Page 1

Ultrasonic Thickness Gage

Quick Guide v. 3.0

Adv ance d m odel

Page 2

Introduction

Introduction

The PosiTector UTG is a hand-held Ultrasonic Thickness Gage

that uses the non-destructive ultrasonic pulse-echo principle to

measure the wall thickness of a wide variety of materials. It

consists of a body (Standard or Advanced) and probe (UTGC or

UTGM, see pg. 2).

This Quick Guide summarizes the basic functions of the instrument. Download the full instruction manual at:

www.defelsko.com/manuals

Quick Start

Quick Start

The PosiTector UTG powers-up when the center navigation

button is pressed. To preserve battery life, the instrument

powers down after approximately 5 minutes of no activity. All

settings are retained.

1. Remove the protective rubber cap from the probe.

2. Power-up Gage by pressing the center navigation button.

3. Zero the probe (see pg. 6)

4. Select the correct velocity of sound (see pg. 7)

5. Measure the part (see pg. 3)

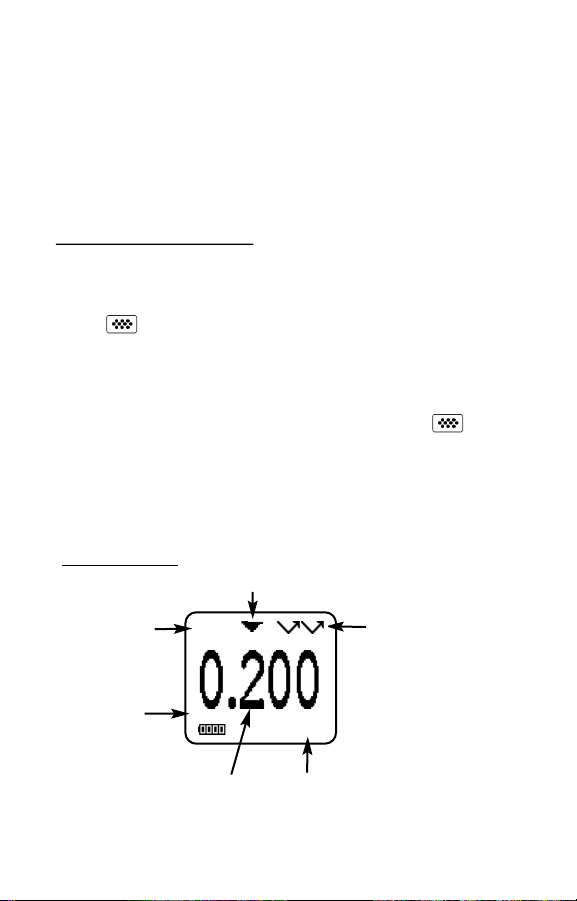

Typical Display

Currently

selected

material

Battery

Icon

The Coupled Symbol appears when the

probe is ultrasonically connected with a

surface.

Steel

Current

Measurement

inch

Unit of

Measurement

Measurement

Mode currently set

to multiple-echo

(UTGM probe only)

