Page 1

NOTES

TABLE OF CONTENTS

1.0 Introduction …………………………………………………………….. 2

1.1 Quality information

1.2 Application

1.3 First setting into operation

2.0 Measuring procedure …………………………………………………. 3

3.0 How to choose type of product ………………………………………. 4

4.0 Verification and correction of switch position ………………………. 5

5.0 Measuring method ……………………………………………………. 5

6.0 Most common reasons for measuring errors ………………………. 6

7.0 Measuring principle …………………………………………………… 7

8.0 Exclusion of liability …………………………………………………… 8

9.0 Care regulations ………………………………………………………. 8

10.0 ISO-approved examination of the instrument ……………………… 9

11.0 Technical data ………………………………………………………… 13

12.0 Warranty ………………………………………………………………. 14

ELECTROMATIC Equipment Co., Inc.

-16-

ELECTROMATIC Equipment Co., Inc.

-1-

Page 2

1.0 INTRODUCTION

1.1 Quality information

We would like to inform you that your meas uring device corresponds to the CE

norms EN50081 and EN50082. The function of your instrument has been

examined and calibrated before delivery.

1.2 Application

P2: Mainly for very strong paper, packing paper, cardboard

P4: Mainly for paper used for offset printing

LM5: Mainly for leather

1.3 First setting into operation

Your measuring device should be supplied with a battery by the manufacturer. If

this is not the case, open the battery compartment and stick a 9 V block battery

or a charged accumulator onto the connecting contacts. Then put the battery in

the battery compartment. Make sure that the power cable does not get caught in

the lid. Press the power switch (ON) at the front of the instrument and the displa y

will go on. If this is not the case, check if the batteries are charged. If you hold

your measuring instrument in the air you will see a certain value on the display

depending on the switch position. Now you can compare th is value to the rated

values according to tables on page 9. Furthermore it is a dvisable to check the

measuring device at the proof plane which is the bottom of the wooden case.

NOTES

ELECTROMATIC Equipment Co., Inc.

-2-

ELECTROMATIC Equipment Co., Inc.

-15-

Page 3

12.0 WARRANTY

ELECTROMATIC Equip’t Co., Inc. warrants to the original purchaser that this

product is of merchantable quality and confirms in kind and quality with the

descriptions and specifications thereof. Product failure or malfunction arising out

of any defect in workmanship or material in the product existing at the time of

delivery thereof which manifests itself within one year from the sale of such

product, shall be remedied by repair or replacement of such product, at

ELECTROMATIC Equip’t Co., Inc.’s option, except where unauthorized repair,

disassembly, tampering, abuse or misapplication has tak en place, as det ermined

by ELECTROMATIC Equip’t Co., Inc.. All returns for warranty or non-warranty

repairs and/or replacement must be authorized by Checkline, in advance, with all

repacking and shipping expenses to the address below to be borne by the

purchaser.

THE FOREGOING WARRANTY’S IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO, THE

WARRANTY OF MERCHANTABILITY AND FITNESS FOR ANY PARTICULAR

PURPOSE OR APPLICATION. CHECKLINE SHALL NOT BE RESPONSIBLE

NOR LIABLE FOR ANY CONSEQUENTIAL DAMAGE, OF ANY KIND OR

NATURE, RESULTING FROM THE USE OF SUPPLIED EQUIPMENT,

WHETHER SUCH DAMAGE OCCURS OR IS DISCOVERED BEFORE, UPON

OR AFTER REPLACEMENT OR REPAIR, AND WHETHER OR NOT SUCH

DAMAGE IS CAUSED BY MANUFACTURER’S OR SUPPLIER’S NEGLIGENCE

WITHIN ONE YEAR FROM INVOICE DATE.

Some State jurisdictions or States do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation m ay not apply to

you. The duration of any implied warranty, includi ng, without limitation, fitness for

any particular purpose and merchantability with respect to this product, is limited

to the duration of the foregoing warranty. Some states do not allow limitations on

how long an implied warranty lasts but, not withstanding, this warranty, in the

absence of such limitations, shall extend for one year from the date of invoice.

ELECTROMATIC Equipment Co., Inc

600 Oakland Ave

Cedarhurst, NY 11516

Every precaution has been taken in the preparation of this manual. ELECTROMATIC

Equipment Co., Inc. assumes no responsibility for errors or omissions. Neither is any

liability assumed for damages resulting from the use of information contained herein. Any

brand or product names mentioned herein are used for identification purposes only, and

are trademarks or registered trademarks of their respective holders.

