Page 1

2

Introduction

Introduction

Principles of Operation

F probes use the magnetic principle to measure the thickness

of non-magnetic coatings on ferrous metals.

N probes use the eddy current principle to measure the

thickness of non-conductive coatings on non-ferrous metals.

FN probes combine the full abilities of both the "F" and "N"

probes.

Throughout this manual, the symbol indicates more

information about the particular topic or feature is available on our

website. Go to: www.defelsko.com/manuals

NOTE:

Certification

All probes include a Certificate of Calibration. For organizations

with re-certification requirements, gages may be returned at

regular intervals for calibration. DeFelsko recommends that

customers establish gage calibration intervals based upon their

own experience and work environment. Based on our product

knowledge, data and customer feedback, a one year calibration

interval from either the date of calibration, date of purchase, or

date of receipt is a typical starting point.

The PosiTector 6000 hand-held, electronic Gage non-

destructively measures the thickness of coatings on all metals,

quickly and accurately. A PosiTector 6000 consists of a Gage

body and probe (see pg.19).

Plastic Lens Shield

The LCD is covered with a thin plastic film for protection against

fingerprints and other marks during shipment. This film, while

usually removed before using the instrument, can be left in place

to protect against paint overspray. Replacements can be

purchased.

Wrist Strap

We recommend attaching and wearing the

supplied wrist strap.

W

1

2

Page 2

3

1.Remove red protective rubber cap (if supplied) from probe.

2.Power-up Gage by pressing the center navigation button.

3.Place the probe FLAT on the surface to be measured. HOLD

STEADY. When a valid measurement is calculated, the Gage

BEEPS twice and the measurement is displayed.

4.Lift probe AT LEAST 2 INCHES (5cm) from the surface between

measurements - OR - leave probe on the surface in the same

location for continuous measurements.

Golden Rule

Golden Rule

Measure your uncoated part first! This quick zero-check

determines if a calibration adjustment is needed for your

substrate. (see pg.5)

Next, lay the included plastic shims onto a bare surface and

measure them individually to ensure the Gage measures a known

thickness within tolerance.

Operation Overview

Operation Overview

The PosiTector 6000 powers-up when the center navigation

button is pressed. To preserve battery life, the Gage powers-down

after approximately 5 minutes of no activity. All settings are

retained.

If memory is ON while continuous measurements are

being taken, only the last value on the display (when the probe is

lifted) is stored into memory. Scan (pg.17) stores ALL

measurements into memory.

NOTE:

