Page 1

TABLE OF CONTENTS

1.0 Introduction …………………………………………………………… 2

1.1 Calibration curves

1.2 Explanation of calibration curves

2.0 Operating the instrument ……………………………………………. 3

3.0 View of the instrument ………………………………………………. 4

4.0 Menu ………………………………………………………………….. 5

5.0 Other symbols and key functions ………………………………….. 6

6.0 Other instrument functions – Overview ………………………….… 7

7.0 Common reasons for incorrect measurements ……………….….. 8

8.0 Temperature behaviour of the sensors ……………………………. 9

9.0 Looking after the instrument ………………………………………... 9

10.0 Changing the batteries ………………………………………………. 10

11.0 Liability ………………………………………………………………… 10

12.0 Optional accessories ………………………………………………… 10

13.0 Technical data ………………………………………………………... 11

14.0 Warranty ………………………………………………………………. 12

Electromatic Equipment Co., Inc.

-1-

Page 2

1.0 INTRODUCTION

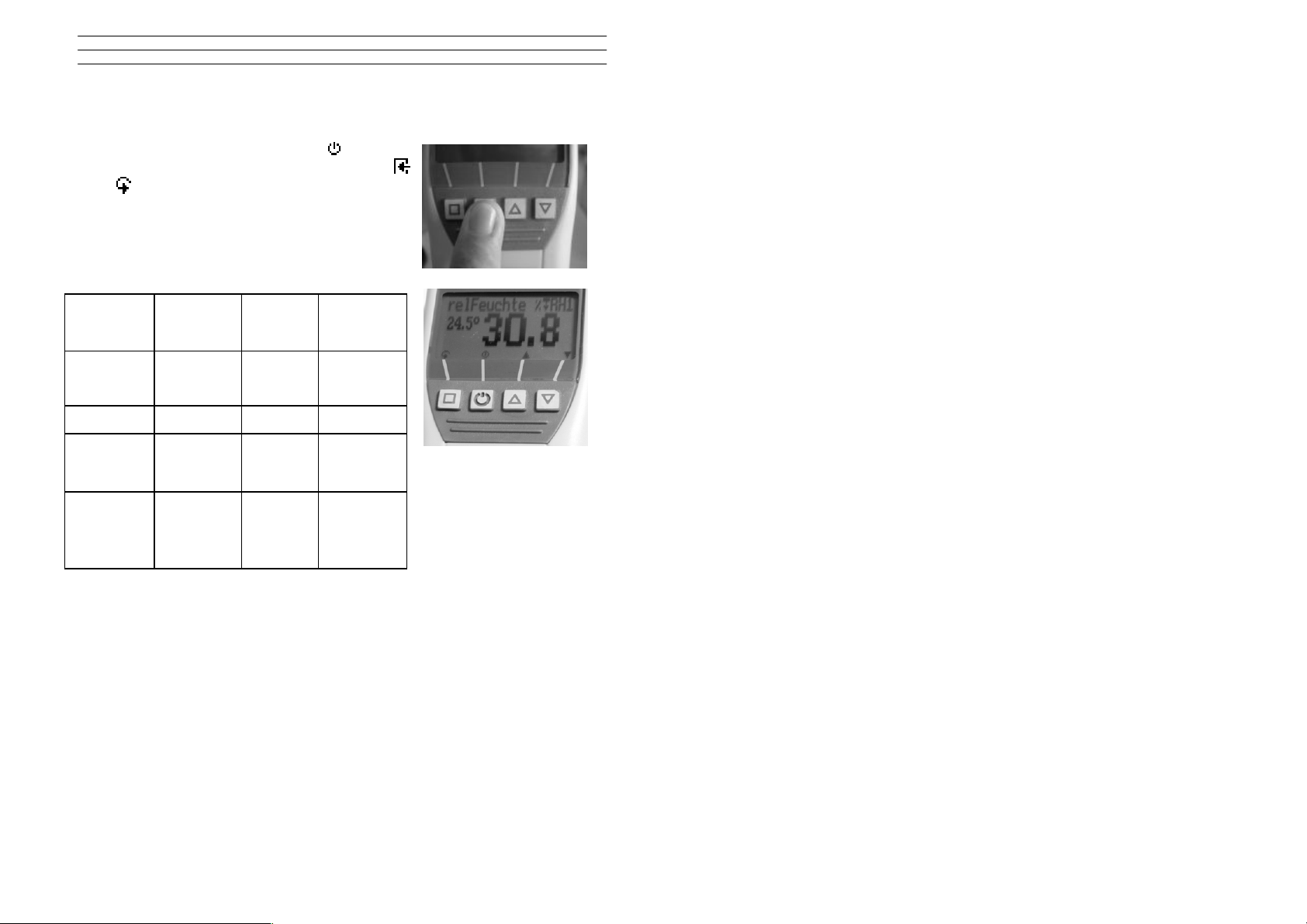

To switch on the instrument, press the key for 3

seconds. If a menu item is shown, press the left key

Exit or Rolling Menu until the measuring window

appears. The measurement value is now shown on the

display.

