Page 1

Specifications subject to change without notice.

2 YEAR WARRANTY (restrictions apply)

Imada, Inc. warrants its products to the original purchaser to be free from defects in workmanship and

material under normal use and proper maintenance for two years (one year for adapters, attachments,

and cables) from original purchase. This warranty only covers defective material and labor and does not

cover calibration, batteries, freight, fees and expenses and shall not be effective if the product has been

subject to overload, shock load, misuse, negligence, accident or repairs attempted by others than Imada, Inc.

During the warranty period, we will, at our option, either repair or replace defective products. Please

call our customer service department for a return authorization number and return the defective product

to us with freight prepaid.

The foregoing warranty constitutes the SOLE AND EXCLUSIVE WARRANTY, and we hereby disclaim

all other warranties, express, statutory or implied, applicable to the products and/or software, including

but not limited to all implied warranties of merchantability, fitness, non-infringement, results, accuracy,

security and freedom from computer virus. In no event shall Imada, Inc. and/or its affiliated companies be

liable for any incidental, consequential or punitive damages in connection with the use of its products

and/or software.

VERTICAL MOTORIZED

TEST STAND

INSTRUCTION MANUAL

FORCE GAUGE AND DIGITAL DISTANCE METER SOLD SEPARATELY

Models: MX2-110 & MX2-275

DIG

IT

AL FORCE GA

U

GE

00.0

NG

Lb

OK +NG

OVERLO

AD

ZERO

SEND PEAK

ON

OFF

Page 2

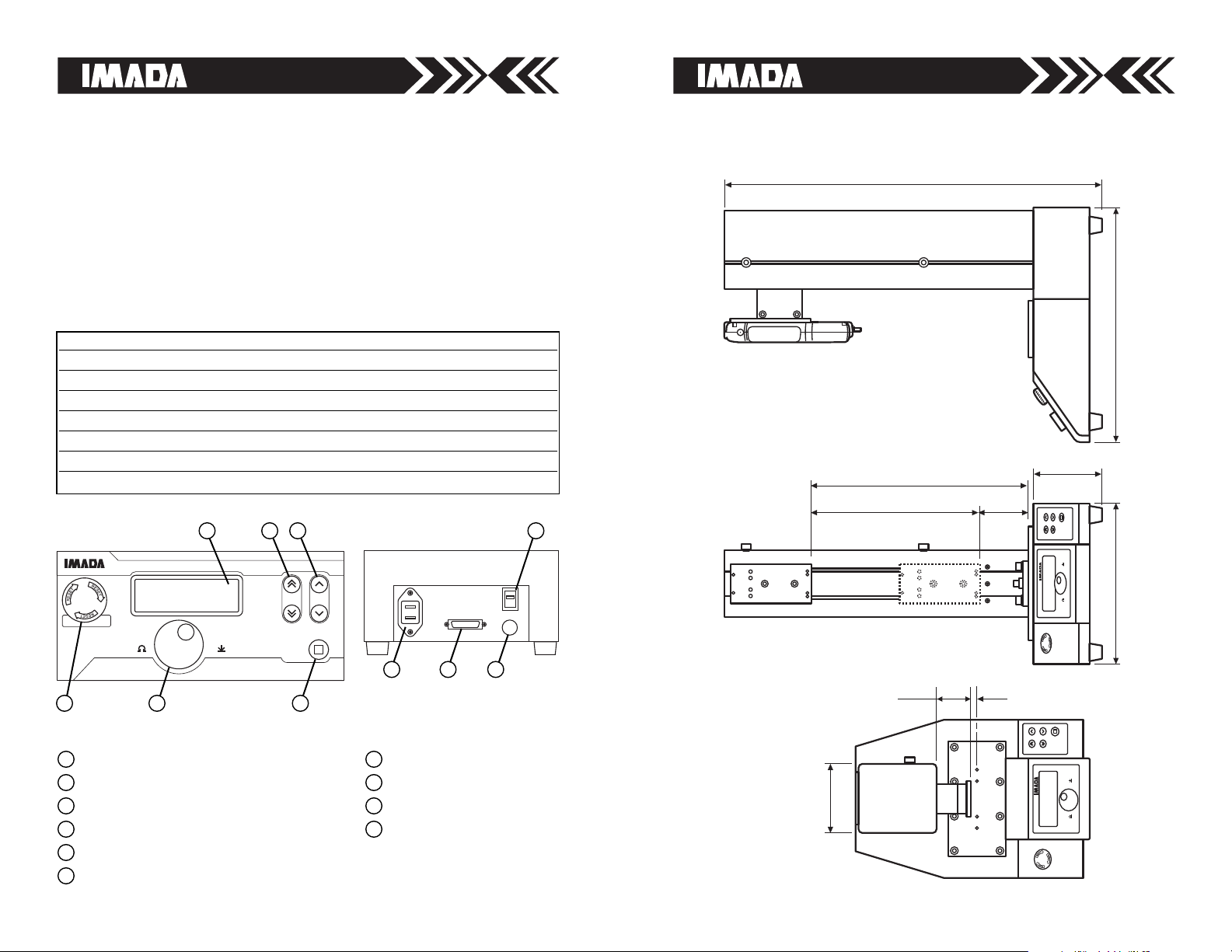

15

DIMENSIONS

MX2-275

Back

280

(11.02")

120

(4.72")

421

(16.57")

660 (25.48")

380 (14.96")

296

(11.65")

84

(3.30")

120

(4.72")

12

(.47")

59.3

(2.33")

Select

Enter

Select

Enter

Back

2

CONTROL PANEL

LCD screen

Program Dial

Single Speed Button

Double Speed Button

Back Button (Mode)

Emergency Stop/Reset

1

2

3

4

5

6

BACK OF STAND

Power Switch

Force Control port

Fuse

AC Power

7

8

9

10

Select

Enter

Back

MANUAL MODE

4.40 in/min

# JOG MOVE

INTRODUCTION

The MX2 Vertical Motorized Test Stand uses a maintenance-free,

brushless, DC motor to provide smooth and powerful operation and

ensure consistent test results. Automated fatigue tests are easy to

setup using the unique program dial and menu screens to control

speed, timer and cycle count. Force controlled non-destructive tests

are also easy to setup and program. Manual mode features unique

movement control in precise increments, for precision testing.

BACK OF STANDCONTROL PANEL

1 7

2

10

5

4

8 9

6

3

SPECIFICATIONS

Model MX2-110 MX2-275

Max Load 110 lbf 275 lbf

Standard Speed .4~12 in/min (10~305 mm/min) .4~12 in/min (10~305 mm/min)

Optional Fast Speed .8~23.5 in/min (20~600 mm/min) .9~23.5 in/min (20~600 mm/min)

Optional Slow Speed .1~3.5 in/min (3~90 mm/min) .1~2.9 in/min (2~75 mm/min)

Stroke 9.44" (240mm) 11.6" (295mm)

