully slide the PC board back

into the indicator housing in the

opposite direction of the arrow.

7. Tighten the retaining screw 11 at

the bottom of the housing.

8. Set the front cover back in place

as described in Section 3.0.

Setting the jumpers:

Damping disabled

Damping enabled

Enable or disable electronic

damping with the jumpers at

the top of the PC board.

-12-

7.2 Zero and Gain Adjustments of the ANALOG Interface

If you change the connected sensor or if you want to fine-tune the

Analog interface you need to recalibrate the interface.

Adjustments to the analog output may only be carried out by

trained electricians whose qualification for performing such work

has been certified in accordance with local regulations.

Only sensors which comply with the specifications given in Section

8.3 may be connected. To avoid random noise and malfunctions,

make sure the cable connecting the TD-1-TE with the sensor is not

laid parallel to powerlines or highly loaded signal lines, regardless

of the type of voltage.

1. Remove the front cover following the instructions outlined in

Section 3.0.

2. Loosen the retaining screw

(11) at the bottom of the

housing.

3. Carefully slide out the PC

board from the indicator

housing in the direction of

the arrow.

Preparations for Calibration

1. Connect the TD-1-TE with sensor to be used in accordance with

the pin assignment illustrated in Section 8.2.

Only sensors which comply with the specifications given in Section

8.3 may be connected. To avoid random noise and malfunctions,

make sure the cable connecting the TD-1-TE with the sensor is not

laid parallel to power lines or highly loaded signal lines, regardless

of the type of voltage.

.

WARNING

WARNING

11

WARNING

11

11

Page 6

-6-

5.0 OPERATION

1. Install the sensor at the desired measuring location.

2. Connect the TD-1-TE with the supplied sensor as described Section 8.2..

Only sensors which comply with the specifications given in

Section 8.3 may be connected.

3. Connect the indicator unit with the power supply as described in Section

8.2 If a longer connecting cable should be required to connect the sensor

with the TD-1-TE, note the pin assignment of the sensor's 8-pin connector

indicated in the specifications of the sensor's Operating Instructions.

To avoid random noise and malfunctions, make sure the cable

connecting the TD-1-TE with the sensor is not laid parallel to power

lines or highly loaded signal lines, regardless of the type of voltage.

NOTE: The requirements of the CIE specification are only complied with

if the TD-1-TE is equipped and operated with sensors and connecting

cables supplied by Electromatic Equipment Company. Certification to the

CIE specification does not extend to, and shall be invalid for any other

combination. Under no circumstances shall Electromatic Equipment

Company be held liable for any resulting damage.

4. Switch on the power to the TD-1-TE. Allow approx. 10 minutes

for thermal stabilization.

5. If the material path is other than vertical or if the process material deviates

significantly from the Electromatic calibration material, you need to carry

a zero and gain adjustment before using, as described in Sections 6.1

and 6.2.

6. Thread the process material through the measuring rollers, following the

red marking on the front of the sensor.

7. The digital display will now show the measured line tension.

Process Material

Material Path Symbol

-11-

7.0 ANALOG INTERFACE

The analog interface is provided for customer signal processing or for connecting a line recorder which conforms to the current industrial standard.

Refer to Sections 8.1 and 8.2 for the specifications for the analog interface.

The TD-1-TE can be set to provide a 4-20 mA or a 0-10 VDC analog output

(non-isolated). It is supplied from the factory set for 4-20 mA output. To

configure the TD-1-TE for 0-10 VDC output a series of three jumpers must

be reconfigured into a different arrangement. To do this the internal PC Board

must be removed from the TD-1-TE housing and the small Input Card must

be removed from the PC Board to expose the jumpers. Refer to Section 7.1

The analog output is adjusted using the Analog Output Zero & Gain Pots

which are located on the right side of the PC Board under the Input Card.

The PC Board must be removed from the TD-1-TE housing to perform this

adjustment, but the Input Card does not have to be removed.

7.1 Changing Analog Output Type

To obtain access to the Analog Output

Adjustment Pots the PC Board must be

removed from the TD-1-TE housing.

