Page 1

2 YEAR WARRANTY (RESTRICTIONS APPLY)

Imada, Inc. warrants its products to the original purchaser to be free from defects

in workmanship and material under normal use and proper maintenance for two

years (one year for adapters, attachments and cables) from original purchase. This

warranty shall not be effective if the product has been subject to overload, shock

load, misuse, negligence,accident or repairs attempted by others than Imada, Inc.

During the warranty period, we will, at our option, either repair or replace

defective products. Please call our customer service department for a return

authorization number and return the defective product to us with freight prepaid.

The foregoing warranty constitutes the SOLE AND EXCLUSIVE WARRANTY, and we

hereby disclaim all other warranties, express, statutory or implied, applicable to the

products and/or software, including but not limited to all implied warranties of

merchantability, fitness, non-infringement, results, accuracy, security and freedom

from computer virus. In no event shall Imada, Inc.and/or its affiliated companies be

liable for any incidental, consequential or punitive damages in connection with the

use of its products and/or software.

Digital Torque Gauge

Specifications subject to change without notice.

Model HTG2

INSTRUCTION MANUAL

Page 2

INTRODUCTION

Model HTG2 is a highly sophisitcated, torque tester which offers

programmable high/low setpoints for go/no go testing. Store up

to 1,000 values into memory, which can be transmitted using

Digimatic or RS-232 formats. Use the Real Time mode to display

torque transients, or the Peak mode to capture the peak torque

achieved during a test. Select measuring units between lbf-in or

ozf, kgf-cm and N-cm.

PRECAUTIONS

HTG2 Torque Tester is a sensitive instrument. The torque sensor

can be damaged regardless of whether the unit is ON or OFF.

Follow these precautions to keep your HTG2 from being damaged.

1. WARNING!! Do not exceed unit’s capacity regardless if power

is on or off.

2. Only use the Imada AC adapter/charger, other brands may cause

serious damage.

3. Accuracy may be affected if unit is exposed to high humidity,

dust or extreme shock.

