Page 1

Notes

Table of Contents

1.0 Introduction ..........................................................................................................

1.1 Models

1.2 Unpacking

2.0 Overview ...............................................................................................................

2.1 Controls

2.2 Complete kit

2.3 Optional accessories

3.0 Set-Up Procedures ................................................................................................

3.1 Battery Insertion and Replacement

3.2 Power On and Off

3.3 Reversing the display

3.4 Zero adjustment of the measuring positon

4.0 Taking A Measurement ........................................................................................

4.1 Inserting the process material

4.2 Measuring the process material

4.3 Removing the process material

5.0 Damping Mode .....................................................................................................

5.1 Switching Damping on and off

5.2 Modifying the Damping Factor

5.3 Setting a new Damping Factor

6.0 Memory Modes ....................................................................................................

6.1 Memory Mode selection

03

04

05

07

08

09

– 28 –

7.0 Data Logging ......................................................................................................... 11

7.1 Data logging in Mode “S” (Standard)

7.2 Data logging in Mode “C” (Continuous)

7.3 Data logging in Mode “L” (Limit)

7.4 Data logging in Mode “F” (Fast)

8.0 Recalling the stored tension values ..................................................................... 15

8.1 Recalling stored tension values in Mode “S” (Standard)

8.2 Recalling stored tension values in Mode “C” (Continuous)

8.3 Recalling stored tension values in Mode “L” (Limit)

8.4 Recalling stored tension values in Mode “F” (Fast)

– 1 –

Page 2

9.0 Memory Management .......................................................................................... 22

9.1 Clearing the KXE memory

9.2 Memory function HOLD

10.0 Error Messages ..................................................................................................... 23

11.0 PC Communications (RS-232 Interface) ........................................................... 24

11.1 TENSION INSPECT program

11.2 Windows Terminal Program

12.0 Specifications ......................................................................................................... 25

13.0 Pin Assignments .................................................................................................... 26

13.1 Interface Signals

13.2 Analog Cable

14.0 Warranty ............................................................................................................... 27

14.0 Warranty

The manufacturer warrants to the original purchaser that this product is of merchantable

quality and confirms in kind and quality with the descriptions and specifications thereof.

Product failure or malfunction arising out of any defect in workmanship or material in

the product existing at the time of delivery thereof which manifests itself within one

year from the sale of such product, shall be remedied by repair or replacement of such

product, at the manufacturer’s option, except where unauthorized repair, disassembly,

tampering, abuse or misapplication has taken place, as determined by the manufacturer.

All returns for warranty or non-warranty repairs and/or replacement must be authorized

by the manufacturer, in advance, with all repacking and shipping expenses to the

address below to be borne by the purchaser.

THE FOREGOING WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO, THE

WARRANTY OF MERCHANTABILITY AND FITNESS FOR ANY PARTICULAR

PURPOSE OR APPLICATION. ELECTROMATIC SHALL NOT BE RESPONSIBLE

NOR LIABLE FOR ANY CONSEQUENTIAL DAMAGE, OF ANY KIND OR

NATURE, RESULTING FROM THE USE OF SUPPLIED EQUIPMENT, WHETHER

SUCH DAMAGE OCCURS OR IS DISCOVERED BEFORE, UPON OR AFTER

REPLACEMENT OR REPAIR, AND WHETHER OR NOT SUCH DAMAGE IS

CAUSED BY MANUFACTURER’S OR SUPPLIER’S NEGLIGENCE WITHIN ONE

YEAR FROM INVOICE DATE.

Some State jurisdictions or States do not allow the exclusion or limitation of incidental

or consequential damages, so the above limitation may not apply to you. The duration

of any implied warranty, including, without limitation, fitness for any particular

purpose and merchantability with respect to this product, islimited to the duration of

the foregoing warranty. Some states do not allow limitations on how long an implied

warranty lasts but, not withstanding, this warranty, in the absence of such limitations,

shall extend for one year from the date of invoice.

Important Operating Notes

To avoid damage, do not move the center roller by hand.

Tensions that exceed the tension range of the instrument by more

than 100% may cause permanent damage to the measuring spring

and must be avoided under any circumstances.

The device must not be operated in potentially explosive areas and

must not come into contact with aggressive substances

– 2 –

Every precaution has been taken in the preparation of this manual. The manufacturer, assumes no responsibility for errors

or omissions. Neither is any liability assumed for damages resulting from the use of information contained herein. Any

brand or product names mentioned herein are used for identification purposes only, and are trademarks or registered

trademarks of their respective holders.

