Page 1

CHECK•LINE

BY ELECTROMATIC

QB-LED

STROBOSCOPE

®

Operating Manual

Page 2

TABLE OF CONTENTS

1.0 Introduction ………………………………………………………..… ................... 02

1.1 Scope of delivery

1.2 Precautions when using

2.0 Overview ................................................................................................................. 03

2.1 Connections, controls and settings

2.2 Display

3.0 Set-Up ................................................................................................................. 05

3.1 Connections

3.2 Set-up steps

3.3 Connect the trigger

4.0 Operation ................................................................................................................. 06

4.1 Controls

4.2 Display

4.3 Standard mode

4.4 Pro mode

4.5 QBS-LED

4.6 Operating modes

5.0 Determining An Object’s Actual Rotational Speeds ............................................ 15

6.0 Technical Data and Accessories ............................................................................. 17

7.0 Faactory Reset ....................................................................................................... 18

8.0 Warranty ................................................................................................................. 19

IMPORTANT: This device is used for inspecting the movement of rotating and

vibrating objects. It may only be used in accordance with these instructions. The

device must not be opened. Modications to the device are not permitted. The

manufacturer shall not be liable for damage resulting from incorrect use or use

contrary to the intended use. Warranty claims will also be invalidated in this event.

– 1 –

Page 3

1.0 INTRODUCTION

The Check-Line QB-LED is a hand-held, battery-powered stroboscope featuring

extremely bright LEDs for the highest light output in its class. Designed for machinery

observation, visual inspection and motion analysis, its robust design is suitable for use in

the toughest industrial environments.

1.1 Scope of Delivery

Check that you have received all of the following:

• Stroboscope: QB-LED design (40 LEDs, no laser)

or QBS-LED design (118 LEDs, with laser)

• Operating instructions

• Calibration certicate

• Charger with connector set

• Trigger plug

• Reective tapes (QBS-LED only)

• Handle

• Foam-tted, plastic carrying case

Note: This device is suitable for use in residential, commercial and industrial area.

1.2 Precautions when using

Risk of injury! Laser class 2: The stroboscope QBS-LED is tted with a

class 2 laser. This is located at the front of the device. The laser beam can damage

eyes. For this reason, do not stare directly at the laser beam and never direct it at

people or animals. Wavelength: 650 nm, output: 1 mW.

Risk of Injury! Flashing lights can cause retina damage: The

stroboscope QB-LED and QBS-LED versions are tted with 40/118 LEDs

respectively. These produce potentially dangerous optical radiation, which can

cause retina damage. Do not stare directly at the light and never direct it at people

or animals.

Risk of injury! Moving objects appear still or in slow motion in stroboscopic

light. Do not touch such objects under any circumstance.

Risk of injury! The device may not be used in potentially explosive areas.

Risk of injury! Stroboscopic light can trigger epileptic seizures in

persons at risk.