1. Unplug all connectors on the rear

side of the unit (sensor, power, etc.)

2. Remove the front cover as

performed during calibration.

3. Remove the PC board retaining

screw located at the bottom of

the housing.

4. Carefully slide out the entire

internal assembly.

5. Remove the Input Card by

grasping it by its edges and pulling

straight up. The three jumpers will

be adjacent to the Analog Output

Adjustment Pots

6. Carefully remove all three jumpers

and re-configure them as shown

in the diagram.

WARNING

WARNING

Page 7

-7-

6.0 CALIBRATION

All tension meters are calibrated with standard material—such as polyamidemonofilament (PA)—according to the Electromatic factory procedure; the

material path is vertical. Any difference in process material size and rigidity

from the standard material may cause a deviation of the accuracy.

In 95% of all industrial applications, the Electromatic calibration has been

proven to provide the best results and is used for comparative purposes.

If required, you can also operate the sensors with a material path other than

vertical. Should the process material differ significantly from the

Electromatic calibration material in size, rigidity and shape, we recommend

special calibration using customer-supplied material. In the case of a material

path other than vertical or special calibration using customer-supplied

material, you need to carry out static zero and gain adjustment once again

as described in Sections 6.1 and 6.2.

When threading the process material through the rollers, follow the

material path symbol on the front of the sensor. If a force is applied

to the middle sensor roller in the incorrect direction,

damage could result.

NOTE: Since zero and gain adjustments are always performed statically, the

display values may differ under dynamic load.

-10-

NOTE: Since zero and gain adjustments are always performed

statically, the display values may differ under dynamic load.

3. Hang a weight that corresponds to the tension to be measured (pay

attention to the correct unit of measure) from the measured material,

vertically, as shown in the figure above (Always use a fresh portion

of the material to be measured.)

The tension value on the digital display should be equal to the

value of the suspended weight.

If this procedure shows a deviation beyond the allowable tolerance and

a reliable operation is no longer allowed, the instrument has to be

readjusted, following the directions in Section 6.3.

Guide rollers 2x

Mounting holes 4 x

Material path

symbol

Measuring

roller

Weight

WARNING

Mounting holes 4 x

Material path

symbol

Guide rollers 2x

Measuring

roller

Weight

Page 8

-8-

6.1 Zero Adjustment

Requirements:

• Decimal point set as described in Section 4.0.

• Front cover removed as described in Section 3.0.

• Sensor mounted at measuring location.

Only sensors which comply with the specifications given in Section

8.2 may be connected. To mold random noise and malfunctions,

make sure the cable connecting the TD-1-TE with the sensor is not

laid parallel to power lines or highly loaded signal lines, regardless

of the type of voltage.

NOTE: The requirements of the CIE specification are only complied

with if the TD-1-TE is equipped and operated with sensors and connecting cables supplied by Electromatic Equipment Company. Certification

to the CIE specification does not extend to, and shall be invalid for any

other combination. Under no circumstances shall Electromatic

Equipment Company be held liable for any resulting damage.

Procedure:

1. Connect the TD-1-TE with supplied sensor as shown in Section 8.2

2. Switch on the TD-1-TE and allow approx. 10 minutes for thermal

stabilization of the unit

3. Thread the process material through the measuring rollers, following

the red marking on the front of the sensor.

4. Hang a weight that corresponds to 10 % of the tension range (pay

attention to the correct unit of measure) from the measured material,

vertically as shown on page 7. (Always use a fresh portion of the

material to be measured.)

5. Adjust the potentiometer ZERO (#7, page 3) using a screwdriver

with a point width of up to2 mm until the tension value on the digital

display is equal to the value of the suspended weight.

For example:

Sensor Model TS - 200: Weight 20 cN = Display 20.0 cN

6. Set the front cover back in place as described in Section 3.0.

-9-

6.2 Gain Adjustment

1. Perform a Zero adjustment carried out as described in Section 6.1.

2. Thread the process material through the measuring rollers.

3. Hang a weight that corresponds to 95 % of the tension range (pay

attention to the correct unit of measure) from the measured material,

vertically as shown on page 7. (Always use a fresh portion of the

material to be measured.)

