Page 1

NOTES

TABLE OF CONTENTS

1.0 Measuring procedure …………………………………………………. 2

2.0 Selection of calibration curve ………………………………………… 3

3.0 Determination of the reference water content ……………………… 3

4.0 Contact-free temperature sensor ……………………………………... 4

5.0 Calibration curves …………………………………………………….. 4

6.0 List of calibration curves ……………………………………………… 4

7.0 Design of the device ………………………………………………….. 5

8.0 Device maintenance instructions ……………………………………. 5

9.0 Menu level overview ………………………………………………….. 6

10.0 Checking the calibration ……………………………………………… 7

11.0 Calibration ……………………………………………………………… 8

12.0 Changing the batteries ……………………………………………….. 9

13.0 Exemption from liability ………………………………………………. 9

14.0 Transfer saved data to the PC ………………………………………. 10

15.0 Print saved data (logs) ……………………………………………….. 11

16.0 Technical data …………………………………………………………. 12

17.0 Common reasons for incorrect measurements ……………………. 13

18.0 Warranty ………………………………………………………………... 14

Electromatic Equipment Co., Inc

-16-

Electromatic Equipment Co., Inc

-1-

Page 2

1.0 MEASURING PROCEDURE

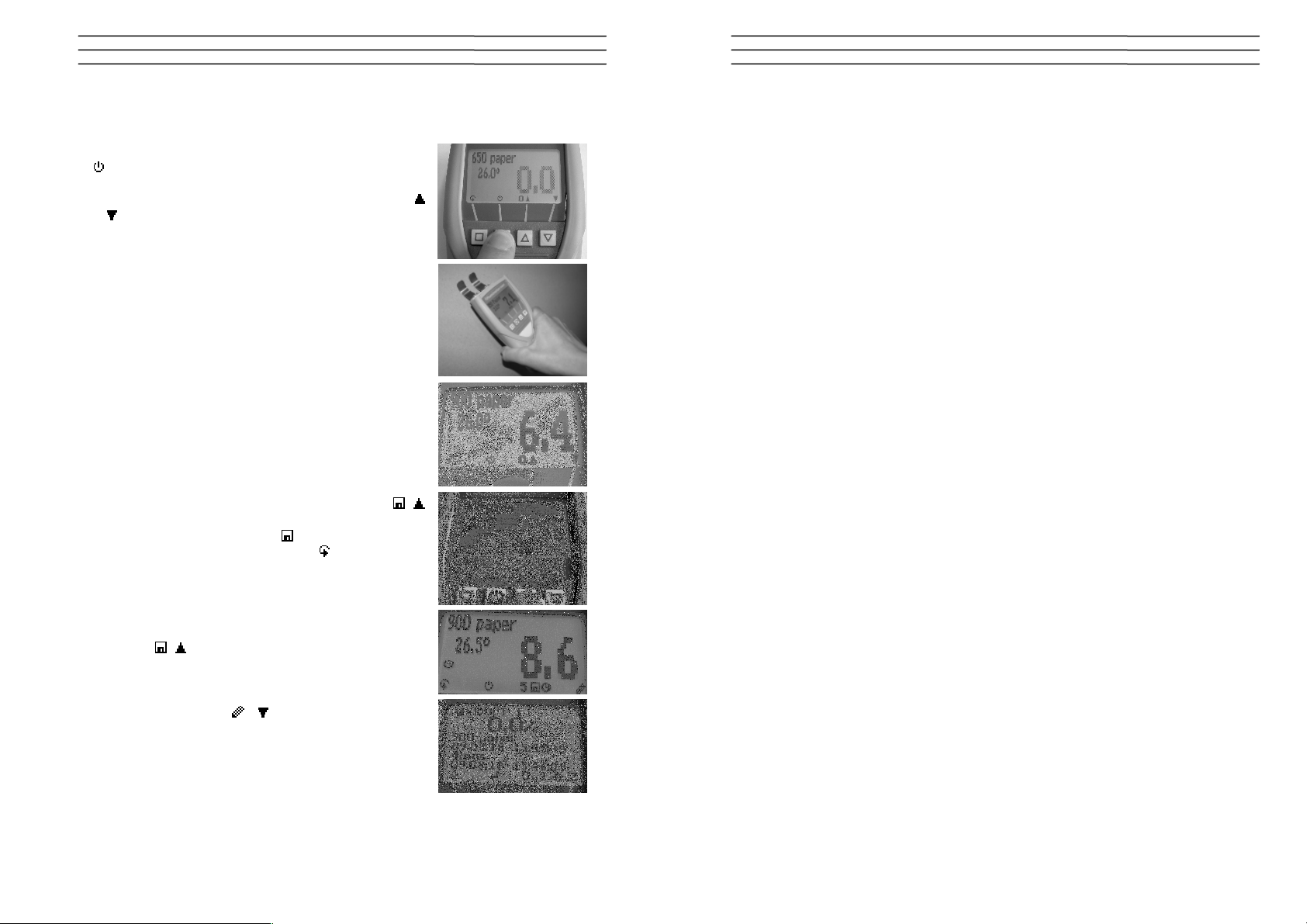

1. Switch on the device by pressing the power button

(

) for 3 sec.

2. Select the right calibration curve using the buttons

or

. The name of the calibration curve is shown at

the top of the display. Please see the instructions for

selection of calibration curve below.

3. Hold the device in one hand and press it onto the

paper roll (at the breadth) resp. onto the paper pile

with gentle compacting pressure (1,0 kg). For

measurement at running rolls the PM4 (contactfree temperature measurement) is necessary!

4. Now the display shows the water content. The

temperature is shown on the left.

5. To save the results in the save menu press the

(

button). The storage was successful when the

number in front of the symbol

the store menu please press the left (

increased. To reach

) button.

6. The menu level „Options -> Log time” offers the

possibility to activate the menu item „3 sec.“. If you

press the

( button) in the measuring window after

activation, the device will save a measuring value

every 3 seconds.

7. Pressing the button ( button) completes the

saving series. Now you can name the saved values

using the arrow keys (supplier 1).

NOTES

Electromatic Equipment Co., Inc

-2-

Electromatic Equipment Co., Inc

-15-

Page 3

18.0 WARRANTY

−=Mn