– 27 –

Page 3

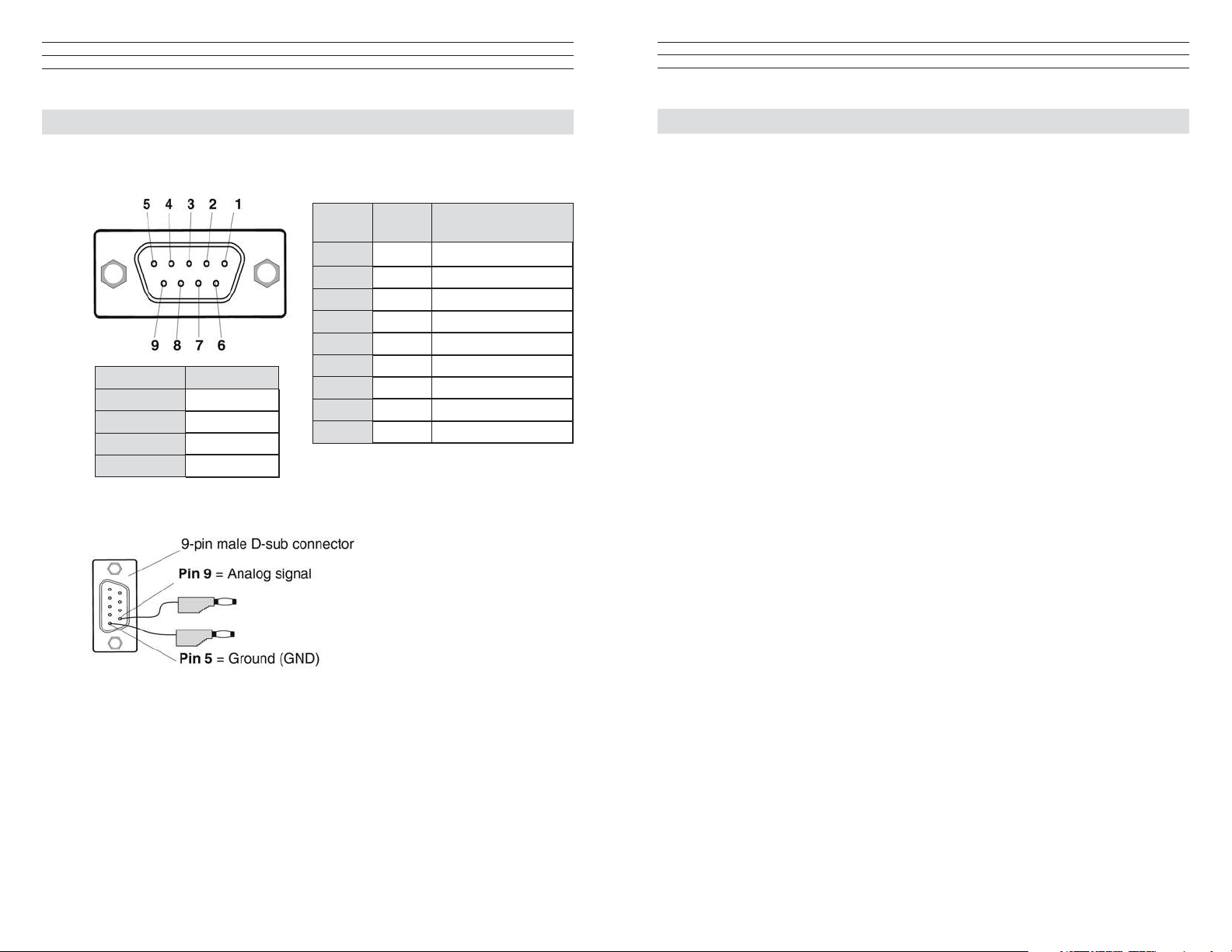

13.0 Pin Assignments

13.1 Pin Assignment and Signals of the Interface (9-Pin D-Sub Connector)

Pin

Number

Signal RS-232-C

Data Bit Bit

Stop Bit 1 Bit

Parity None

Baud Rate 19200

13.2 Pin Assignment of the Analog Cable (Option ETX-CA)

Signal Description

1 Not Assigned

2 TXD 1 Bit

3 RXD None

4 Not Assigned

5 GND Ground

6 Not Assigned

7 RTS READY TO SEND

8 Not Assigned

9 2 V DC Analog Signal

1.0 Introduction

The KXE Warp Tension Meter is designed to measure tensions during warping and

weaving. The unique sensor configuration provided two 25 mm wide cylindrical roller

for the capture of two groups of yarns, one on each side of the sensor for measurement.

Therefore the sensor will be measuring 50 mm of ends while the process is running.

The electronic indicator provides for measurement and storage of the critical high and

low peaks that will be measuring in the weaving operation. These peaks can them be

analyzed and used for process evaluation. Stored data can be transferred to a PC and

analyzed using the FREE Tension Inspect software.

1.1 Models

KXE-20 0.5 – 20.0 daN measuring range.

KXE-50 0.5 – 50.0 daN measuring range.

1.2 Unpacking

Unpack the tension meter and inspect it for any shipping damage. Notices of defect

mustbe filed immediately, in writing, at the latest within 10 days on receipt of the goods.