4. Do not disassemble unit. Disassembly voids warranty.

5. Recommended re-calibration cycle is one (1) year.

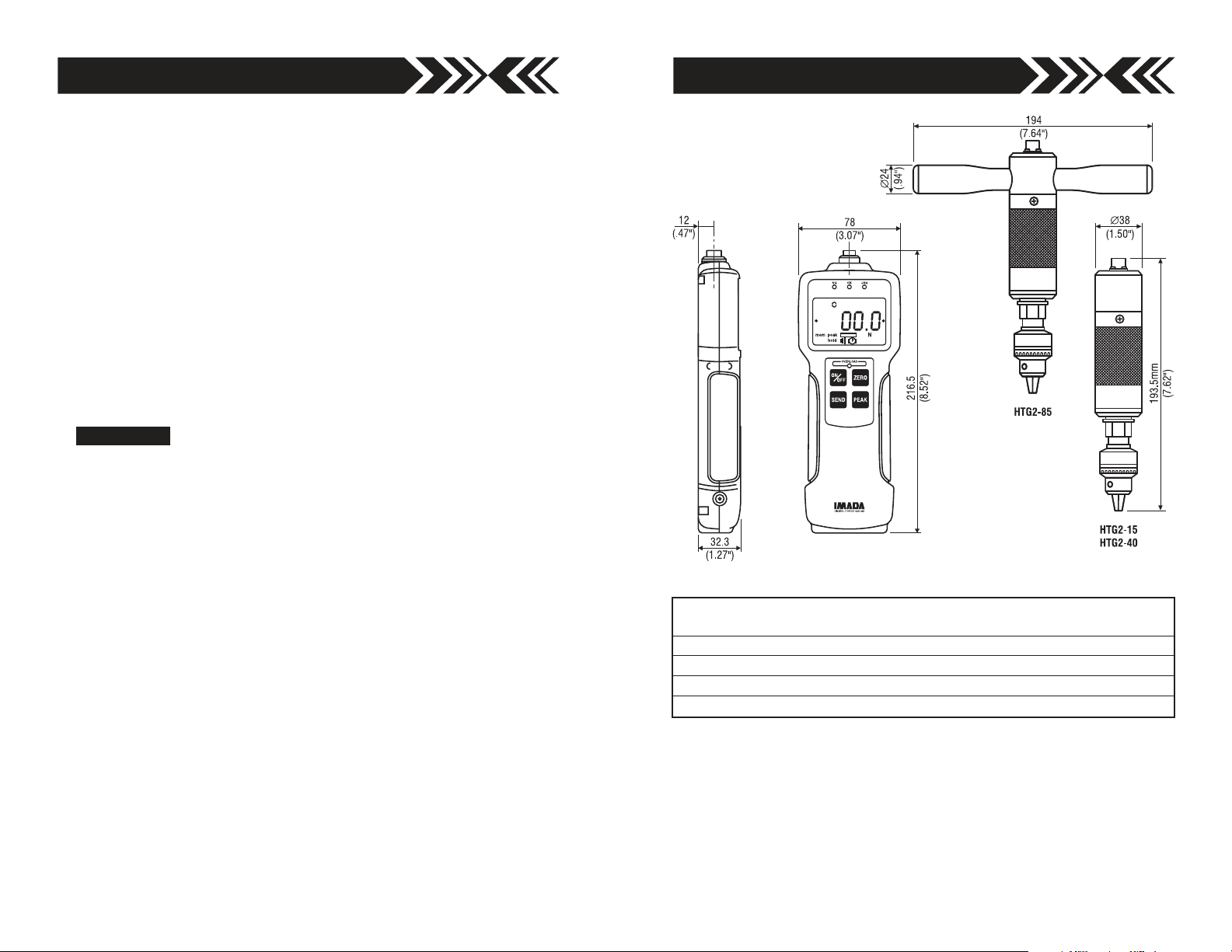

DIMENSIONS

Model Capacity (Resolution)

lbf-in kgf-cm N-cm

HTG2-4 70.00 (0.01 ozf-in) 5.000 (0.001 kgf-cm) 50.00 (0.01 N-cm)

HTG2-15 15.00 (0.01 lbf-in) 20.00 (0.01 kgf-cm) 200.0 (0.1 N-cm)

HTG2-40 40.00 (0.01 lbf-in) 50.00 (0.01 kgf-cm) 500.0 (0.1 N-cm)

HTG2-85 85.0 (0.1 lbf-in) 100.0 (0.1 kgf-cm) 1000 (1 N-cm)

page 15page 2

Page 3

Imada HTG2 Series Specifications

Accuracy ± 0.5% F.S. ± 1 LSD

Selectable Units ozf-in or lbf-in, kgf-cm, and N-cm

Overload Capacity 200% of F.S. Overload indicator flashes beyond 110% of F.S.

Power Rechargeable Ni-MH battery pack or Imada AD120/230 adapter

Battery Indicator Icon flashes when battery is low

Battery Life approx. 8 hours (recharge time approx. 10 hours)

Memory Non-volatile, recall up to 1000 data

Setpoints Programmable high/low setpoints with color-coded LED

indicators and output signal

Outputs RS-232C, Digimatic and ± 2 VDC analog output

Auto Power Off 5, 10, 30, 60 minutes or OFF (selectable)

Operating Temp. 32° to 100°F (0° to 40°C)

