Page 1

User’s Guide

MESURgauge Software

User’s Guide

Page 2

MESURgauge Software

Thank you…

Thank you for purchasing MESURgauge software, a data collection

and analysis program developed to:

Measure

Collect data from digital force gauges, torque gauges, test stands,

travel displays, and other devices.

Graph

View a real time graph of load vs. time or travel.

Analyze

View an analysis graph, calculate statistics, and zoom to selected locations on the graph.

Store

Save results to a file, or export directly to Microsoft

recall previously saved test data, test setups and gauge configurations.

MESURgauge expands the functionality of a Mark-10 testing system,

typically comprising a test stand, force gauge, grips, and accessories.

For details on communicating with an ESM301 motorized test stand,

please refer to page 28.

This User’s Guide provides detailed operating instructions. For additional information or answers to your questions, please do not hesitate

to contact us. Our technical support and engineering teams are eager

to assist you.

®

ExcelTM. Save and

TABLE OF CONTENTS

STARTUP ................................................................................... 2

PORT CONFIGURATION TAB .................................................. 4

TEST SETUP TAB ..................................................................... 7

ACQUISITION TAB .................................................................. 11

ANALYSIS TAB........................................................................ 17

DIGITAL DISPLAY TAB........................................................... 20

GAUGE SETTINGS TAB ......................................................... 21

REPORT TAB........................................................................... 23

COMMUNICATING WITH THE ESM301 TEST STAND.......... 28

1

Page 3

User’s Guide

1 STARTUP

1.1 Computer Requirements

A personal computer running Microsoft

Vista operating system, with screen resolution of 1024 x 768 minimum, is required to run MESURgauge software. An RS-232C serial

port (“COM” Port) is required to communicate with a gauge. A second COM port is needed to communicate with a digital travel display. A CD-ROM drive is needed for software installation.

1.2 Installation Instructions

Insert the MESURgauge installation CD into the computer’s CDROM drive. If AutoRun is enabled on the computer, the setup program will run automatically. If not, the setup program may be run

manually. Click the START button on the Windows task bar, select

“Run…”, type “D:Setup” in the dialog box and press ENTER.

Alternately, using My Computer or Windows Explorer, navigate to

the CD-ROM drive and double-click the file “Setup.exe”.

Follow the prompts on the screen to install MESURgauge.

1.3 Running MESURgauge Software

When the installation is complete, run MESURgauge by clicking the

Windows START button, locating “MESURgauge by Mark-10” under “Programs”, and then clicking “MESURgauge”.

1.4 MENU ITEMS (available in all tabs)

File

Factory Defaults – Click to restore the factory default set-

tings.

Close – Click to exit MESURgauge.

Help

Show Tip Strips – Check this box to show “tip strips” (also

known as “tool tips”). These are text boxes that appear

when the cursor hovers over an object or area of the

®

Windows 2000, XP or

2

Page 4

MESURgauge Software

screen.

MESURgauge User’s Guide – Click to open the user’s

guide PDF document. (Note: Adobe Reader is required

and is downloadable at

Mark-10 Website – Click this to link to the Mark-10 web-

site. (Note: An internet connection and a browser is required).

(About)

Click the MESURgauge logo to display general software

information.

www.adobe.com

).