– 2 –

Page 4

2.0 OVERVIEW

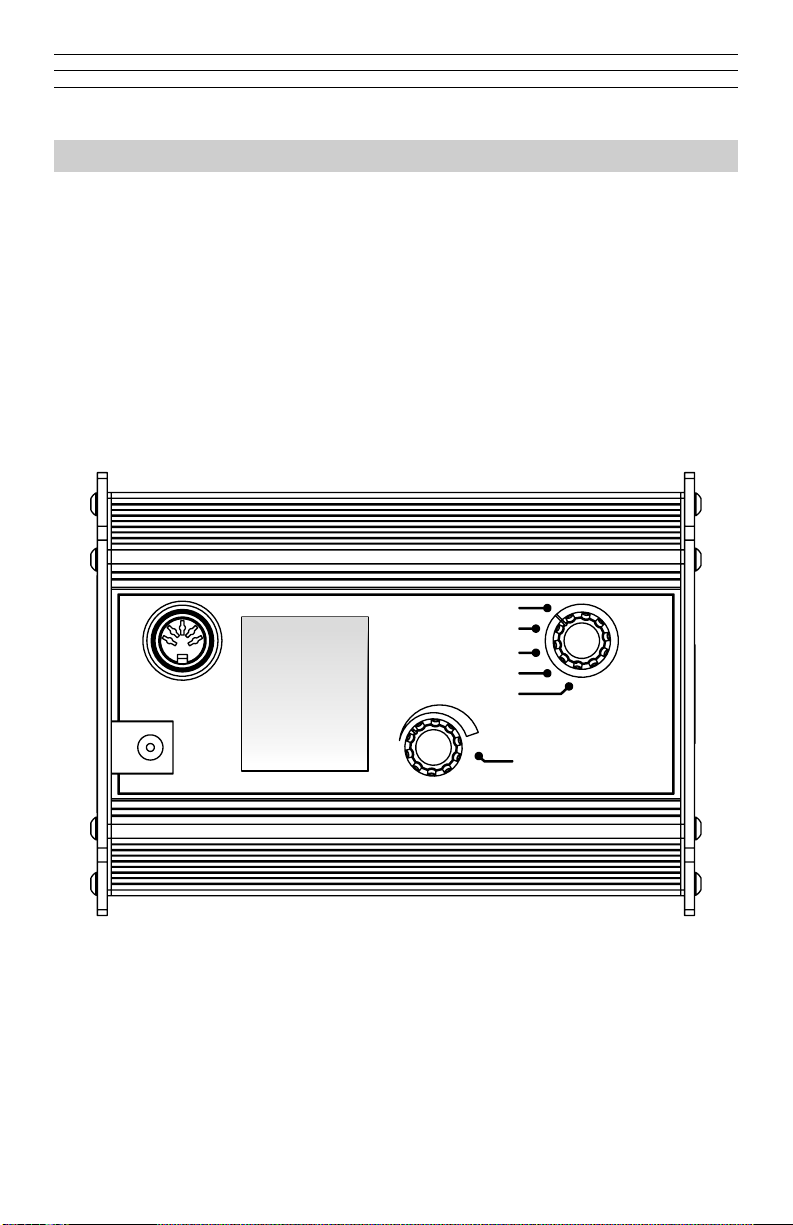

2.1 Connections, controls and settings (QB-LED QBS-LED)

(A) CHARGE = charging socket

(B) INPUT = input for external trigger /24 V power supply for sensors

(C) Display

(D) Rotary/push knob

(E) Selector switch: OFF, FREQUENCY, BRIGHT, MENU, LASER*

*NOTE: LASER Mode only available on QBS-LED model.

OFF

FREQUENCY

BRIGHT

INPUT

(B)

(C)

MENU

LASE R

(E)

(A)

Reset 5 sec.CHARGE

Fig.1 - Stroboscope QB-LED and QBS-LED

– 3 –

(D)

PRESS: FLASH ON /OFF

Page 5

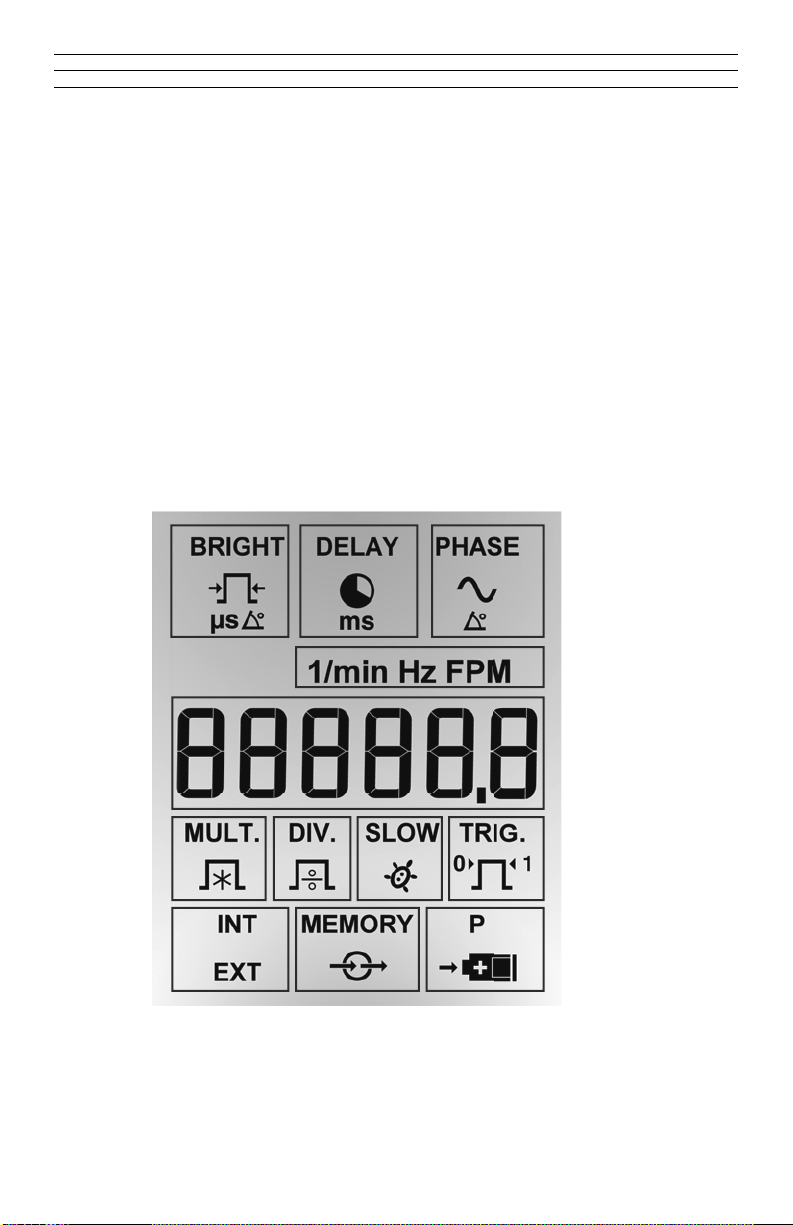

2.2 Display

(1) Brightness in μs and/or degrees (BRIGHT)

(2) Delay in ms and/or degrees (DELAY)

(3) Phase shift (PHASE)

(4) Unit of frequency in rpm, Hz and/or FPM

(5) Value

(6) Multiplier (MULT.)