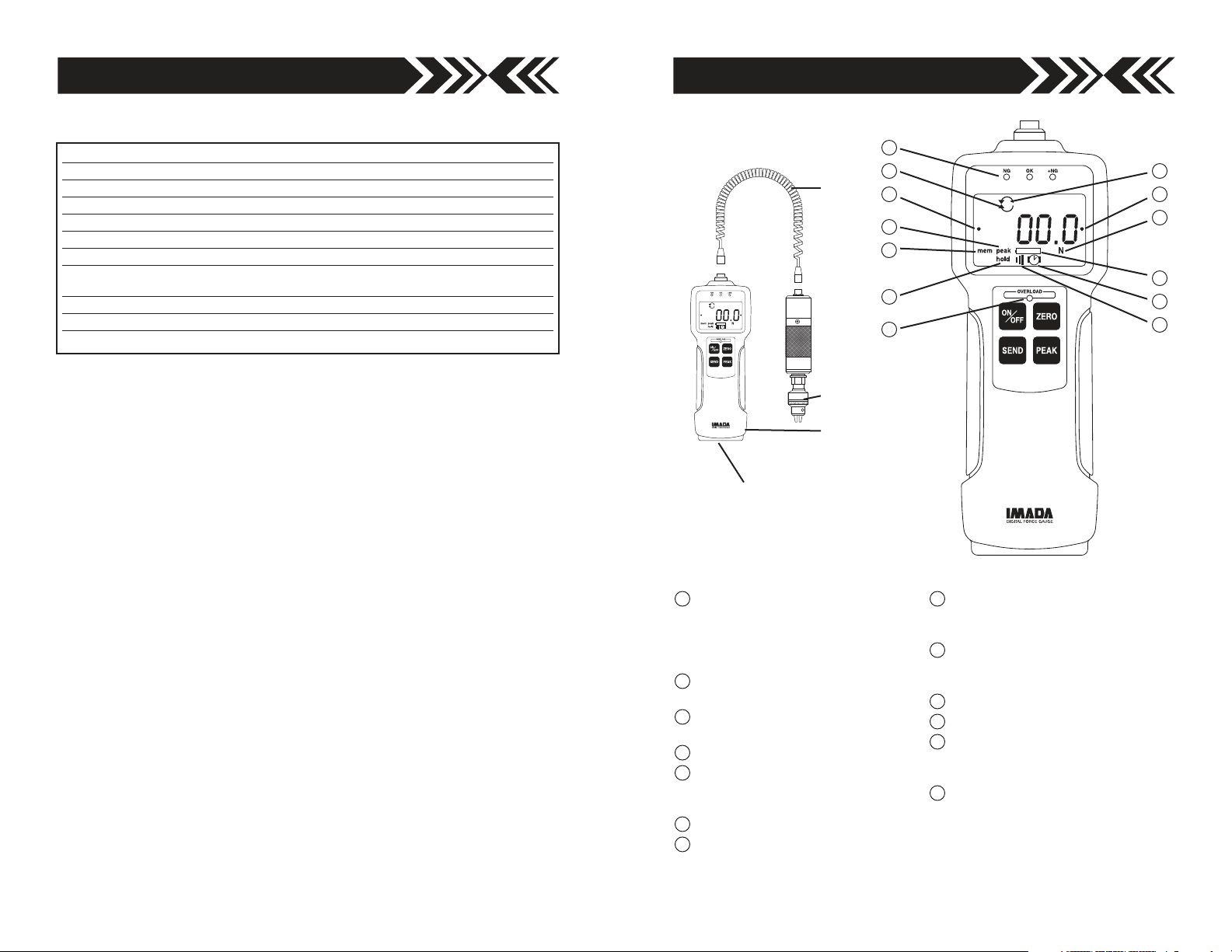

COMMUNICATION PORT

RS-232, DIGIMATIC &

±2VDC ANALOG

CABLE

MEASURING

CHUCK

DISPLAY

UNIT

1

2 3

8

6

9

13

45

12

7

11

10

1

Programmable Setpoint LED’s

When high-low setpoints are set,

LED indicates below (-NG), within

(OK), or above set point value

(+NG).

2

CW icon

Indicates CW measurement.

3

CCW icon

Indicates CCW measurement.

4

Reverse +/– values

5

Auto Zero Reset icon

Programmable auto zero reset

duration

6

Auto Memory - Peak Reset icon

7

Battery icon

Flashes when Ni-MH cells need

charging.

8

PEAK icon

Displays continuously when peak

function is active.

9

HOLD icon

Displays when external hold signal

is active or SEND button is pressed.

