Page 1

CHECK•LINE

BY ELECTROMATIC

LM6

LEATHER MOISTURE METER

®

Operating Manual

Page 2

TABLE OF CONTENTS

1.0 Introduction ………………………………………………………..… ................... 2

1.1 Operation and handling

1.2 Measuring procedure

2.0 Calibration curves ……………….………………………………...… ................ 3

2.1 Selection of calibration curves

3.0 Determination of the reference water content ………………….… .......................... 4

3.1 Short description of norm DIN53304

4.0 Design of the device… ................................................................................................ 5

4.1 Menu

4.2 Key functions in the menu

5.0 Common reasons for incorrect measurements …….…….………..… ...................... 7

6.0 Looking after the instrument ………………………………..………… ................. 7

6.1 Exemption from liability

7.0 Changing the batteries ………………………………………………..… ................ 8

8.0 Calibration ………………………………………….……………………… ............ 9

8.1 Checking the calibration

8.2 Calibration procedure

9.0 Technical data ….…………………………………………………….… ................ 11

10.0 Warranty ………………………………………………………….…… .............. 12

0

–1 –

Page 3

1.0 INTRODUCTION

1.1 Operation and handling

Switching on: Press the button for 3 seconds.

Changing the calibration curve: or key.

Switching on the display lighting: Press the button briey; the lighting

switches off automatically after approx. 20 seconds. Pressing any key activates the

lighting again and prolongs the switch-off time to 4 minutes.

Switching off: Press the key for 5 seconds; the device will switch off after releasing

the key. After approx. 4 minutes the device will switch off automatically.

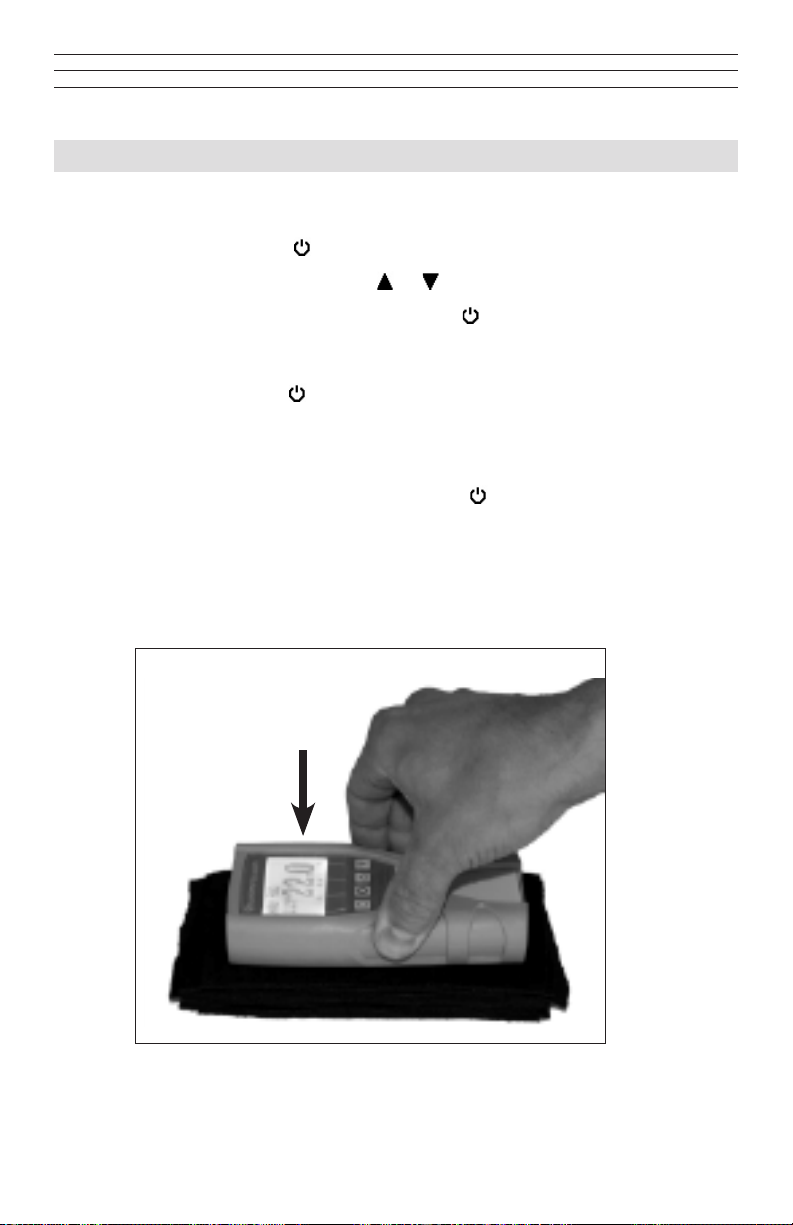

1.2 Measuring procedure

1. Switch on the humimeter LM6 by pressing the key for 3 seconds.

2. Select the appropriate calibration curve using the arrow keys. Hold the device in

one hand and press it onto the leather well-setted (4 kg compacting pressure).