Electromatic Equipment Co., Inc. (Electromatic) warrants to the original purchaser

that this product is of merchantable quality and confirms in kind and quality with the

descriptions and specifications thereof. Product failure or malfunction arising out of

any defect in workmanship or material in the product existing at the time of delivery

thereof which manifests itself within one year from the sale of such product, shall be

remedied by repair or replacement of such product, at Electromatic’s option, except

where unauthorized repair, disassembly, tampering, abuse or misapplication has

taken place, as determined by Electromatic. All returns for warranty or non-warranty

repairs and/or replacement must be authorized by Electromatic, in advance, with all

repacking and shipping expenses to the address below to be borne by the

purchaser.

THE FOREGOING WARRANTY’S IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO, THE

WARRANTY OF MERCHANTABILITY AND FITNESS FOR ANY PARTICULAR

PURPOSE OR APPLICATION. ELECTROMATIC SHALL NOT BE RESPONSIBLE

NOR LIABLE FOR ANY CONSEQUENTIAL DAMAGE, OF ANY KIND OR

NATURE, RESULTING FROM THE USE OF SUPPLIED EQUIPMENT, WHETHER

SUCH DAMAGE OCCURS OR IS DISCOVERED BEFORE, UPON OR AFTER

REPLACEMENT OR REPAIR, AND WHETHER OR NOT SUCH DAMAGE IS

CAUSED BY MANUFACTURER’S OR SUPPLIER’S NEGLIGENCE WITHIN ONE

YEAR FROM INVOICE DATE.

Some State jurisdictions or States do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation may not apply to you.

The duration of any implied warranty, including, without limitation, fitness for any

particular purpose and merchantability with respect to this product, is limited to the

duration of the foregoing warranty. Some states do not allow limitations on how long

an implied warranty lasts but, not withstanding, this warranty, in the absence of such

limitations, shall extend for one year from the date of invoice.

Electromatic Equipment Co., Inc.

600 Oakland Ave. Cedarhurst, NY 11516 - USA

Tel: 1-800-645-7330 / Tel: 516-295-4300 / Fax: 516-295-4399

Every precaution has been taken in the preparation of this manual. Electromatic assumes no

responsibility for errors or omissions. Neither is any liability assumed for damages resulting

from the use of information contained herein. Any brand or product names mentioned herein

are used for identification purposes only, and are trademarks or registered trademarks of their

respective holders.

