Page 1

— WARNING —

1. Test samples can break or shatter, wear eye

and body protection to avoid injury.

2. Do not exceed 500 lbf capacity. Be sure to

set the upper and lower travel limits to avoid

overload.

3. To reset from an overload see page 7.

2 YEAR WARRANTY (restrictions apply)

Imada, Inc. warrants its products to the original purchaser to be free from defects in workmanship and

material under normal use and proper maintenance for two years (one year for adapters, attachments

and cables) from original purchase. This warranty shall not be effective if the product has been subject to

overload, shock load, misuse, negligence, accident or repairs attempted by others than Imada, Inc.

During the warranty period, we will, at our option, either repair or replace defective products. Please

call our customer service department for a return authorization number and return the defective product

to us with freight prepaid.

The foregoing warranty constitutes the SOLE AND EXCLUSIVE WARRANTY, and we hereby disclaim

all other warranties, express, statutory or implied, applicable to the products and/or software, including

but not limited to all implied warranties of merchantability, fitness, non-infringement, results, accuracy,

security and freedom from computer virus. In no event shall Imada, Inc. and/or its affiliated companies be

liable for any incidental, consequential or punitive damages in connection with the use of its products

and/or software.

VERTICAL

MOTORIZED TEST STAND

Model MX-500

11/06

FORCE GAUGE AND DIGITAL DISTANCE METER SOLD SEPARATELY

INSTRUCTION MANUAL

Specifications subject to change without notice.

Page 2

FS

MODE

Manual Operation

Single Cycle

Continuous Cycle

FS Effective

SWITCH SPEED

EMERGENCY

FS Volume

INTRODUCTION

The Model MX-500 Vertical Motorized Test Stand assures

consistent, identical measuring conditions by eliminating

possible human error.