The leather pile has to be at least 10mm high!

3. The display shows the water content immediately (large numbers).

– 2 –

Page 4

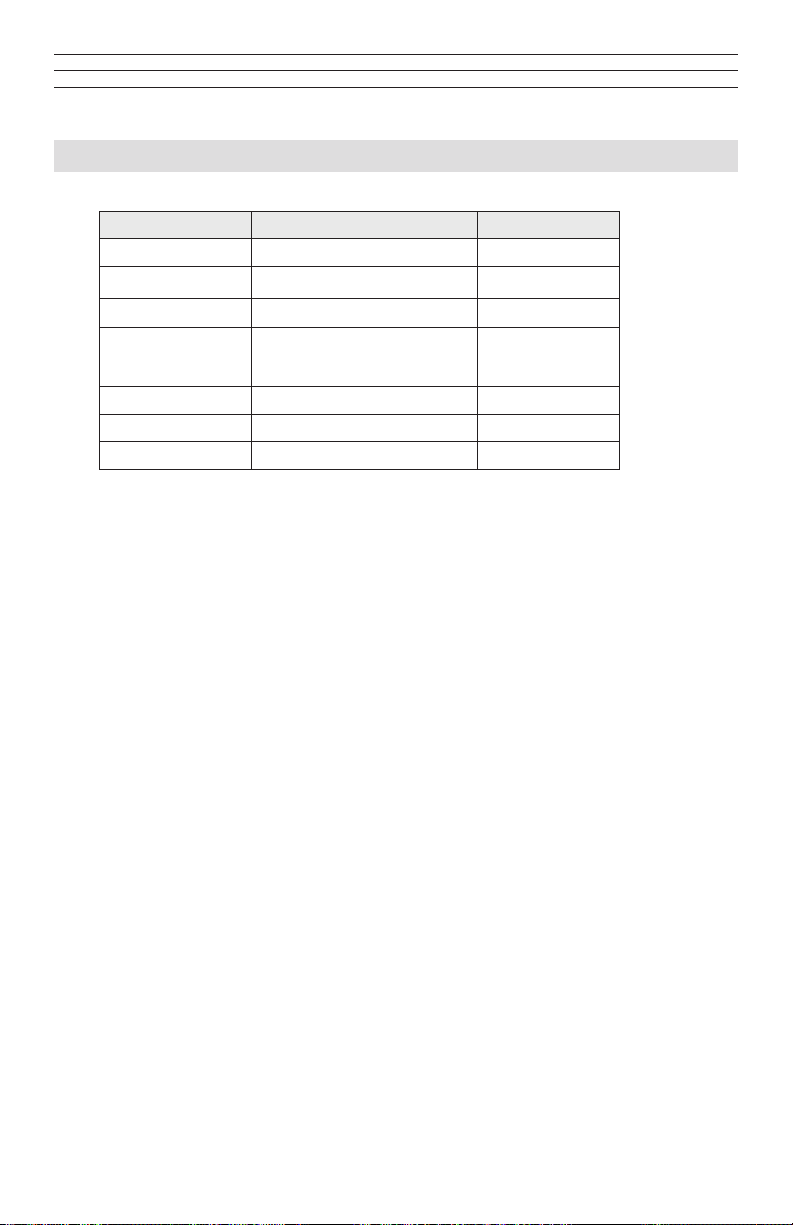

2.0 CALIBRATION CURVES

NAME CALIBRATION CURVE DENSITY

Leather LD Leather of low density 0.55 g/cm³

Leather CR Leather chrome tanned 0.60 g/cm³

Leather MD Leather of medium density 0.65 G/CM³

Leather FOC

Leather HD Leather of high density 0.75 g/cm³

Leather VHD Leather of very high density 0.80 g/cm³

Reference Only for checking the instrument

Leather free of chrome, re

protection leather

0.70 g/cm³

2.1 Selection of calibration curves

Due to different manufacturing methods and different densities of the leather there is no

standardised allocation of calibration curves.