10

Alarm Icon

11

Auto Power Off icon

12

Units icon

Displays selected measuring units.

(ozf-in, lbf-in, kgf-cm, N-cm)

13

Overload Indicator

Flashes at 110% of rated capacity.

page 3page 14

Page 4

NG OK +NG

OVER

LO

A

D

ZERO

F

NG OK +NG

A

D

NG OK +NG

A

D

PREPARATION

Connect the coiled cable to both the measuring chuck and display

unit by rotating the round cable connector to find the matching

groove, then pushing in until positive connection is made.

To disconnect, first slide the ribbed cover of the connector back,

then pull out the connector (DO NOT ROTATE THE CONNECTOR).

TURN CONNECTOR TO FIND

THE GROOVE

PUSH IN UNTIL IT MAKES A POSITIVE

CONNECTION

SLIDE THE RIBBED COVER OF THE

CONNECTOR BACK , THEN PULL

OUT THE CONNECTOR

RIBBED COVER

OPERATION

Selecting Units

Press to turn on the gauge. The LCD display briefly shows the

capacity of the gauge and then zero with a measuring unit (facto-

ry setup is lbf-in or ozf-in). If you want to change to other units:

1. Turn off the gauge.

2. Press again while holding to enter Power-Off program-

Power-Off programming (clear data from memory)

Turn off the gauge. Press again while holding to enter

memory mode.

Memory clear

Memory location and value cycle. Press PEAK or ZERO to increase or decrease memory location (and corresponding value).

Single Memory Clear A memory location with a dot at both ends is the last stored data

and the only one that can be erased. Press SEND to erase, ErASEd is displayed. If you

attempt to erase other locations Error is displayed. Press ON/OFF to exit.

All Memory Clear While a memory value or location is displayed, press SEND for 3 seconds, all data is erased and ErASEd is displayed, then – – – – –. Press ON/OFF to exit.

Power-Off programming

Turn off the gauge. Press again while holding to enter

Power-Off programming (CF9 flashes with solid m0). Press or

to cycle CF9m0, CF9m1, CF9m2, CF9m3(USB models

only) and CF9End. Press to select a function.

CF9 m0 Units selection

Press PEAK or ZERO to cycle; ‘U-01’: kgf-cm, ‘U-02’: N-cm, ‘U-03’: lbf-in or ozf-in

Press SEND to select, CF9End displays. Press SEND to exit.

CF9 m1 Torque dampening Factory set=’Fd6’

Press PEAK or ZERO to cycle: ‘Fd0, Fd 1, Fd2, Fd3, Fd4, Fd5 or Fd6’. Torque dampening averages rapid torque changes over time. Larger numbers allow more dampening.

Press SEND to select, CF9End displays, press SEND to exit (Torque dampening rate

displays each time the gauge is turned on).

CF9 m2 +/– indicator Default=’SC-OFF’

Press PEAK or ZERO to cycle. ‘SC-OFF’: CW (+) and CCW (–) or ‘SC-On’: CW (–) and

CCW (+). Press SEND to select, CF9End displays, press SEND to exit.

ming mode (CF9 flashes with solid nn0).

3. Press to display U-03 with a unit, then press or

to cycle desired units (ozf-in, lbf-in, kgf-cm and N-cm), and

press to select (CF9 flashes with solid End).

4. Press to exit 1st. programming mode.

Once units are selected, the gauge retains them as a default.

Note: All power-on and power-off programming functions except for unit selection and

display orientation can be reset to factory defaults by the following procedure.

Turn on the gauge Press PEAK and ZERO for 3 seconds to display flashing CF9 with

solid F0. Press ZERO and PEAK for 5 seconds until flashing CF9 disappears and

becomes only solid F0. Then release both PEAK and ZERO. Gauge goes back to

measuring mode with factory default settings.

page 4 page 13

Page 5

DIGITAL FORCE GAUGE

00.0

NG

Lb-in

OK +NG

OVERLOAD

ZERO

SEND PEAK

ON

OFF

DIGITAL FORCE GAUGE

00.0

NG

Lb-in

OK +NG

OVERLOAD

ZERO

SEND PEAK

ON

OFF

Power-On programming

Turn on the gauge. Press and for 3 seconds to enter

Reversing the Display

The factory default is standard display.