3

Page 5

User’s Guide

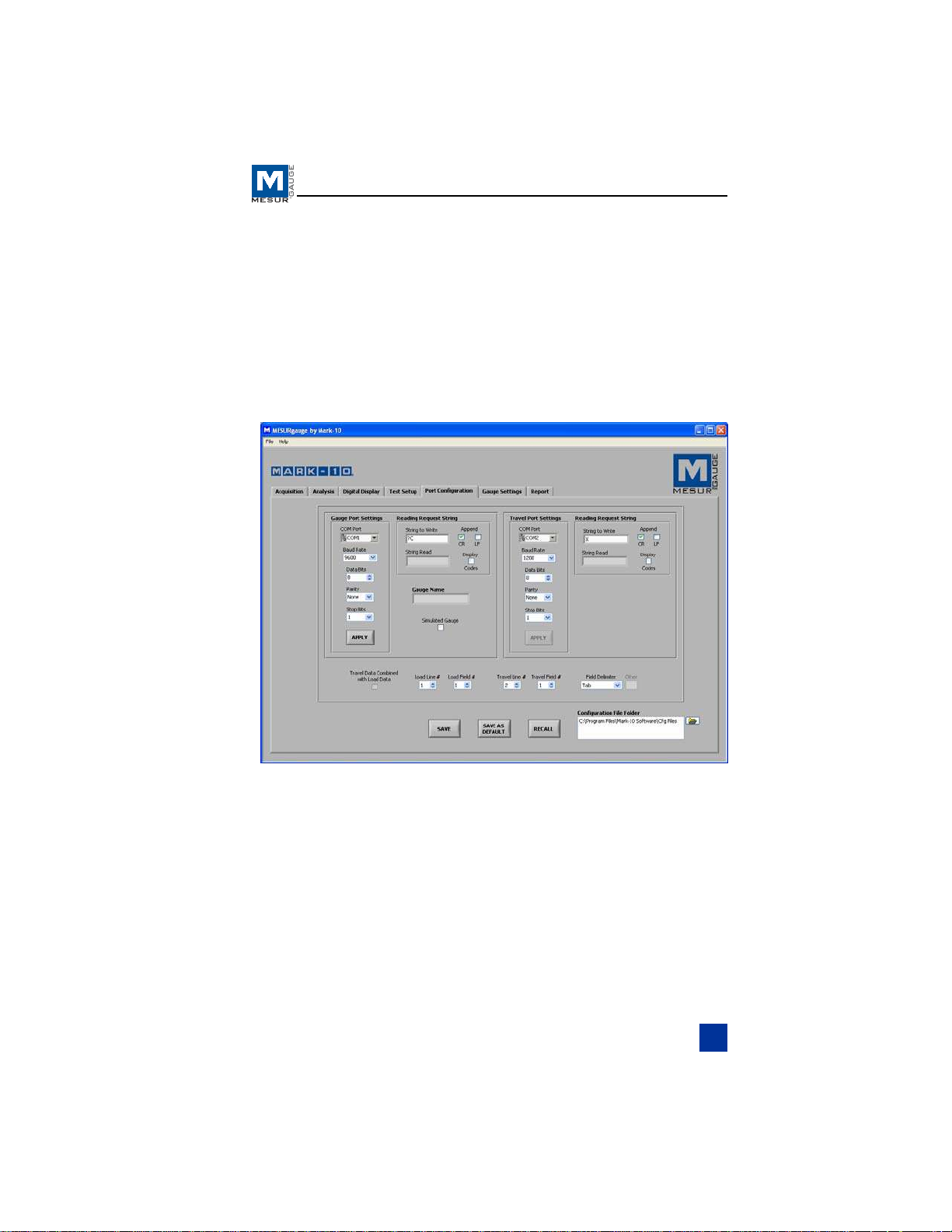

2 PORT CONFIGURATION TAB

Use this screen to configure the computer’s COM port settings to

which the instruments are connected. The default settings are the

same as the factory default settings for Mark-10 gauges. The

setting most likely to be changed is the particular COM port to

which the instrument is connected. MESURgauge can be configured to accept a single string of data (load), two strings of data

(load and travel) on separate COM ports, or two strings of data on

the same COM port.

2.1 Gauge Port Settings

COM Port

Select the COM port that the gauge is connected to from

the drop-down list. Clicking REFRESH updates the list with

all installed ports.

Baud Rate

Select the baud rate of the serial port. The default setting is

9600 baud.

4

Page 6

MESURgauge Software

Data Bits

Select the number of data bits for the serial port, then click

the APPLY button below. The default setting is 8 data bits.

Parity

Select the parity setting of the serial port. The default set-

ting is “None” (no parity).

Stop Bits

Select the number of stop bits for the serial port. The de-

fault setting is 1 stop bit.