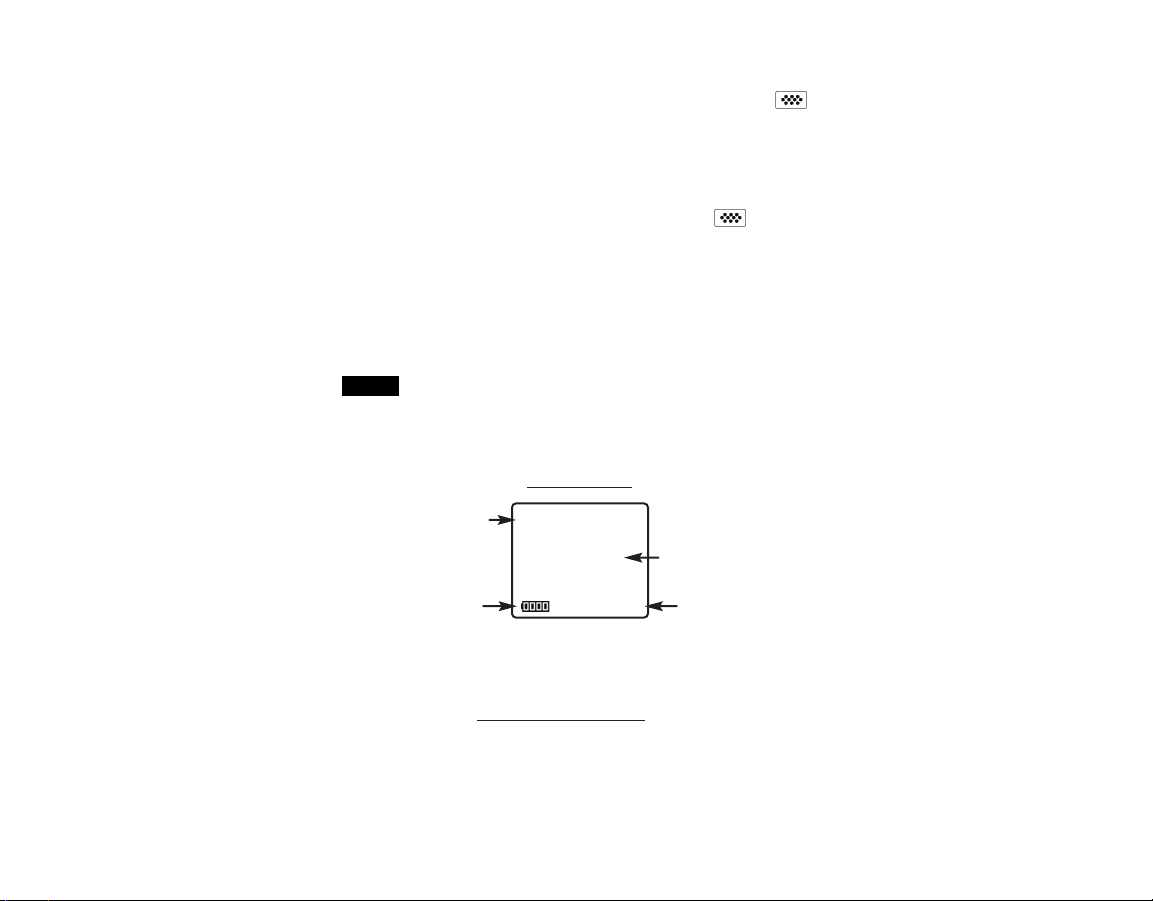

Substrate

Current

Measurement

Battery Indicator

Typical Screen

Unit of

Measurement

Microns

F

56

Page 3

4

Memory

Statistics

Cal Settings

Setup

Connect

Sync Now

USB

Auto Sync

Updates

Menu Operation

Menu Operation

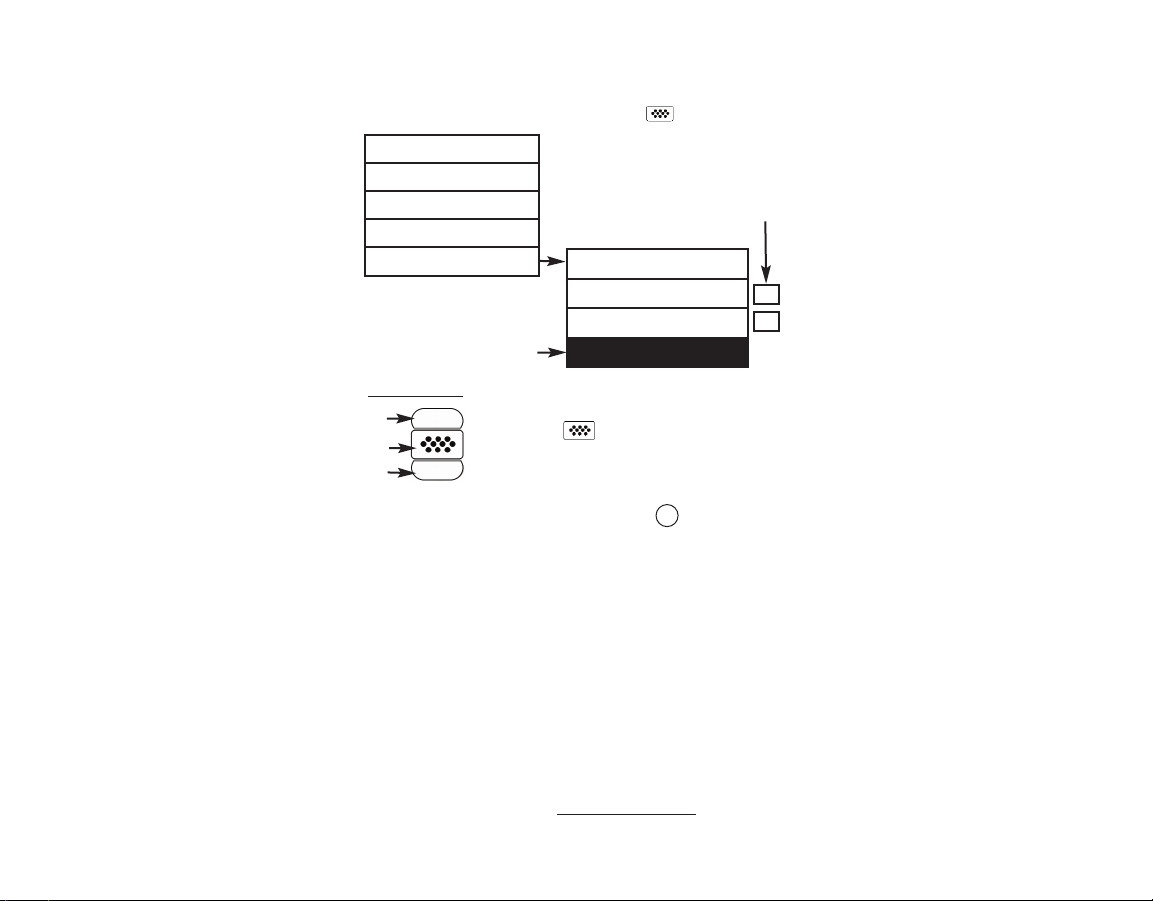

Gage functions are menu controlled. To access the Menu, turn the

Gage on, then press the center navigation button.

Some buttons have a tick box to their

right to indicate current status. An empty

box indicates that feature is not active.

Current selection is displayed

with darkened background

Up

Down

Center

To navigate, use the Up and Down buttons to

scroll and to SELECT.

Select Exit to exit from any menu.

ü

Navigation Button

PosiTector.net

PosiTector.net

To enhance the operation of their Gage, all PosiTector users have

access to the features provided by PosiTector.net. It is a free web-

based application offering secure centralized management of

thickness readings.

PosiTector Desktop Manager (PDM) is a small Windows based

application which allows automatic two-way communication

(synchronization) between the Gage and PosiTector.net (internet

connection required). When installed, PDM runs as a start-up

application and resides in the Windows notification area (system

tray) of a PC. PDM is available as a free download within your

PosiTector.net account.

Register your Gage on PosiTector.net to take full advantage of

your gage’s capabilities. Visit: www.PosiTector.net

W

Page 4

5

Calibration, Verification & Adjustment

Calibration, Verification & Adjustment

Three steps ensure best accuracy…

1. Calibration: typically done by the manufacturer or qualified lab

2. Verification of Accuracy: as done by the user

3. Adjustment: to a known thickness

Calibration

Calibration is the controlled and documented process of

measuring traceable calibration standards and verifying that the

