Page 1

1

Table of Contents

1.0 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 02

1.1 Unpacking

1.2 Repacking and Storage

2.0 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

03

2.1 Mounting

2.2 Interconnections

2.3 Fuse

2.4 Main Chasis

3.0 Internal Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

05

3.1 Controls

3.2 Internal Operation

4.0 External Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 06

5.0 Circuit Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 07

5.1 Normal (RUN) Operation

6.0 Flashlamp Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 08

7.0 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 09

8.0 Appendix: Modification for 230 VAC Operation . . . . . . . . . . . . . . . . . 11

9.0 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

12

5.0 WARRANTY

ELECTROMATIC Equipment Co., Inc. (ELECTROMATIC) warrants to the

original purchaser that this product is of merchantable quality and confirms

in kind and quality with the descriptions and specifications thereof. Product

failure or malfunction arising out of any defect in workmanship or material in the

product existing at the time of delivery thereof which manifests itself within one year

from the sale of such product, shall be remedied by repair or replacement of such

product, at ELECTROMATIC’s option, except where unauthorized repair, disassembly, tampering, abuse or misapplication has taken place, as determined by ELECTROMATIC. All returns for warranty or non-warranty repairs and/or replacement must be

authorized by ELECTROMATIC, in advance, with all repacking and shipping expenses to the address below to be borne by the

purchaser.

THE FOREGOING WARRANTY IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING BUT NOT

LIMITED TO, THE WARRANTY OF MERCHANTABILITY AND FITNESS FOR

ANY PARTICULAR PURPOSE OR APPLICATION. ELECTROMATIC SHALL

NOT BE RESPONSIBLE NOR LIABLE FOR ANY CONSEQUENTIAL DAMAGE,

OF ANY KIND OR NATURE, RESULTING FROM THE USE OF SUPPLIED

EQUIPMENT, WHETHER SUCH DAMAGE OCCURS OR IS DISCOVERED

BEFORE, UPON OR AFTER REPLACEMENT OR REPAIR, AND WHETHER OR

NOT SUCH DAMAGE IS CAUSED BY

MANUFACTURER’S OR SUPPLIER’S NEGLIGENCE WITHIN ONE YEAR

FROM INVOICE DATE.

Some State jurisdictions or States do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation may not apply to you. The duration of any implied warranty, including, without limitation, fitness for any particular

purpose and merchantability with respect to this product, is limited to the duration of

the foregoing warranty. Some states do not allow limitations on how long an implied

warranty lasts but, not withstanding, this warranty, in the absence of such limitations,

shall extend for one year from the date of invoice.

ELECTROMATIC Equipment Co., Inc.

600 Oakland Ave. Cedarhurst, NY 11516—USA

Tel: 1-800-645-4330/ Tel: 516-295-4300/ Fax: 516-295-4399

Every precaution has been taken in the preparation of this manual. Electromatic Equipment Co., Inc., assumes

no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of

information contained herein. Any brand or product names mentioned herein are used for identification purposes only, and are trademarks or registered trademarks of their respective holders.

Page 2

2

1.0 INTRODUCTION

The AS4020, AS4060 and AS4200 Series Machine Vision Strobes provide short duration high intensity light pulses for industrial vision applications. The three models are

identical, excluding the AS4200 which provides higher flash repetition rate at a lower

output energy level than the AS4020 and AS4060. Refer to Specifications for details.

The AS4000 Series unit comes complete with an input power cable and connector,

and an AS type Xenon Flashlamp. Each unit uses a NEMA Type 13 enclosure.

Light output is focused on a port configured to accept a fiber-optic cable. This allows

light transmission to an area remote from the instrument. When coupled to a CCS/CID

camera, the AS4000 Series strobe freezes motion, eliminating blur from the camera

image and enhancing image quality

The AS4000 Series can be used for a variety of industrial robotics production

applications including.

Sorting Color Differentiation Part Recognition

Counting Contaminant Detection Motion Sensing

Label Reading Component Orientation Edge Detection

Motion Sensing Package Integrity Verification Web Printing Inspection

A TTL input pulse from a camera unit is used to initiate the AS4000 Series flash

Operational power requirements are 115VAC or 230VAC, 50/60 Hz single phase

power with a ground. Standard production units are factory set to either 115 VAC

or 230 VAC.

1.1 Unpacking

The AS4000 Series strobe is shipped completely assembled in one container.

Retain a and store all packing material for use during reshipment or return to the

factory.