Deflection .5 mm at maximum load .5 mm at maximum load

Power 115/230 VAC 115/230 VAC

Page 3

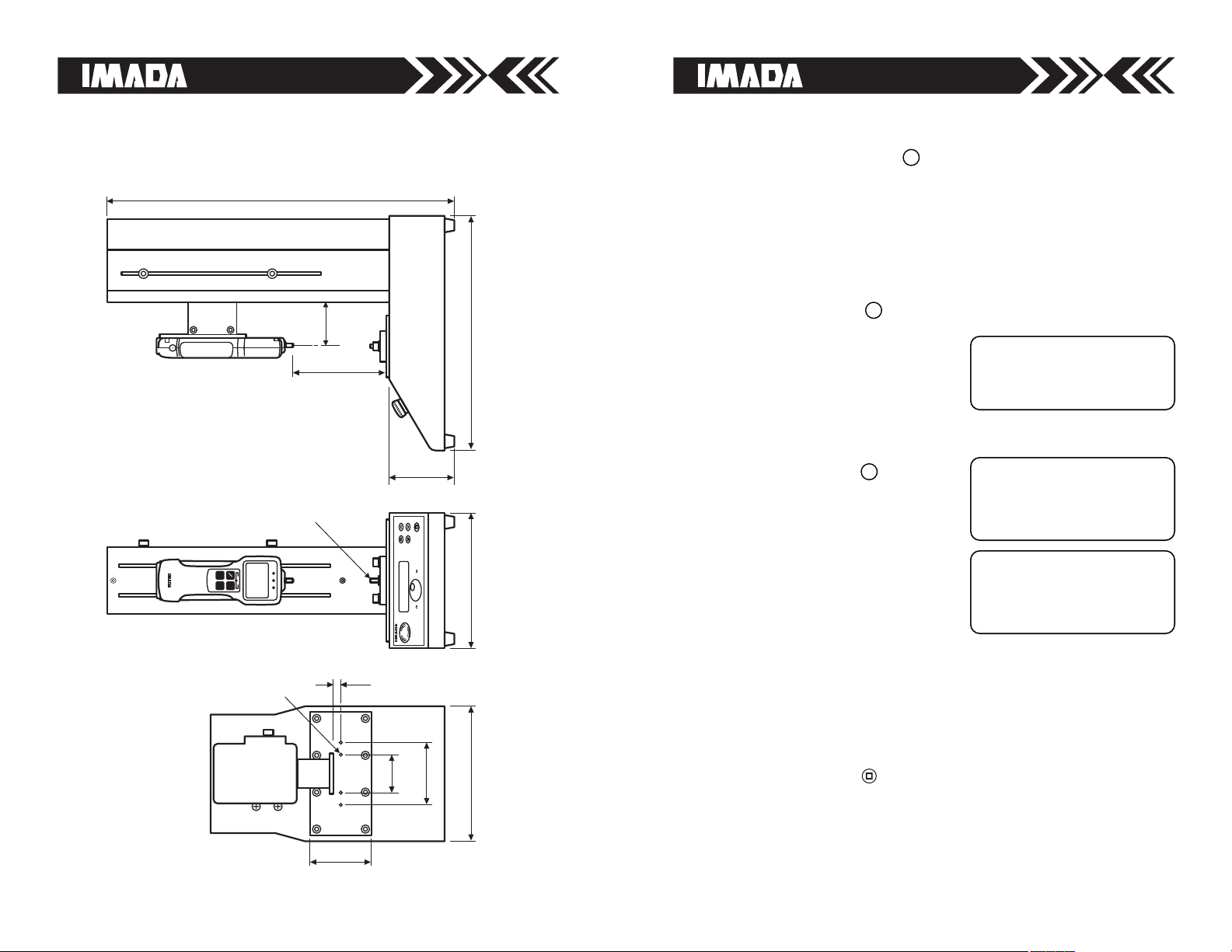

314

DIMENSIONS

MX2-110

71

(2.79")

220

(8.66")

200

(7.87")

380

(14.9")

562

(22.1")

110

(4.33")

0~240

(0~9.44")

M6

12

(.47")

100

(7.87")

60

(2.36")

M8

100

(3.93")

DIGITAL FORCE GAUGE

00.0

NG

Lb

OK +NG

OVERLOAD

ZERO

SEND PEAK

ON

OFF

Select

Enter

Back

Changing Speed Units

1. Press the Back button to

change to Cycle Mode.

2. Press and hold the dial until the

Config Mode screen appears.

3. Turn the dial until Extra Config

appears (arrows

<>indicate

current selection).

4. Press the dial to enter Extra

Config Mode.

5. Turn the dial in Extra Config

Mode until Unit Select appears.

6. Press the dial to enter.

7. Turn the dial to select inch or

millimeter.

8. Press the Back button twice to

exit Extra Config Mode and return

to Cycle Mode. Unit selection is

then retained in memory for

future tests.

5

Check the following before testing

1. Turn the Emergency Stop clockwise to make sure it is

released. Press it whenever you are in an emergency situation.

2. Move the Upper and Lower Travel Limits so that there is

separation between them or the cross head will not move and

and a limit error is displayed on the LCD screen (see page 5).

3. Connect the power cord to the proper AC power.

4. Turn on power switch on the back of the test stand.

When the power is turned on Manual

Mode/Speed Adjust is the startup

screen. The default speed unit is

mm/min.

6

7

MANUAL MODE

5.50 mm/min

# SPEED ADJUST

CONFIG MODE

< EXTRA CONFIG >

ENTER EXTRA CONFIG

EXTRA CONFIG MODE

UNIT SELECT

< INCH

Page 4

13

– WARNING –

1. Test samples can break or shatter, wear eye

and body protection to avoid injury.

2. Do not exceed the capacity of the test

stand. Be sure to set the upper and lower

travel limits to avoid overload.