In the above list of calibration curves you can nd information regarding manufacturing

methods and density that enables a preselection of the calibration curve.

To ensure the best accuracy of your measurement, we recommend to carry out a

comparison measurement by kiln-drying (norm DIN 53304) once:

1. Take a leather pile of 10-15mm of the format A6 with average moisture content.

2. Measure the water content of this leather pile using all available calibration curves

and write down the measuring results of the different calibration curves.

3. Take the 2 top leather pieces of the pile and carry out a reference measurement

according to DIN 53304.

4. Compare the determined reference water content with the measuring results of the

different calibration curves. Use the calibration curve with the measuring result

nearest to the reference water content.

– 3 –

Page 5

3.0 DETERMINATION OF THE REFERENCE WATER CONTENT

100% ×

−

=

Mn

MtMn

WG

Mn: Mass with average moisture content

The humimeter LM6 determines the water content, which means that it calculates the

moisture referred to the total mass (DIN53304):

Mt: Mass of the dried sample

%WG: Calculated water content

3.1 Short description of norm DIN53304

Take a leather piece according to DIN 53302 T2 or DIN 53303 T2. For the

determination of the water content, weigh the leather piece with an accuracy of 0,001

g (mass Mn). Put the piece of leather in a glass bowl that was dried at (102 ± 2) °C

and was weighed after cooling to room temperature. Dry the opened glass bowl in a

drying chamber at (102 ±2) °C for 5 hours. After closing the glass bowl cool it in an

exsiccator. Now determine the mass (Mt). After that, go on with the above described

drying procedure in the drying chamber for one further hour, cool and weigh again. If

the weight after the second drying period decreases less than 0.1 % of the initial weight,

the assay is nished. If the decrease of weight is higher than 0.1 %, the drying has to be

continued. The total period of drying must not exceed 8 hours.

–4 –

Page 6

4.0 DEVICE DESIGN

Calibration Curve

Measuring Value

Temperature

Measuring Value

Moisture

Rolling Menu

Resp, Hold Key

ON/OFF Button

Changing

Calibration Curve

Rubber Protective

Housing

Batteries Slot

(flipside)

– 5 –

Page 7

4.1 Menu

There are 3 menu levels Main menu

The symbols show the key functions in Edit logs

the different menus. Manual logs

1. Type selection: Clear logs

2. Saving: Print logs

3. Main Menu Last Logs

Rolling menu: Use this key to enter the All logs

different menu levels and main menu. Clear logs

Power: Press this key for 3 seconds to Send logs

switch the instrument off or on. Press this Manual logs

key briey to activate the display lighting. Clear logs

Up: This key moves you to the next Options

type/calibration curve. Date / Time

Down: This key moves you to the Logtime

previous type/calibration curve. Language

Disk: Use this key to save measurement Unlock

values. °C / °F

If the number in front of the disk symbol Calibrate

increases, the measuring value has been saved o Userlevel

BL On Time

Alternatively: Auto Off time

Hold: The currently shown Materialcalib.

measurement value is held. It is released Password

when another key is pressed. Reset

View logs: If no logs are active, you can use this SN

symbol to view the saved measuring series Logo

Tm

Alternatively: Admin

Edit logs: If logs are active, Status

you can press this symbol and then enter

e.g. batch number and supplier’s data for the series.

In the saving level, press (rolling menu) to enter the main menu.

4.2 Key functions in the menu

: Conrm – activates menu item

: Up – long press => jumps to the start of the menu

: Down – long press => jumps to the end of the menu

: Exit – exits the menu item or menu

– 6 –

Page 8

5.0 COMMON REASONS FOR INCORRECT MEASUREMENTS

• Wrong calibration curve

Double check the correct selection of the calibration curve before measuring. The

calibration curve “reference” must NOT be used.

• Inadequate thickness of the leather pile

A single leather hide must NOT be measured. Pile the leather to ensure a thickness

of at least 10 mm.

• Metal below the material

During the measurement there must NOT be any metal for at least 100 mm under

the measured material.

• Product temperature out of application range

The application range is between 0 °C and +40 °C

• Discrepancy in temperature between device and material

Please ensure that the device and the material under test are being stored at nearly

the same temperature before measuring. A high temperature difference has a

negative effect on the stability of the measurement results.

6.0 LOOKING AFTER THE INSTRUMENT

Do not drop the instrument or expose it to excessive temperatures. Only clean it with a

lint-free, dry cloth. The instrument is not waterproof.