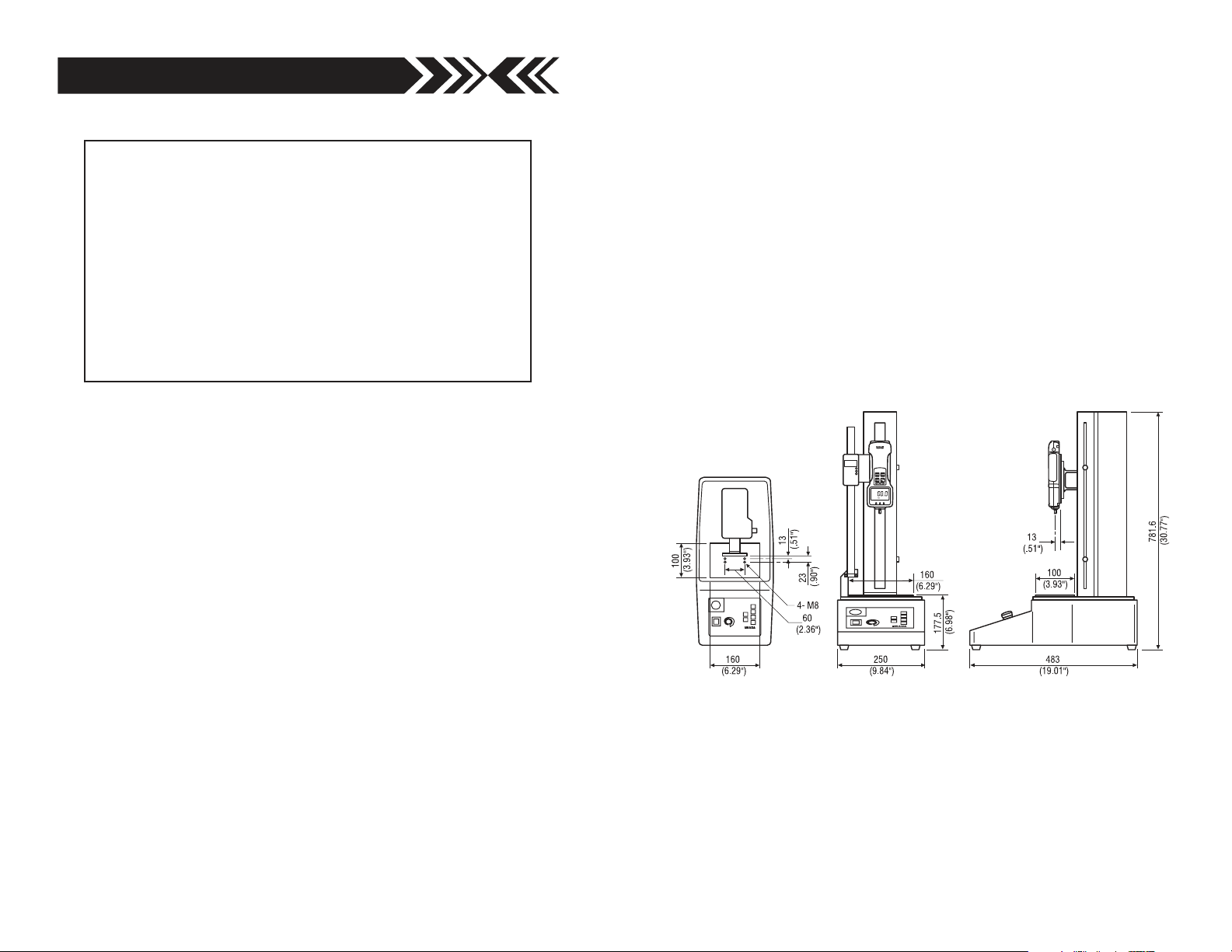

SPECIFICATIONS

Motorized Vertical Test Stand

Model No: MX-500

Max Load: 500 lbf

Speed: 0.2 – 7 in/min

Stroke: 13" (330 mm)

Power: 115/230 VAC

RESET FROM OVERLOAD

If the test stand overloads or locks up during testing, disconnect

the cable connecting the test stand to the force gauge, switch to

Manual Operation and using a direction switch, back off the

crosshead (in the opposite direction from the overload) to

release the load.