1

Page 3

Probes

Probes

To disconne

ins

trum

horizo

body. R

W

hen

d

ete

se

lf-ch

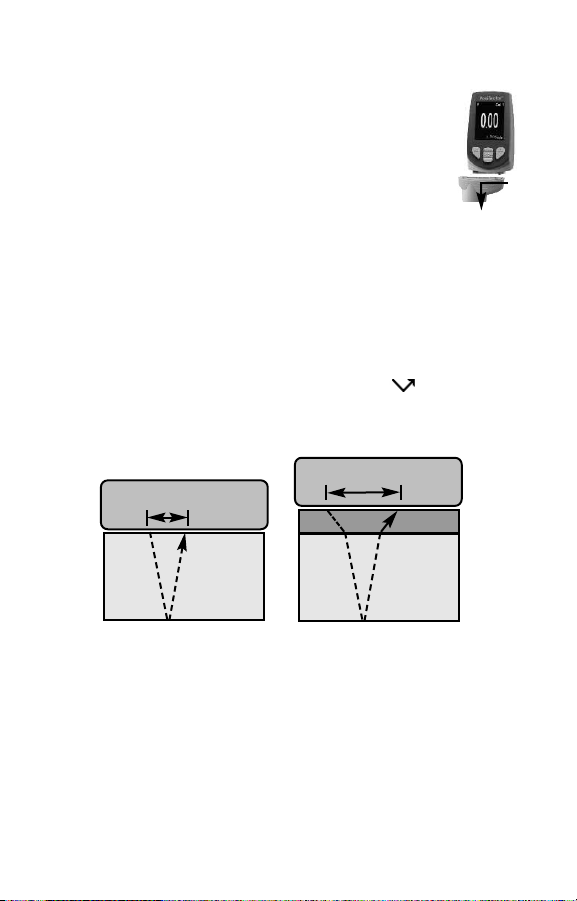

PosiTector UTG probes transmit an ultrasonic pulse into the

material to be measured. This pulse travels through the material

towards the other side. When it encounters an interface such as air

(back wall) or another material, the pulse is reflected back to the

probe. The time required for the pulse to propogate through the

material is measured by the Gage, represented as t1and t2 below.

PosiTector UTGC and UTGM (in single-echo mode) probes

determine thickness by measuring t1(uncoated) or t2 (coated),

dividing it by two and then multiplying by the velocity of sound for

that material (steel). See Figure 1.

ct a

pro

be from

a

ent an

d slide

ntally (in the direction of the arro

everse the

pow

ered-up

rm

in

es what typ

eck.

Probe

the

se steps to attach a n

the

e of probe

t

1

body,

plastic probe

P

osiTector

is attache

powe

w) a

ew probe.

Probe

r-dow

conn

way from

autom

atica

d and doe

t

2

coating

n the

ecto

the

s a

r

lly

steel

Figure 1

For uncoated materials t1relates directly to material thickness.

When a material is coated the propagation time is increased and

is shown above as t

Coatings such as paint have a slower velocity of sound than that

of metal. Thus the single-echo technique will produce a thickness

result greater than the actual combined coating+metal thickness.

.

2

t

steel

t

>

1

2

2

Page 4

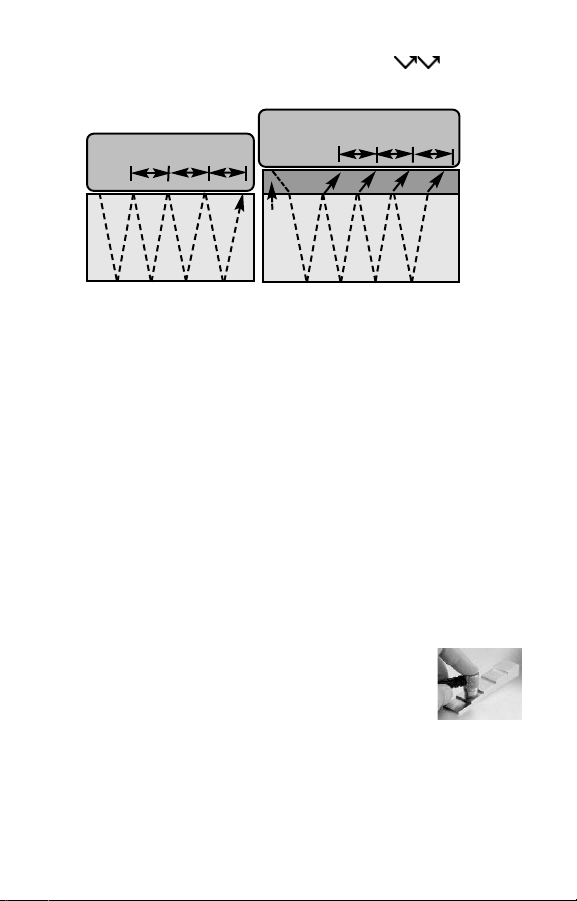

The PosiTector UTGM in multiple-echo mode determines

thickness by measuring the time between at least three consecutive back wall echoes.

t

t

t

1

Probe

2t3

t

Probe

1

t

2

3

Coating

Figure 2

In the figure above, multiple-echo mode measures only the time

between echoes. Regardless of whether the steel is coated or not,

all times between echoes are the same. In multiple-echo mode

the Gage determines thickness by measuring t1+t2+t3, dividing it

by six and then multiplying by the velocity of sound for that material. The resultant thickness calculation made by the instrument is

therefore an accurate measurement of the steel thickness only,

disregarding the coating thickness.

