Page 1

11.0 WARRANTY

ELECTROMATIC Equipment Co., Inc. (ELECTROMATIC) warrants to the original purchaser that this product is of merchantable quality and confirms in kind and quality with the

descriptions and specifications thereof. Product failure or malfunction arising out of any

defect in workmanship or material in the product existing at the time of delivery thereof

which manifests itself within one year from the sale of such product, shall be remedied by

repair or replacement of such product, at ELECTROMATIC’s option, except where unauthorized repair, disassembly, tampering, abuse or misapplication has taken place, as determined

by ELECTROMATIC. All returns for warranty or non-warranty repairs and/or replacement

must be authorized by ELECTROMATIC, in advance, with all repacking and shipping

expenses to the address below to be borne by the purchaser.

THE FOREGOING WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO, THE WARRANTY

OF MERCHANTABILITY AND FITNESS FOR ANY PARTICULAR PURPOSE OR

APPLICATION. ELECTROMATIC SHALL NOT BE RESPONSIBLE NOR LIABLE FOR

ANY CONSEQUENTIAL DAMAGE, OF ANY KIND OR NATURE, RESULTING FROM

THE USE OF SUPPLIED EQUIPMENT, WHETHER SUCH DAMAGE OCCURS OR IS

DISCOVERED BEFORE, UPON OR AFTER REPLACEMENT OR REPAIR, AND

WHETHER OR NOT SUCH DAMAGE IS CAUSED BY MANUFACTURER’S OR SUPPLIER’S NEGLIGENCE WITHIN ONE YEAR FROM INVOICE DATE.

Some State jurisdictions or States do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation may not apply to you. The duration of any

implied warranty, including, without limitation, fitness for any particular purpose and merchantability with respect to this product, is limited to the duration of the foregoing warranty.

Some states do not allow limitations on how long an implied warranty lasts but, not withstanding, this warranty, in the absence of such limitations, shall extend for one year from the

date of invoice.

ELECTROMATIC Equipment Co., Inc.

600 Oakland Ave. Cedarhurst, NY 11516—USA

Tel: 1-800-645-4330/ Tel: 516-295-4300/ Fax: 516-295-4399

Every precaution has been taken in the preparation of this manual. Electromatic Equipment

Co., Inc., assumes no responsibility for errors or omissions. Neither is any liability assumed

for damages resulting from the use of information contained herein. Any brand or product

names mentioned herein are used for identification purposes only, and are trademarks or registered trademarks of their respective holders.

TABLE OF CONTENTS

1.0 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 02

2.0 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 03

2.1 Gauge

2.2 Display

2.3 Complete Kit

3.0 Basic Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 04

3.1 Power

3.2 Selecting Units of Measure

3.3 Manually Setting the Measure Mode (DCFN version only)

3.4 Total Reset to Factory Defaults

3.5 Battery Replacement

4.0 Taking Measurements Using Factory Calibration . . . . . . 07

5.0 Performing A ZERO Procedure (Custom Calibration) . . . 08

5.1 Checking Accuracy

5.2 Clearing a ZERO setting and restoring Factory Calibration

6.0 Online statistics Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.1 Deleting the Statistical Values

7.0 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8.0 Resolution Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

9.0 Measuring Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

10.0 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

11.0 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

16

11.0 WARRANTY

ELECTROMATIC Equipment Co., Inc. (ELECTROMATIC) warrants to the original purchaser that this product is of merchantable quality and confirms in kind and quality with the

descriptions and specifications thereof. Product failure or malfunction arising out of any

defect in workmanship or material in the product existing at the time of delivery thereof

which manifests itself within one year from the sale of such product, shall be remedied by

repair or replacement of such product, at ELECTROMATIC’s option, except where unauthorized repair, disassembly, tampering, abuse or misapplication has taken place, as determined

by ELECTROMATIC. All returns for warranty or non-warranty repairs and/or replacement

must be authorized by ELECTROMATIC, in advance, with all repacking and shipping

expenses to the address below to be borne by the purchaser.

THE FOREGOING WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LIMITED TO, THE WARRANTY

OF MERCHANTABILITY AND FITNESS FOR ANY PARTICULAR PURPOSE OR

APPLICATION. ELECTROMATIC SHALL NOT BE RESPONSIBLE NOR LIABLE FOR

ANY CONSEQUENTIAL DAMAGE, OF ANY KIND OR NATURE, RESULTING FROM

THE USE OF SUPPLIED EQUIPMENT, WHETHER SUCH DAMAGE OCCURS OR IS

DISCOVERED BEFORE, UPON OR AFTER REPLACEMENT OR REPAIR, AND

WHETHER OR NOT SUCH DAMAGE IS CAUSED BY MANUFACTURER’S OR SUPPLIER’S NEGLIGENCE WITHIN ONE YEAR FROM INVOICE DATE.

Some State jurisdictions or States do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation may not apply to you. The duration of any

implied warranty, including, without limitation, fitness for any particular purpose and merchantability with respect to this product, is limited to the duration of the foregoing warranty.