APPLY

Click this button to apply changes to the above settings.

2.2 Reading Request String

String to Write

Enter the command string to request a reading from the

instrument. The default string for Mark-10 gauges is “?

C” (no quotes). Select either or both of the CR and LF

check boxes to append the string as required. CR (default)

or CR-LF may be used for Mark-10 gauges. The default

string can be recalled by right-clicking in the box and selecting "Reinitialize to Default Value".

The ability to specify the request data command adds flexi-

bility in testing. For example, peak or average readings may

be read from the gauge. Additionally, it allows for the compatibility of MESURgauge with gauges not manufactured by

Mark-10.

String Read

This is the raw character string read from the gauge.

Display Codes

Display control character '\' codes (\r = carriage return, \n =

line feed, \s = space).

2.3 Gauge Name

Optionally enter a name to be associated with the gauge settings in

5

Page 7

User’s Guide

this text box. This is helpful in identifying the particular gauge being

used. This name is automatically entered in the file dialog box

which opens when the SAVE configuration button is clicked. Any

name may be used. For further information on saving, see the

SAVE button description in Section 2.6.

2.4 Simulated Gauge

Check this box to simulate data being received from an instrument.

No serial connection is needed to a gauge. To start collecting data,

click the Acquisition tab and click the START button. Data will

populate the graph and table at the specified rate. This is provided

for demonstration purposes only.

2.5 Travel Port Settings

These settings apply to the second COM port. This COM port is

intended for use with a serial port digital travel display which is attached to a test stand (travel measurement is used for tests such as

spring and tensile testing). The information about the settings in

Section 2.1 (Gauge Port Settings) also applies to this section.

2.6 Travel Data Combined With Load Data

Check this box for MESURgauge to accept two strings of data on

one COM port. Configure the data string as required by selecting

the appropriate line numbers, field numbers, and field delimiter.

2.7 Configuration File Folder

Enter a full path or browse for a folder to use for Gauge Configuration (*.cfg) files. To browse for a folder, click the folder icon at the

right of the text box and navigate to or create the desired folder,

then click the "Current Folder" button in the dialog box.

2.8 Shared Buttons

SAVE

Click this button to open a file dialog box prompting to save

the current settings to a configuration file (this file has a .cfg

extension). Any file name may be entered and any folder

may be selected or created.

6

Page 8

MESURgauge Software

SAVE AS DEFAULT

Clicking this button saves the current settings to the default

configuration file “Default.cfg”. (No file dialog box opens.)

RECALL

Click this button to open a dialog box in which to browse for

previously saved configuration files. Parameter fields will be

populated based on the information in the configuration file.