OPTIONAL DISTANCE METER

Available for mounting to test stand.

Distance Meter Specifications

Display Push button for inch/mm, zero set and on/off

Resolution 0.0005"/0.01mm

Accuracy 0.1% of reading or 0.005"/0.1mm, whichever is greater

4

MANUAL MODE

Manual Mode/Jog Move is used mainly to position the cross head

prior to testing and for precise increment testing.

When power is turned on, Manual Mode/Speed Adjust is the startup

screen. There are two menu items in the Manual Mode, Speed Adjust

and Jog Move. Press the program dial to toggle the menu items.

Manual Mode Operation

Press and hold , and the cross head moves up at the speed set in

Speed Adjust, stopping when it reaches the upper travel limit. Press

and hold and the cross head moves down, stopping when it

reaches the lower travel limit. The cross head stops when either

button is released.

Press and hold and the cross head moves up at maximum speed

(displayed on the screen) stopping when it reaches the upper travel

limit. Press and hold and the cross head moves down, stopping

when it reaches the lower travel limit. The cross head stops when

either button is released.

Jog Move Operation

Use Jog Move to test or position by turning the dial to move the

gauge and attachment in precise increments.

Speed Adjust

Speed Adjust is displayed at the

bottom of the screen. Turn the

program dial to set the speed.

Jog Move

Jog Move is displayed at the bottom of

the screen. Turn the dial to make

precise adjustments to the cross head

for positioning and testing.

Each click of the dial moves the cross head (standard speed, under no

load) approximately .015mm for MX2-110 and .01mm for MX2-275.

All the up and down speed buttons work in Jog Move.

MANUAL MODE

5.50 in/min

# SPEED ADJUST

MANUAL MODE

5.50 in/min

# JOG MOVE

Page 5

512

RESET FROM OVERLOAD

If the test stand overloads or locks up during testing, turn off both

test stand and force gauge. Then turn on the test stand and using

the direction switch, back off the cross head (in the opposite

direction from the overload) to release the load.

EMERGENCY BRAKE STOP SWITCH

Push the Emergency Stop whenever you are in an emergency

situation. Turn the switch clockwise to release.

6

====================

EMERGENCY

STOP

====================

====================

RELEASE ALARM

RESTART SYSTEM

====================

CYCLE MODE

====================

LIMIT

====================

CYCLE MODE

====================

COUNTER FULL

====================

Error Screens

Emergency Stop– These first two

screens will display alternately. Turn

the Reset switch clockwise

Comparator Error– Make sure

Comparator menu item in Extra

Config is set to OFF, unless force

control is setup, then comparator

must be ON.

Limit– The travel limit has been

reached. Adjust the travel limit to

allow more space or move in the

opposite direction

Counter Full– Select Cycle Mode

and press the program dial to clear

the counter.

CYCLE MODE

=====================

COMPARATOR ERROR

=====================

TROUBLESHOOTING SETTING TRAVEL LIMITS

For a compression test

loosen the upper travel limit

thumbscrew and move it to

the top. Press and hold to

move the force gauge and

attachment up until there is

adequate clearance for testing.

Then move the upper travel

limit down to this position

and tighten securely. Loosen

and move the lower travel limit to the bottom. *Press and hold to

move the gauge and attachment and stop when they reach the test

material.The distance travelled during compression must be added to

determine the position of the lower travel limit. Be careful, the force

gauge can be overloaded whether on or off. Press and hold or use

Jog Move to move the gauge and attachment to the desired position.

Move the lower travel limt to this position and tighten securely.

For a tension test loosen the lower travel limit thumbscrew and

move it to the bottom. *Press and hold and move the force gauge

and attachment down and stop when they reach the test material.

Press and hold or use Jog Move to engage the test material. Be

careful, the force gauge can be overloaded whether on or off.

Move the lower travel limit to this position and tighten securely. Press

and hold to move the force gauge and attachment up to allow

adequate clearance for testing. Move the upper travel limit to this

position and tighten securely.

*CAUTION: Set the lower travel limit to allow adequate clearance for

the gauge and attachments, so they do not crash into the test material.

To prevent accidental movement of the lower limit position, replace

the thumbscrew with an M4 Allen screw so an Allen wrench will be

required to adjust it.

