Page 1

TABLE OF CONTENTS

1.0 General information ………………………………………………….. 2

2.0 Unlock the humimeter ………………………………………………. 2

3.0 Change the calibration curve name ……………………………….. 3

4.0 Take values ………………………………………………………….. 3

5.0 Temperature compensation ………………………………………… 5

6.0 Measuring range …………………………………………………….. 6

7.0 Completion …………………………………………………………… 6

8.0 Technical Support …………………………………………………… 6

9.0 Warranty …………………..………………………………………… 7

Electromatic Equipment Co. Inc.

-8-

Electromatic Equipment Co. Inc.

-1-

Page 2

1.0 GENERAL INFORMATION

In the device different calibration curves are stored. If the material to be

measured does not conform to any of the stored curves, a new calibration curve

can be created by the customer himself. In the following pages you will find

instructions for creating your own calibration curve.

Depending on the material that you want to test it is up to you to select the

appropriate drying method and moisture determination.

In principle it the setting of your own curve is done assigning a moisture

percentage to a reference voltage that is measured by the gauge.

2.0 UNLOCK THE HUMIMETER

In this menu, the hidden functions (grey letters) of the device can temporarily be

unlocked until the next turn-off of the device. You just have to enter the superuser password.

To use this protected features, you have to enter the four digit password.

Provided by the factory, this password is the serial number. The four digit serial

number is shown in the menu item “status” or when the device is booting.

How to enter the menu point „unlock“:

Press the “Rolling menu” button as long as you enter the main menu.

Navigate to the menu item „options“ and press the

menu item „unlock“ and press the

button again.

button. Navigate to the

Press the button as long as you have reached the

right number and affirm this by pressing the

button.

The character will be affirmed and the cursor jumps to

the next position. Enter the four numbers of your

password and confirm it by pressing the

button.

Press the button and successively to abort the

password check. The button also contains a fast

forward function, starting when you press the button for a few seconds. The

character is affirmed after a few seconds automatically.

9.0 Warranty

Electromatic Equipment Co., Inc. (Electromatic) warrants to the original

purchaser that this product is of merchantable quality and c onfirms in kind and

quality with the descriptions and specifications thereof. Product failure or

malfunction arising out of any defect in workmanship or material in the product

existing at the time of delivery thereof which manifests itself within one year

from the sale of such product, shall be remedied by repair or replacement of

such product, at Electromatic’s option, except where unauthorized repair,

disassembly, tampering, abuse or misapplication has taken place, as

determined by Electromatic. All returns for warranty or non-warranty repairs

and/or replacement must be authorized by Electromatic, in advance, with all

repacking and shipping expenses to the address below to be borne by the

purchaser.

THE FOREGOING WARRANTY’S IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO, THE

WARRANTY OF MERCHANTABILITY AND FITNESS FOR ANY PARTICULAR

PURPOSE OR APPLICATION. ELECTROMATIC SHALL NOT BE

RESPONSIBLE NOR LIABLE FOR ANY CONSEQUENTIAL DAMAGE, OF

ANY KIND OR NATURE, RESULTING FROM THE USE OF SUPPLIED

EQUIPMENT, WHETHER SUCH DAMAGE OCCURS OR IS DISCOVERED

BEFORE, UPON OR AFTER REPLACEMENT OR REPAIR, AND WHETHER

OR NOT SUCH DAMAGE IS CAUSED BY MANUFACTURER’S OR

SUPPLIER’S NEGLIGENCE WITHIN ONE YEAR FROM INVOICE DATE.

Some State jurisdictions or States do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation m ay not apply to

you. The duration of any implied warrant y, including, without limitation, fitness

for any particular purpose and merchantabilit y with respect to this product, is

limited to the duration of the foregoing warranty. Some states do not allow

limitations on how long an implied warranty lasts but, not withstanding, this

warranty, in the absence of such limitations, shall extend for one year fro m the

date of invoice.

Electromatic Equipment Co., Inc.

600 Oakland Ave. Cedarhurst, NY 11516 - USA

Tel: 1-800-645-7330 / Tel: 516-295-4300 / Fax: 516-295-4399

Every precaution has been taken in the preparation of this manual. Electromatic assumes

no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of information contained herein. Any brand or product names

mentioned herein are used for identification purposes only, and are trademarks or

registered trademarks of their respective holders.

Electromatic Equipment Co. Inc.

-2-

Electromatic Equipment Co. Inc.

