Page 1

-1-

TABLE OF CONTENTS

1.0 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1 Unpacking

1.2 Complete Kit

2.0 Operating Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Memory Pointer (optional)

3.0 Verifying Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.1 Textile Durometers

3.2 Shore Durometers

4.0 Available Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

5.0 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6.0 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pressure on the spring-loaded outer ring which exceeds the

range of the instrument by more than 100% may cause permanent

damage to the measuring spring and must be avoided under any

circumstances.

This device must not be operated in explosion hazard areas and

must not come into contact with aggressive substances.

-8-

Model: HPSO

Indentation Body: U-grooved 3/32"

Depth of Indentation: 0 - 2.5 mm

Test pressure*: approx. 12.5 N

Meas. spring force: 0.55 - 8.065 N

Display range: 0 –100 Shore hardness graduation marks

Scale diameter: 54 mm

Working face: 18 mm

Weight approx. 300 g net/ 500 g gross

Dimensions: 50 (L) x 50 (W) x 110mm (L)

*Pressure on test material surface when outer ring is in measuring position.

WARNING

Page 2

-7-

*Pressure on test material surface when outer ring is in measuring position.

5.0 SPECIFICATIONS

Model: HP-2.5, HP-5, HP-10, HP-2.5F, HP -5F, HP-10F

Depth of Indentation: 0 – 2.5 mm

Test pressure*: approx. 12.5 N

Meas. spring force: 0.55 N – 8.065 N

Working face radius: 56 mm (only HP 2.5, HP 5, HP 10)

Working face diameter: 45 mm Ø (only HP 2.5-F, HIP 5-F, HP 10-F)

Display range: 0 –100 hardness graduation marks

Scale diameter: 54 mm

Weight approx. 300 g net/ 500g gross

Dimensions: 50 (L) x 50 (W) x 110mm (L)

Model: HPSD

Indentation Body: Tapered pin 30°, 1.25 mm Ø

Depth of Indentation: 0 - 2.5 mm

Test pressure*: approx. 50 N

Meas. spring force: 0.98 - 44.5 N

Display range: 0 - 100 Shore hardness graduation marks

Scale diameter: 54 mm

Working face diameter: 18 mm

Weight approx. 300 g net/ 500 g gross

Dimensions: 50 (L) x 50 (W) x 110mm (L)

Model: HPSA

Indentation Body: Cone 35°, 1.25 mm Ø

Depth of Indentation: 0 – 2.5 mm

Test pressure*: approx. 12.5 N

Meas. spring force: 0.55 - 8.065 N

Display range: 0 – 100 Shore hardness graduation marks

Scale diameter: 54 mm

Working face diameter: 18 mm

Weight approx. 300 g net/ 500 g gross

Dimensions: 50 (L) x 50 (W) x 110mm (L)

-2-

1.0 INTRODUCTION

This manual covers the operation of both the Checkline TEXTILE and

SHORE Durometers. Textile Durometers are typically used to check the

relative "firmness" or "hardness" of textile yarn packages, bobbins, beams,

spools, cones, etc.They are calibrated to measure on an empirical scale of

0-100 units. The different models types use different sized ball sensors

(2.5, 5 and 10 mm diameter) and are offered in flat-bottomed versions (used

on large diameter cylindrical samples) as well as models with concave-shaped

bottom surfaces for use on small-diameter cylindrical test samples.

Shore Durometers are typically used to measure the hardness of a wide

variety plastics, rubber, elastomers and similar materials. All models have a

flat bottom and differ in the shape of the sensing pin as well as the internal

spring force that resists deflection of the sensing pin. All models are calibrated using standards that are specified in various Test Procedures issues by

ASTM, DIN and JIS Quality organizations worldwide.

