Page 1

Controls

The Series MG force gauges have three keys for

controlling all functions of the instrument.

POWER Turns the instrument on and off.

It is also used to select an option

in the setup mode.

PEAK Used to select Tension Peak,

Compression Peak or normal

(real time) display mode. The

actual peak readings are always

captured and can be displayed

at any time.

ZERO Zeros any tare value (up to the

full capacity of the gauge) and

clears the peak readings stored

in memory.

Display

The display consists of a 4 1/2-digit section and

several indicators. Their functions are listed below.

LO BAT Low battery voltage indicator

C Compressive force indicator

T Tensile force indicator

C PEAK Peak compressive force indicator

T PEAK Peak tensile force indicator

LB, KG, N, G Units of measurement (model

dependent)

- - - - (dashes) Overload (>110% of range)

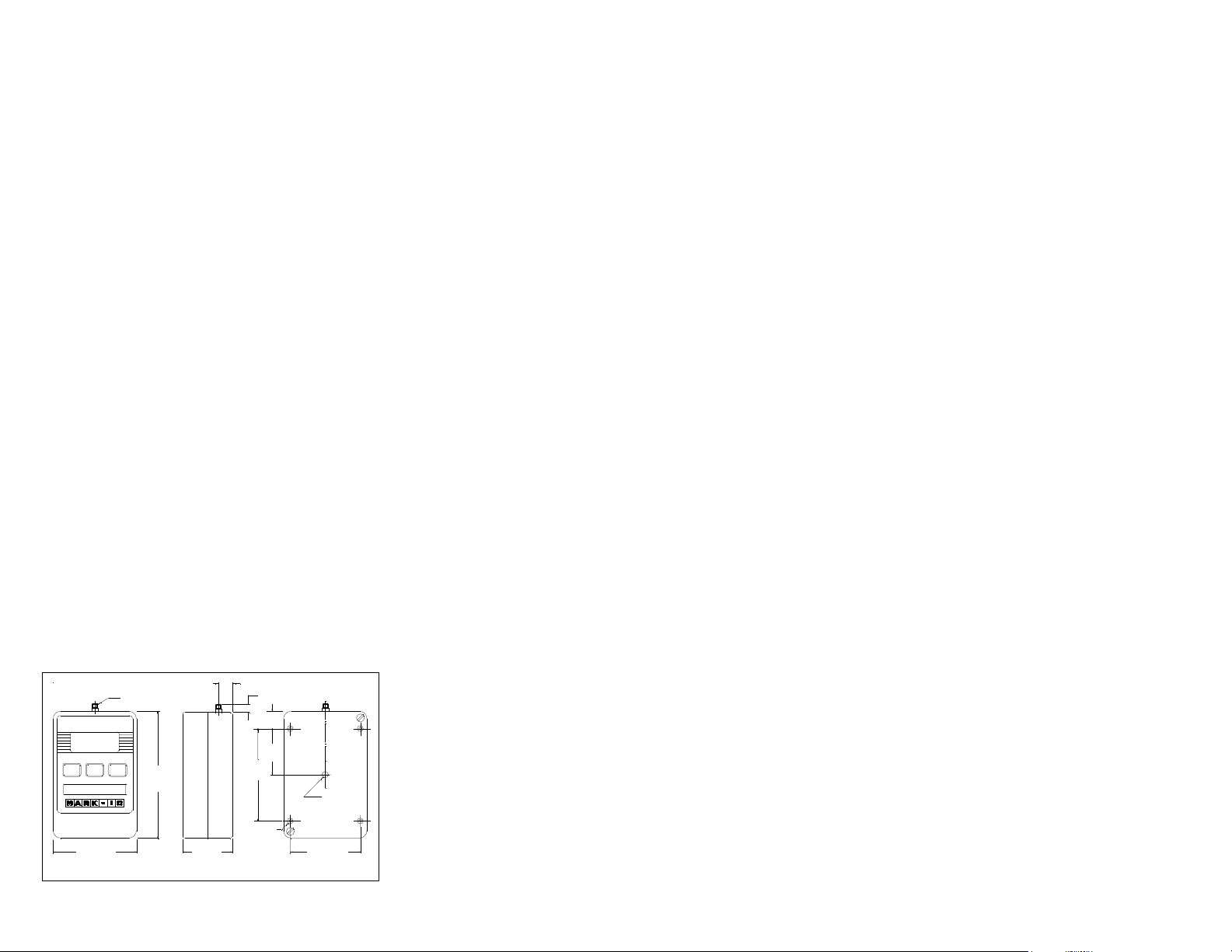

0.42 [10.7]

2.800

[71.12]

#6-32

4 PLCS

0.35 [8.9]

0.52

[13.2]

1.400

[35.56]

0.189

[4.8]

2.125 [53.98]

DIA

IN [MM]

FORCE GAUGE SERIES

PEAKPOWER ZERO

2.53 [64.3]

MG

#10-32

0.19 [4.8] LG

3.84

[97.5]

1.5 [38.1]

Operation

The default mode of operation of the Series MG is

the normal (real time) mode. If the peak readings

are to be observed as they occur, then the mode

of operation can be changed by pressing PEAK

until the desired mode (C PEAK or T PEAK) appears on the display. Please note that this action

affects only the display. The actual tensile and

compressive peak readings are captured automatically and can be cleared from the memory by either pressing ZERO or shutting off the gauge.