-7-

Page 3

6.0 MEASURING RANGE

V

In the menu item „Valid“ the measuring range of the calibration curve is defined.

A valid measuring value is shown in black in the measuring windo w. An invalid

measuring value is shown in grey and is blinking when the water content is out

of range.

This feature can be explained best by an example.

Wanted is a valid range from 16.0% up to 45.0% water content.

Enter the following values in the shown order:

Idx(1) Idx(2) Idx(3) Idx(4) Idx(5) Idx(6)

90.0% 45.1% 45.0% 16.0% 15.9% 0.0%

3 3 0 0 1 1

The measuring range should be defined within the area of the measured

samples!

Explanation:

between 0.0% und 15.9% the value is shown in grey invalid

between 16.0% und 45.0% the value is shown in black valid

between 45.1% und 90.0% the value is grey and blinks invalid

7.0 COMPLETION

If all values of the created calibration curve are stored in the humimeter device,

you can use the new calibration curve for measuring!

8.0 TECHNICAL SUPPORT

Checkline Europe BV

Dennenweg 225B

7545 WE Enschede

Tel: +31-53-4356060

Fax: +31-53-4333570

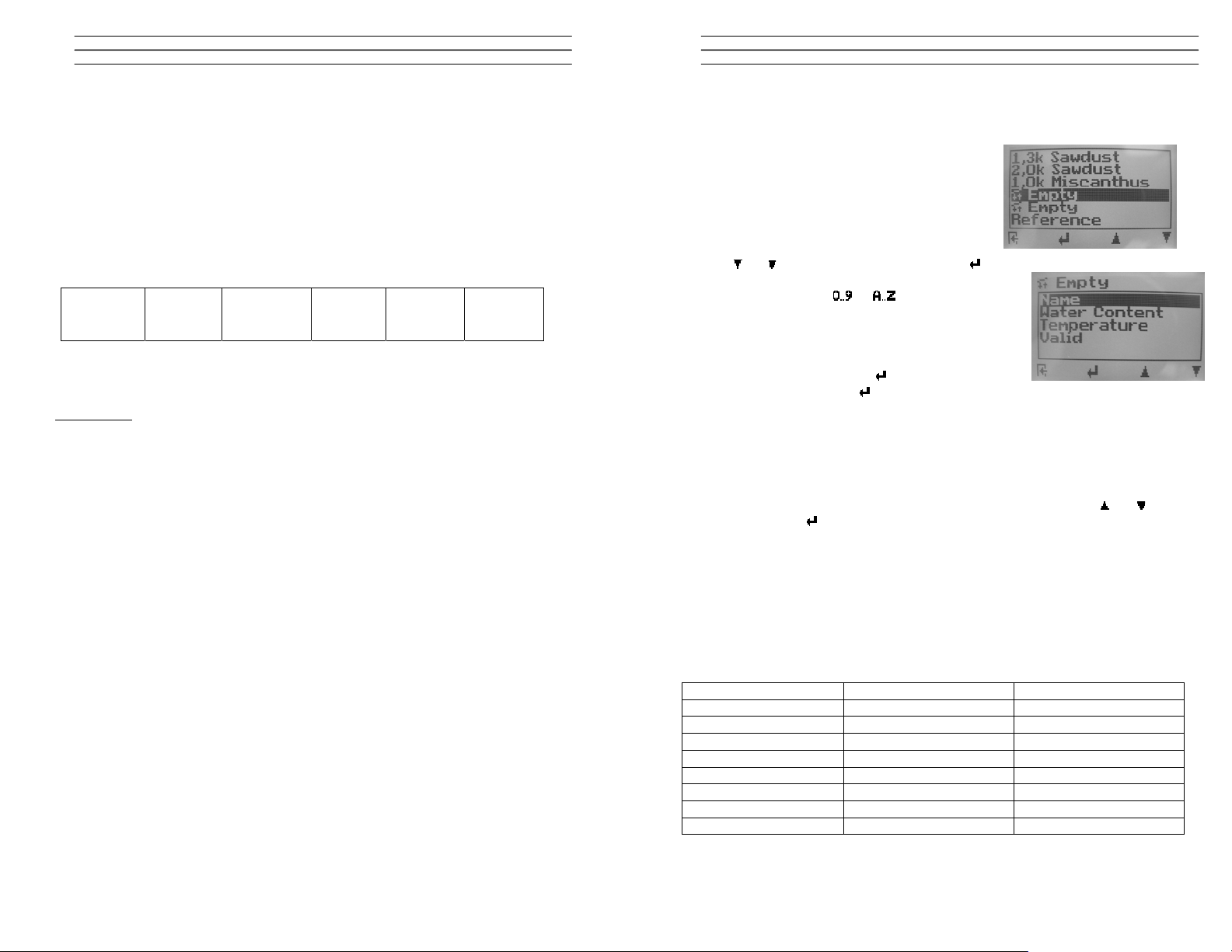

3.0 CHANGE THE CALIBRATION CURVE NAME

If the device is unlocked, the menu point

„Materialcalib.“ is available. A list with all

calibration curves is shown on the display!