Examine the package for signs of damage or mishandling. Contact the carrier

immediately if there are any signs of damage. DO NOT proceed with installation

if there are any signs of damage or mishandling.

The Xenon Flashlamp is a high-pressure gas-filled device.

Wear safety glasses during handling

The Xenon Flashlamp is particularly vulnerable to rough treatment during

shipping. After removing the AS4000 Series unit from the shipping container,

raise the cover of the unit and observe the flashlamp mounted inside. Damage to

the flashlamp should be immediately apparent.

1.2 Repacking and Storage

The AS4000 Series strobe needs to be placed in its original packaging for long

periods of storage, when shipped to another location or returned to the factory

for repair. If the original packing material is not available, the unit should be

packaged in a container with sufficient protective material to ensure that the unit

cannot move within the package and is protected from damage. Store in a dry

area at a temperature of –10 °F to 194 °F (–40 °C to 90 °C).

11

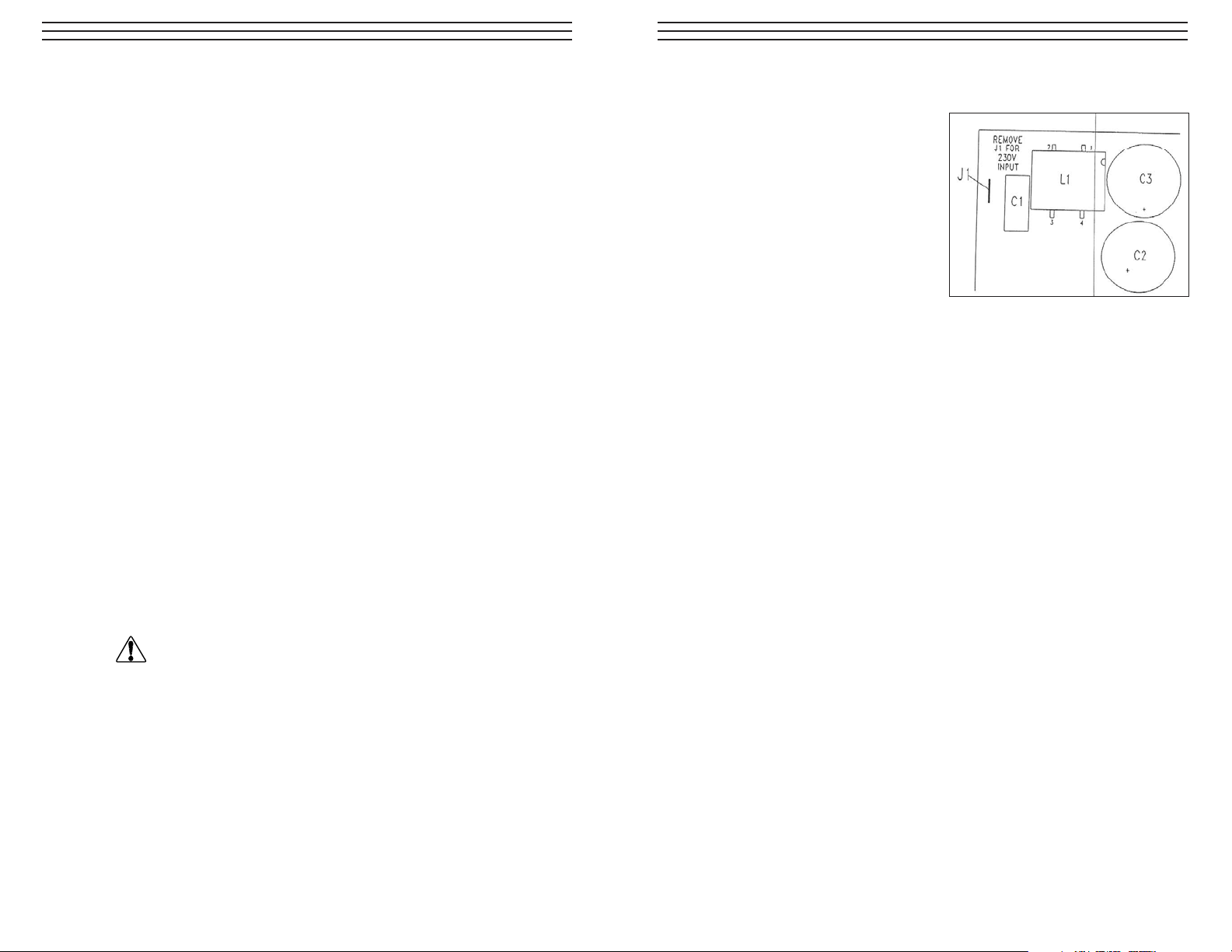

8.0 APPENDIX A: MODIFICATION FOR 230 VAC OPERATION

The 230VAC version of the AS4000 Series

strobe is available direct from the factory,

so that user modification should not be

required. However, in the event that

conversion from 115VAC to 230VAC

becomes necessary in the field, the user

may perform the following:

Cut or Remove the jumper J1 in the

upper left-hand comer of the AS3907

printed circuit board. Cutting J1 converts

the system for 230VAC operation.