To reverse the display:

Power-On programming (CF9 flashes with solid F0). Press or

to cycle CF9 F0, CF9 F1, CF9 F2, CF9 F3, CF9 F4, CF9 F5,

CF9 F6 and CF9 End. Press to select a function.

CF9 F0 Memory recall

Press SEND, memory location and value cycle. Press PEAK or ZERO to increase or

decrease memory number (and corresponding value). Press SEND to exit.

1. Turn on the gauge

2. Press and for 3 seconds to enter

Power-On programming mode (CF9 flashes

with solid F0).

STANDARD

DISPLAY

3. Press 5 times to display flashing CF9 with solid F5, then

press to display -12345. Press or , to cycle between

CF9 F1 High & low setpoints Default=‘0’ both Hi and Lo

Press SEND, –HI– displays, then the high set value (i.e. H 10.0). Press PEAK to

increase and ZERO to decrease, press SEND to select. –LO– displays then the low set

value (i.e. L 5.0). Press PEAK to increase and ZERO to decrease, press SEND to select,

CF9 End displays. Press SEND again to exit.

CF9 F2 Peak mode Default=‘Or’

Press SEND, ‘Or’ or ‘And’ displays. Press PEAK or ZERO to cycle. Press SEND to

select. ‘Or Peak’ records the Peak in either CW or CCW during test. ‘And Peak’ records

both the CW peak and CCW peak during a test.

Zero reset memory store Default=‘AA-OFF’

Auto memory displays after Peak mode is selected. ‘AA-On’ enables automatic memory

storage and reset to zero. ‘AA-OFF’ turns off auto function. Press PEAK or ZERO to

change. Press SEND to select, CF9End displays, press SEND again to exit.

CF9 F3 Auto zero reset Default=‘Ac-OFF’

Press SEND, ‘Ac-On’ or ‘Ac-OFF’ displays. Press PEAK or ZERO to cycle. If ‘AC-On’ is

selected, auto zero reset duration can be programmed. Press PEAK to increase or

ZERO to decrease. Press SEND to select, CF9End displays, press SEND again to exit

(i.e. ‘SEC 3.0’ is displayed for auto zero reset duration of 3 seconds).

CF9 F4 Audible beep Default=‘Sd-On’

Press SEND, ‘Sd-On’ for alarm on, or ‘SD-OFF’ for off displays. Press PEAK or ZERO to

cycle. Press SEND to select. CF9End displays, press SEND again to exit (alarm sounds

for values over HI or under LO setpoints).

Setpoint alarm Default=’’

Setpoint alarm displays after audible beep is selected. ‘AL-On’ for setpoint alarm on or

‘AL-OFF’ for off. Press PEAK or ZERO to cycle. Press SEND to select, CF9End displays,

press SEND again to exit.

CF9 F5 Reverse display

Press SEND, ‘-12345’ for standard or ’ ’ for reverse displays. Press PEAK or

-12345

ZERO to cycle. Press SEND to select. Flashing CF9 with solid End displays. Press

SEND again to exit. (for vertical mounting).

CF9 F6 Auto power off duration Default=‘AO-10’

Press SEND, ‘AO-10’ displays. Press PEAK or ZERO to cycle ‘AO-5’ for 5 min auto

power off duration, ‘AO-10’ for 10 min, ‘AO-30’ for 30 min, ‘AO-60’ for 60 min and ‘AOOFF’ to by-pass auto power off. Press SEND to select, CF9End displays, press SEND

again to exit.

standard and reverse .

4. Press to select, the display flashes CF9 with solid End.

5 Press again to exit Power-On programming mode.

Once desired display is selected, the gauge retains it as a default.

Programming Setpoints (optional)

Program High and Low setpoints for easy GO/NO GO testing.