– 26 –

– 3 –

Page 4

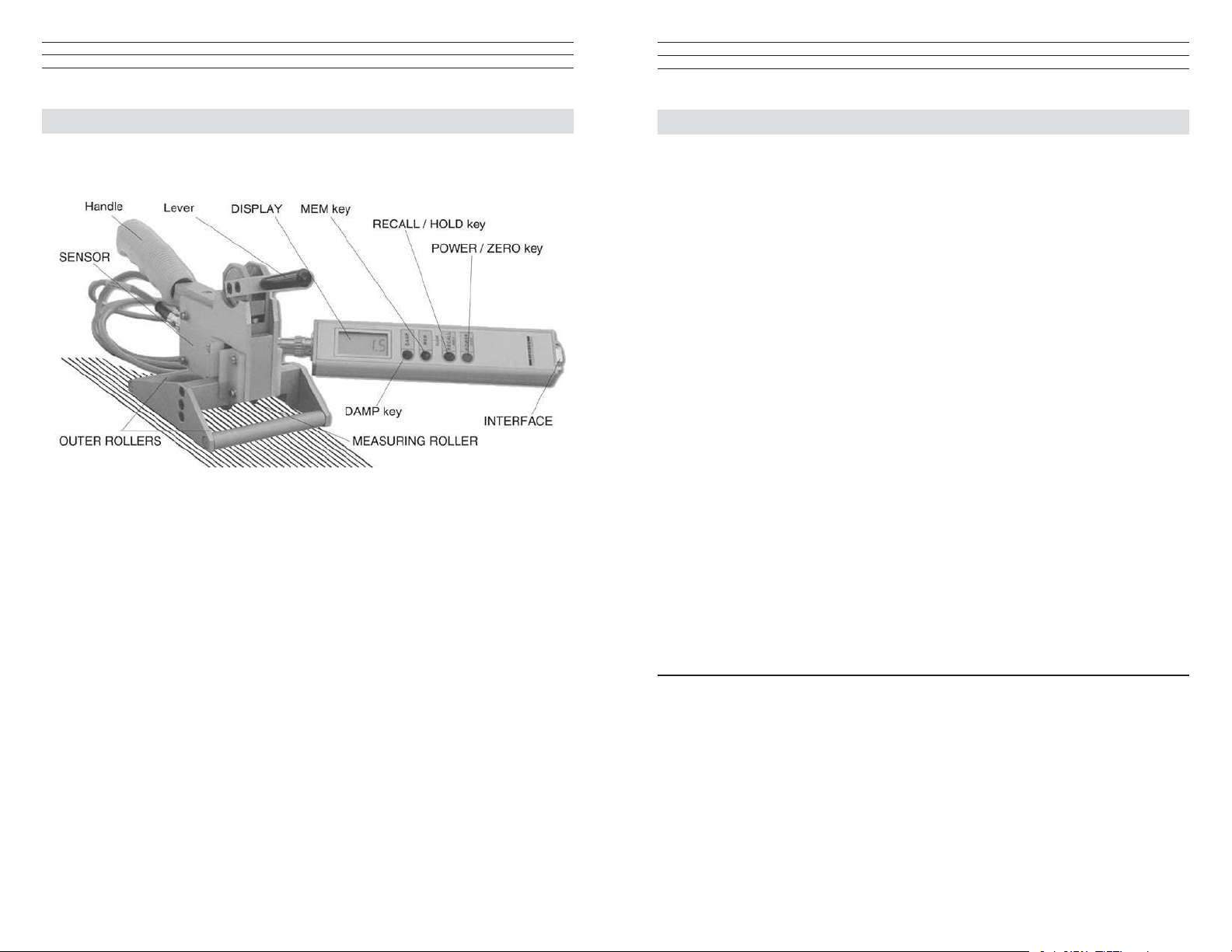

2.0 Overview

12.0 Specifications

2.1 Controls

2.2 Complete kit

• XLETensionMeter.

•9voltbattery.

•Digitalconnectingcable.PartnumberETC-CC.

•TENSIONINSPECTsoftwareforviewingandstoringmeasureddataonaPC,

requires Win 96 or higher. Part number ETC-P2.

•Operatingmanual.

•Carryingcase.

2.3 Optional accesories

Display Unit Calibration According to factory procedure

Units of Measure daN

Accuracy ± 1% FS* ± 1 digit (typically ± 0.5% FS*)

Overrange 10% FS*, without accuracy guarantee

Overload Protection 150% FS*

Measuring Principle Strain gauge bridge

Signal Processing Digital 16 bit A/D converter

Damping Adjustable electronically (averaging)

Measuring Frequency Approx. 5 kHz internally

Display Update Rate 2x per second

Display 4-digit LCD, height of digit 11 mm

Memory Average, last value, MAX, MIN, MAX PEAK, MIN PEAK

Memory Modes 3 - for up to 4000 readings

Temperature Coefficient Gain: less than ± 0.01% FS*/°C

Analog Output Signal 0 - 2 V DC (linearized) RLoad > 1 kΩ ± approx.1%

Converter Frequency 100 Hz

Digital Output Signal RS232 (9600, 8, N, 1) (2 readings per sec.)

(with Tension Inspect > 50 readings/sec possible)

Temperature Range 10 - 45 ° C

Air Humidity 85% RH, max.

Auto Power Off Automatically after approx. 3 min. of non-use

Power Supply 9 V E block

9 V lithium for about 80 hours of continuous use

Housing Material Aluminium profile with plastic outer casing (PVC)

Housing Dimensions 230 mm x 45 mm x 48 mm (L x W x H)

Weight, net

(gross) Approx. 370 g / 1050 g *FS = Full Scale

ETX-CA Connecting cable for analog signal.

ET-AKKU Rechargeable 9 V battery (NiCd).

ET-AC-115 Battery charger for 115 V AC.

ET-AC-230 Battery charger for 230 V AC.

– 4 –

Sensor:

Measuring Rollers 2x 22 mm ball bearing rollers

Width of Outer Rollers 100 mm (ball bearing rollers)

Total Width of Rollers 50 mm

Reference Frame Height

Adjustment 24 mm

Material Anodized aluminium

Dimension 165 x110 x 140 mm (L x W x H)

Weight, net

(gross) 1050 g (1500 g)

– 25 –

Page 5

.6

Peak Mem Damp g cN

Peak Mem Damp g cN

8.8.8.8

11.0 PC Communication (RS-232-C Interface)

11.1 The TENSION INSPECT Program

The TensionInspect software from Electromatic is described in a separate user manual.

11.2 WINDOWS Terminal Program

The measured values and the memory contents can be transmitted over the RS232

interface to a personal computer. You can connect the computer to the INTERFACE of

the KXE by using the ETX-CC special cable which is available as an accessory.

The pin assignment of the INTERFACE is described in Section 13.

Requirements: A communication program, such as Termina or HyperTerminal

(provided on MS Windows Version 3.0 or later), must be installed and configured on

the computer.