How often you need to check the instrument depends on the use and the required level

of accuracy in your eld of operation. For a fee, Messtechnik Schaller GmbH can also

carry out a calibration at their factory. In this case you will also receive a calibration

certicate.

6.1 Exemption from liability

For miss-readings and wrong measurements and of this resulting damages we refuse

any liability. As this rapid measurement procedure is inuenced by product-specic and

application-specic conditions, we recommend to carry out a plausibility check on the

measurement results. Each instrument has a serial number and a warranty seal. If this is

broken we cannot provide warranty. If the instrument is defective, contact Messtechnik

Schaller GmbH or your supplier.

–7 –

Page 9

7.0 CHANGING THE BATTERIES

Your new device is provided with batteries.

Please nd enclosed the manual for changing of batteries:

1. At rst remove the rubber protective housing. For that, hold the rubber housing at

the upper side and pull it over. If your humimeter is provided with an optional USB

port, you have to remove the protection cap before. Press with your nger onto the

arrow of the battery cap und pull it back.

2. Remove the empty batteries.

3. Put four new batteries in the device. Make sure that the position of the battery poles

is correct.

4. Press down the batteries and close the cap.

– 8 –

Page 10

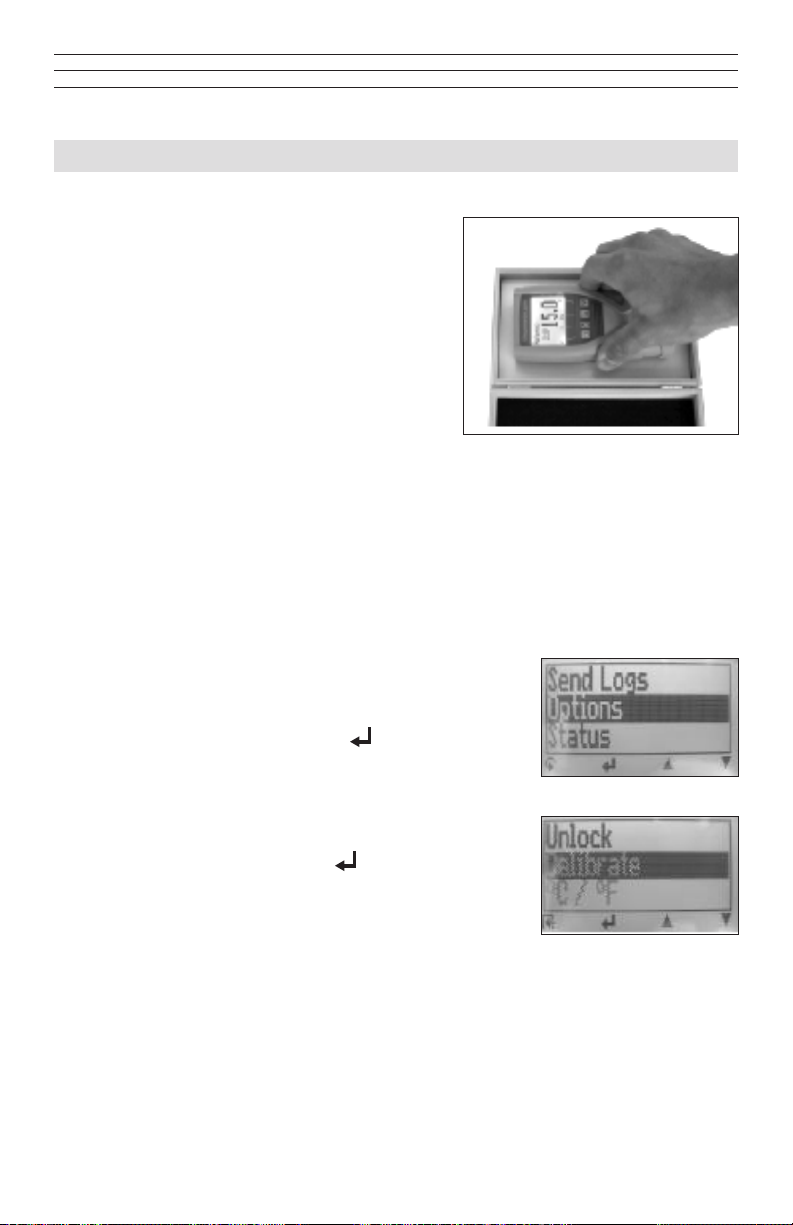

8.0 CALIBRATION

8.1 Checking the calibration

We recommend to check the calibration of the

humimeter LM6 every 4 weeks, using the proof

plate delivered with the device. For this check

the device has to show a temperature between

18.0 and 24.0°C.