FORCE GAUGE

UPPER TRAVEL LIMIT

THUMBSCREW

LOWER TRAVEL LIMIT

THUMBSCREW

CROSS HEAD

ATTACHMENT

Page 6

116

Force Control Operation

Maintain Force Between High/Low Setpoints

Press either single arrow button or and the cross head moves

at Start Speed, stops at the low setpoint on the Z Series force gauge

and Keeps (holds) applied force between the force gauge’s high/low

setpoints for the programmed Timer Limit using Measuring Speed

and then moves to starting travel limit at Return Speed. The cycle is

repeated until the Counter Limit is reached.

Increase Force to High Setpoint and Stop

Using the same programming setup, press either double arrow or

and the cross head moves at Start Speed and slows to Measuring

Speed at the low setpoint on the Z Series force gauge. When the

applied force reaches the gauge’s high setpoint movement stops

and the position is held for the programmed Timer Limit. The cross

head then moves back to the starting travel limit at Return Speed.

This cycle is repeated until the Counter Limit is reached.

Conditional Overload Prevention

When a Z Series force gauge is mounted and connected to an MX2

stand with a CB-704 or CB-707 cable, Conditional Overload Prevention

engages at 110% of gauge capacity and stops test stand movement.

Depending upon test speed and other variables, movement may be

stopped quickly enough to prevent damage to the gauge in most

cases, but due to the wide variety of testing conditions a guarantee

is not possible.

STATUS INDICATOR

READY: READY TO TEST

START: TEST AT START SPEED

SLOW: TEST AT MEASURING SPEED IN FORCE CONTROL

KEEP: HOLD DURATION TIME

BACK: RETURN TO START

CYCLE MODE

Cycle Mode is used for automated single or multiple cycle tests such

as fatigue testing.

Turn on the stand and press Back button to enter Cycle mode.

The Cycle Mode main screen displays as below.

CYCLE MODE

READY 0.00 in/min

0 / 1

00'00.0 / 00'00.0

ACTUAL CYCLE COUNT

ACTUAL ELAPSED KEEP (HOLD DURATION TIME)

RESETS AUTOMATICALLY TO ZERO AT START

COUNTER LIMIT

(PROGRAMMED

NUMBER OF CYCLES

65,535 MAX.)

TIMER LIMIT

(PROGRAMMED HOLD DURATION TIME

99' 59.9 SEC MAX.)

ACTUAL SPEED

Programming Cycle Mode

Config Mode Menu

1. In Cycle Mode, press and hold the program dial until Config

Mode appears.

2. Turn the dial to view menu items and press the dial to select a

menu item (the arrows

<>indicate the current selection).

3. Turn the dial to make adjustments or select options for that item.

4. Press the dial again to confirm and return to menu items.

5. Press the Back button to exit Config Mode and return to Cycle

Mode. Selections are then saved in memory.

To reset the actual cycle count press

the dial and turn it to select Yes or

No and press the dial to confirm

(not possible if count is zero).

CYCLE MODE

CLEAR COUNTER?

YES >NO

00'00.0 / 00'00.0

Page 7

710

CONFIG MODE

< START SPEED

7.00 in/min

CONFIG MODE

< COUNTER LIMIT >

{}

CONFIG MODE

< TIMER LIMIT >

00'00.8

CONFIG MODE

< MEASURING SPEED >

1.90 in/min

CONFIG MODE

< RETURN SPEED >

11.50 in/min

Start Speed– the cross head

advances toward the travel limit at

this speed

Measuring Speed– skip this item in

Cycle Mode

Extra Config– skip this item in

Cycle Mode

Return Speed– the cross head

returns to the starting travel limit at

this speed

Timer Limit– Keep (hold time

duration) 99' 59.9 seconds max.,

default is 1 second

Counter Limit– counts up to 65,535

cycles max., default is 1 cycle,

{} = continuous cycle, doesn’t stop

Press the Back button to exit Config

Mode and return to Cycle Mode.

Selections are then saved in memory.

CONFIG MODE

< EXTRA CONFIG >

ENTER EXTRA CONFIG

Cycle Mode Operation

Press a direction button , , or and the cross head moves

at Start Speed, stops for the programmed Timer Limit at the travel

limit, then returns to the opposite travel limit at the programmed

Return Speed. The cycle is repeated until the Counter Limit is

reached.