results are within the stated accuracy of the Gage. Calibrations

are typically performed by the Gage manufacturer or by a certified

calibration laboratory in a controlled environment using a

documented process.

Verification

Verification is an accuracy check performed by the user using

known reference standards. A successful verification requires the

Gage to read within the combined accuracy of the Gage and the

reference standards.

Adjustment

Adjustment, or Calibration Adjustment is the act of aligning the

Gage's thickness readings to match that of a known sample in

order to improve the effectiveness of the Gage on a specific

surface or in a specific portion of its measurement range. 1-point

or 2-point calibration adjustments are possible.

The symbol disappears whenever a calibration

adjustment is made to the Gage.

The PosiTector 6000 is factory calibrated and performs an

automatic self-check each time it takes a measurement. For

many applications, no further adjustment is necessary after a

Reset (pg.16). Just check ZERO on the uncoated substrate, then

measure.

NOTE:

W

W

Page 5

6

Sometimes Gage readings can be influenced by changes in substrate shape, composition, surface roughness or by measuring in

a different location on the part. This is why Calibration

Adjustments are made possible.

1- or 2-point Calibration Adjustments may be performed if

readings are not falling within the expected range of thickness for

the application being measured.

If a calibration adjustment method has not been specified, use a

1-point method first. If measuring the included shims reveals

inaccuracies, use the 2-point method. Factory Calibration

settings can be restored at any time by performing a Reset

(pg.16), creating a NEW calibration setting (pg.9), or by

DELETING the adjustments made to the Cal 1 calibration setting

(pg.9). The symbol appears on the display whenever factory

calibration settings are in use.

