Page 1

INSTRUMENT ZERO CHECK

Prior to use, and/or occasionally, place the instrument on a smooth, fl at

“reference surface”. Be sure sled-bottom and ski-contact surfaces are

resting fi rmly on the reference

Normally, indicator should read “0” with dial hand at the 12 o’clock

position. If not, loosen BEZEL LOCK SCREW (4) and rotate dial to

line up “0” with dial hand. Tighten lock screw.

NOTE: Dial will not read “0” when instrument is removed from the

reference surface.

CARE

This precision instrument should be handled with extreme care. Ideally ,

the work area should be free of dust, vibrations, excessive moisture and

extreme temperature differentials. Store in an enclosure when not in use.

Never depress the thumb-lever to retract the ski and allow it to free fall.

This will likely damage the indicator’s delicate internal components.

Occasionally clean the sled and ski warp contacting surfaces with a soft

cloth or paper wiper.

WARP TENSION METER

WT-100

Do not apply oil to any parts.

Any apparent damage to this instrument should necessitate returning for repair

http://www.checkline.com

Operating Instructions

Page 2

WARP TENSION METER

TENSIOMETER GAGING PROCEDURE

PRINCIPLES & USE

This hand held tension comparator provides a loom operator with a visual

calibrated dial indication of warp tension. The dial readings are arbitrary

values unrelated to pounds, ounces, or grams, whereby each discernible

reading simplifies the maintenance and record keeping of the tension forces.

The reliability of this instrument is its ability to maintain repeat readings

throughout the gaging range of the warp tension force.

The above characteristics contribute to the observation and set up

of single and multi loom production applications. The warp tension

of one loom standard may be applied to the set up of another loom

producing the same fabric.

WARP PRELIMINARIES

1) Select a definite number of warp-ends (approximate 1‰ wide)

preferably towards the center of the loom and midway on its open

length. This designated number of warp-ends may be segregated for

repeat tensions checks using a wire-drop or string loop.

EXAMPLE: -60 ends for the average woolen fabric

-150 ends for 75 denier rayon.

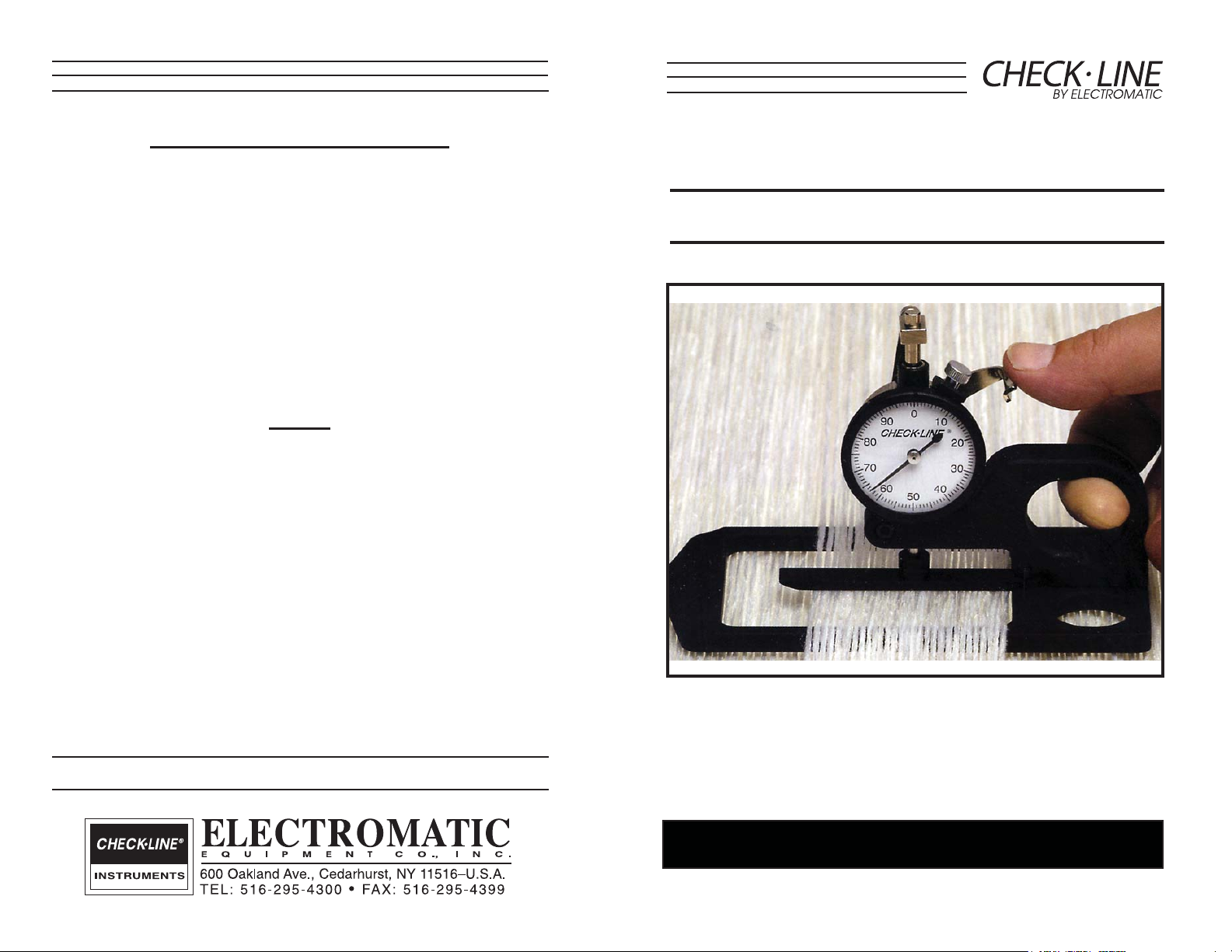

After having taken the “warp preliminaries” into consideration, hold

instrument in right hand as illustrated on the front cover photograph.