If a reverse conversion (230VAC to 115VAC) becomes necessary, return the unit to the

factory. An attempt by the user to replace J1 will void the warranty and may result in

damage to the unit.

WARNING

Page 3

3

2.0 INSTALLATION

2.1 Mounting

Four holes in the base of the AS4000 Series unit provide for secure mounting in

any position. Mounting hardware is not provided with the unit. Refer to Figure

above.

2.2 Interconnections

Two connectors and a fuse are provided at the rear

of the AS4000 Series enclosure. Refer to Figure.

Power Connector: The input power cable

(supplied) is connected to the smaller connector.

Operating power is 115VAC or 230VAC (depending on the modification),

50/60 Hz single phase power with a ground.

Control Cable: A control cable (not supplied) is connected to the larger

connector signal input. Th signal inputs are:

Pin 1: Trigger input—5V, 20mA pulse. Triggers on positive-going edge.

Pin 2: No connection.

Pin 3: Isolated input common for return of Pin 1 and Pin 5.

Pin 4: An external reference input signal voltage, 0 to 6V maximum

or 1.7V minimum to keep lamp flashing.

Pin 5: Lamp failure signal output. This signal confirms the lamp has flashed as

programmed. It is 12V high, with a width approximately the same as

the light pulse (5µS).

Pin 6: External reference return. Chassis ground.