With “FN” probes, calibration adjustments for “F” and “N” prin-

ciples are stored independent of one another.

Once adjusted, you may “lock” the current calibration

adjustment to prevent further modification. (See “Cal Lock” on pg.8)

1-point Calibration Adjustment

Also known as an offset or correction value, there are 4 ways to

perform this adjustment:

(1) Simple

Zero Calibration Adjustment

Measure your uncoated part. If the Gage does not read "0" within the

tolerance of the probe being used, lift the probe from the surface and

adjust the display down (-) or up (+) until it reads "0". Measure and

adjust until the average of a series of readings on the uncoated surface

is within tolerance of "0" .

(2) Average

Zero Calibration Adjustment

To establish “0” on a rough or curved surface a preferred method

is to take several readings on the uncoated part and average the

result.

NOTE:

NOTE:

Page 6

7

1.Select the Zero menu option.

2.Press (+) to select the number of readings to be used to obtain

an average, typically 3 to 10 readings. The greater the variation

between readings, the more readings should be taken to obtain

an average.

3.Repeatedly measure the uncoated part. The Gage will wait 2

seconds between readings to allow the user to correctly position

the probe on the surface. After the last measurement the Gage

will calculate and display "0" which represents the average of all

the Zero readings taken.

(3) Simple Adjustment to a Known Thickness

It is sometimes desirable to adjust the Gage to a known thickness,

such as a shim, rather than adjusting it to zero.

Measure the object. If the expected reading is not obtained (within

tolerance), lift the probe from the surface and adjust the displayed

reading down (-) or up (+) to the expected thickness. Hold the

button down to increase the rate of adjustment.

(4) Average Adjustment to a Known Thickness

On rough or curved surfaces a preferred method is to take several

readings on the known thickness and average the result.

1.Select 1 Pt Adjust from the Cal Settings menu.

2.Press (+) to select the number of readings to be used to obtain

an average, typically 3 to 10 readings. The greater the variation

between readings, the more readings should be taken to obtain

an average.

3.Repeatedly measure the known thickness reference. The Gage

will wait 2 seconds between readings to allow the user to

correctly position the probe on the surface. After the last

measurement the Gage will calculate and display the reading

which represents the average of all the measurements taken. If

the expected reading is not obtained (within tolerance) lift the

probe from the surface and adjust the reading down (-) or up (+)

to the expected thickness and press .

Zero

1 Pt Adjust

Page 7

8

2-point Calibration Adjustment

Preferred method for very unusual substrate materials, shapes or

conditions. Provides greater accuracy within a limited, defined

range.

This method requires taking two readings at known thickness

values: a thin value (often zero) and a thicker value. These values

should be on either side of the thickness range to be measured.

1.Select 2 Pt Adjust from the Cal Settings menu.

2.Press (+) to select the number of readings to be used to obtain

an average on the thinner item, typically 3 to 10 readings. The

greater the variation between readings, the more readings

should be taken to obtain an average.

3.Repeatedly measure the thinner item. The Gage will wait for 2

seconds on the surface to allow the user to correctly position the

probe on the surface. After the last measurement the Gage will

calculate and display a thickness value which represents the

average of all the readings taken using the factory calibration

settings.

4. Lift the probe from the surface and adjust the displayed reading

down (-) or up (+) to the known thickness value of the thin item.

Press to accept this value.

5.Repeat steps 2 - 4 for the thicker item.

When selected, the icon will appear and all calibration settings

are “locked” to prevent further user adjustments.

2 Pt Adjust

Cal Lock

ü

Select Non-Ferrous Lock (N Lock) when operating regularly on

non-ferrous substrates. The icon will appear and the probe will

only use the eddy current principle when measuring. N Lock is

useful when measuring coatings on plated steel.

N Lock

ü

(FN ferrous/non-ferrous combination probes only)

C

N

W

Page 8

9

It is often convenient to store a particular calibration adjustment

before making another. Then, if you return to that part, the

corresponding calibration setting

can be restored.

A “setting” is any calibration adjustment. The PosiTector 6000

always displays the current calibration setting (ex. Cal 3) in the

upper right corner of the display.

The setting called Cal 1 has unique features. It can be adjusted

but never deleted, and is always made active with factory settings

after a Reset (pg.16).