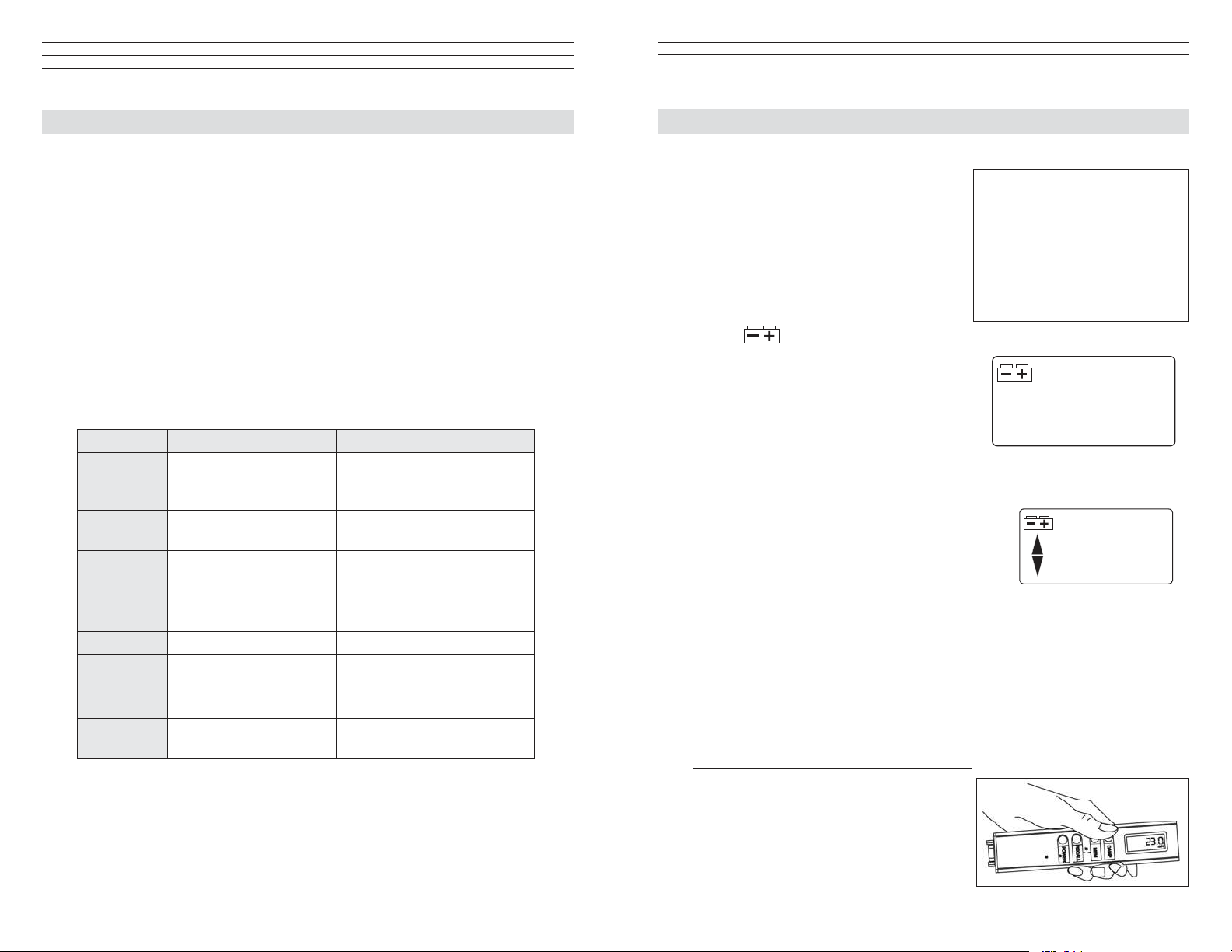

3.0 Set-Up Procedures

3.1 Battery insertion and replacement

Before the first use of your tension meter, you

need to insert the battery

1. Open the battery compatment on the rear

side of the tension meter and insert a

9V battery (E Block), making sure that the

polarity of the battery matches the polarity

marked on the battery compartment. Close

the battery compartment.

2. If the

display, the battery is low and must

be replaced immediately. Operating the

tension meter with a low battery may cause

measurement errors.

symbol is shown on the

Photo Battery

Compartment

ASCII Code Function Description

D Continuous transmission Continuous transmission of

the readings. press any key to

stop transmission.

d Send Transmit current reading to

PC once.

m Save Start logging of measuring

date. Stop data logging.

r Output Output the memory contents

to the PC.

c Clear memory Delete the memory content.

a Damping ON/OFF Switch damping on or off.

z Zero Carry ot zero adjustment of

the instrument

u Toggle unit of measure Switch from g to cN, and vice

versa

NOTE: If the instrument will not be used for

an extended period of time, the battery should

be removed.

3.2 Power On/Off

Power On: Press the POWER/ZERO key until all

symbols are shown on the display. When you release

the key, the display momentarily shows the tension

range and the shoftware version, e.g. E 1.0, followed

by random valuse or “0.”

Power Off: Press the POWER/ZERO key for 5 seconds.

Auto Power Off: The tension meter switches off after 3 minutes of non use.

3.3 Reversing the display

When you shift the tension meter from the right to the left hand, you can rotate the

readings on the DISPLAY by 180° to make them easier to read.

Measuring with the display unit in the left hand:

1. Switch off the tension meter switched off as

described in Section 3.

2. Press and hold the DAMP and POWER

keys until the display shows the readings

the other way around.

– 24 –

– 5 –

Page 6

Measuring with the display unit in the right hand (default position):

1. Tension meter switched off as described in

Chapter 3.2

2. Press and hold the DAMP and POWER

keys until the display shows the readings

in the default position.