10

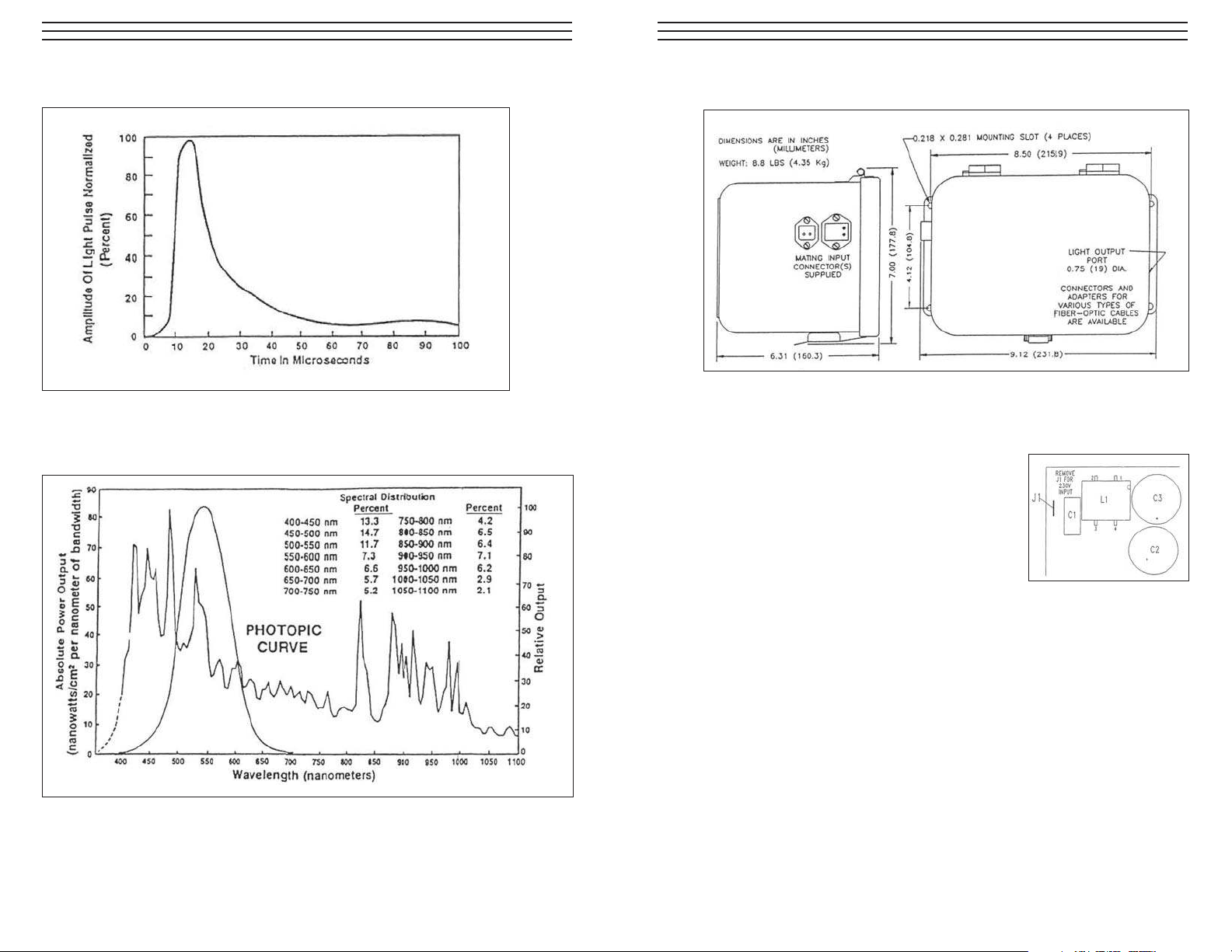

Light Output Waveform

Spectral Distribution Of Light Pulse

Page 4

4

CCOONNNNEECCTTOORR HHAARRDDWWAARREE

Part No. Type Description

CN104 Power Connector plug with strain relief, Hirschmann

Type STAK 20 (Included on line cord)

CN103 Power Connector plug for panel mounting,

Hirschmann Type STASEI 2 (Included with unit)

CN106 Power Security bracket, Hirschmann Type STASI 3

(Included with unit)

CN105 Control Connector for cable mounting, Hirschmann

Type Stak 5, 5+ ground signal connector

(for cable) with six crimp contacts

CN102 Control Connector plug for panel mounting, Hischmann

Type STASEI 5, 5+ ground connector

(Included with unit)

CN100 Control Security bracket, Hirschmann Type STASI 2

(Included with unit)

2.3 Fuse

A one amp fuse located on the NEMA enclosure provides AC line input

protection.

2.4 Main Chasis

9

7.0 SPECIFICATIONS

Optical

Broadband light output 20 millijoules per flash at fiber-optic plane

Flash repetition rate AS4020 - 20 flashes per second maximum

AS4060 - 60 flashes per second maximum

AS4200 - 200 flashes per second maximum

Input energy to flashlamp AS4020 - 2.0 joules per flash maximum at 20 Hz

AS4200 - 0.2 joules per flash maximum at 200 Hz

Light output pulse Less than 25 µS pulse width at all energy settings

at 1/3 of peak energy

Lifetime of flash.lamp 103flashes while maintaining more than 70%

of initial intensity (estimated)

Electrical

Power Line Requirement 115/230 VAC, 50/60 Hz

Power Consumption 0.5A maximum

Trigger Signal +5V at 20mA (optically isolated)

Trigger Pulse Width 10 µS (minimum)

Non-Synchronizing Time 200 µS (minimum)

Before Pulse

Turn-On Delay Command l0 µS (Typical)

To Flash

Environmental

Operating Temperature Range –10 to 110 °F (-23 to +43 °C)

Storage Temperature Range –40 to +194 °F (–40 to +90 °C)

Operating Altitude Range Sea Level to 10,000 ft. (3,000 m)

Operating Humidity Range 0 to 90% noncondensing

Shock and Vibration 1.5g, 5 to 200 Hz, per MIL-STD-810C

Enclosure NEMA Type 13; Confirms to JIC Std, EGP-1-1967

and European Std IEC 529, 1P65; Listed by

Underwriters Laboratories, Inc.

Flash Intensity

Power Indicator

& Mode Switch

(remove cover

for access)

Page 5

8

6.0 FLASHLAMP REPLACEMENT

1. Disconnect power from unit.

2. Wait one minute to allow the lamp to cool and energy to capacitor to discharge.

3. Raise the cover.

4. Ground the rear lamp e1ectrode holder using a screwdriver.

5. Loosen both socket head screws on lamp supporting bracket.

6. Remove lamp cathode ground screw.

7. Gently grasp the cathode ground wire and remove lamp.

8. To install a new lamp reverse the removal procedure,

9. The lamp is in the correct axial alignment when the rear electrode butts

the back of the electrode holder.

Install a new lamp by reversing the removal procedure. Reconnect the anode

wire to the trigger circuit. Secure the ground wire to the PC board.