(7) Trigger divider (DIV.)

(8) Slow motion (SLOW)

(9) Trigger signal edge (TRIG.)

(10) Internal/external trigger (INT / EXT)

(11) Store / read parameters (MEMORY IN / MEMORY OUT)

(12) Pro mode (P)

(13) Battery status – full, half full or low

(1)

(2) (3)

(4)

(5)

(6) (7)

(8) (9)

(10) (11)

(12) (13)

Fig. 2 - Display

– 4 –

Page 6

3.0 SETUP

(EN 60130-9)

5

3.1 Connectors (see Fig. 1)

No. Marking Term Description

(A) CHARGE Charging Socket Device is charged using a charger

(B) INPUT Input socket Input for external tripper/24 V

3.2 Set-up steps

Please follow the steps below when setting up the device:

1. Charge the device by plugginh the charger into the CHARGE (A) socket to the

rear of the device (see Fig. 1)

2. Direct the device at a moving object and switch it on. Turn the selector switch (E)

one notch to the left to “FREQUENCY.”

The device will start to ash immediately. For this reason, do not

direct it at people or animals.

NOTE: The device will ash at the frequency that was set most recently. The display

shows the selected ash frequency in the unit that was set most recently (rpm, Hz or

FPM). If the ash frequency coincides with the frequency of the motion, a static

image appears.

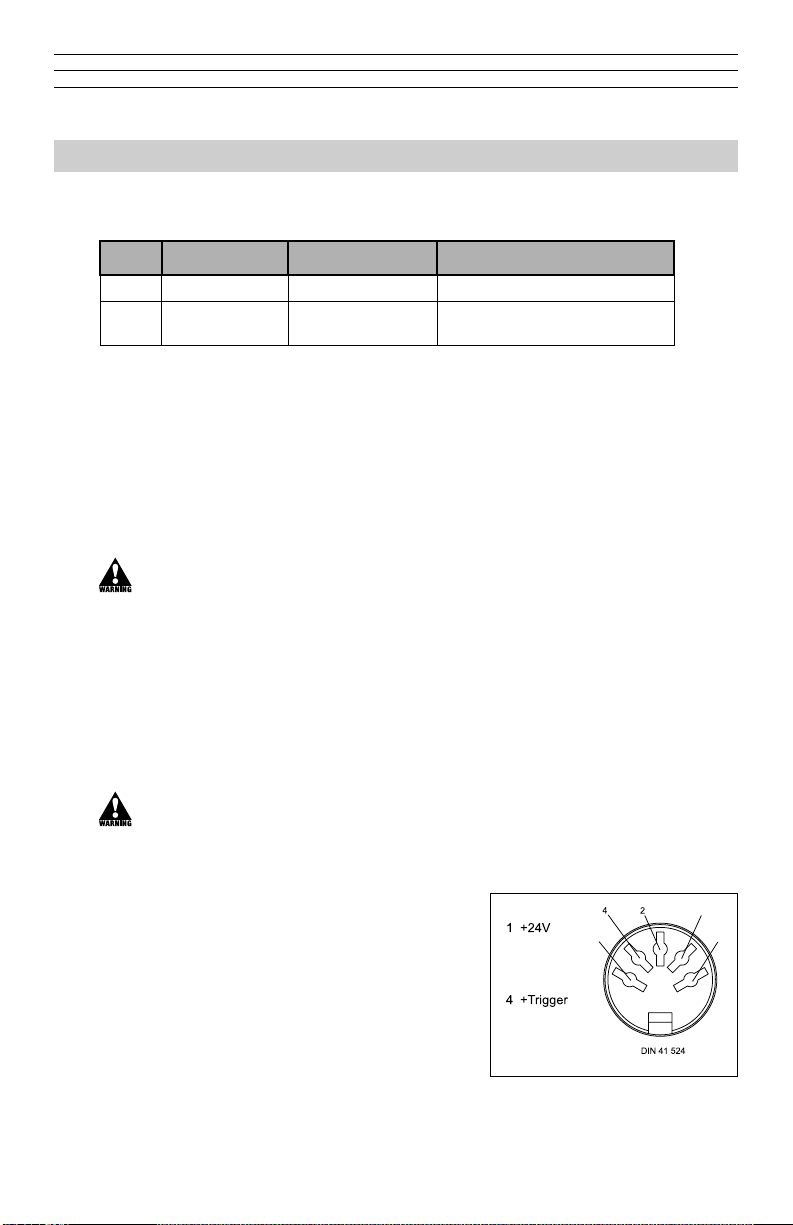

3.3 Connect the trigger

power supply

The device has the option of being externally triggered.