NOTE: The selected display orientation

remains stored in the KXE memory even after

the instrument is switched off.

3.4 Zero adjustment of the measuring position.

Before starting measurement you need to carry out zero adjustment,

as described below, each time the tension meter is switched on. This

procedure is necessary to compensate for the weight of the measuring

roller in the measuring position. The zero adjustment for the new

measuring path only remains effective until the instrument is switched

off. Zero adjustment must be repeated whenever the material path is

changed or the tension meter does not display “0.”

NOTE: The process material must not yet be inserted into the tension

meter!

To carry out a zero adjustment:

1. Holding the SENSOR at the HANDLE, place it in the desired measuring position.

Be careful to hold the instrument absolutely steady.

10.0 Error Messages

EEE

cN

The DISPLAY shows EEE. The upper limit of the tension range was

exceeded by more than 10%. Reduce the line tension.

OR

AUTO ZERO is no longer possible. Recalibrate the instrument

following the directions in Section 3.4.

-EEE

cN

The DISPLAY shows -E.E. The lower limit of the tension range was

fallen below by more than 10%. Properly insert the process material.

OR

AUTO ZERO is no longer possible. Recalibrate the instrument

following the directions in Section 3.4.

6

cN

The DISPLAY shows the battery symbol. The battery is low and must

be replaced immediately. Operating the tension meter with a low

battery may cause measurement errors.

2. Press the POWER key.

The display momentarily shows

The KXE is now adjusted for the new material path and is ready to measure.

0000

– 6 –

and then switches to

0

.

– 23 –

Page 7

9.0 Memory Management

9.1 Clearing the KXE Memory

If values are stored in the KXE memory, the DISPLAY shows e.g.

with the MEM indicator.

To clear the memory:

1. Simultaneously press the MEM and RECALL keys.

3

Mem

4.0 Taking A Measurement

The DISPLAY shows e.g.

deleted.

9.2 Memory Function HOLD

When the tension meter memory is empty, you can retain the last reading on the

DISPLAY by using the memory function HOLD.

To retain the last reading:

1. Press the RECALL / HOLD key once for about 1 second.

3

; all values stored in the memory have been

The DISPLAY shows the last reading

To switch back to measuring mode:

1. Press the RECALL / HOLD key once for about 1 second. The tension meter

switches back to measuring mode.

2:3.3

and the “:” colon symbol.

4.1 Inserting the process material

1. Turn on the power, then perform as zero adjustment as described in Section 3.4.

2. Push the LEVER in the direction of the arrow to lift the REFERENCE FRAME

and the OUTER ROLLERS.

3. Insert the MEASURING ROLLER Into the warp.

4 Push the LEVER back into the original position to move the REFERENCE

FRAME and the OUTER ROLLERS down again. It is important to assure that

the warp passes smoothly between the MEASURING ROLLERS and the OUTER

ROLLERS.

4.2 Measuring the process material:

The display now shows the measured tension values. Error messages which might be

displayed are described in Section 10.0

– 22 –

4.3 Removing the process material:

1. Push the LEVER in the direction of the arrow to lift the REFERENCE FRAME

and the OUTER ROLLERS.

2. Remove the MEASURING ROLLER from the warp.

– 7 –

Page 8

5.0 Damping Mode

The KXE is equipped with an electronic damping which ensures steady readings when

tension fluctuates. This is achieved by averaging the measured values at the set update

rate.

NOTE: Before switching on the damping mode, it is recommended that you measure

the first values without damping enabled.

5.1 To switch damping on and off:

1. Insert process material and take a mesurement as directed in Section 4.0

3. The DISPLAY blinks, showing

measuring period (POS: 1) and the

4. Press the RECALL key. The DISPLAY blinks, showing

last value (LAST) of the measuring period.

5. Press the RECALL key. The DISPLAY blinks, showing

maximum value (MAX) of the measuring period and the

22

symbol.

the average value (AVG) of the first

23

24

symbol.

the

the

2. Press the DAMP key. The display shows the set damping factor.

3. Release the DAMP key.

The display shows DAMP below the currently measured value.

3. To switch off damping, press the DAMP key again.

The display shows only the currently measured value.

5.2 Modifying the Dampling Factor

The tension meter is factory preset to a damping factor of 12. The tension values are

averaged for the display in the following way:

12 old values + 4 new values

16

The damping factor can be modified in 15 steps from 01 = low damping:

1 old value + 15 new values

16

to 15 = high damping:

15 old values + 1 new value

16

0000

0000

Damp

Peak

21

symbol.

26

Peak

showing the

6. Press the RECALL key. The DISPLAY blinks, showing

minimum value (MIN) of the measuring period and the

7. Press the RECALL key. The DISPLAY blinks, showing

maximum peak value (PEAK MAX) of the measuring period, the PEAK indicator

and the

8. Press the RECALL key. The DISPLAY blinks,

minimum peak value (PEAK MIN) of the measuring period, the PEAK indicator

and the

9. Press the RECALL key. The measured values no. 1 — 10 of the first measuring

period can be recalled.

10. Press the RECALL key. The next measuring period (POS: 2) is shown on the

DISPLAY and the sequence is repeated, starting with the average value (AVG).

symbol.

19

symbol.

the

the

– 8 –

– 21 –

Page 9

26

7. Press the RECALL key. The DISPLAY blinks, showing

Peak

maximum peak value (PEAK MAX) of the measuring period, the PEAK indicator

and the

8. Press the RECALL key. The DISPLAY blinks,

symbol

19

Peak

showing the

minimum peak value (PEAK MIN) of the measuring period, the PEAK indicator

and the

symbol.