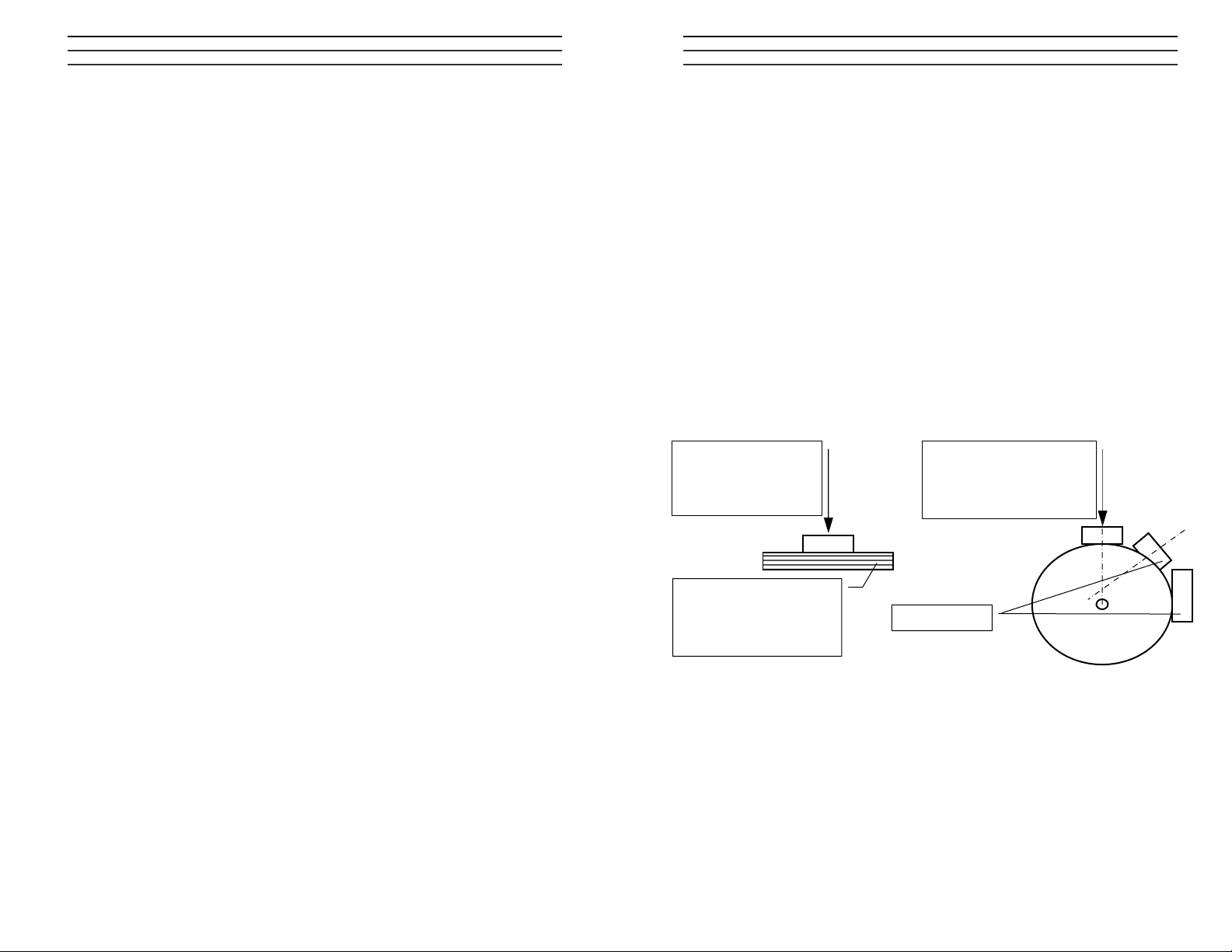

2.0 MEASURING PROCEDURE

Exact measuring results can best be achieved by adjusting the measuring

instrument to the respective product temperature. So you shoul d store the device

near the object you wish to measure. A temperature difference of m ore than 5 ° C

results in a falsified measured value. Adjust the switch by shifting it to the correct

position (refer to type of product). Turn on your measuring device and put it on

the product with suitable pressure or move it with constant pressure lengthwise

along the product roll to detect the wet streak.