DO NOT trigger the device with signals in excess or 300,000 FPM.

Material damage may occur.

NOTE: Use only original material from the manufacturer to connect the trigger signal.

The trigger input is isolated and is suitable for PNP

and NPN signals. A trigger plug suitable for this

input socket is included with the device.

1. Plug the trigger plug into the input socket

2 nc

3 GND

1

INPUT (B).

2. Screw in trigger plug.

3. Assign the connection socket as per Fig. 3.

NOTE: The device must be manually switched

between external and internal trigger signals (see

How select an internal/external trigger, page 9).

5 -Trigger

Fig. 3 - Assignment of the

connection socket.

– 5 –

3

Page 7

4.0 OPERATION

Note: This device comes in two versions.

• QB-LED (40 LEDs, no laser)

• QBS-LED (118 LEDs, with laser)

Both versions are available in Standard and Pro modes (see section 4.3, Standard mode

and section 4.4, Pro mode).

4.1 Controls

No. Term Description

(D Rotary/Push Knob

(E) Selector Switch Choose between OFF, FREQUENCY, BRIGHT, MENU and LASER

4.2 Display

Note: Preset values are retained in each mode (Standard or Pro mode)

Position of

the selector

switch (E)

OFF —

FREQUENCY FPM

BRIGHT BRIGHT deg •

MENU PHASE deg • • •

INT/EXT • • • •

Following functions are only available in the PRO mode

1/min/Hz/FPM • • •

MULT. • •

BRIGHT deg/µs • • •

DELAY ms • • •

DIV • •

SLOW • •

TRIG. • •

MEM IN • • •

MEM OUT • • •

• Tur n the knob to select the value and push to conrm. The

adjustment increment depends upon the rotational speed.

• Turning the knob while simultaneously pushing it, effects the

adjustment increment in steps of 100.

• The ash can be turned off by pushing the knob once and

turned on again by pushing the knob once again.

(QBS-LED version) by turning the switch to the desired position

OVERVIEW OF ADJUSTABLE PARAMETERS

Display Available with Functions of the rotary/push knob (D)

Internal

trigger

External

trigger

Set value Select parameter

– 6 –

Page 8

4.3 Standard Mode

NOTE: Not all of the setting shown in Fig 2 are available in Standard Mode.

No. Position of the

Selector Switch

(E)

(4) OFF — Device is switched off

(4) FREQUENCY FPM Frequency selection; FPM: ashes per

How to select FREQUENCY

1. Turn the selector switch (E) to the FREQUENCY position. All settings, will appear in the display for a few

seconds, followed by S

2. Select the desired frequency by turning the rotary/push knob (D).

(1) BRIGHT BRIGHT deg Selection of brightness

Brightness (BRIGHT in deg)

Flash duration: This function allows the ash duration to be adjusted, which inuences the brightness

and focus of the object being viewed. In the Standard mode, this setting can only be made in relative form

(degrees), whereas the Pro mode also features the additional setting of measuring brightness in absolute

form (microseconds).

Adjustable

Parameters

Description

minute

- Turning the knob while pushing

it simultaneously, the adjustment

increment is effected in steps of 100.

- The ash can be turned off by

pushing the knob once and turned

on again by pushing the knob once

again.

(in 1/1,000 degrees)

– 7 –

Page 9

No. Position of the

Selector Switch

(E)

(3) MENU PHASE deg:

Phase sift (PHASE in deg)

Phase shift setting (in degrees, relative to the frequency) between the trigger signal and ash. This value

allows a xed angle to be set between the trigger signal and ash.

• Example without external connection: The viewing position can be extremely precisely adjusted without

changing the ash frequency. You can shift the viewing position within a movement cycle.

• Example with external connection: The external trigger signal is triggered before the desired observation

point (= ash position of the stroboscope). This would mean that the connected stroboscope would

regularly ash too early. The PHASE deg setting adjusts the delay, altering the ash position of the

stroboscope by a set angle. This setting is not affected by the current rotational speed, which means that

the stroboscope will ash at the desired position even during rotational speed uctuations or during the

start-up period.

How to select in the MENU

1. Turn the selector switch (E) to the MENU position.

2. Select which parameter (e.g. PHASE deg) you want to change by turning the rotary/push knob (D).

3. Push the rotary/push knob (D) to conrm a parameter selection. The number shown in the display will

begin to ash.

4. Select the desired value by turning the rotary/push knob (D.)

5. Conrm and exit selection by pushing the rotary/push knob (D).

The setting is now active.

Adjustable

Parameters

0…359

Description Display

Delay setting between the trigger signal

and ash (in degrees relative to the

frequency

NOTE: The display and adjustable value can be changed by turning the rotary/push knob (D).