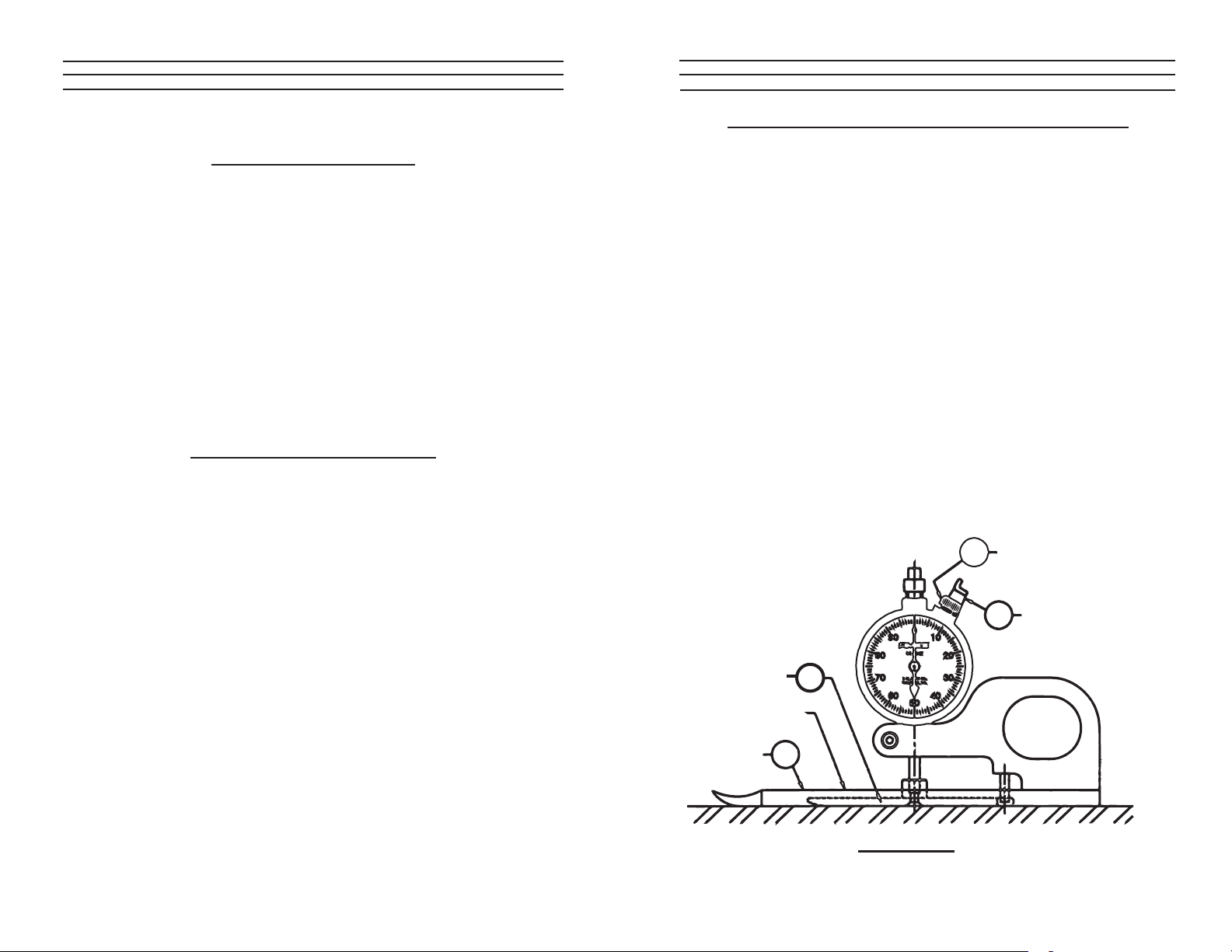

As defi ned in FIGURE #1, depress the thumb retract LEVER (1) to

fully retract SKI (2).

Utilizing front lip of SLED (3), enter sled under the designated warp ends

(within wire drop), so that these warp ends are centralized under the ski.

Cautiously release thumb lever allowing ski to contact the warp ends.

Remove right hand so as to allow the instrument to rest on the warp

ends remaining on the bottom surface of the sled.

The observed dial reading represents a comparative warp tension value.

This reading may be used for either monitoring and resetting a particular

loom or setting up multi-loom productions.

BEZEL LOCK SCREW

4

LEVER

1

2) The two methods of obtaining warp tension readings are with the

loom idle or running. In either case, the warp should have had a chance

to stabilize before taking readings. The stability of the idle loom offers

stable indicator readings, whereas, the running loom causes readings to

fluctuate such that the maximum and minimum values will have to be

carefully observed and/or recorded.

SKI

UPPER

CONTACTING

SURFACE

SLED

3

2

FIGURE #1

Loading...

Loading...