1.1 Calibration curves

Name of

calibration

Meaning Unit Instrument

curve

Relative

relHum

humidity of

%RH RH1 / RH5

Air

Dew Point Dew point °C or °F RH1 / RH5

absHum

EMC Wood

Absolute

humidity of

Air

Equilibrium

moisture

content of

wood

g/m³ RH1

%EMC RH1

1.2 Explanation of calibration curves:

relHum: This shows the relative air humidity in %RH (relative humidity) and the

temperature in the selected unit (°C or °F).

absHum: This shows the absolute air humidity in g/m³ (grams of water per cubic

meter of air) and the temperature in the selected unit (°C or °F).

Dew Point: This shows the dew point and the temperature in the selected unit (°C

or °F).

EMC Wood: This shows the equilibrium moisture content of wood (for the timber

stored under these conditions) in % moisture cont. of wood and the temperature in

the selected unit (°C or °F).

Electromatic Equipment Co., Inc.

-2-

Page 3

2.0 OPERATING THE INSTRUMENT

Switching on: Press for 3 seconds.

Changing the calibration curve: or .

Setting the time: Press three times - Options – Date / Time

Hold the measurement value (HOLD): Press the key (this must be set in the

menu Log Time)

Switching on the display lighting: Press the key briefly; the display lighting

switches off automatically after approx. 20 seconds. Pressing any key activates the

display lighting.

Switching off: Press the key for 5 seconds. The instrument switches off when

you stop pressing this key. The instrument switches off approx. 4 minutes after the

last key has been pressed.

Changing the menu language: Options – Language – select the language

required.

Moving from the simple user level to the menu: The instrument must be

switched off. Switch the instrument on and as soon as the display lighting comes on,

press AND simultaneously until the menu appears.

Electromatic Equipment Co., Inc.

-3-

Page 4

3.0 VIEW OF THE INSTRUMENT

14.0 WARRANTY

Electromatic Equipment Co., Inc. (Electromatic) warrants to the original purchaser

that this product is of merchantable quality and confirms in kind and quality with the

descriptions and specifications thereof. Product failure or malfunction arising out of

any defect in workmanship or material in the product existing at the time of delivery

thereof which manifests itself within one year from the sale of such product, shall be

remedied by repair or replacement of such product, at Electromatic’s option, except

where unauthorized repair, disassembly, tampering, abuse or misapplication has

taken place, as determined by Electromatic. All returns for warranty or non-warranty

repairs and/or replacement must be authorized by Electromatic, in advance, with all

repacking and shipping expenses to the address below to be borne by the

purchaser.

THE FOREGOING WARRANTY’S IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO, THE

WARRANTY OF MERCHANTABILITY AND FITNESS FOR ANY PARTICULAR

PURPOSE OR APPLICATION. ELECTROMATIC SHALL NOT BE RESPONSIBLE

NOR LIABLE FOR ANY CONSEQUENTIAL DAMAGE, OF ANY KIND OR

NATURE, RESULTING FROM THE USE OF SUPPLIED EQUIPMENT, WHETHER

SUCH DAMAGE OCCURS OR IS DISCOVERED BEFORE, UPON OR AFTER

REPLACEMENT OR REPAIR, AND WHETHER OR NOT SUCH DAMAGE IS

CAUSED BY MANUFACTURER’S OR SUPPLIER’S NEGLIGENCE WITHIN ONE

YEAR FROM INVOICE DATE.

Some State jurisdictions or States do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation may not apply to you.

The duration of any implied warranty, including, without limitation, fitness for any

particular purpose and merchantability with respect to this product, is limited to the

duration of the foregoing warranty. Some states do not allow limitations on how long

an implied warranty lasts but, not withstanding, this warranty, in the absence of such

limitations, shall extend for one year from the date of invoice.

Electromatic Equipment Co., Inc.

600 Oakland Ave. Cedarhurst, NY 11516 - USA

Tel: 1-800-645-7330 / Tel: 516-295-4300 / Fax: 516-295-4399

Every precaution has been taken in the preparation of this manual. Electromatic assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting

from the use of information contained herein. Any brand or product names mentioned herein

are used for identification purposes only, and are trademarks or registered trademarks of their

respective holders.

Electromatic Equipment Co., Inc.

-4-

Electromatic Equipment Co., Inc.