2.0 SELECTION OF CALIBRATION CURVE

Due to the countless number of paper types there is no standardised allocation of

calibration curves. The different calibration curves refer to the different densities of

paper or paper rolls.

The list of calibration curves below shows suggestions for paper types.

To ensure the best accuracy of your measurement you have to carry out a

comparison measurement using your online moisture measuring system or by kilndrying (according to DIN 287) once.

1. Measure the water content of your paper (on the roll or the pile) using all

calibration curves that offer realistic results and write down the measuring

results of the different calibration curves.

2. Now please note the effective water content determined by your online

measurement system or carry out a reference measurement according to EN

ISO 287.

3. Compare the determined reference water content with the measuring results of

the different calibration curves. Use the calibration curve with the measuring

result nearest to the reference water content. Info: The name of the calibration

curve can be modified to your specific paper name!

3.0 DETERMINATION OF THE REFERENCE WATER CONTENT

The humimeter PM3 determines the water content, which means that it calculates

the moisture referred to the total mass (EN ISO 287):

WG

MtMn

100% ×

Mn: Mass of the sample before drying

Mt: Mass of the dried sample

Electromatic Equipment Co., Inc

-14-

Electromatic Equipment Co., Inc

-3-

Page 4

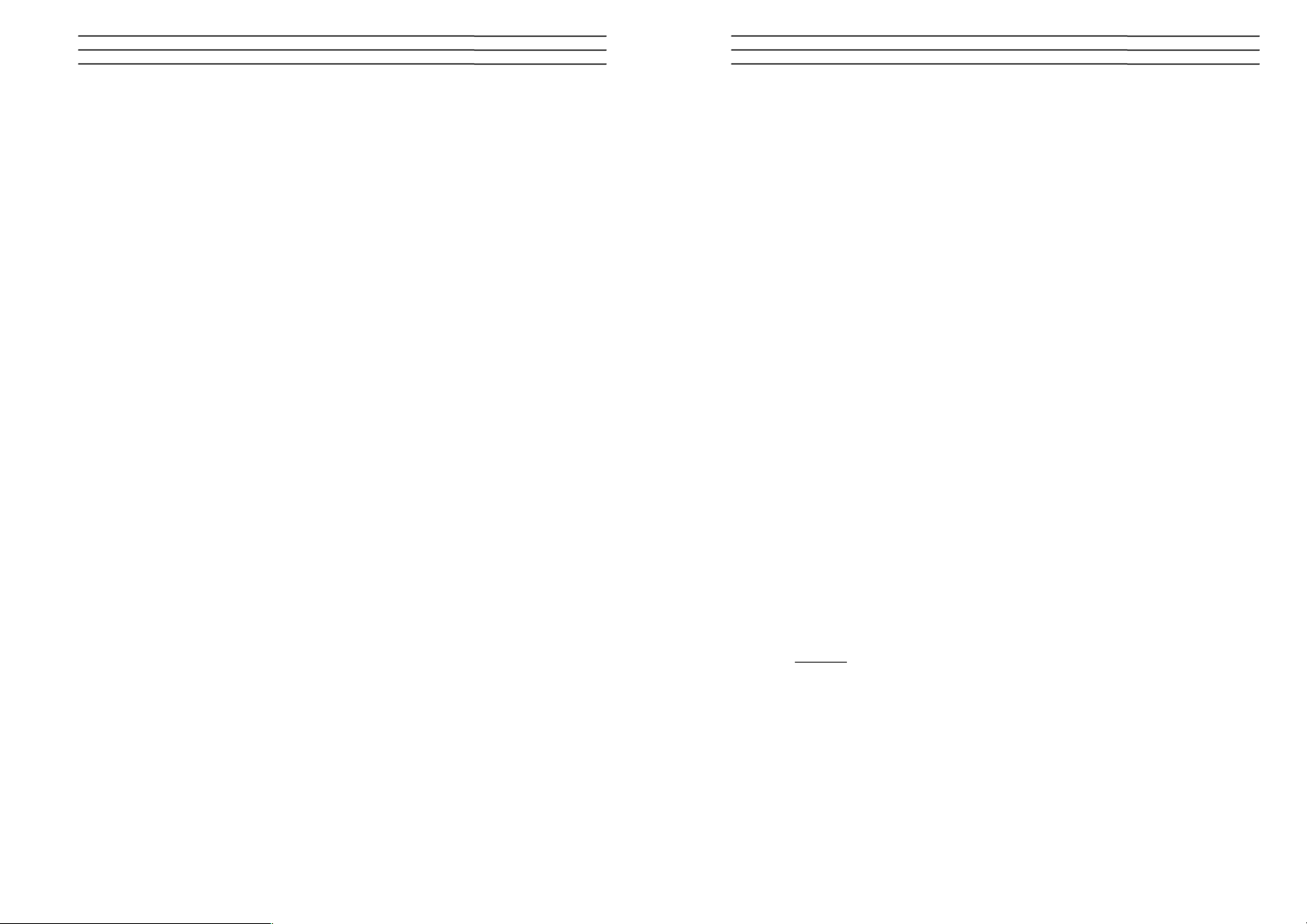

4.0 CONTACT-FREE TEMPERATURE SENSOR

name

paper type

density

600 paper

650 paper

700 paper

750 paper

800 paper

850 paper

900 paper

950 paper

1000 paper

1050 paper

1100 paper

1200 paper

1300 paper

1400 paper

1500 paper

1600 paper

Empty 1700

Empty 975

Empty 550

reference

The back side of the humimeter PM4 contains

an embedded temperature sensor for the

contact-free temperature measurement below

the sensor. This ensures the determination of

the temperature of the product within seconds

and consequently the temperature

compensation of the displayed water content.

The sensor must not be covered by a hand or

any other object!

5.0 CALIBRATION CURVES

Very low density paper 600 kg/m³

Low density paper 650 kg/m³

Low density paper 700 kg/m³

Fluting, Schrenz 750 kg/m³

Newsprint paper 800 kg/m³

Kraftliner brown 850 kg/m³