Some states do not allow limitations on how long an implied warranty lasts but, not withstanding, this warranty, in the absence of such limitations, shall extend for one year from the

date of invoice.

ELECTROMATIC Equipment Co., Inc.

600 Oakland Ave. Cedarhurst, NY 11516—USA

Tel: 1-800-645-4330/ Tel: 516-295-4300/ Fax: 516-295-4399

Every precaution has been taken in the preparation of this manual. Electromatic Equipment

Co., Inc., assumes no responsibility for errors or omissions. Neither is any liability assumed

for damages resulting from the use of information contained herein. Any brand or product

names mentioned herein are used for identification purposes only, and are trademarks or registered trademarks of their respective holders.

1

TABLE OF CONTENTS

1.0 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 02

2.0 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 03

2.1 Gauge

2.2 Display

2.3 Complete Kit

3.0 Basic Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 04

3.1 Power

3.2 Selecting Units of Measure

3.3 Manually Setting the Measure Mode (DCFN version only)

3.4 Total Reset to Factory Defaults

3.5 Battery Replacement

4.0 Taking Measurements Using Factory Calibration . . . . . . 07

5.0 Performing A ZERO Procedure (Custom Calibration) . . . 08

5.1 Checking Accuracy

5.2 Clearing a ZERO setting and restoring Factory Calibration

6.0 Online statistics Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.1 Deleting the Statistical Values

7.0 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8.0 Resolution Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

9.0 Measuring Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

10.0 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

11.0 Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

16

1

Page 2

1.0 INTRODUCTION

DCF-3000EZ = For measurement on steel / iron

DCFN-3000EZ = For measurements on steel / iron and on

non-ferrous metals

The Check•Line 3000EZ Series of coating thickness gauges provide

accurate, non-destructive measurement of:

• All non-magnetic coatings, such as varnish, paint, enamel,

chromium, copper, zinc, etc. on steel and iron. Measurements

in the F mode (Ferrous) are carried out according to the

Magnetic-Induction method.

• All electrically insulating coatings, such as varnish, paint, enamel

on non-ferrous metals (aluminum, brass, stainless steel, etc).

Measurments in the N mode (Non-ferrous) are carried out

according to the Eddy-Current method.

NOTE: 3000EZ Series gauges operate in accordance with the

following international standards related to coating thickness

measurment:

Magnetic Induction

DIN EN ISO 2178, ASTM B499, DIN 50 982

Eddy-Current:

DIN EN ISO 2360, ASTM D1400

10.0 ERROR MESSAGES

Error 1 = The probe is too close to the metal

Error 2 = Error of gauge due to the effect of electro-magnetic

interference fields

Error 3 = The probe is defective

For Technical Assistance contact:

Electromatic Equipment Company

Telephone: 1-800-645-4330 (USA & Canada)

1-516-295-4300

Fax: 1-516-295-4300

Email: info@checkline.com

2

1.0 INTRODUCTION

DCF-3000EZ = For measurement on steel / iron

DCFN-3000EZ = For measurements on steel / iron and on

non-ferrous metals

The Check•Line 3000EZ Series of coating thickness gauges provide

accurate, non-destructive measurement of:

• All non-magnetic coatings, such as varnish, paint, enamel,

chromium, copper, zinc, etc. on steel and iron. Measurements

in the F mode (Ferrous) are carried out according to the

Magnetic-Induction method.

• All electrically insulating coatings, such as varnish, paint, enamel

on non-ferrous metals (aluminum, brass, stainless steel, etc).

Measurments in the N mode (Non-ferrous) are carried out

according to the Eddy-Current method.

NOTE: 3000EZ Series gauges operate in accordance with the

following international standards related to coating thickness

measurment:

Magnetic Induction

DIN EN ISO 2178, ASTM B499, DIN 50 982

15

10.0 ERROR MESSAGES

Error 1 = The probe is too close to the metal

Error 2 = Error of gauge due to the effect of electro-magnetic

interference fields

Error 3 = The probe is defective

For Technical Assistance contact:

Electromatic Equipment Company

Telephone: 1-800-645-4330 (USA & Canada)

1-516-295-4300

Fax: 1-516-295-4300

Email: info@checkline.com

Eddy-Current:

DIN EN ISO 2360, ASTM D1400

2

15

Page 3

9.0 MEASURING LIMITS

Minimum Radius for Convex Surfaces 0.2" (5mm)

Minimum Radius for Concave Surfaces 2" (50mm)

Minimum Headroom 4" (100mm)

Minimum Sample Diameter 0.5" (13mm)

Minimum Substrate Thickness - F 20 mils (0.5mm)

Minimum Substrate Thickness - NFe 2 mils (50 µm)