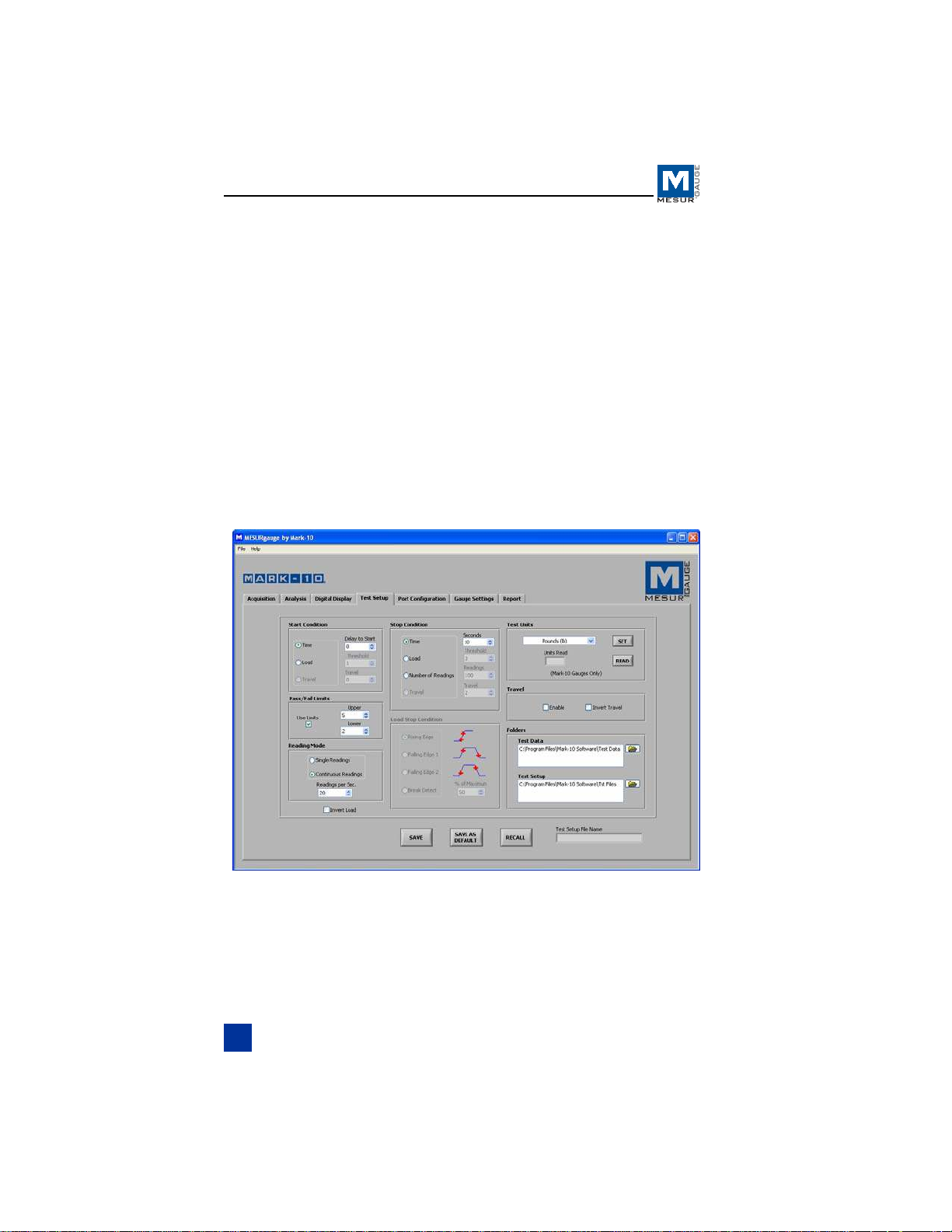

3 TEST SETUP TAB

Use this tab to configure various parameters for the test. This includes test start and stop conditions, pass/fail limits, selection of

continuous or discrete readings, and data sampling rate.

3.1 Start Condition

Select an option button for time delay, load threshold, or travel to

begin the test.

Time

Set time delay, in seconds, to begin the test.

7

Page 9

User’s Guide

Load

Set a load threshold to begin the test (The load units are as

specified in the Select Units drop-down list box in the upper right area of this tab).

Travel

Set a travel threshold to begin the test. The second COM

port must be enabled for this selection to be made (the

travel units are as specified with the Inches / Millimeter

option buttons in the right-center area of this tab).

3.2 Stop Condition

Select an option button for time, load, the number of readings, or

travel to stop the test.

Time – Seconds

Set the duration of the test, in seconds.

Load – Threshold

Set the load threshold at which to terminate the test (the

load units are as specified in the Select Units drop-down

list box in the upper right area of this tab). See Stop

Threshold Options below for various load stop threshold

options.

Number of Readings – Readings

Set the number of readings at which to terminate the test.

Travel

Set the travel threshold to end the test. The second COM

port must be enabled for this selection to be made (the

travel units are as specified with the Inches / Millimeter

option buttons in the right-center area of this tab).

3.3 Load Stop Condition

Four test stop options based on load threshold are available:

Rising Edge

Stop threshold is higher than the start threshold (increasing

load).

8

Page 10

MESURgauge Software

Falling Edge 1

Stop threshold is lower than start threshold (decreasing

load).

Falling Edge 2

Stop threshold is higher than Start threshold, but the load is

decreasing.