Kraftliner White Top, Testliner brown 900 kg/m³

Testliner white, copy paper 950 kg/m³

Copy paper, LWC raw 1000 kg/m³

Copy paper calendered 1050 kg/m³

Copy paper calendered 1100 kg/m³

LWC calendered 1200 kg/m³

Flysheet paper 1300 kg/m³

Flysheet paper 1400 kg/m³

Flysheet paper high density 1500 kg/m³

Flysheet paper very high density 1600 kg/m³

For creation of customer calibration curve

For creation of customer calibration curve

For creation of customer calibration curve

! Only for checking the instrument !

6.0 LIST OF CALIBRATION CURVES

By pressing one of the arrow keys in the measuring

window for approx. 3 seconds a list of all available

calibration curves opens. Now you can select your

desired curve using the arrow keys and confirm by

pressing

.

17.0 COMMON REASONS FOR INCORRECT MEASUREMENTS

• Wrong calibration curve

Double-check the correct selection of the calibration curve before measuring.

The calibration curve „reference“ must NOT be used.

• Inadequate thickness of the paper pile

A single sheet of paper must NOT be measured. Make sure that the paper pile

below the steel clamps has a thickness of at least 100 mm.

• Electro conductive material

Every metallic object as well as electro conductive packing material e.g. paper

coloured by soot or wire has a negative effect on the accuracy of your

measurement. Make sure that in an area of 20 cm below the sensor steel

clamps there is no such material.

• Product temperature out of application range

The application range is between 0 and +60°C.

• Discrepancy in temperature between device and material

Please ensure that the device and the material under test are being stored at

nearly the same temperature before measuring. A high temperature difference

has a negative effect on the stability of the measurement results.

• Measurement at the front side

A measurement at the front side of a paper roll will bring different measuring

results. For that you have to select a different calibration curve.

• Bended steel clamps

If the steel clamps (measuring area) are bended you might get wrong measuring

results.

Please note:

• After measuring at the running paper roll for a longer period the steel clamps will

get hot – don´t touch! => risk of getting burned!

• Measuring fine paper at the running roll may cause pressure marks on the paper

=> for possible damages at the paper we refuse any liability.