DANGER – The Xenon Flash lamp is a high-pressure, gas-filled

device. Wear Safety glasses during handling

DANGER – HIGH VOLTAGE. Disconnect power cable and

control cable before replacing Flashlamp.

CAUTION – During installation, do not apply torque to the lamp

end seals.

5

3.0 INTERNAL OPERATIONS

3.1 Controls

In the AS4000 Series, a cover interlock

switch automatically breaks the circuit

whenever the unit is opened. this is to

help protect the operator from danger

of electric shock. To operate the unit

while the cover is open, pull up on the

interlock tab.

A test/run switch is provided for testing

the unit in the absence of input signals.

when the switch is th the TEST position,

the unit is on and the lamp flashes at

a fixed rate of 20 pps. For remote

operation, the switch must be placed

in the RUN position.

Light output intensity can be varied over

a range of approximately 10:1 by means

of an output control. A two-position slide

switch is used to select either internal

mode of control or external reference

control from the input connector.

Light output can be varied by means of

the output control knob.

3.2 Internal Test & Operation

Check the AS4000 Series Strobe for proper operation using the following

procedures (refer to figure above):

1. Disconnect power from unit

2. Lift the lid opening the enclosure

3. Visually inspect the flashlamp for damage

4. Place the TEST/RUN Switch in the TEST position

5. Reconnect power to the unit

6. Place the EXT/INT Reference Switch in the INT REF position

7. Lift the cover interlock switch to its up position

Avoid looking directly at the high intensity light flash, either at the

unit itself or at the end of the fiber-optic cable. This could result in

damage to the eyes.

DANGER – HIGH VOLTAGE. Use extreme caution when

operating the interlock switch, avoid contact with the front

electrode of the flashlamp

WARNING

WARNING

Page 6

6

08. The strobe should pulse at 20 pps.

09. Allow the cover interlock switch to return to the downward position.

This will cut off power to the unit.

10. Turn the veristor HV ADJ control through its complete range, stopping

at intervals to lift the cover interlock switch. Observe that light output

variations occur over the total range of th HV ADJ control

11. Return the TEST/RUN Switch to RUN position. Return the EXT/.INT

Reference Switch to the EXT REF position.

4.0 EXTERNAL OPERATION

Operate the AS4000 Series Strobe in a production environment using the following

procedure

1. Mount the AS4000 Series unit on a stable base in a location convenient to

the production line to be viewed

2. Using option Nosepiece Adapter, connect a fiber-optic cable to the AS4000 Series

light output port. Position the cable to distribute light to the desired area.

3 Lift the lid, opening the enclosure.

4. Place the TEST/RUN Switch in the RUN position.

5. Place the EXT/INT Reference Switch in the EXT/REF position

6. Close and secure the cover.

7. Connect power to the unit.

8. Connect a signal level input cable to the connector at the rear of the unit.

9. Connect the signal level input cable to a CCD/CID camera system that

will provide TTL pulses to initiate flashes.

The system in now set to stop motion in the desired industrial vision application.

7

5.0 CIRCUIT DESCRIPTION

5.1 Normal Operation (RUN MODE)

The AS4000 Series strobe is made up of four functional circuit elements.

1. AS3906 Power Supply Board

2. AS3907 Voltage Control Board

3. AS3908 Add-On Board

4. Flashlamp storage capacitor and triggering circuit

A power cable supplied with the unit provides input power. A signal level input

cable supplied by the customer provides operational support.

An energy storage capacitor stores energy provided by the AS3906 Power

Supply Board. A trigger pulse discharges the capacitor into the flashlamp

causing the lamp to flash.

The Power Supply Board recharges the energy storage capacitor during the

interval between flashes.

During normal operation, the lamp will flash a maximum repetition rate of 60

when a trigger input pulse is applied between pins I and 3 of the signal input

connector.

A transformer in the flashlamp circuit senses flashlamp current. Pins 3 and 5

of the signal input connector monitor the resulting signal. This signal is

12 volts high with a width approximately th same as the light pulse (5 µS),

Page 7

MACHINE VISION STOBOSCOPES

AS4000 SERIES

Operating Instructions

CHECK•LINE

®

BY ELECTROMATIC

ELECTROMATIC

E Q U I P M E N T C O., I N C.

600 Oakland Ave., Cedarhurst, NY 11516–U.S.A.

TEL: 516-295-4300 • FAX: 516-295-4399

CHECK•LINE

®

INSTRUMENTS

Loading...

Loading...