Break Detect

Stop the test when the load decreases to a specified percentage of the maximum (peak) reading during the test.

3.4 Reading Mode

Single Readings

When this option is selected, single readings are taken from

the gauge each time READ is clicked, or the DATA button

on the gauge is pressed. This button appears below the

graph in the Acquisition tab when this option is selected.

Continuous Readings

When selected, readings are taken from the gauge at a rate

set in the Readings per Second field.

Readings per Second

This numeric box sets the number of readings per second

that MESURgauge requests data from the gauge in the

“Continuous Readings” mode. Available range is 0.001 to

50 readings per second.

Note: When using a Mitutoyo brand travel display, it is recommended to limit the readings per second at 4, to prevent

communication errors.

3.5 Invert Load

Check this box to invert the polarity (sign) of the load reading. This

is useful, for example, in tensile strength testing. Tension readings,

which have a negative sign, can be reversed so that the graph

shows increasing values instead of decreasing values.

Note: There is another instance of this check box in the Acquisition

tab. Checking one box automatically checks the other.

9

Page 11

User’s Guide

3.6 Test Units

Note: Reading and setting units is possible with Mark-10 gauges

only.

Select Units

The gauge’s unit of measurement can be set by clicking on

the appropriate selection from the drop-down menu.

SET

Sets the gauge to the units of measurement selected.

READ

Reads the unit of measurement to which the gauge is currently set.

Units Read

Displays the unit of measurement to which the gauge is

currently set.

3.7 Travel Port

This is a second COM port from which data from a travel display is

received. Travel readings are tabulated and plotted vs. load, as opposed to time vs. load.

Enable

Check this box to enable the second COM port for travel

data collection. The settings for this port can be configured

in the Port Configuration tab.

Invert Travel

Check this box to invert the polarity (sign) of the readings

from the travel display.

3.8 Pass / Fail Limits

Check this check box to enable high and low indicators for go / no

go type testing. When checked, Pass, Fail High, and Fail Low indi-

cators appear in the Acquisition tab, below the STOP button.

3.9 Folders

Enter full paths or browse for folders to use for Test Data (*.log) and

10

Page 12

MESURgauge Software

Test Setup (*.tst) files. To browse for a folder, click the folder icon at

the right of the text box and navigate to or create the desired folder,

then click the "Current Folder" button in the dialog box.

3.10 Shared Buttons

SAVE

Opens a file dialog box in which to save the current settings

to a test setup file (.tst extension). Any file name may be

entered and any folder may be selected or created.

SAVE AS DEFAULT

Clicking this button saves the current settings to the default

test setup file, “Default.tst”.

RECALL

Click this button to open a dialog box in which to browse for

previously saved test setup files. Parameter fields will be

populated based on the information in the test setup file.

11

Page 13

User’s Guide

4 ACQUISITION TAB

Use this tab to view tabular and graphical data from a gauge as it is

being received. When the START button is clicked, data received

from the connected gauge(s) will be graphed and tabulated as they

are being received. The test ends automatically when the stop condition in the Test Setup tab is met. The test can also be ended at

any time by clicking the STOP button. Specific load and time (or

travel) data points are displayed in the fields below the table.

4.1 START

Starts a test. Readings from the gauge are captured when the start

condition in the Test Setup tab is met. When data is being captured, the “Acquiring Data” indicator above the START button turns

on (bright green).

4.2 STOP

Stops a test. The test will stop automatically when the selected stop

condition in the Test Setup tab has been met. When the test is

completed, the “Acquiring Data” indicator will turn off (dark green).

12

Page 14

MESURgauge Software

4.3 Table

Contains the reading number, load reading from the gauge, and

relative time stamp (or travel datum) for each data point.

Scroll to, or manually enter, the desired reading in the Reading box

to display corresponding load and time (or travel) data in the indicators to the right.