1. Switch on the instrument and select the

calibration curve “reference” using the

arrow keys.

2. Hold the humimeter LM6 in one hand and

press it onto the grey proof plate (compacting pressure of 4.0kg). The shown

measuring value should range between 14.5 and 15.5.

3. If the shown value is out of this range, you have to carry out a calibration

(see instructions below)

8.2 Calibration procedure

By a zero point adjustment you can correct a too high deviation of the calibration check.

For that please proceed as follows:

1. Press the left key twice to reach the menu level.

Navigate to the menu item Options using the arrow

keys. Conrm by pressing the button.

2. Select the menu item Calibrate using the arrow keys a

znd conrm by pressing the button.

3. This menu item has to be unlocked. For that you have to enter the 4-digit serial

number of your humimeter LM6. You can nd the serial number on the top right

edge of your display a short time after switching on the instrument, or on the sticker

in the battery slot.

– 9 –

Page 11

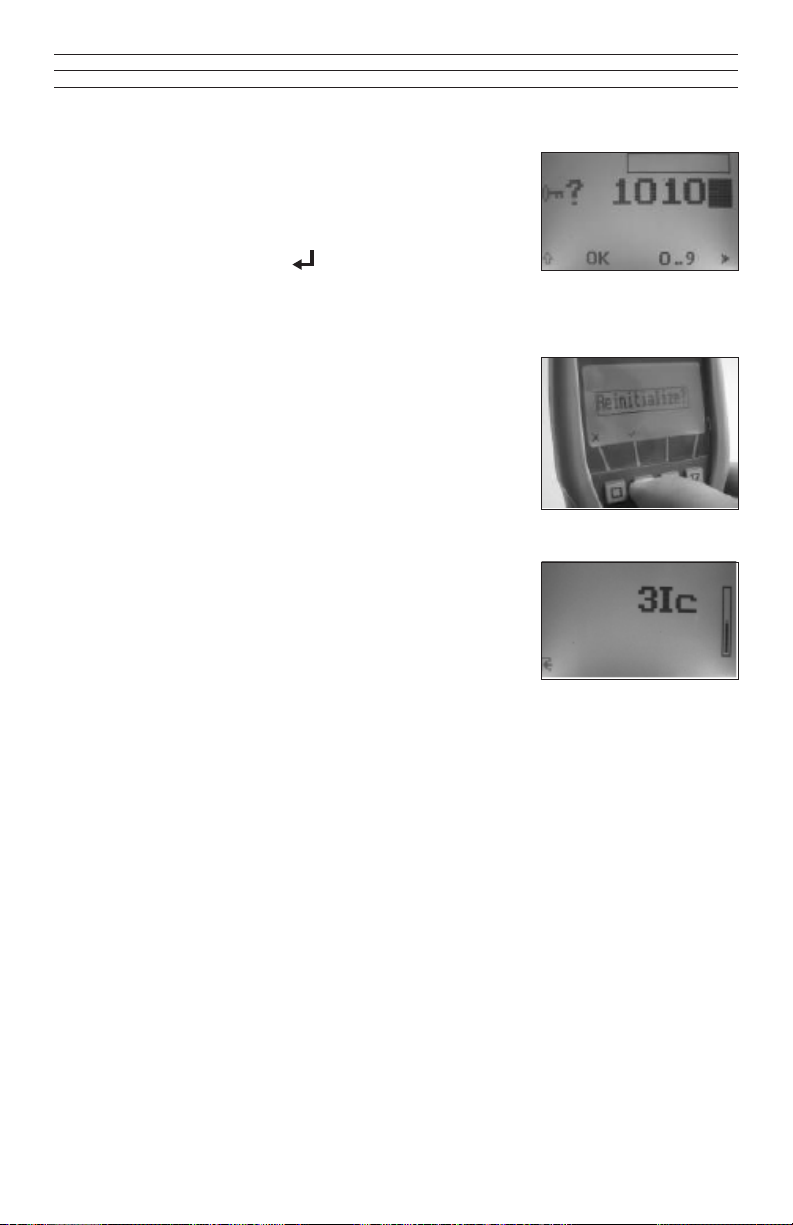

4. Press the third button as long as the black bar stands

on the rst digit of the serial number. After a waiting

time of a few seconds the device accepts the entered

digit. Now the other 3 digits have to be entered.

When the 4-digit number has been entered correctly

(see picture), press the button to conrm.