Choose an “empty” calibration curve, or a curve

you do not need.

Choose the menu item “Name” by pressing the

buttons

name can contain up to ten characters. Enter the

name using the buttons or . The name should

consist of the filling quantity and the variety (e.g.

2,50k material). If you press the button for a few

seconds, the fast forward modus will be activated. If

the cursor is in the right position and shows the right

letter or character, press the

whole name by pressing the

4.0 TAKE VALUES

Select the menu item “water content” by pressing the buttons

confirm by pressing

There are 8 index points that make up the curve.

It is IMPORTANT that you do not change the first (1) and last index point

(8)!

These values set the measuring range of the gauge within a reasonable limit.

Another important point is that the index points start at the highest moisture

value and run down to the lowest moisture content value.

For example:

or and confirm by pressing the button. Your calibration curve

button. Confirm the

button.

.

Index point [ldx]

oltage Value [V] Moisture Value [%]

1 7.990 99.0

2 4.810 99.0

3 4.800 70.0

4 3.500 47.0

5 2.050 22.0

6 0.452 0.0

7 0.450 0.0

8 0.000 0.0

or and

Electromatic Equipment Co. Inc.

-6-

Electromatic Equipment Co. Inc.

-3-

Page 4

In order for you to create a curve you need to take several measurements of

material with different moisture contents.

You need to log the voltage and assign a moisture value to this voltage.

It is possible to do this live while taking a measurement by p[alcing the ga uge

on the material.

Then you have to press the right button

(„V“). By

pressing this button you transfer the voltage value of

the sample. If this was successful, you will jump

automatically to the next line. The actual calculated

water content has to be typed in by hand.

To save the values you have to leave the menu item

by pressing the shift button (

the symbol with the opened door (

) first, and afterwards

).

In case you have no moisture content value at the point you take this

measurement, it is best you create a list and enter the curve at a later point in

time.

Both values can be set manually.

There is a maximum of 16 index points available. Ho wever, as many calibration

points as possible should be affiliated.

With the final calibration curve you can measure up to the driest calibration

point you determinate. For example: lowest measured point: 22.0% => material

over 22.0% water content can be measured!

We recommend that the captured voltage and water contents are inscribed in a

graphic. Not linear points can be corrected. The values should be (as shown in

the example below) almost on a straight line.

V%

2,878 49,20

2,722 44,90

2,488 41,00

2,311 36,70

2,102 32,50

1,798 28,20

1,600 24,50

1,400 19,10

50,00

40,00

30,00

20,00

10,00

11,522,53

1,200 15,60

To save the values you have to leave the menu item by pressing the shift

button (

) first, and afterwards the symbol with the opened door ( ).

To be sure that all values are correct and in the right order, please double

check the whole values in the calibration curve!

5.0 TEMPERATURE COMPENSATION

For the temperature compensation a factor is specified by the manufacturer.

In almost all products the entered values will be correct. You do not have to

change this value in general!

If you however still need to determine some new values, please advance as

follows: To achieve a very precise factor take several pr obes of your sample

with exactly the same water content and pack them into air proof plastic bags

(or something else). Now you have to align the samples to different

temperatures. One sample at 20°C (68°F), a further at 5°C (41°F) and a third at

40°C (104°F). After the aligning you have to measure the three samples again.

IMPORTANT: Let your humimeter also align to the different temperatures.

Using the following calculation you can determinate the temperature

compensation coefficient. e.g.: You measure the sample with the humimeter at

20°C and get a value of 30% water content, and the sample at 5°C you

measure just 28%.

So you can calculate:

30

TK

28

So the factor is: 1.07 at 5°C

07.1

Electromatic Equipment Co. Inc.

-4-

Electromatic Equipment Co. Inc.

-5-

Page 5

Calibration Manual

PM3/PM4

OPERATING INSTRUCTIONS

Loading...

Loading...