– 8 –

Page 10

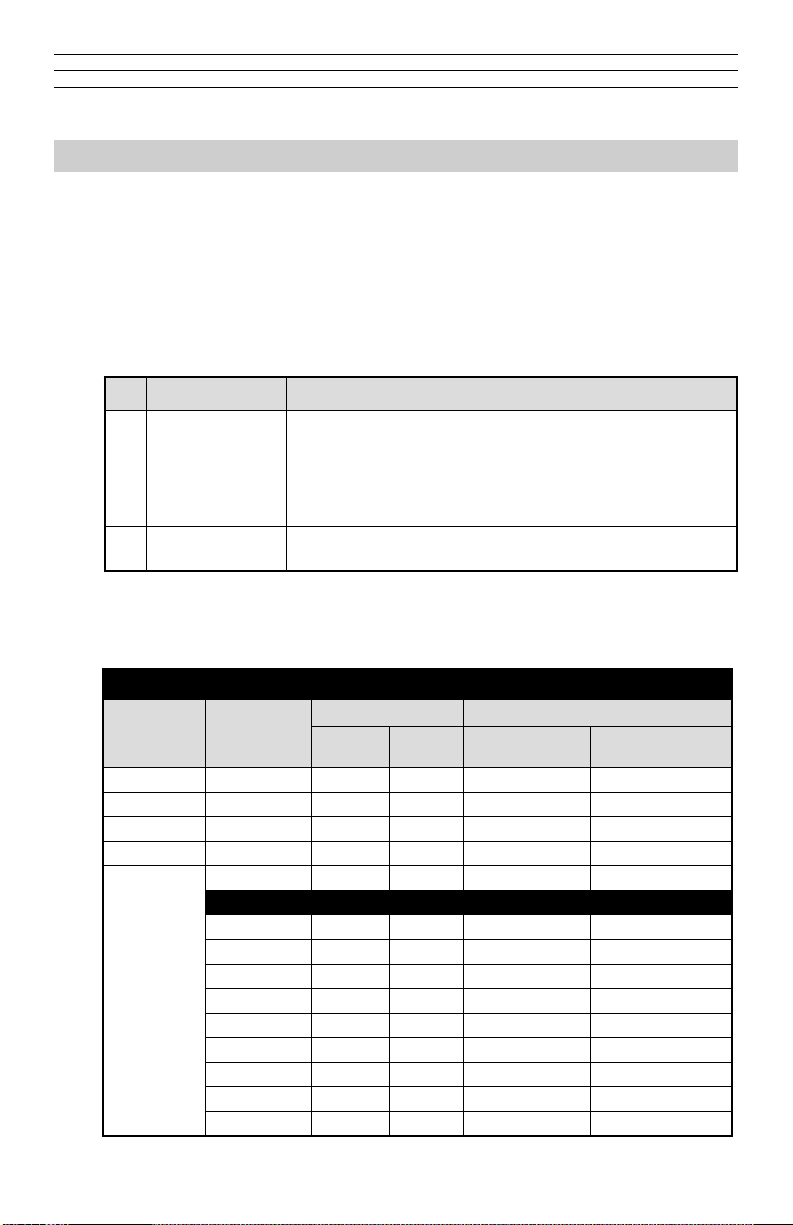

No. Position of the

Selector Switch

(E)

(10) MENU INT /EXT Internal /external trigger

How to select an internal / external trigger

1. Turn the selector switch (E) to the MENU position.

2. Select the INT / EXT parameter by turning the rotary/push knob (D).

3. Push the rotary/push knob (D) to conrm the parameter selection. The display will now show the

selection of INT and EXT parameters, the active setting will begin ashing.

4. Select the desired parameter by turning the rotary/push knob (D).

5. Conrm and exit selection by pushing the rotary/push knob (D).

The setting is now active.