Take care that you hold your measuring instrument with a moderate but sufficient

pressure on the product because the compressed density influences the

measuring result. Make sure that you always exert the same amount of pressur e

since the density of the material increases when it is pressed tig hter or softer; so

you could get different measuring results every time you measure the material.

The absolute density can immediatel y be seen on the LC-Display. Please note

that the bigger the supporting surface of the sensor, the more exact is the

measurement (refer to sketch). The device turns off automatically after 90

seconds or when the measuring range has been exceeded.

Firmly press the

instrument on the

pile in the middle

Paper piles must be at

least 2 cm thick,

leather piles at least 1

cm

Press the instrument

only lengthwise on the

paper roll

incorrect

ELECTROMATIC Equipment Co., Inc.

-14-

ELECTROMATIC Equipment Co., Inc.

-3-

Page 4

3.0 HOW TO CHOOSE TYPE OF PRODUCT

M

Since there is no unified manufacturing process of the me asuring products the

adjustment of the switch can not be standardized. But there is always the

possibility of having your device calibrated by Checkline Europe. In this case we

need a pile of your product (2 cm thick) size A4 in a plastic wrapping that is as

tight as possible. You can classify your products by means of a comparison

measurement applying methods appropriate for verification according to

DIN20287. Take a 2 cm thick pile with an averag e quantity of moisture size A5,

weigh some of the sheets and dry them in a dryi ng stove. Store the rest of the

paper in a plastic wrapping to preserve the moisture. T he dried sheets of paper

are weighed again. By using the following formula the absolute moisture is

calculated.

Caution! The dried sheets of paper must not be used for measurement again.

M

: mass of sheets with an average moisture.

n

: mass of dried sheets

M

t

%F: calculated absolute moisture.

MtMn

F

n

100%

Now take the rest of the pile out of the plastic wrapping and measure it with your

measuring device. Adjust the switch until the most exact value can be seen on

the display and note down the position of the switch.

11.0 TECHNICAL DATA

dissolution 0.1% moisture of material

depth of measurement P2, P4:13mm

LM5: 5mm

measuring range P2: 3-10% moisture of paper

P4: 3-8% moisture of paper

LM5: 8-20% moisture of leather indication of %

refers to wet weight P2, P4: switch position 4,

working temperature 5°C to 35°C

temperature compensation P2:0,04%/°C,P4:0,03%/°C

LM5: 0,05%/C°

power supply 9V alkaline batteries or accumulator

drawing of current 5mA, sufficient for about 4000 measuring

display three-digit LC-Display

size 60 x 120 x 26 mm

weight without battery about 140 gramms

delivery wooden case, proof plate, 9V alkaline

LM5: switch position 2

procedures, when BAT appears on the display,

still about 200 measurements are possible

compound battery, case protection made of

rubber

ELECTROMATIC Equipment Co., Inc.

-4-

ELECTROMATIC Equipment Co., Inc.

-13-

Page 5

Copy this table and fill in the displayed values – without temperatur e correction –

and the ambient temperature. Enclose a copy of the data if the instrument should

be adjusted again by the factory.

serial number measuring instrument:____________

serial number proof plate:_____________

temperature :______°C date :_____________

set

switch-

position

measuring

value

S1 11,9 1,5

S2 11 1,3

S3 10,1 1,1

S4 9,2 1

S5 8,2 0,9

S6 7,2 0,8

displayed

value

LM5

temperature-

compensation

value

drift

in % readjust

tolerance

4.0 VERIFICATION AND CORRECTION OF SWITCH POSITION

Now weigh the rest of the material sample, store it in more humid or drier

ambient conditions than where your calibration has been carried out. Do not

forget to adapt the measuring device to the corresponding temperature. Then

weigh your pile once more, calculate the moisture value by means of weight

applying the formula of control value calculation, measure this moisture value

and compare the result with the display

Control value calculation:

M

: Calculated dry mass of your control sample

ter

: mass of the remaining material

M

nk

Mter

%100 FMnk

100

: new mass by drying or moistening

M

nneu

%F

: new moisture value for comparison measurement

neu

Now insert the switch position in the table.

Please note: Checkline Europe provides special versions of P2, P4 and LM5

adapted to certain products. Refer to additional information on leather, page 10.