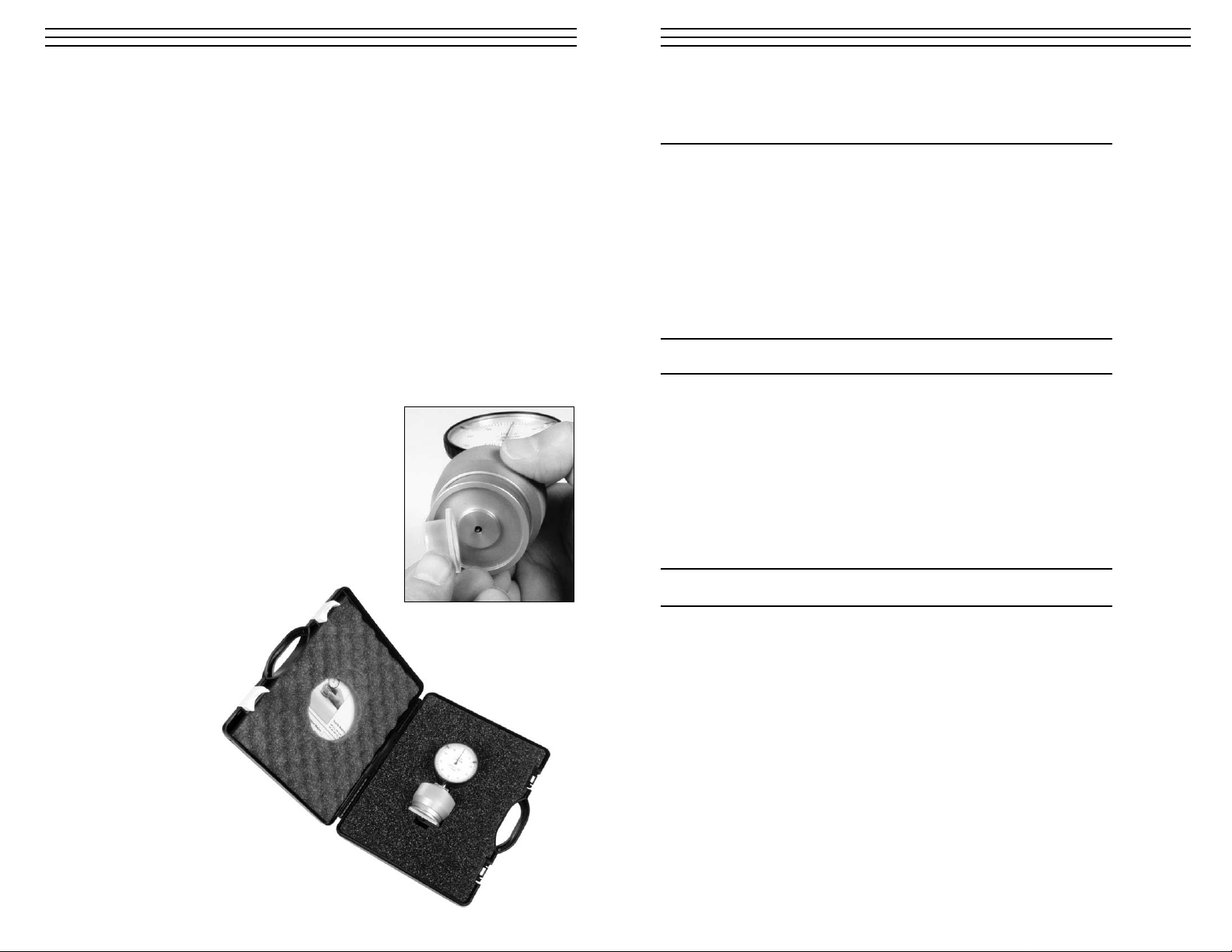

1.1 Unpacking

Unpack the HP Durometer carefully and

inspect it for any damage. If damage is

found, contact Electromatic immediately by

telephone at 516-295-4300 or send email to

info@checkline.com.

1.2 Complete Kit

HP Series Durometers are supplied

as a complete kit, including:

• Durometer

• Operating manual

• Carrying case.

Durometer with protective

plastic cap

Page 3

2.0 OPERATING PROCEDURES

1. Place the instrument on the material

to be tested. The durometer must be

level, and the sensing pin must be

perpendicular to the material to be

tested.