4.4 SAVE

Click this button to open a file dialog box in which to save the data

from the table to a tab-delimited text file. Enter a file name and optionally browse to any desired folder location. The default file folder

location for the test data files is set in the Test Data Folder box in

the Test Setup tab. After saving, the file can then be opened by

common Windows programs such as Notepad and Excel. Note:

Saving cannot be performed until the test has been completed.

4.5 Last Reading

The most recent reading received from the gauge.

4.6 Total Readings

The total number of readings taken during the test.

4.7 Units

The unit of measurement received with the data (the gauge[s] must

be configured to send units information).

4.8 Graph

The graph plots load versus time or load versus travel (time is default). Scale minimum and maximum values can be set by doubleclicking on the numerals long the X and Y axes. Change the numbers to the desired values and press ENTER or click away from the

numbers.

Several options are available by right-clicking anywhere within the

graph. A pop-up menu appears as follows:

13

Page 15

User’s Guide

The menu items are provided for quick access and convenience to

some common functions. The AutoScale X and Y items are equivalent to the “padlock” icon on the scale palette at the lower right of

the graph, described below.

4.9 Tools (under the graph)

View

Clicking on this button brings up the following six viewing

options:

Set a zoom window with adjustable x- and ydimensions for a specific part of the graph

Set a zoom window with adjustable x-dimension for

a specific part of the graph

Set a zoom window with adjustable y-dimension for

a specific part of the graph

View entire graph

Zoom out

Zoom in

14

Page 16

MESURgauge Software

Pan

This allows the user to reposition the graph. Click on the

graph, move the mouse to the desired location, and release

the mouse button.

4.10 X- & Y-scale Settings

Auto-scale lock

When in the locked position, the scale is in auto-scale

mode.

Auto-scale

Click to auto-scale the axis.

Scale & grid properties

Click to adjust various scale and grid properties. A pop-up

context menu provides access to these properties.

4.11 Plot Palette (upper right corner of the graph)

Several plot options are available by clicking on the Plot Palette

icon. A menu of options will appear as follows:

15

Page 17

User’s Guide

Plot settings and graph properties can be configured as desired.

4.12 Graph Colors

Background Color Picker Box

Select the background color of the graph.

Set

Sets the graph to the selected background color.

Defaults

Restores the background, plot, and grid colors to factory

defaults.

16

Page 18

MESURgauge Software

4.13 Pass/Fail Indicators

When the Use Limits check box in the Pass/Fail Limits frame in the

Test Setup tab is checked, the Pass/Fail indicators, shown below,

become visible. While acquiring data, the load values received are

compared to the upper and lower limits set in the Test Setup tab,

and the appropriate indicator illuminates. A fail condition is represented by a bright red indicator. A pass condition is represented by

a bright green indicator.

4.14 Pass/Fail Limit Lines

Horizontal lines corresponding to the pass/fail limits set are displayed on the graph in red.

4.15 Invert Load

See Section 3.5.

4.16 Invert Travel

This checkbox is not visible unless the travel port is enabled in the

Test Setup tab. For details see Section 3.7.

4.17 CLEAR

Sends a command to a Mark-10 gauge to clear peaks and start a

new average or external trigger test (if so enabled).

4.18 ZERO

Sends a command to a Mark-10 gauge to zero the display and per-

17

Page 19

User’s Guide

form the CLEAR function, as described above.

The ZERO and CLEAR buttons in MESURgauge perform the same

functions as the ZERO and CLEAR buttons on Mark-10 gauges.

5 ANALYSIS TAB

This tab is used to analyze the data obtained during a test. Statistics are calculated and displayed automatically upon completion of

the test. The graph cursor tools can be used to zoom to a specific

area of the graph. Statistics may then be calculated for that region

of the graph. Graph and table data from the Acquisition tab is automatically transferred to this graph and table when the test has been

completed.

5.1 Graph

Graph functionality and tools are the same as in the Acquisition

tab, with one additional active icon:

18

Page 20

MESURgauge Software

Cursor Movement Tool

Clicking this button allows the X-Y cursor to be dragged to

the desired position.

Pass/Fail Limit Lines

Horizontal lines corresponding to the pass/fail limits set are

displayed on the graph in red.