Adjustable

Parameters

Description Display

– 9 –

Page 11

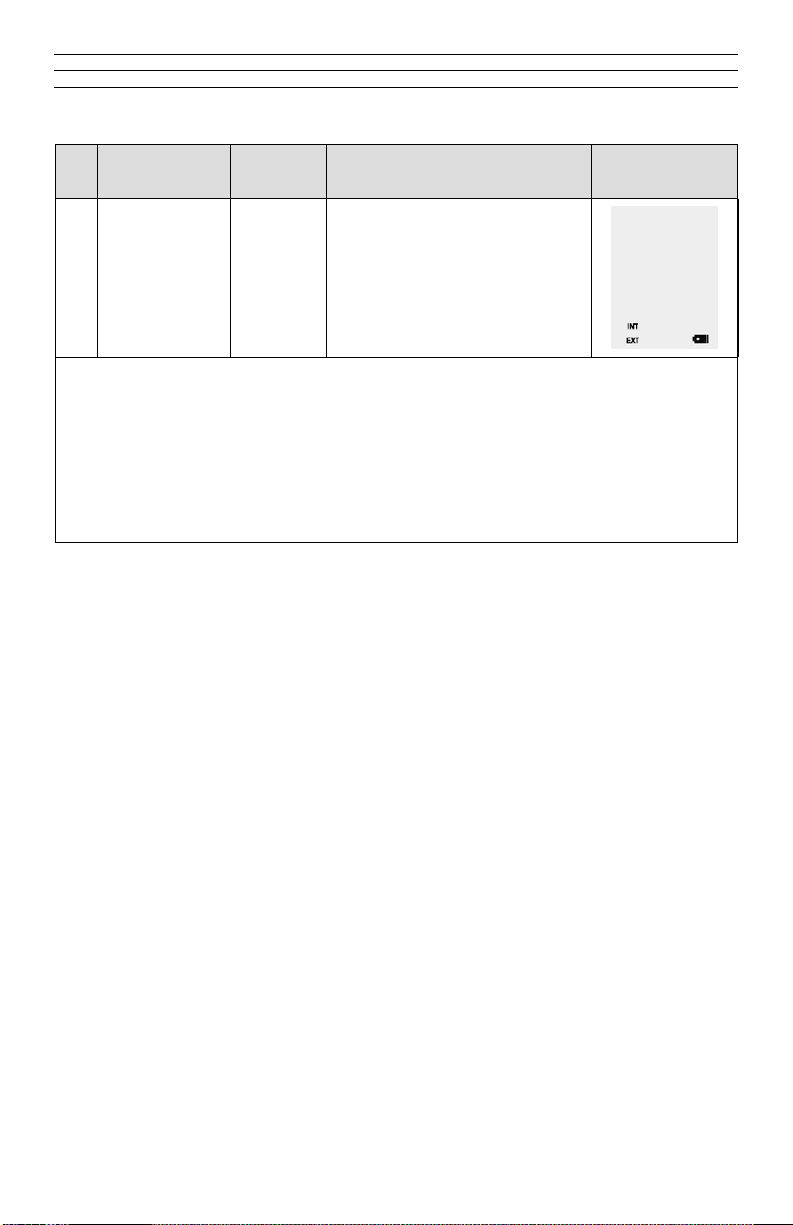

4.4 Pro Mode

Follow the steps below to access the pro mode:

1. Turn the selector switch (E) from OFF to the required position while

simultaneously holding the rotary/push knob (D) until the PRO notication

appears in the display.

2. When the Pro mode is activated, a P appears in the bottom right area of the display

NOTE: If you have selected settings in Pro Mode and then switch the device off, these

settings will ONLY be active when the device is switch back on if pro mode is activated.

Otherwise, only the standard mode settings will be active.

No. Position of the

Selector Switch

(E)

(4) FREQUENCY FPM Description: Frequency selection; FPM:

(1) BRIGHT BRIGHT deg Selection of brightness

(3) MENU PHASE deg:

(10) MENU INT /EXT Internal /external trigger

Adjustable

Parameters

0…359

Description Display

ashes per minute

- Turning the knob while pushing

it simultaneously, the adjustment

increment is effected in steps of 100.

- The ash can be turned off by

pushing the knob once and turned on

again by pushing the knob once again.

(in 1/1,000 degrees)

Delay setting between the trigger signal

and ash (in degrees relative to the

frequency

NOTE: See also section 4.3 Standard Mode for examples and explanation regarding the above mentioned

display messages.

– 10 –

Page 12

No. Position of the

Selector Switch

(E)

(4) MENU rpm / Hz /

Adjustable

Parameters

FPM

Description Display

Unit of frequency selection:

- rpm: unit for measuring rotational

speed

- Hz: ash frequency per second

- FPM: ashes per minute

(6) MENU MULT:

Multiplier (MULT)

At this function the adjusted frequency can be divided or multiplied with integer values to check the

harmonic multiple images (see section XX Determining the actual rotational speed of an object).

(1) MENU BRIGHT:

Brightness (BRIGHT in deg / BRIGHT in µs

At this function the adjusted frequency can be divided or multiplied with integer values to check the

harmonic multiple images (see section 5.0, Determining the actual rotational speed of an object).

(2) MENU DELAY ms:

x1, x2,

x3…/ +1,

+2, +3, …

respectively.

The selected

ash

frequency is

immediately

multiplied/

divided by

1, 2, 3 …

PULSE deg

PULSE µs

0.0…2.000

Multiplier:

This function is only possible when the

internal trigger is selected

Selection of brightness unit (in degrees

or micro-seconds)

Delay time setting (in milliseconds)

between the trigger signal and ash.

–11–

Page 13

No. Position of the

Selector Switch

(E)

(7) MENU DIV:

Pulse divider (DIV)

The pulse divider can be used to set a value x, by which the external trigger signal is then divided.

Example: when scanning a cog wheel, an external trigger (e.g. rotational speed sensor) sends our a signal

for each cog scanned. With a DIV value of 10, it will only ash once every 10 signals.