Any angle other than perpendicular

(90°) mauy cause errors

2. Holding the knurled, spring-loaded

outer shell between fingers, press

downwards until the lower edge of

the shell meets the red line marked

on the housing. This ensures that

sufficient pressure is applied as

specified in the standard. It also

ensures that the same amount of

pressure is applied from measurment

to measurement, and when the

durometer is used by different

operators.

3. Record reading after approximately

2–3 seconds. Release pressure on

the outer shell and remove the

durometer from the test material.

2.1 Memory Pointer (optional)

The Memory Pointer moves with the

measurement pointer when a measurement is taken. However, when pressure

on the outer shell is released, and the

measurement pointer returns to zero, the

Memory Pointer remains in position,

marking the last measurement.

To return the Memory Pointer to the

zero position prior to taking another

measurement, rotate the knurled knob

on the face of the instument counterclockwise until the pointer has been

reset. See figure at right.

Textile Durometer

Shore Durometer

Scale

Spring-Loaded

Outer Ring

Spring-Loaded

Outer Ring

Color Marking

Color Marking

Scale

-3--6-

Model Indentor Decriptions Typical Applications

HPSA Truncated Cone Soft rubber, elastomers, natural rubber products, etc.

35° Included Angle

HPSB Conical Rubber, elastomers, use when off the high end of the

35° Included Angle “A” scale

HPSC Truncated Cone Medium hard rubber or plastics, use when off the low

35° Included Angle end of the “D” scale

HPSD Tapered pin 30° Hard rubber, rigid thermoplastic products

HPSO U-grooved 3/32 in. Soft elastomers, textile fabrics

HPDO Spherical 3/32 in. Dense textile winding, medium printing rollers

Model Sensor Ball Bottom Typical

Diameter Surface Applications

HP-2.5 2.5 Ball Closely wound bobbins of synthetic fibers

HP-5 5 Ball Loosely wound bobbins of synthetic fibers

and closely wound natural fibers, yarns and threads

HP-10 10 Ball Very loosely wound bobbins of thick yarns,m such as

carpet yarns

HP-2.5F 2.5 Flat Same as Model HP-2.5 with a flat working face for

measuring warp beams, or for bobbin diameters with

over 400mm

HP-5F 5 Flat Same as Model HP-5 with a flat working face for

measuring warp beams, or for bobbin diameters with

over 400mm

HP-10F 10 Flat Same as Model HP-10 with a flat working face for

measuring warp beams, or for bobbin diameters with

over 400mm

4.0 AVAILABLE MODELS

Shore Durometers

Textile Durometers

Memory

Pointer

Page 4

-4-

3.0 VERIFYING CALIBRAION

3.1 Textile Models (HP-2.5, HP-2.5F, HP-5, HP-5F, HP-10, HP-10F)

The Textile Durometers utilize a 0-100 units scale. The units have not formal

engineering classification and are not related to a specific Shore value or

other known value. These Textile Durometers are designed to obtain objective

comparative values that are effective for classifying the end-product quality.

Therefore, there are no standards that can be used to compare against and it is

for this reason that an NIST-Traceable Calibration Certification can not be

performed.

You can however test that the gauge is functional and un-damaged by pressing the flat-bottomed models ("-F" models) against a smooth surface (such as

glass or marble). When fully pressed down, the dial should perform one complete rotation and go back to "0". When released, it should un-coil, and return

to "0" as well. If not, please contact the factory immediately.

On model with a concave base (for measurement on small bobbins or cones),

you can perform a similar "full scale" test using the optional Zero Test Block

(part number HP-TB).

1. Press the Textile Durometer

down on the test plate, which is

available as an accessory and

can be ordered under item

number HP-TB (see Fig. 1).

Do not move the spring-loaded

outer ring.

2. The scale pointer should make

one full turn on the scale, from

zero to zero, when you press

down on the instrument. If it

does not, contact Electromatic

for assistance.

NOTE: Do not loosen the holding screws of the movement under any

circumstances. Loosening these screws may alter the calibration of the

instrument.