Creates a new calibration setting using the next available number

(Maximum of 10). By default, these new Cal settings are initially

created with the Gage’s factory settings. This is indicated with the

icon which appears at the bottom of the display. A warning

message will prevent the creation of a new Cal Memory if a batch

is open and has readings. Delete the batch first (pg.12).

Removes a setting completely from the list. That Cal number can

be reused later with the New command. A setting cannot be

deleted if readings have been stored into a batch

using that

calibration setting. Delete all readings in that batch first (pg.12).

Although Cal 1 cannot be deleted, the Delete function will return

it to factory settings.

View stored Calibration Settings.

Loads an existing setting. Use the Up or Down buttons to scroll

until the desired setting appears, then press . A warning message will prevent the opening of a stored Cal setting if a batch

is

open and has readings. Create a new batch first or open a batch

containing no readings (pg.10).

View

Delete

Open

New

Cal Memory

(Advanced models only)

Calibration Memory

Calibration Memory

Page 9

10

New Batch

Memory Management

Memory Management

Memory

The PosiTector 6000 can record measurements in memory for

printing, transfer to a computer or synchronizing with

PosiTector.net. Readings are time-stamped as they are taken.

Closes open batch and creates a new batch name using the next

higher number. For example, if only Batch 1 and Batch 3 exist,

then Batch 4 would be created and made the current batch. The

icon appears and basic statistics are displayed. Each

measurement will be displayed and stored into this new batch. Onscreen statistics are immediately updated with each measurement.

New batch names are date stamped at the time they are created.

Shortcut:

Standard models store up to 250 readings in one group. The

following appears within the Memory menu:

On

: turns memory on and begins recording

Off: stops recording (stored readings remain in memory)

Clear: removes all readings from memory

View

: lists all stored readings on the display. It will begin by

showing the last several measurements. Use the Up and Down

buttons to page through all readings

Advanced models store 100,000 readings in up to 1,000

batches (groups). The following appears within the Memory menu:

When a batch is open, press (+) to create a new batch

New Sub-Batch

(appears only if a batch is currently open)

Creates a new sub-batch within the currently opened batch.

When a sub-batch is open, create a new sub-batch by

pressing (+)

Shortcut:

In the following example, B2s2 is a sub-batch of Batch 2. Subbatching allows the user to group related batches so that statistics

W

Page 10

11

Determines if a coating system complies with the IMO

performance standard for protective coatings.

New PA2

New 90/10

Helps determine if film thickness over a large area conforms to

user specified min/max levels.

Open

Selects a previously created batch or sub-batch name to open and

make current. If it contains measurements, on-screen statistics will

immediately reflect values calculated from this batch. The

calibration setting (i.e. Cal 2) associated with this batch is also

opened (pg.9).

A solid triangle is displayed to the right of the batch

name when sub-batches are present. Press to view subbatches. This also applies to the following Delete, View and Print

options.

current batch

current sub-batch

statistics

(see pg. 13)

current reading

# of sub-batches in

current batch

NOTE:

can be accumulated for them. Batch 2 contains the statistics for

B2s1 and B2s2.

The following user selectable display options are available:

Display

(appears only if a batch is currently open)

When a batch is open, press Up to scroll through the

above display options.

Chart: A real-time x-y chart of batch or sub-batch readings.

Image: An image uploaded (synchronized) from PosiTector.net.

Notes: Instructions or notes uploaded from PosiTector.net.

None

: default screen showing statistics information when a

batch is open.

microns

B2

71.3

1.5

s=3

s3

n5

72.4

74

72

Shortcut:

W

W

W

x

↨

σ

↨

x

72

0.9

σ

# readings in current

sub-batch

Page 11

12

Sends a statistical summary to the optional Bluetooth wireless

printer. Individual measurements with their time stamp are printed

if the Readings box is ticked. A histogram is printed if the Graph

box is ticked. HiLo calculations are printed using current HiLo

settings if HiLo Alarm is turned on (see pg.13).

NOTES:

Print

Close

Delete

View

Stops the recording process, closes the current batch or subbatch, and removes the statistics from the display.

Removes a batch or sub-batch completely from memory. The

name is deleted and all measurements are erased. Sub-batches

can be deleted individually. To delete all related sub-batches,

simply delete the top-level batch.