The velocity of sound is expressed in inches per microsecond or

meters per second. It is different for all materials. For example,

sound travels through steel faster (~0.233 in/µs) than it travels

through plastic (~0.086 in/µs).

How to Measure

How to Measure

1. Remove rubber cap from probe. Couplant (glycol

gel - included) must be applied to the surface to be

tested to eliminate air gaps between the wear face

and the surface. A single drop of couplant is sufficient

when taking a spot measurement.

2. Place the probe flat on the surface. Use moderate pressure to

press against the top of the probe with the thumb or index finger.

steel

3

Page 5

When the probe senses echoed ultrasound, a coupled symbol

will appear on the display and thickness values will be displayed. While the probe is coupled, the PosiTector UTG continually updates the display.

3. When the probe is removed from the surface, the last measurement will remain on the display.

Occasionally, excess couplant will remain on the probe when the

probe is lifted from the surface. This may cause the PosiTector

UTG to display a final measurement value different from those

observed when the probe was on the surface. Discard this value

and repeat the measurement.

Surface Conditions

Surface Conditions

Ultrasonic measurements are affected by the condition,

roughness and contour of the surface to be tested.

Measurement results may vary on coarse surfaces. Where

possible, it is recommended to seat the transducer on a smooth

flat surface that is parallel to the opposite side of the material.

On rough surfaces, the use of a generous amount of couplant

minimizes the surface effects and serves to protect the transducer

from wear, particularly when dragging the probe across a surface.

UTGM Probes:

(in multiple-echo mode) may occasionally be unable to give a

measurement result even when the "coupled" symbol appears.

Use additional couplant and lighter pressure on the probe when

measuring. Alternatively, laying a plastic shim on the surface with

couplant applied to both sides to simulate a painted surface will

help produce a steel-only thickness measurement (multiple-echo

mode). Switching the Gage to single-echo SE mode (see pg. 9)

will also help produce a steel-only thickness measurement.

On smooth, uncoated metal surfaces the Gage

4

Page 6

Calibration, Verification and Adjustment

Calibration, Verification and Adjustment

Three steps ensure best accuracy…

1.Calibration - typically done by the manufacturer or a qualified

lab. All probes include a Certificate of Calibration

2.Verification of Accuracy - as done by the user on known

reference standards such as calibration step blocks.

3.Adjustment - to a known thickness or sound velocity for the

material to be measured

Calibration

Calibration is the controlled and documented process of

measuring traceable calibration standards and verifying that the

results are within the stated accuracy of the Gage. Calibrations

are typically performed by the Gage manufacturer or by a certified

calibration laboratory in a controlled environment using a

documented process.

Verification

Gage accuracy can and should be verified using known reference

standards of the material to be tested.

Verification is an accuracy check performed by the user using

known reference standards. A successful verification requires the

Gage to read within the combined accuracy of the Gage and the

reference standards.

Adjustment

Adjustment, or Calibration Adjustment is the act of aligning the

Gage's thickness readings to match that of a known reference

sample. See Calibration Adjustment pg. 6.

5

Page 7

Cal Settings Menu

Cal Settings Menu

Zero

PosiTector UTG probes can be "zeroed" to compensate for tem-

perature and wear. This action is not required when operating in

multiple-echo mode (UTG M probes only) except when the instrument is new and after a Reset (pg. 8). However it ensures best

accuracy when operating in SE (single-echo) mode. Therefore it is

a good idea to "zero" the probe before each work shift and when

the temperature of the part changes. During zeroing, it does not

matter what the current velocity setting is.

1. Make sure the instrument is on and the probe is wiped clean.

2. Apply a single drop of couplant onto the zero plate located on

the underside of the probe connector. DO NOT apply couplant

directly onto the probe face.

3. Select the Zero menu option and follow the on-screen prompts.

Calibration Adjustment

The PosiTector UTG is factory calibrated. But in order for it to take

accurate thickness measurements of a particular material it must

be set to the correct sound velocity for that material. Be aware that

material composition (and thus its sound velocity) can vary from

stated tables and even between lots from a manufacturer.