Fig. 1

3.2 Shore Models (HPSA, HPSB, HPSC, HPSD, HPSO, HPDO)

The Shore Durometers model are calibrated against industry standards as

specified in ASTM, DIN and JIS Test Procedures. Calibrated Test Samples

CAN NOT BE USED for verification of the calibration, as these test samples

are subject to change due to temperature, sunlight and other ambient conditions. Certification of the calibration is normally done at test facilities that

can independent test the internal spring forces of the Durometer and check

the travel/reading accuracy of the dial indicator.

Contact factory for the optional NIST-Traceable Calibration Certifications.

1. Press the Shore Durometer

down on a glass plate

(see Fig. 2). Do not move

the spring-loaded outer

ring.

2. The scale pointer should

make one full turn on the

scale, from zero to zero,

when you press down on

the instrument. If it does

not, contact Electromatic

for assistance.

NOTE: Do not loosen the holding screws of the movement under any

circumstances. Loosening these screws may alter the calibration of the

instrument.

-5-

Fig. 2

Scale

Holding screws

Color marking

Test block

Part No.: HP-TB

Spring-loaded

outer ring

Scale

Holding screws

Spring-loaded

outer ring

Color marking

Glass plate

Page 5

6.0 WARRANTY

ELECTROMATIC Equipment Co., Inc. (ELECTROMATIC) warrants to the original

purchaser that this product is of merchantable quality and confirms in kind and quality with

the descriptions and specifications thereof. Product failure or malfunction arising out of any

defect in workmanship or material in the product existing at the time of delivery thereof

which manifests itself within one year from the sale of such product, shall be remedied by

repair or replacement of such product, at ELECTROMATIC’s option, except where unauthorized repair, disassembly, tampering, abuse or misapplication has taken place, as determined

by ELECTROMATIC. All returns for warranty or non-warranty repairs and/or replacement

must be authorized by ELECTROMATIC, in advance, with all repacking and shipping

expenses to the address below to be borne by the purchaser.

THE FOREGOING WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO, THE WARRANTY

OF MERCHANTABILITY AND FITNESS FOR ANY PARTICULAR PURPOSE OR

APPLICATION. ELECTROMATIC SHALL NOT BE RESPONSIBLE NOR LIABLE FOR

ANY CONSEQUENTIAL DAMAGE, OF ANY KIND OR NATURE, RESULTING FROM

THE USE OF SUPPLIED EQUIPMENT, WHETHER SUCH DAMAGE OCCURS OR IS

DISCOVERED BEFORE, UPON OR AFTER REPLACEMENT OR REPAIR, AND

WHETHER OR NOT SUCH DAMAGE IS CAUSED BY MANUFACTURER’S OR

SUPPLIER’S NEGLIGENCE WITHIN ONE YEAR FROM INVOICE DATE.

Some State jurisdictions or States do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation may not apply to you. The duration of any

implied warranty, including, without limitation, fitness for any particular purpose and merchantability with respect to this product, is limited to the duration of the foregoing warranty.

Some states do not allow limitations on how long an implied warranty lasts but, not withstanding, this warranty, in the absence of such limitations, shall extend for one year from the

date of invoice.

ELECTROMATIC Equipment Co., Inc.

600 Oakland Ave. Cedarhurst, NY 11516—USA

Tel: 1-800-645-4330/ Tel: 516-295-4300/ Fax: 516-295-4399

Every precaution has been taken in the preparation of this manual. Electromatic Equipment Co., Inc.,

assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting

from the use of information contained herein. Any brand or product names mentioned herein are used for

identification purposes only, and are trademarks or registered trademarks of their respective holders

Page 6

HP SERIES

TEXTILE DUROMETERS

AND SHORE DUROMETERS

Operating Instructions

CHECK•LINE

®

BY ELECTROMATIC

OI-503HP

ELECTROMATIC

E Q U I P M E N T C O., I N C.

600 Oakland Ave., Cedarhurst, NY 11516–U.S.A.

TEL: 516-295-4300

• FAX: 516-295-4399

CHECK•LINE

®

INSTRUMENTS

Textile Models

HP-2.5, HP-2.5F, HP-5,

HP-5F, HP-10, HP-10F

Shore Models

HPSA, HPSB, HPSC,

HPSD, HPSO, HPDO

Loading...

Loading...