Lists all readings onto the display from the current or most recently

used batch or sub-batch. It begins by showing the last several

measurement values. Scroll using the (-) or (+) buttons. Hold for 1

second to scroll a page at a time.

Remove the last reading from the current open batch by pressing

(-).

Calibration adjustments cannot be made if any measurements

were taken with that setting and stored into a batch.

If memory is ON while continuous measurements are being taken,

only the last value on the display (when the probe is lifted) is stored

into memory. Scan stores ALL measurements into memory

(pg.17).

Each batch can contain a maximum of 10,000 readings

Page 12

13

Clear

Statistics Menu

Statistics Menu

When selected, a icon and statistical summary will appear on

the display.

Remove the last measurement by pressing the (-) button. Press

(+) to clear statistics.

Allows the Gage to visibly and audibly alert the user when

measurements exceed user-specified limits.

When HiLo Alarm is selected, the current Lo setting is displayed.

Adjust down (-) or up (+). Alternatively, measure a coating with a

thickness close to the required value and make final adjustments

with the buttons. Select NEXT to accept this value. The current Hi

setting is now displayed. Follow the same procedure to adjust the

Hi setting.

The icon will appear on the display.

Measurements will be compared to your defined HiLo limits. The

Gage beeps if results are within those limits. A single low tone will

sound if the reading is below the Lo limit, and a high tone if it is

above the Hi limit. Press (+) to clear HiLo readings.

Mean

(average)

Standard

Deviation

# of

measurements

Minimum

measurement

Statistics

Icon

Last

reading

Statistics

ü

HiLo Alarm

ü

Clears all on-screen Statistics and HiLo tabulations.

50

microns

n6

49.8

52

48

x

x

x

↨

σ

↨

1.3

Maximum

measurement

W

Page 13

14

Immediately initiates synchronization with PosiTector.net when

connected (USB or Bluetooth) to an internet connected PC running PosiTector Desktop Manager (pg.4).

Sync Now

Connect

Connect Menu

Connect Menu

The Gage uses a USB mass storage device class which provides

a simple interface to retrieve data in a manner similar to USB flash

drives, cameras or digital audio players.

When the "USB Drive" option is selected with a tick mark , any

computer can view and download measurements stored in

memory (in batches) by navigating a virtual drive labeled

“PosiTector” using the included USB cable.

A formatted HTML report is viewed by selecting the "index.html"

file found in the root directory. Optionally, text ".txt" files located in

each batch folder provide access to measurement values. Stored

readings and graphs can be viewed or copied using universal

PC/Mac web browsers or file explorers. The "logo.jpg" file can be

replaced with a corporate logo.

USB

ü

Auto Sync

ü

Allows the Gage to automatically synchronize with PosiTector.net

when connected (USB or Bluetooth) to an internet connected PC

running PosiTector Desktop Manager (pg.4).

Additional measurements added to memory while

connected are synchronized only when the USB cable is

unconnected, then reconnected or when Connect>Sync Now is

selected.

NOTE:

ü

While the USB cable is connected to a computer, new

measurements will not be included in reports and text files until the

USB cable is unconnected and then reconnected.

NOTE:

W

W

W

Page 14

15

Determines if a software update is available for your gage (must be

connected to an internet connected PC with PosiTector Desktop

Manager (pg.4)). If an update is available, a prompt will appear

allowing the user to choose to perform the update at this time or

not.

Updates

Ensure that stored measurements are backed up to a PC

or PosiTector.net. The Gage may Reset (pg.16) after completion of

the update and ALL readings in memory would be erased.

NOTE:

Allows individual readings to be sent to a computer or compatible

handheld device as they are taken using Bluetooth wireless

technology.

On: Turns Bluetooth functionality On. When selected, the icon

will appear on the display. To deactivate Bluetooth, select Off.

The Gage and receiving device must be paired before

readings can be transmitted.

NOTE:

Bluetooth

(Advanced models only)

2 / 3

DO NOT unplug the Gage during the update operation.

currently installing

update 2 of 3 total

progress bar

Updates

- Sample Screen

!

When connected, power is supplied through the USB

cable. The batteries are not used and the base unit will not

automatically power down. If rechargeable (NiMH) batteries are

installed, the Gage will trickle charge the batteries.