5.0 MEASURING METHOD

Even if the kiln drying method is the only measuring procedure appr opriate for

verification according to DIN 20287 it is time consuming, in-situ application can

very seldom be carried out; the method also has the disadvantage that the

samples are destroyed. Checkline Europe has developed the P2, P4 and LM5

generation – a measuring method which provides exact measurin g results within

seconds. Yet it is not possible to develop a measuring device that is ideal under

every single condition; even P2, P4 and LM5 have a certain limited range to

provide optimum results. In order to minimize incorrect applications resulting from

that fact we have provided you with a list.

ELECTROMATIC Equipment Co., Inc.

-12-

ELECTROMATIC Equipment Co., Inc.

-5-

Page 6

6.0 MOST COMMON REASONS FOR MEASURING ERRORS

Product temperature beyond ambient conditions: The temperature of the

measuring device and of the product should be nearly equal.

Wrong switch position

Uneven pressing

Wrong application on rolls

Press your measuring device lengthwise to the longitudinal axis of the

product roll, otherwise the bearing area of the sensor is too small.

Product pile not thick enough

Electrically conductive material

All metallic objects as well as electrically conductive packaging film or paper

coloured with carbon black influence the measur ing result in a negative wa y

and must no be positioned within a range of 500 mm below the sensor area.

Exceeding of measuring range:

This can occur depending on the type of product and the position of the

selector switch. It is indicated on the display by blinking and means that the

measuring accuracy is less precise.

P2 Examination table

Copy this table and fill in the displayed values – without temperatur e correction –

and the ambient temperature. Enclose a copy of the data if the instrument should

be adjusted again by the factory.

serial number measuring instrument:_____________

serial number proof plate:______________

temperature :______°C date :_____________

set

switch-

position

measuring

value

S1 6.4 0.6

S2 5.7 0.6

S3 5.1 0.5

S4 4.5 0.5

S5 3.8 0.4

S6 3.1 0.4

P4 Examination table

Copy this table and fill in the displayed values – without temperatur e correction –

and the ambient temperature. Enclose a copy of the data if the instrument should

be adjusted again by the factory.

displayed

value

P2

temperature-

compensation

value

drift

in % readjust

tolerance

ELECTROMATIC Equipment Co., Inc.

-6-

serial number measuring instrument:____________

serial number proof plate:_____________

temperature :______°C date :_____________

switch-

position

set

measuring

value

displayed

value

P4

temperature-

compensation

value

drift

in % readjust

tolerance

S1 4,3 0,6

S2 4 0,6

S3 3,7 0,5

S4 3,3 0,5

S5 3 0,4

S6 2,6 0,4

LM5 Examination table

ELECTROMATIC Equipment Co., Inc.

-11-

Page 7

This example has only been calculated for P2, but the temperature correction

can be calculated for both P4 and LM5. Yo ur measuring device is adjusted to a

temperature of 28°C. The display of P2 with switch position S1 on proof plane

PP2 is 6.1%.

Tcf: Temperature correction factor corresponds to 0.04% (S1) moisture o f paper

per 1°C.

Tcv: Temperature compensated value

Tcv = displayed value + (ambient temperature - 20°C) x Tcf

P2: Tcv= 6,1 + (28 – 20) x 0,04 results 6,4%

If your value is beyond the set range of adj ustment tolerance a new adjustment

by the factory is necessary. If there is a linear deviation fro m the set values, you

can adjust the device to the zero point adjustment yourself. This is done as

follows:

Zero point adjustment

Shift the selector switch to S1, put off the lid of the battery compartment, take out

the battery (which must still be stuck to the connecting contacts). Then put off the

serial number tag carefully. Now hold the device into the air with one hand and

adjust the inner potentiometer as long as the following values appear on the

display: P2:1.3%, P4: 2.5%, LM5: 3.7%. Again the temperature correction value

must be taken into consideration. Put on the serial number tag again, insert the

battery and close the lid.

inner Potentiometer

Additional information ( for LM 5 only)

Switch positions 1 to 6 serve as an approach to the real quantit y of moisture of

the material. The density of the material has the biggest influence on the

measuring result. For leather, the relevant range of densit y corresponds to 0.45

gram/cm³ for switch position 1 and 0.85 gram/cm³ for switch position 6. Various

manufacturing procedures can result in a change of up to two switch positions. A

higher moisture value is indicated on the display when measuring values lie

below or above the set measuring range. These values can be used as

reproducible comparative values and with the help of a conversion ta ble you get

values corresponding to absolute moisture values. W hen measuring leather it is

especially important that the pressure against the material is the same pressure

when determining the switch position.