5. The request Reinitialize? will appear at the display.

Hold the humimeter LM6 in one hand and make sure

that nothing stands behind the measuring eld (black

plate).

6. Now press the second button (✔) with one nger. The

calibration procedure will take a few seconds. During

that time, the instrument has to be held up in the air

and the measuring eld must NOT be touched.

7. The device is ready when the shown picture on the

right disappears automatically.

– 10 –

Page 12

9.0 TECHNICAL DATA

Measuring depth 0.197 in (5mm)

Minimum material thickness 0.394 (10mm)

Resolution 0.1% water content ; 0.1°C ; 0.3°F

Measuring range 3% to 65% water content

Temperature measuring range 14 °C to 122 °F (–10°C to +50°C)

Operation temperature range 32 °F to 104 °F (0 °C to +40 °C )

Storage temperature –4 °F to 140 °F (–20°C to 60°C)

Temperature compensation Automatic

Memory for measured value Approx. 10.000 values

Menu language German, English, French, Italian,

Spanish, Russian

Power supply 4 x 1.5 Volt AA Alkaline batteries

(for approx. 900 measurements)

Switch off time After approx. 4 minutes

Power consumption 60 mA (with display lighting)

Display 28 x 64 matrix display,

with LED- backlighting

Dimensions 5.79 in x 2.95 x 1.18 in

(147mm x 75mm x 30mm)

Weight (incl. batteries) 9.35 oz. (265g)

Protection class IP 40

Scope of supply LM6, 4 x 1.5 Volt AA Alkaline batteries,

wooden case, proof plate, rubber

protective housing, user manual

Options PC interface including software and cable,

mobile printer (only with option 1)

– 11 –

Page 13

WARRANTY

ELECTROMATIC Equipment Co., Inc. (ELECTROMATIC) warrants to the original

purchaser that this product is of merchantable quality and conrms in kind and quality

with the descriptions and specications thereof. Product failure or malfunction arising

out of any defect in workmanship or material in the product existing at the time of

delivery thereof which manifests itself within one year from the sale of such product,

shall be remedied by repair or replacement of such product, at ELECTROMATIC’s

option, except where unauthorized repair, disassembly, tampering, abuse or

misapplication has taken place, as determined by ELECTROMATIC. All returns

for warranty or non-warranty repairs and/or replacement must be authorized by

ELECTROMATIC, in advance, with all repacking and shipping expenses to the address

below to be borne by the purchaser.

THE FOREGOING WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO, THE

WARRANTY OF MERCHANTABILITY AND FITNESS FOR ANY PARTICULAR

PURPOSE OR APPLICATION. ELECTROMATIC SHALL NOT BE RESPONSIBLE

NOR LIABLE FOR ANY CONSEQUENTIAL DAMAGE, OF ANY KIND OR

NATURE, RESULTING FROM THE USE OF SUPPLIED EQUIPMENT, WHETHER

SUCH DAMAGE OCCURS OR IS DISCOVERED BEFORE, UPON OR AFTER

REPLACEMENT OR REPAIR, AND WHETHER OR NOT SUCH DAMAGE IS

CAUSED BY MANUFACTURER’S OR SUPPLIER’S NEGLIGENCE WITHIN ONE

YEAR FROM INVOICE DATE.

Some State jurisdictions or States do not allow the exclusion or limitation of incidental

or consequential damages, so the above limitation may not apply to you. The duration

of any implied warranty, including, without limitation, tness for any particular

purpose and merchantability with respect to this product, is limited to the duration of

the foregoing warranty. Some states do not allow limitations on how long an implied

warranty lasts but, not withstanding, this warranty, in the absence of such limitations,

shall extend for one year from the date of invoice.

ELECTROMATIC Equipment Co., Inc.

600 Oakland Ave. Cedarhurst, NY 11516—USA

Tel: 1-800-645-4330/ Tel: 516-295-4300/ Fax: 516-295-4399

Every precaution has been taken in the preparation of this manual. Electromatic

Equipment Co., Inc., assumes no responsibility for errors or omissions. Neither is any

liability assumed for damages resulting from the use of information contained herein.

Any brand or product names mentioned herein are used for identication purposes only,

and are trademarks or registered trademarks of their respective holders.

– 12 –

Page 14

CHECK•LINE

INSTRUMENTS

®

ELECTROMATIC

E Q U I P M E N T C O., I N C.

600 Oakland Ave., Cedarhurst, NY 11516 – USA

TEL: 516-295-4300 • FAX: 516-295-4399

Loading...

Loading...