NOTE:

W

W

Page 15

Setup

Setup Menu

Setup Menu

Reset

16

NOTES:

Hi Res = OFF

Memory = OFF

Statistics Mode = OFF

Hi Lo Alarm = OFF

Cal Lock = OFF

Display = None

N Lock = OFF

Fast Mode = OFF

Scan Mode = OFF

Backlight = Night

SYNC = ON

USB = ON

Bluetooth = OFF

A more thorough Reset can be performed when the Gage is

powered down by simultaneously holding both the center and

(+) buttons until the Reset symbol appears. This is handy when

the Gage fails to power-up or operate properly. It performs the

same function as a menu Reset with addition of:

- Keep the Gage away from metal during a Reset.

- Date and Time are not affected by a Reset.

Units = microns

Flip Display = Normal

White on Black = OFF

Language = English

Battery Type = Alkaline

Reset restores factory settings and returns the Gage to a

known, out-of-the-box condition. It is handy when settings

have been changed, if the Gage behaves unusually, or if a

calibration adjustment is not possible.

The following occurs:

- all batches are closed and stored measurements, images and

batch names are erased.

- all calibration adjustments and Cal Memory are cleared and

returned to the Gage’s factory calibration settings.

- the factory calibration symbol appears on the display: It

disappears if a calibration adjustment is made by the user.

- menu settings are returned to the following:

Page 16

17

Gage Info

Displays the Gage model number, serial number, software

packages, PosiTector.net registration key and the amount of

remaining memory for storage of readings.

For security purposes, the registration key is required to

add the Gage to your PosiTector.net account.

NOTE:

Increases the displayed Gage resolution as follows:

Hi Res

ü

Resolution Range

0.01 mil 0.00 - 99.00 mils

0.1 mil 100.0 - 999.9 mils

0.1 um 0.0 - 999.9 um

1.0 um over 1000 um

Gage accuracy is not affected.

NOTE:

Increases measurement speed for most probes. Useful for quick

inspection or when measuring large areas with thick coatings

where proper probe positioning is not critical. Swift up/down probe

movement is required. Reduced accuracy may be noted.

Useful when taking several measurements in a small area and

storing them into memory while the probe is in contact with the

surface. May reduce the life of the probe. Recommended for

smooth surfaces only.

Scan

ü

Fast

ü

(Advanced models only)

This option causes the display to read upside down. Ideal for use

on a worktable (separate cable probes) and overhead (removable

built-in probes) with the resultant display conveniently pointed

toward the operator.

Flip Display

Page 17

Selects display brightness (Sun, Normal or Night). All settings will

dim slightly after a period of no activity to conserve battery life.

Press the Down button to brighten the display.

Backlight

(Advanced models only)

18

Converts the display from inch to metric or vice versa. Stored

measurements in memory are not converted.

All batches are date-stamped when created, and all

measurements are time-stamped (24 hour format) when stored

into memory. It is therefore important to keep both the date and

time current using this menu option. Use the Up and Down

buttons to scroll. Press (-) (+) buttons to adjust value. Select OK.

Units

Set Clock

Selects the type of batteries used in the Gage from a choice of

“Alkaline”, “Lithium” or “NiMH” (Nickel-metal hydride

rechargeable). If NiMH is selected, the Gage will trickle charge the

batteries while connected via USB to a PC or optional AC charger.

A proper selection calibrates the battery state indicator icon for the

battery type. No damage will occur if the wrong battery type is

selected.

DeFelsko recommends the use of eneloop (NiMH)

rechargeable batteries.

Battery Type

Switching units will turn off Statistics, HiLo Alarm, and

closes Memory.

NOTE:

White on Black

Inverses the LCD display to white on a black to provide better

readability in some surroundings.

(Advanced models only)

NOTE:

Page 18

19

The PosiTector 6000 consists of a gage body

and a probe

. A wide selection of

interchangeable probes are available. Each

retain their own unique calibration information. All

Gage bodies accept all probes

. To disconnect,

power-down the Gage and pull the plastic probe

connector horizontally (in the direction of the arrow)

away from the Gage body.