(8) MENU SLOW:

SLOW (slow motion)

The SLOW function allows the viewer to view movement in slow motion. The speed of the slow motion

depends on the ash frequency and corresponds to the value selected.

(10) MENU TRIG:

Adjustable

Parameters

1…2550

0…600

0 / 1

Description Display

Pulse divider, max value 255.

This function is only possible when the

external trigger is selected

The ash frequency exceeds the trigger

frequency by the value selected.

This function is only possible when the

external trigger is selected

Selection of trigger signal edge

(increasing 0, decreasing 1.

This function is only possible when the

external trigger is selected

(11) MENU MEM IN:

1 … 5

(11) MENU MEM OUT:

1 … 5

Selected settings can be backed up in

ve separate storage locations.

It is possible to read backed-up

settings.

–12–

Page 14

4.5 Stroboscope QBS-LED

NOTE: The model QBS-LED features both a higher number of LEDs (118) as well as a

Laser for automatic rotational speed measurement and “Auto-Synching” with target.

Risk of injury. The model QBS-LED is tted with a class 2 laser. The laser beam

can damage eyes. For this reason, do not stare directly at the laser beam and

never direct it a people or animals.

To use the laser, you must rst afx a reective marking onto the object to be measured.

Direct the stroboscope at the rotation object. The laser will recognize the marking and

measure the rotations.

No. Position of the

Selector Switch

(E)

(11) MENU MEM OUT:

(11) MENU MEM OUT:

(11) MENU MEM OUT:

Adjustable

Parameters

1 … 5

1 … 5

1 … 5

Description Display

It is possible to read backed-up

settings.

It is possible to read backed-up

settings.

It is possible to read backed-up

settings.

–13 –

Page 15

4.6 Operating Modes

The following operating modes may be displayed:

No. Position of the

Selector Switch

(E)

Battery Status Fully charged.

Battery Status Half charged.

Battery Status Low (symbol will ash).

LASER / EXT /

SLOW

Adjustable

Parameters

Description Display

The trigger frequency is below the

measurement range

LASER / EXT /

SLOW

The trigger frequency is above the

measurement range

NOTE: The symbol of a parameter that differs from the factory settings will ash

during operation. The stroboscope will be automatically switched off after 15 minutes of

running on battery power.

–14 –

Page 16

5.0 DETERMINING THE ROTATIONAL SPEED OF OBJECTS

The stroboscope can be used as a digital revolution indicator to determine an object’s

actual rotational speed and/or the frequency of cyclical movements. The stroboscope

does this by visually “freezing” the object’s movement and then taking a reading of the

rotational speed or frequency from the LCD display. As is the case with all stroboscopes,

it is vital to ensure that this “frozen” image is not a harmonic of the object’s actual

rotational speed.

Useful information:

• It’s helpful to have a rough idea of the object’s rotational speed beforehand.

• Regular shaped objects, e.g. a fan with several vanes or a motor shaft, must be afxed

with an identication marking (using color or a reective strip etc.) in order to be able

to differentiate its orientation of movement.

• A still image always appears exactly at integer division of the speed of the object’s

actual rotational speed!

Example 1 (marking required)

e example shows the importance of using identication markings. Say you

want to determine the actual rotational speed of this ventilator.

e only thing you know is that its rotational speed is less than 3,500 rpm. e

following “frozen” images will appear if you reduce the ashing rate based on

3,500 FPM (ashes per minute):

What is the actual rotational speed of the fan? Images 1, 3, 5, 6 and 8 correspond to the

original one, which means the rotational speed could be 3300, 1650, 1100, 825 or 550 rpm.

–15 –

Page 17

Which is correct?

To determine the fan’s actual rotational speed, one of the ventilator vanes is

attached with a marking and the test is repeated.

e orientation marking conrms that the images at 3,300, 1,650 and 825 rpm are harmonic

multiple images. ree identication marks appear in each of these images.

Still images appear at 1,100 rpm and again 550 rpm, each displaying just one mark. Remember that a still image always appears exactly at integer division of the speed of the actual

rotational speed of an object. 550 is half of 1,100. is means that the rotational speed of the

ventilator must be 1,100 rpm

Example 2 (no marking required)

is example shows how the actual rotational speed of an object can be determined

without using an orientation marking. is is only possible for suitably shaped objects.

Let’s assume the only thing we know about this cam is that it rotates at

less than 7,000 rpm. Its clear shape eliminates the need for an orientation

marking. e following “frozen” images will appear if the ashing rate of

7,000 is reduced:

Image No. 1 2 3 4

Flashing rate 6.000 4.000 3.000 1.500

e images showing 6,000 and 4,000 rpm are double or multiple images rather than single

images. Still images appear at 3,000 and again at 1,500 rpm. 1,500 is half of 3,000. is

means that the actual rotational speed is 3,000 rpm.