Electromatic Equipment Co., Inc

-4-

Electromatic Equipment Co., Inc

-13-

Page 5

16.0 TECHNICAL DATA

(backside)

calibration curve

Measuring depth 50 mm

Minimum material thickness 100 mm

Resolution 0,1% water content; 0,1°C; 0,3°F

Measuring range 1 to 25% water content

Angle temperature sensor 90°

Paper temperature 0°C to +80°C; 32°F to 176°F

Surrounding temperature 0°C to +50°C; 32°F to 122°F

(for measuring device)

Storage temperature -20°C to +60°C; 32°F to 122°F

(for measuring device)

Temperature compensation automatically

Memory for measured values approx. 10.000 values

Menu languages German, English, French, Italian, Spanish,

Russian

Power supply 4 pcs. 1,5 Volt AA Alkaline batteries

(for approx. 900 measurements)

Switch off time after approx. 4 minutes

Power consumption 60 mA (with display lighting)

Display 128 x 64 matrix display, with LED backlighting

Dimensions 182 x 75 x 54 mm (with rubber housing)

Weight 340g (incl. accu and rubber housing)

Protection class IP 40

Scope of supply humimeter PM4, accumulator, USB data

interface, contact-free temp. sensor, plastic

case, proof plate, protective rubber housing, user

manual

Options Mobile printer

7.0 DESIGN OF THE DEVICE

steel clamp

(sensor area)

name of

calibration curve

measuring value

temperature

rolling menu

button

ON-OFF button

8.0 DEVICE MAINTENANCE INSTRUCTIONS

To provide a long life of your device please do not expose it to strong mechanical

loads or heat e.g. dropping it or direct sunlight exposure.

The instrument is not rainproof. Keep it in dry areas. Clean the device only with a

dry cloth. For cleaning the steel clamps you can also use alcohol. Please do not

deform the steel clamps.

Do not touch the contact-free temperature sensor. Clean it by blowing, but do

not use compressed air.

If the device is not used for a longer period (2 months) or when the batteries are

empty, they should be removed to prevent a leakage of the battery acid.

USB Socket

measuring value

water content

changing the

protective rubber

housing

(removable)

batteries slot

Electromatic Equipment Co., Inc

-12-

Electromatic Equipment Co., Inc

-5-

Page 6

9.0 MENU LEVEL OVERVIEW

Keypad symbols

OK

Type selection menu

Next calibration curve

Previous calibration curve

Power off (3 sec.)

Store menu

Watch last saved data

Save new value

Power off (3 sec.)

Main menu

Data storage

Manual logs

Auto logs

Clear logs

Print logs

Last logs

All logs

Clear logs

Send logs

Manual Logs

Auto logs

Clear Logs

Options

Switch upper

Switch lower

Open this menu / Enter

Overview main menu

Measuring window:

data

data

Menu:

Options

Date / Time

Log Time

Language

Unlock

°C / °F

Calibrate

o Userlevel

BL On Time

Auto Off Time

Materialcalib.

Password

Reset

SN.

Logo

TM

Admin

Rolling Menu

Power ON / OFF

Switch upper

Switch lower

Save

Hold

Watch saved

Add supplier’s

Enter

Switch upper

Switch lower

Back

Enter numbers

Enter letters

Next or right

Left

Yes

No

Shift

15.0 PRINT SAVED DATA (LOGS)

To print your saved data, connect the device to the printer

using the printer cable that was delivered with your

device. Carefully loose the protection cap on the

humimeter PM3. At first plug in the side of the connector

with the close plastic casing at the humimeter PM3. Then

switch on the device.

Not till then the other side of the cable has to be plugged

in at the printer. Switch on the printer by pressing

the green LED is blinking. If it does not blink, please

change the batteries and try again.

Press the

menu (see image on the right). Select „Print Logs“ and

confirm by pressing

Now you can select if you want to print the last saved

measuring series or all saved measuring series (logs).

Confirm by pressing

printed out now.

To save paper, please think of clearing the data storage

regularly.

Emission ratio

The infrared temperature measurement depends on the

emission ratio of the measured product. By default, the

humimeter PM4 contains the emission ratio of paper

(0.950). For changing this value, please proceed as

follows:

Press the

Choose the menu item “Options” and confirm by pressing

. Then choose the item “emission ratio” and confirm

with

button at your humimeter until you reach the

.

again. The selected logs are

key as long as you reach the main menu.

again.

. Now

Electromatic Equipment Co., Inc

-6-

Electromatic Equipment Co., Inc

-11-

Page 7

14.0 TRANSFER SAVED DATA TO THE PC

To send your saved logs to the PC, connect the humimeter device to your PC using

the USB cable that was delivered with your device. Carefully loose the protection

cap on your humimeter and plug in the USB mini B connector. The bigger connector

has to be connected to a USB slot on your PC.