EXTRA CONFIG MODE

<CLEAR ALL CONFIG >

YES >NO

EXTRA CONFIG MODE

< SEND SIGNAL >

OFF

TIP: Programming Z Series Force Gauge High/Low Setpoints

For further instructions refer to the Z Series manual.

1. Turn on the gauge. Press PEAK and ZERO for 3 seconds to enter

Power-On programming (CF9 flashes with solid F0).

2. Press PEAK or ZERO to view the selections. Select CF9 F1 and

press SEND.

3. –HI– displays, then the high set value (i.e. H

10.0). Press PEAK to increase and ZERO to

decrease, press SEND to select. –LO–

displays then the low set value (i.e. L 5.0).

Press PEAK to increase and ZERO to

decrease, press SEND to select, CF9 End

displays. Press SEND again to exit.

EXTRA CONFIG MODE

UNIT SELECT

< INCH

Output Test– Factory use only

Send Signal– Sends one data to

gauge memory at Keep (hold) point

requires CB-704 cable. Saving data to

computer and gauge memory requires

CB-707 cable.

Unit Select– inch or millimeter

Clear All Config– Yes/No Returns to

factory setup

Press the Back button twice to

return to Cycle mode. Selections are

then saved in memory.

EXTRA CONFIG MODE

< OUTPUT TEST >

Page 8

9

EXTRA CONFIG MODE

< ZERO ON START >

OFF

EXTRA CONFIG MODE

< INPUT MONITOR >

EXTRA CONFIG MODE

< RECORD TRIGGER >

OFF

EXTRA CONFIG MODE

<BUZZER ON COUNT UP>

ON

EXTRA CONFIG MODE

< COMPARATOR >

ON

Buzzer On Count Up– ON or OFF

beeps when programmed number of

cycles is completed.

Comparator– ON or OFF

On for force control; test stand and

force gauge must be connected with

CB-704 or CB-707 cable or screen

will display “Comparator Error” on

startup

Record Trigger– OFF (Factory use

only)

Zero On Start– ON or OFF

Tares the gauge before starting

Input Monitor– Factory use only

Programming Force Control Mode (cont’d)

Extra Config Mode Menu

5. Turn the dial until Extra Config

appears on the screen.

6. Press the dial to enter Extra Config

Mode.

7. Turn the dial to view menu items and press the dial to select a

menu item (the arrows

<>

indicate the current selection).

8. Turn the dial to make adjustments to that item or select options.

9. Press the dial again to confirm and return to menu items.

10. Press the Back button twice to exit Extra Config Mode and

return to Cycle Mode. Unit selection is then retained in memory

for future tests.

CONFIG MODE

< EXTRA CONFIG >

ENTER EXTRA CONFIG

Start Speed– the cross head advances

toward the travel limit at this speed

Measuring Speed– engages in force

control mode when applied force

reaches the low setpoint on the Z

Series force gauge. Measuring speed

cannot exceed Start Speed

Return Speed– the cross head

returns to the starting travel limit at

this speed

Timer Limit– Keep (hold time

duration) 99' 59.9 seconds max.,

default is 1 second

Counter Limit– counts up to 65,535

cycles max., default is 1 cycle,

{} = continuous cycle, doesn’t stop

CONFIG MODE

< START SPEED

7.00 in/min

CONFIG MODE

< MEASURING SPEED >

1.90 in/min

Programming Force Control Mode

Config Mode Menu

1. Turn on the stand and press Back button to enter Cycle Mode.

2. Press and hold the program dial until Config Mode appears.

3. Turn the dial to view menu items and press the dial to select a

menu item (the arrows

<>

indicate the current selection).

4. Turn the dial to make adjustments to that item or select options.

5. Press the dial again to confirm and return to menu items.

CONFIG MODE

< TIMER LIMIT >

00'00.8

CONFIG MODE

< RETURN SPEED >

11.50 in/min

CONFIG MODE

< COUNTER LIMIT >

{}

FORCE CONTROL MODE

Force Control Mode is used for automated single or multiple cycle

non-destructive tests. The stand must be connected to a Imada Z Series

force gauge with a CB-704 or CB-707 cable. The following menu items

must be set; speeds, timer limit, counter limit and comparator set to

On. Z Series force gauge high/low setpoints must be also programmed.

8

Loading...

Loading...