4. Adjust the potentiometer GAIN (#8, page 3) using a screwdriver

(with a point width of up to 2mm until the tension value on the

digital display (#1) is equal to the value of the suspended weight.

For example:

Sensor Model TS - 200: Weight 190 cN = Display 190.0 cN

5. Check the calibration with a fresh portion of the process material and

repeat the adjustments if required, following the directions in

Section 6.0.

6. Set the front cover back in place as described in Section 3.0.

6.3 Checking the Calibration

For general information, refer to Section 6.0.

Requirements:

• Decimal point set as described in Section 4.0.

• Front cover removed as described in Section 3.0.

• Sensor mounted at measuring location.

• TD-1-TE connected with supplied sensor as described in Section 8.2.

Procedure:

1. Switch on the power to the TD-1-TE. Allow Approx. 10 minutes for

thermal stabilization of unit.

2. Thread the process material through the measuring rollers, following

the red marking on the front of the sensor

When threading the process material through the rollers, follow the

material path symbol on the front of the sensor. If a force is applied

to the middle sensor roller in the incorrect direction, damage could

result.

WARNING

WARNING

Page 9

9.0 WARRANTY

ELECTROMATIC Equipment Co., Inc. (ELECTROMATIC) warrants to the original

purchaser that this product is of merchantable quality and confirms in kind and quality with

the descriptions and specifications thereof. Product failure or malfunction arising out of any

defect in workmanship or material in the product existing at the time of delivery thereof

which manifests itself within one year from the sale of such product, shall be remedied by

repair or replacement of such product, at ELECTROMATIC’s option, except where unauthorized repair, disassembly, tampering, abuse or misapplication has taken place, as determined

by ELECTROMATIC. All returns for warranty or non-warranty repairs and/or replacement

must be authorized by ELECTROMATIC, in advance, with all repacking and shipping

expenses to the address below to be borne by the purchaser.

THE FOREGOING WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO, THE WARRANTY

OF MERCHANTABILITY AND FITNESS FOR ANY PARTICULAR PURPOSE OR

APPLICATION. ELECTROMATIC SHALL NOT BE RESPONSIBLE NOR LIABLE FOR

ANY CONSEQUENTIAL DAMAGE, OF ANY KIND OR NATURE, RESULTING FROM

THE USE OF SUPPLIED EQUIPMENT, WHETHER SUCH DAMAGE OCCURS OR IS

DISCOVERED BEFORE, UPON OR AFTER REPLACEMENT OR REPAIR, AND

WHETHER OR NOT SUCH DAMAGE IS CAUSED BY MANUFACTURER’S OR

SUPPLIER’S NEGLIGENCE WITHIN ONE YEAR FROM INVOICE DATE.

Some State jurisdictions or States do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation may not apply to you. The duration of any

implied warranty, including, without limitation, fitness for any particular purpose and merchantability with respect to this product, is limited to the duration of the foregoing warranty.

Some states do not allow limitations on how long an implied warranty lasts but, not withstanding, this warranty, in the absence of such limitations, shall extend for one year from the

date of invoice.

ELECTROMATIC Equipment Co., Inc.

600 Oakland Ave. Cedarhurst, NY 11516—USA

Tel: 1-800-645-4330/ Tel: 516-295-4300/ Fax: 516-295-4399

Every precaution has been taken in the preparation of this manual. Electromatic Equipment Co., Inc.,

assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting

from the use of information contained herein. Any brand or product names mentioned herein are used for

identification purposes only, and are trademarks or registered trademarks of their respective holders

Page 10

ELECTROMATIC

E Q U I P M E N T C O., I N C.

600 Oakland Ave., Cedarhurst, NY 11516–U.S.A.

TEL: 516-295-4300 • FAX: 516-295-4399

CHECK•LINE

®

INSTRUMENTS

TD-1-TE

WITH TE TENSION SENSORS

Operati n g In str ucti ons

CHECK•LINE

®

BY ELECTROMATIC

xxxxxxxx

Loading...

Loading...