7.0 MEASURING PRINCIPLE

The material in the measuring field is penetrated by an electromagnetic field

whose features change due to the material's quantity of moisture. Because of the

characteristic polarity of the water molecule and the thus resulting high relative

permittivity of water (about 83) the capacity of the measuring field changes

together with the changing moisture of the measuring sample.

Measuring plate at the

back of the instrument

8 x 5 cm

7 x 4,5 cm

Measuring instrument

P2, P4 Measuring plate

8cm long x 5cm broad x 1,3cm depth

LM5 Measuring plate

7cm long x 4,5 cm broad x 0,5cm depth

Caution! When the material thickness is below a certain limit, the measuring

result is falsified.

ELECTROMATIC Equipment Co., Inc.

-10-

ELECTROMATIC Equipment Co., Inc.

-7-

Page 8

8.0 EXCLUSION OF LIABILITY

The producer can not be made liable for any measuring errors and the d amage

that might result from it. This measuring principle is a quick measuring procedure

which can be influenced by product and user-specific margin conditions.

Therefore it is recommended to carry out a pl ausibility check of the measured

values. In every measuring device there is a serial number and a seal of

warranty. If this seal is broken no warranty claims will be accepted. In case of

defect send back your measuring device to Checkline Europe. The device must

be sufficiently packaged for protection reasons. (refer to technical support)

9.0 CARE REGULATIONS

In order to guarantee that your measuring device is kept in good condition,

please take care that it is not imposed to too much mechanical strain (it should

not be dropped or exposed to excessive temperatur es). Always use a dry cloth

when cleaning your measuring device because it can be destroyed by incoming

water or other cleaning agents.

Do not leave your device unattended – put it back into the delivered wooden

case after the measuring procedure.

We recommend an ISO-approved examination of the device in regular intervals

by applying the kiln method or by using the enclosed proof plane PP2 (base plate

of the wooden case)!

If needed, Checkline Europe will also carry out a calibr ation at your expense. In

this case a calibration certificate will be issued and delivered.

ELECTROMATIC Equipment Co., Inc.

-8-

10.0 ISO-APPROVED EXAMINATION OF THE INSTRUMENT

The surface of the proof plane PP2 must not be scratched and must be free of

dust, dirt, fats and moisture.

Field of application: temperatures ranging from 10°C to 30°C, relative humidity

30-80%

Procedure of examination

Torn on the device, place it in the middle of the pr oof plane PP2 and press firmly

onto it. Now check the values on the display against the set measuring v alues in

the table and fill them in the provided table. We have defined the ideal

temperature for your device – 20°C, but it can range between 17°C and 23°C. If

an adjustment is not possible, a calculated correction of the temp erature of the

displayed value is necessary. The corrected value and the set value must be

within the range of tolerance.

Set measuring values for PP2 should be at a temperature of 20°C.

Switch

position

set measuring

value

adjust

tolerance

readjust

tolerance P2 P4

S1 6.4 4.3 0.6 0.9

S2 5.8 4 0.6 0.9

S3 5.1 3.7 0.5 0.8

S4 4.5 3.3 0.5 0.7

S5 3.8 3 0.4 0.6

S6 3.1 2.6 0.4 0.6

Value when held up in the air at switch position 1 is: P2= 1.3% and P4= 2.5%

range of adjustment tolerance by the plant 0.6%

set measuring

switch

position

value

LM5

adjust

tolerance

readjust

tolerance

S1 11,9 0,9 1,5

S2 11 0,8 1,3

S3 10,1 0,8 1,1

S4 9,2 0,7 1,0

S5 8,2 0,6 0,9

S6 7,2 0,5 0,8

Value when held up in the air at switch position 1 is: LM5= 3,7%

range of adjustment tolerance by the plant 0,8%

Example of temperature correction

ELECTROMATIC Equipment Co., Inc.

-9-

Page 9

P2, P4, LM5

PAPER MOISTURE METER

OPERATING INSTRUCTIONS

Loading...

Loading...