1. Turn on the gauge

2. Press and for 3 seconds to enter Power-On program-

ming mode (CF9 flashes with solid F0).

3. Press to display flashing CF9 with solid F1,

then press to display –HI– and then the

high set value (i.e. H 10.0).

4. Press to increase and to decrease the

High set value, then press to display –LO–

and then low set value (i.e. L 5.0). Press to

increase and to decrease the Low set value and press

to display flashing CF9 with solid End.

5. Press again to exit Power-On programming mode.

-12345

HIGH SETPOINT

LOW SETPOINT

page 12 page 5

REVERSE

DISPLAY

Page 6

Peak or Real time Measuring Mode

Press to turn on and the gauge automatically

enters real time measuring mode. For peak mea-

REAL TIME MODE DISPLAY

surement press . The “Peak icon” appears on

the display. Peak readings will not change until a

higher value is measured. Press again to

return to real time mode.

PEAK MODE DISPLAY

“Or PEAK“ is the factory default which measures peak CW torque

or peak CCW torque. “And PEAK“ measures both peak CW torque

and peak CCW torque during a test. Refer to the F2 function of

the Power-On programming table for the “And PEAK” function.

RECHARGING NI-MH BATTERY

1. To maximize the life of the battery, power is automatically shut

off after 10 minutes of non-use or user-defined interval.

Automatic shut off is bypassed during USB output or when

used with the AC adapter/charger.

2. Battery icon will flash when the gauge needs to be

recharged.

3. Push to turn off power. Only use the IMADA AC adapter/

charger provided, AD120 for 115VAC, AD230 for 230VAC. Plug

into the correct AC output. It takes 10 hours to charge fully.

Tare

KEY

Clamp test sample firmly by tightening the

key. If necessary, press to tare before the

test. Pressing also clears the peak reading.

TURN MEASURING

CHUCK BY HAND

If High and Low setpoints have been programmed (see page 5),

for example, 5 lbf-in is set as Low and 10 lbf-in as High, the

ORANGE LED light for measurements less than 5 lbf-in (Low setpoint). GREEN lights between 5–10 lbf-in and RED lights over 10

lbf-in (High setpoint). Setpoint output is available through the

Communications port (see page 7).

After measuring, press the button to transmit data to:

RS-232 models: RS-232C or Digimatic devices

Storing Data into Memory

During measurement whether Peak or Real Time, press to store

and display up to 1000 torque values into memory. (If no data is

stored – – – – – is displayed then flashing CF9 with solid End).

4. When the gauge is turned off, make sure the AC adapter/charger

is disconnected to avoid overcharging.

OPTIONAL CABLES

10' Analog cable

CB-104

10' RS-232C cable, 9 pin female

CB-204

10' Digimatic Cable

CB-304

page 11page 6

Page 7

2. Mitutoyo Digimatic Signal

Connect the CB-304 cable to the communications port and

the device receiving the data. Set up parameters as instructed

from the Mitutoyo processor manual.

Recalling Data from Memory

1. Turn on the gauge.

2. Press and for 3 seconds to enter Power-On program-

ming (CF9 flashes with solid F0). Press and the display

3. ±2 VDC Analog Signal

Connect the CB-104 analog cable to the communications port

and the device receiving the data.

4. External Switch Display Freeze

By connecting #10 and #12

of the communications port,

the gauge instantaneously

captures the critical reading

and holds the display from

remote locations (use contact

closure and DO NOT apply

voltage across #10 and #12).

(1) Pay extra attention to avoid overload as display

value will not change during display hold.

(2) Use contact closure only and DO NOT apply

voltage across #10 and #12 port pins.

5. External Switch Display Clear

By connecting #8 and #12 of the communications port, display can be cleared from remote locations (use contact closure and DO NOT apply voltage across).

cycles memory location and value. Press to increase loca-

tion and to decrease. Press to exit.

Clearing Data from Memory

1. Turn off the gauge.

2. Press again while holding to enter memory mode.

Single Memory Clear

A memory location with a dot at both ends is the last stored value

and the only one that can be erased. Press to erase and ErASEd

is displayed. If you erase any other location Error is displayed.