-13-

Page 5

13.0 TECHNICAL DATA

Calibration

c

urve

Temperature

Humidity

Rolling Menu /

ON-OFF key

Unit of the

Sensor name

Keys for

Batteries

(rear)

Sensors

Measurement: Meas. Range / Resolution / Accuracy

Rel. humidity: 0 to 100%RH / 0,1% / ±1,5% (0 - 90% at 25°C)

Temperature Pt1000 DIN B °C:

-10 to +60°C / 0,1°C / ±0,4°C (at 25°C)

Temperature °F: -14 to 140°F / 0,3°F / ±0,7°F (at 77°F)

Dew point °C: -55 to +60°C / 0,1°C

Dew point °F: -67 to 140°F / 0,3°F

abs. humidity: 0 to 130g/m³ / 0,1g/m³

Equilibrium moisture

content of wood: 2 to 30% / 0,1% / ±0,5% (at 25°C)

Operating temp. range -10°C to 60°C / 14 to 140°F

Storage temp -20°C to 60°C / -4 to 140°F

Temperature compensation Automatic

Memory for meas. values approx. 10.000 meas values

Menu languages Deutsch, English, Français, Italiano

Power supply 4 x 1,5 Volt AA Alkaline Batteries

(approx. 1800 measurements)

Switchoff time after approx. 4 minutes

Power consumption 55 mA (with display lighting)

Display 128 x 64 matrix display,

with LED-backlighting

Dimensions: Housing Sensor Weight

RH1: 145 x 63 x 24mm 100mm x Ø 12mm 220 g

RH5: 145 x 63 x 29mm 295mm x 20mm x 4mm 220 g

Protection class IP 40

Delivery includes Wooden case

4 x 1,5Volt AA Alkaline Batteries

Short instruction manual

measurement

value

measurement

value

HOLD-Key

humidity

measurement

value

Instrument

name

selecting the

calibration

curve

Electromatic Equipment Co., Inc.

-12-

Electromatic Equipment Co., Inc.

-5-

Page 6

4.0 MENU

There are 4 menu levels. The symbols show the key

functions in the different menus.

1. Type selection:

2. Saving:

3. Additional level:

Rolling Menu: Use this key to enter the different

menu levels and main menu.

Power: Press this key for to switch the instrument

off (5 sec.) or on (3 sec.). Press this key briefly to

activate the display lighting.

Up: This key moves you to the next type/calibration

curve.

Down: This key moves you to the previous

type/calibration curve.

Disk: Use this key to save measurement values.

If this symbol and a number are beside the disk

symbol an AutoLog series is started.

If only a number is shown in front of the disk symbol the

measurement value can be saved manually (manual

log). Zero means that the number of values saved at that

time is zero.

Alternatively: Hold: The currently shown

measurement value is held. It is released when another

key is pressed.

View logs: If no logs are active (the last

measuring series has been completed), you can use this

symbol to view the saved measuring series.

Alternatively: Edit logs: If logs are active (the current

measuring series is not yet completed), you can press

this symbol and then enter e.g. batch number and

supplier’s data for the series.

Edit type: Needed to calibrate user-defined

calibration curves

In the additional level, press (Rolling Menu) to enter

the main menu.

4. Main menu

Edit Logs

Manual Logs

Auto Logs

Clear Logs

Print Logs

Last Logs

All Logs

Clear Logs

Send Logs

Manual Logs

Auto Logs

Clear Logs

Options

Date / Time

Log Time

Language

Unlock

°C / °F

Userlevel

BL On Time

Auto Off Time

Calibrate

Materialcalib.

Password

Reset

Status

10.0 CHANGING THE BATTERIES

Batteries are supplied in the instrument when delivered.

Changing the batteries:

Use a finger to press the arrow on the battery cover and

pull it back.

Remove the flat batteries and replace them with four

new 1.5 Volt AA Alkaline Batteries. Make sure you place

the battery poles in the right positions.

Press the batteries down so you can close the cover.

11.0 LIABILITY

The manufacturer is not liable for any incorrect measurements and resulting

damages.

As this rapid measurement procedure is influenced by product-specific and

application-specific conditions, we recommend you carry out a plausibility check on

the measurement results. Each instrument has a serial number and warranty seal. If

this is broken we cannot provide warranty. If the instrument is defective, contact

Electromatic via www.checkline.com.

12.0 OPTIONAL ACCESSORIES

Wall holder / table stand Two-in-one holder for the RHx instrument series made of

acrylic glass.

Interface for printing saved data on a portable printer and/or transferring data to a

PC incl. Software humimeter LogMemorizer

Humimeter LogMemorizer data recording and analysis software for Windows®

PCs based on a database; for recording data, direct analysis of measurement

values in the program, numerous export functions.