5.2 REFRESH GRAPH

Redraws the graph based on the data collected during the test.

5.3 Cursor Palette

19

Center Cursor

Centers the cursor in the graph area.

Cursor Control

Click on the quadrants of this icon to move the cursor in the

corresponding direction.

Cursor Table

Displays the cursor position’s X and Y values.

Page 21

User’s Guide

Reading Number at Cursor

Reading number corresponding to the current position of

the cursor.

5.4 Graph Colors

The graph color selection functionality is the same as described in

the Acquisition tab.

5.5 Statistics

This frame displays statistical data for the test.

Maximum

The maximum load reading measured during the test.

Minimum

The minimum load reading measured during the test.

Average

The average (mean) of the readings. Note that in situations

where load fluctuates between positive and negative values, this function considers polarity, not the absolute values

(for example, the average of +5 and -5 is calculated as 0).

Area Under Curve

The average of the absolute values of the load readings

multiplied by the selected time interval.

The above statistics are based on the data range specified in the Xscale Settings frame. This range defaults to the full range at completion of the test. This range can be modified by entering the desired range in the Minimum and Maximum numeric boxes. Click the

CALCULATE button to calculate the statistics for the specified

range. The graph will automatically adjust to reflect the new range.

5.6 Table

The table functionality is the same as described in the Acquisition

tab.

5.7 RECALL

Opens a file dialog box prompting to recall a previously saved test

20

Page 22

MESURgauge Software

data file. The table and graph will be populated with the previously

saved data, and the statistics will automatically be calculated.

Note: When recalling a test which used the travel port for travel

measurement, or single readings, those options must be selected in

the Test Setup tab in order for the x-axis label of the graph and the

statistics to be displayed correctly.

5.8 SAVE

Opens a file dialog box prompting to save the data from the table to

a tab-delimited text file. Enter a file name and optionally browse to

any desired folder location. The default file folder location for the

test data files is set in the Test Data Folder box in the Test Setup

tab. After saving, the file can then be opened by common Windows

programs such as Notepad and Excel.

5.9 Export to Excel

Clicking this button launches Microsoft

separately) and populates a worksheet containing reading numbers, load, and time or travel directly into a worksheet.

®

ExcelTM (if installed, sold

21

Page 23

User’s Guide

6 DIGITAL DISPLAY TAB

This tab is provided to display real time load readings (and, if the

travel port is enabled, travel readings) in large numerals. If the

“Graph and Tabulate Data” check box is checked, the graph and

table in the Acquisition tab is populated. See image on the next

page.

7 GAUGE SETTINGS TAB

This tab provides a convenient utility with which to read and set

gauge configuration parameters from a PC. Settings are applicable

only for Mark-10 gauges. Refer to your instrument’s user’s guide for

details on the various parameters.

In the lower left-hand part of the screen, it is possible to enter commands to send to any gauge via the primary serial port. This facility

allows the user to communicate with any gauge.

22

Page 24

MESURgauge Software

7.1 READ

Populates the fields above with current settings from a Mark-10

gauge.

7.2 SAVE

Saves the current gauge settings to the gauge’s non-volatile memory. These will be the default settings when the gauge powers on.

Note: The desired settings must be individually written to the gauge

(by clicking the Set button adjacent to the parameter menu) before

clicking SAVE. It is recommended to click the READ button to confirm the current settings before clicking SAVE.

7.3 Set Buttons (all)

Click to set the Mark-10 gauge with the parameter selected from

the drop-down menu adjacent to the respective Set button.

7.4 String to Send to Gauge

Enter a command to send to the gauge via the primary serial port.

This facility allows the user to communicate with and send commands to any gauge. Click Send to send the command.

23

Page 25

User’s Guide

7.5 String Read from Gauge

This text box shows the response string, if any, that is received in

response to the above command.

7.6 Display Codes

Display control character '\' codes (\r = carriage return, \n = line

feed, \s = space).

Note: This tab and all gauge-related functions cannot be used while

MESURgauge is collecting data from an ESM301 test stand. See

Section 9 for details on communicating with the ESM301.