9. Press the RECALL key. The measured values no. 1 — 10 of the first measuring

period can be recalled.

10. Press the RECALL key. The next measuring period (POS: 2) is shown on the

DISPLAY and the sequence is repeated, starting with the average value (AVG).

8.4 Recalling the Stored Tension Values in Mode “F“ FAST

1. Tension meter switched on as described in Chapter 3.3.1.

2. Press the RECALL key.

NOTE: You can end recall any time by pressing the POWER key.

Memory Mode CONTINUOUS

Pos: 1 Pos: 12 Pos: 3 Pos:

AVG: 22.0 AVG: 12.0 AVG: 12.0 AVG:

Last: 23.0 Last: 22.1 Last: 22.1 Last:

MAX: 24.0 MAX: 22.1 MAX: 22.1 MAX:

MIN: 21.0 MIN: 5.4 MIN: 5.4 MIN:

PEAK

PEAK

: 26.0 PEAK

MAX

: 19.0 PEAK

MIN

10.8 14.2 14.1

10.0 19.4 11.2

7.3 22.9 8.9

6.1 17.3 10.2

n n n

: 28.1 PEAK

MAX

: 1.8 PEAK

MIN

: 28.1 PEAK

MAX

: 1.8 PEAK

MIN

MAX

MIN

the

:

:

12.0

22.1

22.1

5.4

28.1

1.8

15.4

18.3

17.5

7.8

5.3 Setting a new Damping Factor

1. Press and hold the DAMP key. The display shows the set damping factor.

2. You can now increase the damping factor by pressing the MEM key and decrease it

by pressing the RECALL key.

3 Once the new factor appears on the display, release the DAMP key. The tension

meter switches back to measuring mode.

NOTE: The selected damping factor remains stored in the KXE memory even after the

instrument is switched off.

6.0 Memory Modes

The tension meter features a data

logger with a memory capacity for

up to 4000 readings, with which

you can store different measuring

periods at one or more machine

positions. The readings are saved 2x

per second, synchronously with the

display update rate, in all memory

modes except the “F” mode in which

they are saved 100x per second. All

saved readings and statistics can be

4

shown on the display or transmitted

to a PC (e.g. for further processing in Excel). The memory can be allocated to different

measuring periods, depending on the memory mode.

NOTE: The selected memory mode remains stored in the KXE memory even after the

instrument is switched off.

Memory mode “S” STANDARD (default)

The following values of a measuring period are calculated and saved at a rate of 2

readings per second:

Average value,

Last value,

Maximum value (MAX),

Minimum value (MIN),

Minimum peak value (MIN PEAK)

n

Maximum peak value (MAX PEAK)

Individual readings are not saved. You can save up to 255 measuring periods.

Memory Mode S C L F

Meas. periods,

max.

Readings, max.

Max. no. of

readings per

position

Statistics

Save Readings

255 255 255 255

– 4000 4000 4000

– Any 10 Any

Yes Yes Yes Yes

– Yes Yes Yes

– 20 –

– 9 –

Page 10

Memory mode “C” CONTINUOUS:

The following values of a measuring

period are calculated and all readings are additionally saved at a rate of 2 readings per

second:

Average value,

Last value,

Maximum value (MAX),

Minimum value (MIN),

Minimum peak value (MIN PEAK)

Maximum peak value (MAX PEAK)

You can save up to 4000 readings, split up into up to 255 measuring periods.

Memory mode “L” LIMIT:

The following values of a measuring period are calculated and 10 readings are

additionally saved at a rate of 2 readings per second:

Average value,

Last value,

Maximum value (MAX),

Minimum value (MIN),

Minimum peak value (MIN PEAK)

Maximum peak value (MAX PEAK)

You can save up to 255 measuring periods with 10 readings each.

8.3 Recalling the Stored Tension Values in Mode “L“ LIMIT

1. Tension meter switched on as described in Chapter 3.2.

2. Press the RECALL key.

NOTE: You can end recall any time by pressing the POWER key.

Memory Mode CONTINUOUS

Pos: 1 Pos: 12 Pos: 3 Pos:

AVG: 22.0 AVG: 12.0 AVG: 12.0 AVG:

Last: 23.0 Last: 22.1 Last: 22.1 Last:

MAX: 24.0 MAX: 22.1 MAX: 22.1 MAX:

MIN: 21.0 MIN: 5.4 MIN: 5.4 MIN:

PEAK

PEAK

: 26.0 PEAK

MAX

: 19.0 PEAK

MIN

10.8 14.2 14.1

10.0 19.4 11.2

7.3 22.9 8.9

6.1 17.3 10.2

n 10 10

: 28.1 PEAK

MAX

: 1.8 PEAK

MIN

: 28.1 PEAK

MAX

: 1.8 PEAK

MIN

MAX

MIN

4

12.0

22.1

22.1

5.4

:

28.1

:

1.8

15.4

18.3

17.5

7.8

10

Memory mode “F” FAST:

The following values of a measuring period are calculated and all readings are

additionally saved at a rate of 100 readings per second:

Average value,

Last value,

Maximum value (MAX),

Minimum value (MIN),

Minimum peak value (MIN PEAK)

Maximum peak value (MAX PEAK)

You can save up to 4000 readings, split up into up to 255 measuring periods.

– 10 –

3. The DISPLAY blinks, showing

measuring period (POS: 1) and the

22

symbol.

the average value (AVG) of the first

4. Press the RECALL key. The DISPLAY blinks, showing

last value (LAST) of the measuring period.