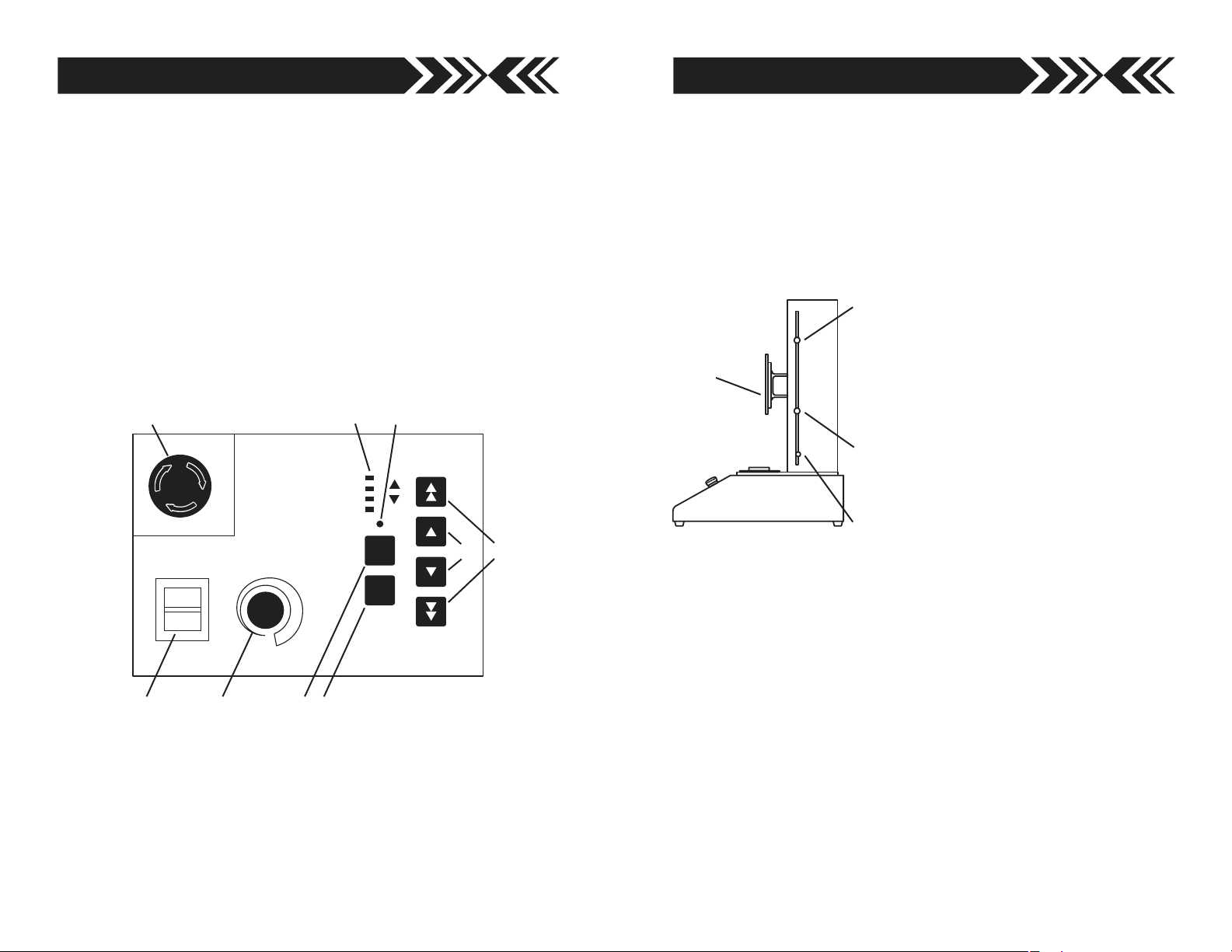

TRAVEL LIMITS

UPPER TRAVEL LIMIT

Cross Head stops moving up when it

reaches this position. To adjust the

CROSS

HEAD

stroke, loosen screw and move the limit

to desired position. Re-tighten screw

securely.

MIDDLE TRAVEL KNOB

Slows the cross head to the speed set by

the Speed Adjust Knob.

LOWER TRAVEL LIMIT

Cross Head stops moving down when it

reaches this position. To adjust the

stroke, loosen screw and move the limit

to desired position. Re-tighten screw

securely.

CAUTION:

Make sure to set the lower travel limit high enough to allow

CONTROL PANEL

Power Switch

Adjustable Speed Direction

Switch

Maximum Speed Direction

Switch

Emergency Stop Switch

Mode Switch

Mode Indicators

Fixed Speed Switch

Fixed Speed Adjustment

adequate clearance for the force gauge and attachments, so it

will not be overloaded.

To prevent accidental movement of the lower limit position,

replace the thumbscrew with an M5 Allen screw so that an Allen

wrench will be required to adjust it.

Speed Adjust Knob

2 7

Page 3

3. Press Mode Switch and select Continuous Cycle. Press

Mode switch again and the Continuous Cycle light

begins blinking.

GENERAL OPERATION

Make sure of the following before plugging the power cord into

the 115VAC output.

4. Select test speed:

A. Turn the Speed Adjust Knob or

B. Press Fixed Speed Switch , the Mode Indicator lights.

(overrides Speed Adjust Knob). Fixed Speed can be

adjusted by using a small screwdriver to adjust the FS

Volume potentiometer.

5. Press ZERO switch on Z2 or ZP gauge and start testing.

Single Preset One Way Force Control

Press the Maximum Speed Direction Switch . The cross

head moves (up or down) at maximum speed until the force

value reaches the Low setpoint. The speed then changes to

either the speed set by the Speed Adjust Knob or the

Fixed Speed Switch if FS has been pressed. When the force

value reaches the High setpoint programmed on the Z2 or ZP

force gauge, the test stops.

High/Low Setpoints Force Control

Press the Adjustable Speed Direction Switch . The cross

head moves (up or down) at either the speed set by the Speed

Adjust Knob or the Fixed Speed Switch if FS has been

pressed. When the force value reaches the Low setpoint, force

control is activated to maintain the force between the High

and Low setpoints programmed on the Z2 or ZP force gauge.

To end force control, press a or direction switch or the

Emergency Switch .

EMERGENCY BRAKE STOP SWITCH

Push the Emergency Stop Switch whenever you are in an

emergency situation. To re-engage the Emergency Stop Switch,

simply turn the switch clockwise.