All Memory Clear

While a memory location or value is displayed, press for 3

seconds, all data is erased, ErASEd is displayed, then – – – – – and

flashing CF9 with solid End. Press to exit. (See page 14-15).

Downloading Data from Memory

Choose between the following download methods.

Digimatic Data Download from Memory

1. Connect the gauge and device receiving data with CB-304 cable.

2. Turn on the gauge. Press and for 3 seconds to enter

Power-On programming (CF9 flashes with solid F0).

3. Press to transmit all data.

Use contact closure only and DO NOT apply voltage

across #8 and #12 port pins.

4. Press again to exit.

RS-232C Data Download from Memory

Connect the gauge and device receiving data with a CB-204

cable. Use the I[CR] ASCII command to transmit data (uppercase

ASCII character format).

page 7page 10

Page 8

COMMUNICATIONS PORT

1

13

14

26

DIGITAL FO

RCE GA

UGE

NG OK

+

NG

0-200N

0-20 kgf 0-44lb

OVERLOAD

ZERO

SEND PEAK

ON

OFF

M

ode

l:

DPZ-200N

1. RS-232C bi-directional interface functions

All functions can be duplicated remotely by using the RS-232C

interface. Commands must be sent in uppercase ASCII character format followed by a carriage return [CR].

RS-232C Signal: 8 data, 1 stop, no parity. Baud Rate: 19200 bps

26 PIN CONNECTOR

RS-232C INTERFACE FUNCTIONS (Upper case ASCII format)

COMMAND FUNCTION RESPONSE*

T[CR] Select real time mode R[CR]

P[CR] Select peak mode R[CR]

If OR peak is programmed

P[CR] = peak

If AND peak is programmed

COMMUNICATIONS PORT PIN DEFINITIONS

PIN# DEFINITION

1 RS-232C Signal Output

2 RS-232C Receive Signal

3 RS-232C Ground

4 Analog Output ±2VDC

5 Analog Ground

6

7

8 External Switch Display Clear

9 External Switch for Peak/Real Time Modes

10 External Switch Display Freeze

11

12 Ground

13 Ground

14

15

16 Digimatic Data Request

17 Digimatic Data Ready

18 Digimatic Data Clock

19 Digimatic Data Signal Out

20 Digimatic Data Ground

21 +NG Output

22 OK Output

23 -NG Output

24 Overload Output

25 Common

26 Common

RS-232C Output

Analog Output

External Inputs

Digimatic Output

High/Low Setpoint and Overload

Output (open collector=

30V, 10mA max)

Z

[CR]

D[CR] Transmit display data [direction][value][units][mode]

V[CR] Transmit Peak data P+[value][units][CR]

g[CR] Continuous data output (10 data/sec)

Y[CR] Stop continuous data output

K[CR] Select “kgf-cm” units R[CR]

N[CR] Select “N-cm” units R[CR]

O[CR] Select “lbf-in” units R[CR]

B[CR] Delete last data stored in memory R[CR]

M[CR] Store data R[CR]

I[CR] Recall memory data Data format is the same as D

C[CR] Clear memory R[CR]

EXXXXYYYY Set high/low setpoints(4 digit) R[CR]

[CR] XXXX=High, YYYY=Low

E[CR] Read high/low EXXXXYYYY[CR]

*Note: E[CR] response if the command is not accepted.

P[CR] (1st time)= +peak

P[CR] (2nd time)= – peak

Tare Display R[CR]

[go/nogo/overload][CR]

[direction] +=CW

–=CCW

[value] 4 digits w/decimal

[units] K, N, or O

[mode] T=real time value

P=peak value

H=Hold value

M=Memory value

[go/nogo] H=+NG

O=OK

L=-NG

E=Overload

P– [value][units][CR]

command response. It will output END[CR] at the end of data

setpoint values (4 digit)

XXXX=High, YYYY=Low

page 8 page 9

Loading...

Loading...