5. Press the RECALL key. The DISPLAY blinks, showing

maximum value (MAX) of the measuring period and the

6. Press the RECALL key. The DISPLAY blinks, showing

minimum value (MIN) of the measuring period and the

– 19 –

23

24

symbol.

21

symbol.

the

the

the

Page 11

Peak

24

symbol.

21

symbol.

26

Peak

showing the

the

the

the

5. Press the RECALL key. The DISPLAY blinks, showing

maximum value (MAX) of the measuring period and the

6. Press the RECALL key. The DISPLAY blinks, showing

minimum value (MIN) of the measuring period and the

7. Press the RECALL key. The DISPLAY blinks, showing

maximum peak value (PEAK MAX) of the measuring period, the PEAK indicator

and the

8. Press the RECALL key. The DISPLAY blinks,

minimum peak value (PEAK MIN) of the measuring period, the PEAK indicator

and the

9. Press the RECALL key. The measured values no. 1 — n of the first measuring

period can be recalled.

10. Press the RECALL key. The next measuring period (POS: 2) is shown on the

DISPLAY and the sequence is repeated, starting with the average value (AVG).

symbol

19

symbol.

6.1 Memory Mode Selection

1. Turn on the tension meter and clear the memory by simultaneously pressing the

MEM and RECALL keys.

2 Press and hold the MEM key. The display shows S

DAMP or RECALL key to change the memory mode.

MEMORY MODE “S” STANDARD (default)

If the display shows S. The STANDARD memory mode is set.

MEMORY MODE “C” CONTINUOUS

If the DISPLAY shows C, the CONTINUOUS memory mode is set.

MEMORY MODE “L” LIMIT

If the DISPLAY shows L , the LIMIT memory mode is set.

MEMORY MODE “F” FAST

If the DISPLAY shows F , the FAST memory mode is set.

When you have selected the desired memory mode, you can release the MEM key. The

selected memory mode is now active and the tension meter switches back to measuring

mode.

L

F

C

S

S

. Press the

– 18 –

NOTE: The selected memory mode remains stored in the KXE memory even after the

instrument is turned off.

7.0 Data Logging

7.1 Data Logging in Mode “S” Standard

1. Turn on the tension meter and select the “S” Standard Memory Mode as described

in Section 6.1.

2. Insert the process material as described in Section 4.1.

3. To save the first measuring period, press and hold the MEM key

until the display shows the memory mode “S” and the current

memory number .

4. Release the MEM key.

The tension meter starts logging the data.

– 11 –

S1

Page 12

3

Mem

While the tension data are stored, the MEM indicator blinks

display and the currently measured value is displayed

To stop data logging:

When you want to end the measuring period, press the MEM key once again. The

statistical values are calculated from the logged tension data and stored in the following

order:

on the

19

8. Press the RECALL key. The DISPLAY blinks,

minimum peak value (PEAK MIN) of the measuring period, the PEAK indicator

and the

9. Press the RECALL key. The next measuring period (POS: 2) is shown on the

DISPLAY, starting at the beginning of the sequence with the average value (AVG).

symbol.

Peak

showing the

Average value,

Last value,

Maximum value (MAX),

Minimum value (MIN),

Minimum peak value (MIN PEAK),

Maximum peak value (MAX PEAK).

3

The MEM

tension meter shows the current reading and changes back to measuring mode.

To save the next measuring period:

1. Press the MEM key again. The display shows the memory mode “S” and the next

memory number

7.2 Data Logging in Mode “C” Continuous

1. Turn on the tension meter and select the “C” Continuous Memory Mode as

described in Section 6.1.

2. Insert the process material as described in Section 4.1.

3. To save the first measuring period, press and hold the MEM key

until the display shows the memory mode “C” and the current

memory number .

Mem

indicator stops blinking and remains on the display. The

S2

. You can save up to 255 measuring periods.

C1

8.2 Recalling the Stored Tension Values in Mode “C“ CONTINUOUS

1. Tension meter switched on as described in Chapter 3.2.

2. Press the RECALL key.

NOTE: You can end recall any time by pressing the POWER key.

Memory Mode CONTINUOUS

Pos: 1 Pos: 12 Pos: 3 Pos:

AVG: 22.0 AVG: 12.0 AVG: 12.0 AVG:

Last: 23.0 Last: 22.1 Last: 22.1 Last:

MAX: 24.0 MAX: 22.1 MAX: 22.1 MAX:

MIN: 21.0 MIN: 5.4 MIN: 5.4 MIN:

PEAK

PEAK

: 26.0 PEAK

MAX

: 19.0 PEAK

MIN

10.8 14.2 14.1

10.0 19.4 11.2

7.3 22.9 8.9

6.1 17.3 10.2

n n n

: 28.1 PEAK

MAX

: 1.8 PEAK

MIN

: 28.1 PEAK

MAX

: 1.8 PEAK

MIN

MAX

MIN

:

:

4

12.0

22.1

22.1

5.4

28.1

1.8

15.4

18.3

17.5

7.8

n

4. Release the MEM key. The tension meter starts logging the data.

While the tension data are stored, the MEM indicator blinks

display and the currently measured value is displayed.

– 12 –

3

Mem

on the

3. The DISPLAY blinks, showing

measuring period (POS: 1) and the

4. Press the RECALL key. The DISPLAY blinks, showing

last value (LAST) of the measuring period.

22

symbol.

– 17 –

the average value (AVG) of the first

23

the

Page 13

8.0 Recalling the stored tension values

Using the TENSION INSPECT software included with your tension meter, you can

easily and accurately evaluate the stored tension values and export them to an Excel

sheet.