Adjustment to a sample of known thickness of the material to be

measured ensures that the Gage is adjusted as close as possible

to the sound velocity of that specific material. Samples should be

flat, smooth and as thick as the maximum expected thickness of

the piece to be tested.

The PosiTector UTG allows four simple adjustment choices. All

four methods are based on the simple premise of adjusting the

sound velocity. The first three adjustment methods make 1-point

calibration adjustments to optimize the linearity of the PosiTector

UTG over small ranges. The fourth method makes a 2-point

calibration adjustment to allow for greater accuracy over a large

range.

6

Page 8

Thickness

The most common method of adjustment is to measure a sample

of known thickness. Select a reference standard of material as

close as possible in composition to the intended application. For

best results, the thickness of the reference standard should be

equal to or slightly greater than the thickness of the part to be

measured.

Material

If a known thickness of the material is not available, but the material is known, this quick adjustment allows the user to load one of

several preprogrammed material velocities.

Velocity

If the sound velocity for the test material is known, the Gage can

be adjusted to that specific sound velocity.

2 Pt Adjust

A 2-Point adjustment allows for greater accuracy while

simultaneously adjusting probe zero. Select two reference

standards as close as possible in composition to the intended

application. For best results, the thickness of the thicker reference

standard should be equal to, or slightly greater than the thickest

part to be measured. The thickness of the thinner reference

standard should be as close as possible to the lower end of the

expected measurement range.

Cal Lock

When checked, the icon appears and the current Cal settings

are “locked” to prevent further user adjustments. Uncheck to make

further adjustments.

7

Page 9

Setup Menu

Setup Menu

Reset

Reset (soft reset) restores factory settings and returns the

instrument to a known condition. The following occurs:

- All batches, stored measurements, images, and batch names

are erased.

- All calibration adjustments are cleared and returned to the

Gage’s factory calibration settings.

- Menu settings are returned to the following:

Memory = OFF

Statistics Mode = OFF

Hi Lo Alarm = OFF

Scan Mode = OFF

A Scan = OFF

B Scan = OFF

Cal Lock = OFF

Bluetooth = OFF

Display = None

SE Mode = OFF

Perform a more thorough Hard Reset by powering down the

instrument, waiting several seconds, then simultaneously holding

both the center and (+) buttons until the Reset symbol

appears. This returns the instrument to a known, “out-of-the-box”

condition. It performs the same function as a menu Reset with the

addition of:

- Bluetooth Pairing info is cleared.

- Menu settings are returned to the following:

Units = millimeter

Flip Display = Normal

Auto Sync = OFF

White on Black = OFF

Language = English

- Date and Time are not affected by either Reset.

NOTE:

Battery Type = Alkaline

Backlight = Normal

Bluetooth Streaming = OFF

USB Drive= ON

Scan

Normally, the PosiTector UTG takes a single spot measurement

at a rate of 6 readings per second while in contact with a surface.

When the probe is lifted, the last reading will remain on the display.

It is sometimes necessary to examine a larger region to locate the

thinnest point. When Scan is selected, the PosiTector UTG will

measure at a rate of 20 readings per second and display min/max

values.

8

Page 10

A Scan

A display in which the received pulse amplitude is

represented along y axis and the travel distance

of the ultrasonic pulse is represented along the x

axis.

(Advanced models only)

B Scan

A display in which a cross sectional profile of the

test material is represented.

SE Mode

Switches from multiple-echo to single-echo mode:

- To detect pits and flaws

- To increase the measurement range

- To obtain thickness measurements in circumstances where

multiple-echo can not

Battery Type

from a choice of “Alkaline”, “Lithium” or “NiMH” (Nickel-metal hydride

rechargeable). If NiMH is selected, the instrument will trickle charge the

batteries while connected via USB to a PC or optional AC charger (gage

must be powered ON). The battery state indicator icon is calibrated for the

selected battery type. No damage will occur if the wrong battery type is

selected. DeFelsko recommends eneloop (NiMH) rechargeable batteries.

Statistics

A statistical summary will appear on the display. Remove the last

measurement by pressing the (-) button. Press (+) to clear

statistics.