Portable measurement value printer – Battery-powered direct thermal printer

Sword cover for RH5 to protect the sword-shaped sensor for use with heavy

stacks.

Sword cover remover for RH5 for removing the sword cover from heavy stacks.

Checking unit and humidity standards: For checking your own RHx humimeter.

Electromatic Equipment Co., Inc.

-6-

Electromatic Equipment Co., Inc.

-11-

Page 7

8.0 TEMPERATURE BEHAVIOUR OF THE SENSORS

During humidity and temperature measurement there are many parameters which

affect the time required until the real measurement value is displayed.

The parameter which may cause the largest measuring errors, is the difference in

temperature between the sensors or between the measuring instrument and the

substance to be measured or the air.

To shorten the time required for the sensors/instrument to reach the same

temperature as the substance or air, proceed as follows:

• RH1: Move the instrument around in the air

o Hold the instrument securely in your hand and move it carefully backwards

and forwards. Do not hit other objects with the instrument!

• RH5: Move the sword-shaped sensor into the paper stack

o First push the sword only a short distance into the stack (10 cm). At brief

intervals (10 seconds), push it a few more centimetres into the stack.

If the temperature difference is large, repeat this procedure (several

times if necessary).

o If you use the sword cover to protect the sword-shaped sensor, make sure

they are both the same temperature.

• In this case, push the sword cover little by little into the stack and leave

the sword-shaped sensor in the cover long enough to ensure a correct

measurement result!

9.0 LOOKING AFTER THE INSTRUMENT

Do not drop the instrument or expose it to excessive temperatures. Only clean it

with a lint-free, dry cloth. The instrument is not waterproof. Do not immerse the

sensor in liquid.

For more information on looking after the instrument, see www.checkline.com

How often you need to check the instrument depends on the use and the required

level of accuracy. You can check humimeter RHx instruments yourself (see Optional

accessories)

For a fee we can also carry out a calibration at the factory. In this case you will also

receive a calibration certificate.

5.0 OTHER SYMBOLS AND KEY FUNCTIONS

Menu:

Confirm – activates menu item

Up – long press => jumps to the start of the menu

Down – long press => jumps to the end of the menu

Exit – exits the menu item or menu

Keys in menu items:

Shift – 2nd functional level of the keys

Show the measurement values of the series

Up – next measurement series (chronological)

Down – previous measurement series (chronological)

Change additional data

Delete the measuring series or measurement value

Next measurement value (chronological)

Previous measurement value (chronological)

Enter digits

Enter characters

Continue or move one character to the right

Move one character to the left

Yes

No

: OK

Electromatic Equipment Co., Inc.

-10-

Electromatic Equipment Co., Inc.

-7-

Page 8

6.0 OTHER INSTRUMENT FUNCTIONS – OVERVIEW

• Manual saving of single measurement values in a measurement series

• Automatic saving of measurement values in a measuring series

• Selection of the automatic saving interval (3 seconds to 4 hours)

• Display of the measuring series and measurement values directly on the

instrument

• Printout of the saved measuring series

• Transfer and saving of the measuring series on a PC

• Display of the memory and battery status

• Selection of the menu language (DE, EN, FR, IT)

• Temperature shown in degrees Celsius or degrees Fahrenheit

• Activation of a simple user operation

7.0 COMMON REASONS FOR INCORRECT MEASUREMENTS

Sunlight or other sources of heat or cold which do not correspond to the

ambient temperature

Measuring errors due to differences in temperature

To show how important it is that the temperature of the instrument is the same as

the temperature of the substance to be measured, the table below shows measuring

errors due to a temperature difference of only 1°C / 1.8°F between the measuring

instrument and the substance to be measured at different ambient temperatures.

10°C (50°F) 20°C (68°F) 30°C (86°F)

10%r.H. ± 0.7% ± 0.6% ± 0.6%

50%r.H. ± 3.5% ± 3.2% ± 3.0%

90%r.H. ± 6.3% ± 5.7% ± 5.4%

At room temperature (20°C/68°F) and assumed paper m oisture value of 50%r.H. a

deviation of 1°C / 1.8°F between the measuring sens or and the substance to be

measured results in a measuring error of 3.2%r.H. A deviation of 3°C / 5.4°F would

result in a measuring error of over 10%.

Further examples are given in the „Mollier i-x“ diagram.

Dripping or sprayed water

Irreversible damage to the sensor element due to aggressive gases

Danger of condensation following temperature changes

Dirty moisture sensor

Foreign objects on the sensor

Electromatic Equipment Co., Inc.

-8-

Electromatic Equipment Co., Inc.

-9-

Page 9

RH1 & RH5

RELATIVE HUMIDITY METER

OPERATING INSTRUCTIONS

Loading...

Loading...