When powered-up the PosiTector 6000 automatically

determines what type of probe is attached and does a

self-check. Probes “sense” when they are near metal

and immediately attempt a measurement followed by another

every 2 seconds. They stop when removed from the vicinity of

metal and power-down after 5 minutes of no activity.

This continuous measurement feature is intended to allow careful

probe placement on small or odd-shaped surfaces. Ignore all

readings taken before the probe is properly placed.

Standard probes

These constant-pressure, stainless steel probes

are hermetically sealed to be totally waterproof ideal for underwater use. Hold them at the 2

knurled rings and push the outer spring-loaded

sleeve down.

FN Combination Probe

An FN probe combines the capabilities of both "F"

and "N" probes. Switching between the two is

automatic. First, the probe attempts a

measurement using the magnetic principle. If the

coating is non-magnetic over steel, a reading is

displayed with a letter "F". If not, the probe automatically attempts

a measurement using the eddy current principle. If the coating is

non-conductive over metal, a reading is displayed with the letter

"N (see also N Lock pg.8).

Do this...

Not this!

Probes

Probes

Page 19

20

Temperature

Temperature

Operating range: +32° to +120°F (0 to +50°C)

The PosiTector 6000 compensates automatically for

temperature. Allow a few minutes for the probe to reach ambient

temperature before measuring.

Discard the first measurement taken in a notably different

temperature condition. When measuring surfaces much hotter or

colder than ambient, lift the probe at least 6 inches (15cm) and

allow 1 second off the surface between measurements.

The battery indicator displays a full bar with fresh alkaline

or fully charged batteries installed. As the batteries weaken, the

bar will be reduced. When the battery symbol is low the

Gage can still be used, but the batteries should be changed at the

earliest opportunity. The Gage will turn off automatically when

batteries are very low, preceded by a Low Battery Warning on the

display.

To retain all user settings and stored memory readings, only

replace the batteries after the Gage has automatically powereddown.

Power Supply / Battery Indicator

Power Supply / Battery Indicator

Power Source: 3 AAA alkaline, Lithium or optional Nickel-metal

hydride (NiMH) rechargeable batteries. For best battery indicator

results, ensure the appropriate Battery Type is selected in the

Gage Setup>Battery Type menu (pg.18).

Battery performance decreases at low temperatures.

eneloop Batteries (available option)

DeFelsko recommends the use of eneloop (NiMH) rechargeable

batteries.

eneloop batteries combine the advantages of rechargeable

batteries and disposable (Alkaline) batteries. They discharge very

slowly and can be stored for long periods without having self

discharge concerns.

!

Page 20

21

Returning for Service

Returning for Service

Before returning the Gage for service…

1.Install new batteries in the proper alignment.

2.Examine the probe tip for dirt or damage. The probe should

move up and down freely.

3.Perform a Gage Reset (pg.16).

4.Place a plastic shim onto bare metal (steel or non-steel,

depending upon whether you have an "F" or "N" probe) and

attempt a measurement.

If you must return the Gage for service, describe the problem fully

and include measurement results, if any. Be sure to also include

the Gage, probe, your company name, company contact, telephone number and fax number or email address.

Website: www.defelsko.com/support

Troubleshooting

Troubleshooting

Some common reports received by our Service Department along

with possible causes are located on our website. Most conditions

however can be cleared with a Reset (pg.16).

Available Options

Available Options

A variety of accessories are available to help you get the most

from your PosiTector 6000 coating thickness gage.

W

W

Page 21

22

Limited Warranty, Sole Remedy and Limited

Limited Warranty, Sole Remedy and Limited

Liability

Liability

DeFelsko's sole warranty, remedy, and liability are the express

limited warranty, remedy, and limited liability that are set forth on

its website:

www.defelsko.com/terms

www.defelsko.com

© DeFelsko Corporation USA 2011

All Rights Reserved

This manual is copyrighted with all rights reserved and may not be reproduced or transmitted, in whole

or part, by any means, without written permission from DeFelsko Corporation.

DeFelsko and PosiTector are trademarks of DeFelsko Corporation registered in the U.S. and in other

countries. Other brand or product names are trademarks or registered trademarks of their respective

holders.

Every effort has been made to ensure that the information in this manual is accurate. DeFelsko is not

responsible for printing or clerical errors.

Loading...

Loading...