Start the LogMemorizer software on your PC and switch

on your humimeter PM4.

The data transfer can be started on your humimeter or on

the software:

Starting the data transfer on the humimeter:

Press the

key until you reach the menu (see image on

the right). Then select „Send Logs“ and confirm by

pressing the

confirm by pressing

key. Now select „Manual Logs“ and

again. All saved logs will be sent to

your PC.

Starting the data transfer on your PC:

Press the button „remote control“ in the LogMemorizer

software. A drop-down menu with several options opens

(see image below).

For transferring the data you can select „Import last

manual log“ (the last saved measuring series is

transferred) or „Import all manual logs“ (all saved logs are

transferred).

If you click on one of these menu items, the transfer starts

immediately.

For the basic adjustments of the software please look

through the instructions on the LogMemorizer CD.

10.0 CHECKING THE CALIBRATION

We recommend to check the calibration of your humimeter PM4 every 4 weeks,

using the proof plate delivered with the device. For this check the device has to

show a temperature between 18,0 and 24,0°C.

Switch on the instrument and select the calibration curve

„reference“ using the arrow keys. Hold the humimeter

PM4 in one hand and press it onto the grey proof plate

(compacting pressure of 1,0kg). Make sure that you hold

the device horizontally and the steel clamps are

positioned at least 1 cm from the edge of the proof plate.

The shown measuring value should range between 18.5 and 20,5. If the shown

value is out of this range, you have to carry out a calibration (see instructions

below).

Electromatic Equipment Co., Inc

-10-

Electromatic Equipment Co., Inc

-7-

Page 8

11.0 CALIBRATION

By a zero point adjustment you can correct a too high deviation at the calibration

check.

For that please proceed as follows:

Press the left key twice to reach the menu level. Navigate

to the menu item „Options“ using the arrow keys. Confirm

by pressing the

button.

Select the menu item „Calibrate“ using the arrow keys

and confirm by pressing

.

This menu item has to be unlocked. For that you have to enter the 4-digit serial

number of your humimeter PM4. You can find the serial number on the top right

edge of the display a short time after switching on the instrument, or on the sticker in

the battery slot.

Press the third button as long as the black bar stands on

the first digit of the serial number. After a waiting time of a

few seconds the device accepts the entered digit. Now

the other 3 digits have to be entered. When the 4-digit

number has been entered correctly (see picture), press

the

button to confirm.

Hold the humimeter PM4 in one hand up in the air and

make sure that nothing stands behind the steel clamps

(distance min. 200 mm). Now press the second button

(

) with one finger.

The calibration procedure will take a few seconds. During

that time, the instrument has to be held up in the air and

the measuring field (steel clamps) must NOT be touched.

The device is ready when the shown picture on the right

disappears automatically.

12.0 CHARCHING THE BATTERIES

Connect the provided USB cable to the device and the

other end of the cable to a PC or another USB charging

adapter. It takes about 6 hours to charge the completely

discharged batteries. Please make sure that the

temperature during the charging process is between

0°C and 45°C , as otherwise the batteries may be

destroyed.

Hardware Reset

In case that your humimeter device does not respond to any

key press or cannot be switched on, there can be carried

out a hardware reset directly by the customer. Please note:

the accumulator must be charged before your start the

following procedure:

Slide a pair of tweezers or a small screw driver below the

cover cap. If your tool stick, try again at another position

(the arrows on the image show the positions). Do not use

any force. Open the cover cap and push the push button

using your tool. Now the humimeter will restart. Fix the

cover cap again.

If it will not restart, please contact your technical support.

13.0 EXEMPTION FROM LIABILITY

For miss-readings and wrong measurements and of this resulting damage we refuse

any liability. This is a device for quick determination of moisture. The moisture

depends on multiple conditions and multiple materials. Therefore we recommend a

plausibility check of the measuring results. Each device includes a serial number

and the guarantee stamp. If those are broken, no claims for guarantee can be

made. In case of a faulty device, please contact Checkline Europe.

Electromatic Equipment Co., Inc

-8-

Electromatic Equipment Co., Inc

-9-

Page 9

PAPER ROLL MOISTURE METER

PM4

OPERATING INSTRUCTIONS

Loading...

Loading...