HiLo Alarm

Allows the Gage to visibly and audibly alert the user when

measurements exceed user-specified limits.

x - Average

↑

(Advanced models only)

(UTGM multiple-echo probes only)

Selects the type of batteries used in the instrument

Statistics Mode

Statistics Mode

x

- Maximum Value

σ - Standard Deviation

↓ - Minimum Value

9

Page 11

Memory Management

Memory Management

The PosiTector UTG can record readings in memory for printing

to the optional Bluetooth wireless printer, downloading or

synchronizing with PosiTector.net. Readings are time-stamped as

they are taken.

Scroll through display modes

(Advanced only)

Delete last reading

Access the Menu

Create a new batch

(Advanced only)

Restore brightness

after dimming

(Advanced only)

Standard models

store up to 250 readings in one batch.

Advanced models store 100,000 readings in up to 1,000

batches. “New Batch” closes any currently opened batch and

creates a new batch name using the lowest available number. The

icon appears. New batch names are date stamped when they

are created.

NOTE:

instrument. Download the full instruction manual at:

www.defelsko.com/manuals

Screen Capture

Press both (-)(+) buttons at any time to capture and save an image

copy of the current display. The last 10 screen captures are stored

in memory and can be accessed when connected to a computer

(see USB mass storage pg. 11).

USB mass storage - connect your PosiTector to a PC/Mac using

the supplied USB cable to access and print stored readings and

graphs. No software or internet connection required.

PosiTector.net - a free web-based application offering secure

centralized storage of thickness readings. Access your readings

from any web connected device. www.PosiTector.net

This Quick Guide summarizes the basic functions of the

Outputting Stored Readings

Outputting Stored Readings

10

Page 12

Connect Menu

Sync Now

Immediately initiates synchronization with PosiTector.net when

connected (USB or Bluetooth) to an internet connected PC

running PosiTector Desktop Manager.

Auto SYNC

Allows the instrument to automatically synchronize with

PosiTector.net when initially connected to an internet connected

PC running PosiTector Desktop Manager.

Additional measurements added to memory while connected are

synchronized only when the USB cable is disconnected, then

reconnected or when Connect>Sync Now is selected.

USB Drive

The instrument uses a USB mass storage device class which

provides a simple interface to retrieve data in a manner similar to

USB flash drives, cameras or digital audio players.

NOTE:

cable. The batteries are not used and the body will not

automatically power down. If rechargeable (NiMH) batteries are

installed, the instrument will trickle charge the batteries.

Allows individual readings to be sent to a computer or compatible

device as they are taken using Bluetooth wireless technology.

See www.defelsko.com/bluetooth

Determines if a software update is available for your instrument.

Must be connected to an internet connected PC running

PosiTector Desktop Manager. See www.defelsko.com/update

NOTE:

When connected, power is supplied through the USB

Bluetooth

Updates

The instrument may perform a Hard Reset (pg. 8)

Connect Menu

(Advanced models only)

11

Page 13

Returning for Service

Returning for Service

Before returning the instrument for service…

1.Install new or newly recharged batteries in the proper alignment

as shown within battery compartment.

2.Examine the probe tip for dirt or damage.

3.Perform a Hard Reset (pg. 8) and a Zero (pg. 6)

If you must return the instrument for service, describe the problem

fully and include measurement results, if any. Be sure to also

include the probe, your company name, company contact,

telephone number and fax number or email address.

Website: www.defelsko.com/support

Limited Warranty, Sole Remedy and Limited

Limited Warranty, Sole Remedy and Limited

Liability

Liability

DeFelsko's sole warranty, remedy, and liability are the express

limited warranty, remedy, and limited liability that are set forth on

its website: www.defelsko.com/terms

www.defelsko.com

© DeFelsko Corporation USA 2012

This manual is copyrighted with all rights reserved and may not be reproduced or transmitted, in whole

or part, by any means, without written permission from DeFelsko Corporation.

DeFelsko and PosiTector are trademarks of DeFelsko Corporation registered in the U.S. and in other

countries. Other brand or product names are trademarks or registered trademarks of their respective

holders.

Every effort has been made to ensure that the information in this manual is accurate. DeFelsko is not

responsible for printing or clerical errors.

All Rights Reserved

12

Loading...

Loading...