– 16 –

Page 18

6.0 TECHNICAL DATA

General Parameters QB-LED Both QBS-LED

Number of LEDs 40 118

Frequency Range 30–300,000 flashed per minute

Display LCD, multiline

Accuracy ±0.02% (±1 digit/±0.025 µs)

Resolution ± 0.1 (30.0 ... 999.9 FPM)

External Trigger Input 3 - 30 V / max. 5 mA

Certifications EMV / EMC 2004/108/EG; 2006/95 EG; DIN EN 61010-1:2011;

DIN EN 62471:2009; CE; DIN EN 60825-1:2008 (Version QBS-LED)

Flash Parameters QB-LED Both QBS-LED

Light Duration Adjustable

Light intensity approx.. 1,750 Lux @ 1° approx 1,750 Lux @ 1°

Flash Color approx. 5,000 – 8,000 K

Power Supply

Power Supply QB-LED QBS-LED

Continuous Use Time approx. 7:00 h @ 0.500° (~875 Lux) approx. 2:30 h @ 0.500° (~4,000 Lux)

approx. 4:00 h @ 2,000 Lux (1.140°) approx. 5:00 h @ 2,000 Lux (0.250°)

Housing QB-LED Both QBS-LED

Material Aluminum

Dimensions 6.0 x 5.1 x 4.4 in. (150 x 130 x 112 mm)

Weight approx 1,050 g approx 1,150 g

Ambient Conditions

Temperature 32 – 104 °F (0 – 40 °C)

Type of Protection IP30

± 1 (1,000 ... 9,999 FPM)

± 10 (10,000 ... 300,000 FPM)

(isolated optocoupler)

DIN 41524 5-pin standard connector

Uout = 24 VDC, 60 mA

NOTE: Warranty void! The device may only be repaired by the manufacturer or the supplier.

NOTE: Correct disposal! The electronic components in the device contain environmentally

harmful substances. They must be disposed of in accordance with the environmental

regulations in the country of use.

– 17 –

Page 19

7.0 FACTORY RESET

To reset the factory settings, press and hold the rotary/push knob (D) for at least 5

seconds

–18 –

Page 20

8.0 WARRANTY

ELECTROMATIC Equipment Co., Inc. (ELECTROMATIC) warrants to the original

purchaser that this product is of merchantable quality and conrms in kind and quality

with the descriptions and specications thereof. Product failure or malfunction arising

out of any defect in workmanship or material in the product existing at the time of

delivery thereof which manifests itself within one year from the sale of such product,

shall be remedied by repair or replacement of such product, at ELECTROMATIC’s

option, except where unauthorized repair, disassembly, tampering, abuse or

misapplication has taken place, as determined by ELECTROMATIC. All returns

for warranty or non-warranty repairs and/or replacement must be authorized by

ELECTROMATIC, in advance, with all repacking and shipping expenses to the address

below to be borne by the purchaser.

THE FOREGOING WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO, THE

WARRANTY OF MERCHANTABILITY AND FITNESS FOR ANY PARTICULAR

PURPOSE OR APPLICATION. ELECTROMATIC SHALL NOT BE RESPONSIBLE

NOR LIABLE FOR ANY CONSEQUENTIAL DAMAGE, OF ANY KIND OR

NATURE, RESULTING FROM THE USE OF SUPPLIED EQUIPMENT, WHETHER

SUCH DAMAGE OCCURS OR IS DISCOVERED BEFORE, UPON OR AFTER

REPLACEMENT OR REPAIR, AND WHETHER OR NOT SUCH DAMAGE IS

CAUSED BY MANUFACTURER’S OR SUPPLIER’S NEGLIGENCE WITHIN ONE

YEAR FROM INVOICE DATE.

Some State jurisdictions or States do not allow the exclusion or limitation of incidental

or consequential damages, so the above limitation may not apply to you. The duration

of any implied warranty, including, without limitation, tness for any particular

purpose and merchantability with respect to this product, is limited to the duration of

the foregoing warranty. Some states do not allow limitations on how long an implied

warranty lasts but, not withstanding, this warranty, in the absence of such limitations,

shall extend for one year from the date of invoice.

ELECTROMATIC Equipment Co., Inc.

600 Oakland Ave. Cedarhurst, NY 11516—USA

Tel: 1-800-645-4330/ Tel: 516-295-4300/ Fax: 516-295-4399

Every precaution has been taken in the preparation of this manual. Electromatic

Equipment Co., Inc., assumes no responsibility for errors or omissions. Neither is any

liability assumed for damages resulting from the use of information contained herein.

Any brand or product names mentioned herein are used for identication purposes only,

and are trademarks or registered trademarks of their respective holders.

– 19 –

Page 21

NOTES

–20 –

Page 22

CHECK•LINE

INSTRUMENTS

®

ELECTROMATIC

E Q U I P M E N T C O., I N C.

600 Oakland Ave., Cedarhurst, NY 11516 – USA

TEL: 516-295-4300 • FAX: 516-295-4399

Loading...

Loading...