The gauge is equipped with an automatic shutdown

feature which will shut it off after a selected period

of inactivity (readings do not change by more than

±10 counts and no keys are pressed). The entire

display will flash for 5-7 seconds as a warning of

the imminent shutdown. If during this time any condition indicating activity occurs, the internal timer

will be reset and the instrument will continue its

operation. To change the default setting of 30 minutes, hold PEAK while turning on the gauge. Press

PEAK repeatedly until 'AOFF' appears. Press

POWER to select this function. The current setting

will flash on the display. Use the PEAK key to scroll

through the displayed choices and POWER to select. Press POWER again at the 'donE' prompt in

order to save the setting.

The displayed units of measurement and the default mode of operation (peak or normal) can be

changed by entering the setup mode as described

above, pressing POWER at the 'init' prompt and

selecting the desired settings using the PEAK and

the POWER keys.

Power

The gauge may be powered by the internal 9V battery, or by the included AC adapter. The need for

the battery replacement is indicated by a 3-step

sequence: 1 - a steady LO BAT appears on the

display indicating the last 10% of the battery life, 2

- LO BAT begins to flash indicating the need for an

immediate battery replacement, 3 - the entire dis-

play except LO BAT flashes for several seconds

and then the instrument shuts off.

Calibration

To properly calibrate this instrument, application of

an exact load appropriate for your model will be required. It must be in pounds as indicated by the

model number. For example, the MG50 requires a

50 lb calibration weight regardless of displayed units.

While holding PEAK, turn the gauge on. Press PEAK

repeatedly until ‘CAL’ appears on the display and

press POWER three times to select the calibration

mode. At the ‘null’ prompt press ZERO. At the ‘SPAn’

prompt apply your test weight and press POWER.

The display will show “uuuu” or “nnnn” if the test

weight is insufficient or excessive accordingly. If this

happens, the only way to terminate the calibration

mode is by momentarily disconnecting the battery or

connecting the AC adapter without plugging it into a

wall outlet. This will stop the calibration procedure

without making any changes to the previous calibration data.

A successful calibration is indicated by ‘donE’ on

the display. Press POWER to save the changes and

resume normal operation.

Model Capacity x graduation

MG025 0.25 x 0.0002 lb, 100 x 0.1gF, 1 x 0.001N

MG05 0.5 x 0.0005 lb, 250 x 0.2 gF, 2.5 x 0.002 N

MG2 2 x 0.002 lb, 1 x 0.001 kgF, 10 x 0.01 N

MG10 10 x 0.01 lb, 5 x 0.005 kgF, 50 x 0.05 N

MG20 20 x 0.02 lb, 10 x 0.01 kgF, 100 x 0.1 N

MG50 50 x 0.05 lb, 25 x 0.02 kgF, 250 x 0.2 N

MG100 100 x 0.1 lb, 50 x 0.05 kgF, 500 x 0.5 N

MG200 200 x 0.2 lb, 100 x 0.1 kgF, 1000 x 1 N

Mounting

The instrument housing is reversible and may be

rotated 180° for test stand mounting by unscrewing two screws on the back, rotating the housing

and reassembling. In addition to the #6-32 screws,

a 0.188" [4.77 mm] dia. load-carrying pin should

be utilized so as not to stress the threads.

Page 2

Specifications

Series MG

ACCURACY ±0.5% of full scale ±1digit

SAMPLING 30 readings/second

RATE

DISPLAY 2.5/s in normal mode, 30/s in

RATE peak mode

SAFE 150% of gauge capacity. Display

OVERLOAD shows ---- (dashes) above 110%

POWER 9V battery or AC adapter

BATTERY 30 hours of continuous operation

LIFE

SIZE 3.7" x 2.5" x 1.5"

(94.0mm x 63.5mm x 38.1mm)

WEIGHT 0.65 lb (0.3 kg)

Mark-10 Corporation has been an innovator in the

Force and Torque measurement field since 1979.

We strive to achieve 100% customer satisfaction

through excellence in product design, manufacturing and customer support. In addition to our standard line of products, we can provide modifications

for special applications. Please contact us for further information or with suggestions for improvement.

DIGITAL FORCE GAUGE

USER'S GUIDE

Warranty

Mark-10 Corporation expressly warrants to its buyer for one year from the date of

delivery that the goods sold are free from defects in workmanship and materials.

Mark-10 Corporation will, at its option, repair or replace or refund the purchased

price of goods found to be defective. This remedy shall be the buyer's sole and

exclusive remedy. Any modification, abuse, exposure to corrosive environment or

use other than intended will void this warranty. This warranty is in lieu of all other

warranties, including implied warranties of merchantability and fitness for an intended purpose. In no event shall Mark-10 Corporation be liable for any incidental

and consequential damages in connection with goods sold or any part thereof.

ELECTROMATIC Equipment Co., Inc

600 Oakland Ave, Cedarhurst, NY 11516

TEL (800) 645-4330 / (516) 295-4300

FAX (516) 295-4399

Web: www.checkline.com

Email: info@checkline.com

0996

Loading...

Loading...