8.1 Recalling the Stored Tension Values in Mode “S“ STANDARD

1. Tension meter switched on as described in Chapter 3.2.

2. Press the RECALL key.

NOTE: You can end recall any time by pressing the POWER key.

Memory Mode STANDARD

Pos: 1 Pos: 12 Pos: 3 Pos:

AVG: 22.0 AVG: 12.0 AVG: 12.0 AVG:

Last: 23.0 Last: 22.1 Last: 22.1 Last:

MAX: 24.0 MAX: 22.1 MAX: 22.1 MAX:

MIN: 21.0 MIN: 5.4 MIN: 5.4 MIN:

PEAK

PEAK

: 26.0 PEAK

MAX

: 19.0 PEAK

MIN

: 28.1 PEAK

MAX

: 1.8 PEAK

MIN

: 28.1 PEAK

MAX

: 1.8 PEAK

MIN

MAX

MIN

To stop data logging:

When you want to end the measuring period, press the MEM key once again. The

statistical values are calculated from the logged tension data and stored in the following

order:

Average value,

Last value,

Maximum value (MAX),

Minimum value (MIN),

Minimum peak value (MIN PEAK),

Maximum peak value (MAX PEAK).

Tension Value - 1 Tension Value - 2 -

4

12.0

22.1

22.1

5.4

:

28.1

:

1.8

To save the next measuring period:

Tension Value - N - (up to 4000 tension values in up to 255 measuring periods)

3

The MEM

tension meter shows the current reading and changes back to measuring mode.

1. Press the MEM key again. The display shows the memory mode “C” and the next

Mem

indicator stops blinking and remains on the display. The

3. The DISPLAY blinks, showing

measuring period (POS: 1) and the

4. Press the RECALL key. The DISPLAY blinks, showing

last value (LAST) of the measuring period.

5. Press the RECALL key. The DISPLAY blinks, showing

maximum value (MAX) of the measuring period and the

6. Press the RECALL key. The DISPLAY blinks, showing

minimum value (MIN) of the measuring period and the

7. Press the RECALL key. The DISPLAY blinks, showing

maximum peak value (PEAK MAX) of the measuring period, the PEAK indicator

and the

symbol

22

symbol.

– 16 –

the average value (AVG) of the first

23

24

symbol.

21

symbol.

26

Peak

the

the

the

the

memory number

maximum of 4000 readings.

7.3 Data Logging in Mode “L” Limit

1. Turn on the tension meter and select the “L” Limit Memory Mode as

described in Section 6.1.

2. Insert the process material as described in Section 4.1.

3. To save the first measuring period, press and hold the MEM key

until the display shows the memory mode “L” and the current

memory number .

4. Release the MEM key. The tension meter starts logging the data.

While the tension data are stored, the MEM indicator blinks

display and the currently measured value is displayed.

C2

. You can save up to 255 measuring periods with a

3

Mem

– 13 –

L1

on the

Page 14

To stop data logging:

When you want to end the measuring period, press the MEM key once again. The

statistical values are calculated from the logged tension data and stored in the following

order:

Average value,

Last value,

Maximum value (MAX),

Minimum value (MIN),

Minimum peak value (MIN PEAK),

Maximum peak value (MAX PEAK).

Tension Value - 1 Tension Value - 2 -

To stop data logging:

When you want to end the measuring period, press the MEM key once again. The

statistical values are calculated from the logged tension data and stored in the following

order:

Average value,

Last value,

Maximum value (MAX),

Minimum value (MIN),

Minimum peak value (MIN PEAK),

Maximum peak value (MAX PEAK).

Tension Value - 1 Tension Value - 2 -

Tension Value - 10 - (up to 10 tension values in up to 255 measuring periods)

3

The MEM

tension meter shows the current reading and changes back to measuring mode.

To save the next measuring period:

1. Press the MEM key again. The display shows the memory mode “L” and the next

memory number

maximum of 10 readings each.

7.4 Data Logging in Mode “F” Fast

1. Turn on the tension meter and select the “F” Fast Memory Mode as

described in Section 6.1.

2. Insert the process material as described in Section 4.1.

3. To save the first measuring period, press and hold the MEM key

until the display shows the memory mode “L” and the current

memory number .

4. Release the MEM key. The tension meter starts logging data at the rate of 100

readings per second

While the tension data are stored, the MEM indicator blinks

display and the currently measured value is displayed.

Mem

indicator stops blinking and remains on the display. The

L2

. You can save up to 255 measuring periods with a

F1

3

Mem

on the

Tension Value - N - (up to 4000 tension values in up to 255 measuring periods)

3

The MEM

tension meter shows the current reading and changes back to measuring mode.

To save the next measuring period:

1. Press the MEM key again. The display shows the memory mode “F” and the next

memory number

maximum of 4000 readings.

Mem

indicator stops blinking and remains on the display. The

F2

. You can save up to 255 measuring periods with a

8.0 Recalling the stored tension values

Using the TENSION INSPECT software included with your tension meter, you can

easily and accurately evaluate the stored tension values and export them to an Excel

sheet.

8.1 Recalling the Stored Tension Values in Mode “S“ STANDARD

1. Tension meter switched on as described in Chapter 3.2.

2. Press the RECALL key.

NOTE: You can end recall any time by pressing the POWER key.

– 14 –

– 15 –

Page 15

CHECK•LINE

BY ELECTROMATIC

Warp Tension Meter

Model KXE

®

CHECK•LINE

INSTRUMENTS

®

ELECTROMATIC

E Q U I P M E N T C O., I N C.

600 Oakland Ave., Cedarhurst, NY 11516 – USA

TEL:516-295-4300•FAX:516-295-4399

Operating Instructions

Loading...

Loading...