8 REPORT TAB

Use this tab to set up a report for the test. The report may be

printed to the selected printer or saved as an HTML file. A report

template may be saved and recalled.

8.1 Select Printer

24

Page 26

MESURgauge Software

Select the printer to which the report will print. The Windows default

printer is selected initially.

8.2 PRINT

Prints the report on the selected printer.

8.3 HTML Report Folder

Enter or browse for a folder in which to save the report files.

8.4 SAVE

Opens a file dialog box prompting to save the report. Enter a file

name and optionally browse to any desired folder location. The default file folder location for report files is set in HTML Report

Folder, as described above.

8.5 Left Header Text

Enter text to appear in the upper left corner of the report. The text

will appear as bold in the report.

8.6 Right Header Check Boxes

Check the Date and/or Time boxes to include the current date and/

or time in the right header of the report. Date and time will appear

as bold in the report.

8.7 Initial Text

Enter any initial text here.

8.8 Additional Text

Enter any additional text here.

8.9 Conclusion Text

Enter any concluding text here.

8.10 Left Footer Text

Enter text to appear in the lower left corner of the report. The text

25

Page 27

User’s Guide

will appear as bold in the report.

8.11 Right Footer Text

Enter text to appear in the lower left corner of the report. The text

will appear as bold in the report.

Use the above text boxes to enter information and comments pertaining to the test. This information can be saved to a file as a template and can be recalled.

8.12 Include Graph

Check this check box to include an image of the graph in the report.

8.13 Include Table

Check this check box to include the table data in the report.

8.14 Include Table Grid

Check this check box to include a grid for the table.

8.15 Save Template

Saves a template of all the information in the text boxes and selected settings to a file for recall.

8.16 Recall Template

Recalls a previously saved template.

A sample HTML report is shown below as it would appear in a

browser:

26

Page 28

MESURgauge Software

27

Page 29

User’s Guide

9 COMMUNICATING WITH THE ESM301

TEST STAND

MESURgauge can collect data from an ESM301 test stand. The

test stand can output either force data only or force data combined

with travel data (if the ESM301-001 integrated travel indication option is installed). To communicate with MESURgauge, certain settings in the test stand, force gauge, and software must be changed

as follows:

9.1 Force data only

1. Check physical connections (refer to the ESM301 user’s guide).

2. Force gauge settings (refer to the gauge’s user’s guide).

1. Set to automatic output of every sample.

2. Disable Mitutoyo BCD output.

3. Test stand settings

1. Set the baud rate to 115,200.

2. Set the Control mode to Console.

9.2 Force and travel data simultaneously

1. Check physical connections (refer to the ESM301 user’s guide).

2. MESURgauge settings

1. Test Setup tab

1. Under Travel check the Enable box. Under

Reading Mode, if Continuous Readings is selected, Readings per Sec. defaults to 4. This

value can be increased.

3. Port Configuration tab

28

Page 30

MESURgauge Software

1. Identify a working com port, and select the appropriate port in Gauge Port Settings.

2. Under Gauge Port Settings, change baud rate to

115,200.

2. Under Reading Request String change String to

Write to “n” (lowercase, no quotes). Uncheck the

CR box.

3. Check the box labeled Travel Data Combined

with Load Data. No changes are needed to the

default lines, fields, and delimiter.

4. Click APPLY after making any changes in the

Gauge Port Settings area.

3. Force gauge settings (refer to the gauge’s user’s guide)

1. Set to automatic output of every sample.

2. Disable Mitutoyo BCD output.

4. Test stand settings

1. Set the baud rate to 115,200.

2. Set the Control mode to Console.

5. The Gauge Settings tab and all other gauge-related functions

cannot be used while MESURgauge is connected to the ESM301. It

is intended for use only when connected to a Mark-10 force gauge

directly.

29

Page 31

User’s Guide

NOTES:

30

Page 32

MESURgauge Software

32-1088

REV 2 0309

27

Loading...

Loading...