1. Turn Speed Adjustment Knob to a middle position.

2. Turn the Emergency Switch clockwise to make sure the

Emergency Brake is re-engaged.

3. Move the upper and lower travel limits so that there is

separation between them (see Page 7 of this manual).

4. Connect power cord to stand and plug into 115/230 VAC outlet.

5. Turn on Power Switch . The Orange power lamp will light.

MANUAL OPERATION

When the Power is turned on, startup mode is Manual Operation

the appropriate Mode Indicator will light. Manual Mode is for

initial test position setup.

1. Press either Adjustable Speed Direction Switch to jog the

cross head in that direction or press and hold, and the cross

head moves until you release the switch. (The cross head speed

is set by either the Speed Adjust Knob or the Fixed Speed

Switch ).

Press either Maximum Speed Direction Switch to jog the

cross head in that direction or press and hold, and the cross

head moves at maximum speed until you release the switch.

2. Select speed

A. Turn the Speed Adjust Knob or

B. Press Fixed Speed Switch , to override the Speed

Adjust Knob (the Mode Indicator lights). Fixed Speed

can be adjusted by using a small screwdriver to adjust the

FS Volume potentiometer.

3. Regardless of the preset speed, when either Maximum Speed

Direction Switch is pressed, the cross head moves at

maximum speed.

6 3

Page 4

SINGLE-CYCLE OPERATION

When the Power is turned on, startup mode is Manual Operation.

1. Press Mode Switch and select Single Cycle, the Mode

Indicator lights.

2. Test Operation

Adjustable Speed Testing

Press either Adjustable Speed Direction Switch and the

cross head moves (up or down) at the speed set by the Speed

Adjust Knob . When the cross head reaches the lower or upper

travel limit it stops, then returns to the opposite travel limit.

Fixed Speed Testing

Press the Fixed Speed Switch , the Mode Indicator will

light. Press either Adjustable Speed Direction Switch and

the cross head moves (up or down) at the speed set by the

Fixed Speed Switch . When the cross head reaches the

lower or upper travel limit it stops, then returns to the

opposite travel limit.

Maximum Speed Testing

Press either Maximum Speed Direction Switch and the

cross head moves (up or down) at maximum speed. When the

cross head reaches lower or upper travel limit it stops and

then returns to the opposite travel limit.

CONTINUOUS CYCLE OPERATION

When the Power is turned on, startup mode is Manual Operation.

1. Press Mode Switch and select Continuous Cycle, the Mode

Indicator lights.

2. Test Operation

Adjustable Speed Testing

Press either Adjustable Speed Direction Switch and the

cross head moves (up or down) at the speed set by the Speed

Adjust Knob . When the cross head reaches the lower or

upper travel limit it stops, then returns to the opposite travel

limit. The cross head automatically repeats this cycle until a

or direction switch or the Emergency Switch is pressed.

Fixed Speed Testing

Press the Fixed Speed Switch , the Mode Indicator will

light. Press either Adjustable Speed Direction Switch and

the cross head moves (up or down) at the speed set by the

Fixed Speed Switch . When the cross head reaches the lower

or upper travel limit it stops, then returns to the opposite travel

limit. The cross head automatically repeats this cycle until a

or direction switch or the Emergency Switch is pressed.

Maximum Speed Testing

Press the Maximum Speed Direction Switch (up or down).

The cross head moves (up or down) at maximum speed until it

reaches the lower or upper travel limit and then stops and

returns to the opposite travel limit. The cross head automatically

repeats this cycle until a or direction switch or the

Emergency Switch is pressed.

FORCE CONTROL OPERATION

MX-500 test stand becomes a force control system when connected

to an IMADA Z2 or ZP digital force gauge with a CB-501 interface

cable. This feature may be used as overload protection and can

help prevent overload damage in most cases, but due to the wide

variety of testing conditions a guarantee is not possible.

1. Connect MX-500 test stand and IMADA Z2 or ZP force gauge

with a CB-501 interface cable.

2. Program High and Low setpoints on IMADA Z2 or ZP force

gauge. (Refer to Z2 or ZP Manual, Programming Setpoints

section)

4 5

Loading...

Loading...