2.0 OVERVIEW

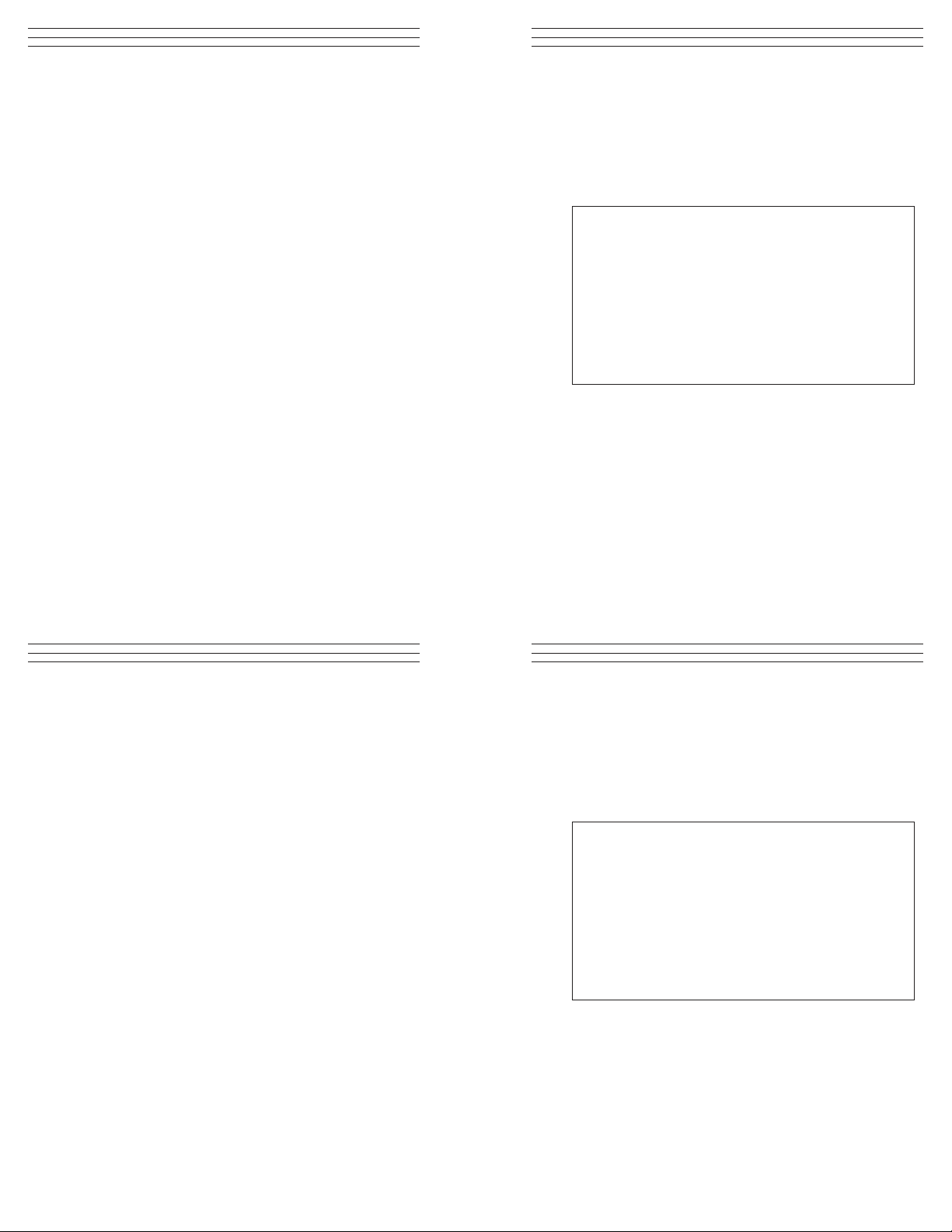

2.1 Gauge

STATISTICS Key

Battery Compartment

(On rear)

LCD Display

ZERO Key

ON/OFF Switch

14

9.0 MEASURING LIMITS

Minimum Radius for Convex Surfaces 0.2" (5mm)

Minimum Radius for Concave Surfaces 2" (50mm)

Minimum Headroom 4" (100mm)

Minimum Sample Diameter 0.5" (13mm)

Minimum Substrate Thickness - F 20 mils (0.5mm)

Minimum Substrate Thickness - NFe 2 mils (50 µm)

3

2.0 OVERVIEW

2.1 Gauge

STATISTICS Key

Battery Compartment

(On rear)

LCD Display

ZERO Key

ON/OFF Switch

14

3

Page 4

2.3 Display

ZERO icon

Statistical values

2.3 Complete Kit

3000EZ Series gauges

are supplied as a complete

kit, with gauge, plastic

test shim, 2x AAA

batteries, soft carrying

pouch, manual and manufacturer’s calibration

certificate.

DCF models include a

steel zero plate. DCFN

models include steel and

aluminum zero plates

Current measurement

Low Battery Indicator

Measurement

mode

Units of

measure

8.0 RESOLUTION TABLE

Mils

0- 99.9 mils 0.1 mils

100.0 - 140.0 mils 0.2 mils

Microns (µm)

0 - 999 µm 1 µm

1.000 - 2.498 mm 0.002 mm

2.500 - 3.500 mm 0.005 mm

2.3 Display

ZERO icon

Statistical values

2.3 Complete Kit

3000EZ Series gauges

are supplied as a complete

kit, with gauge, plastic

test shim, 2x AAA

batteries, soft carrying

pouch, manual and manufacturer’s calibration

certificate.

DCF models include a

steel zero plate. DCFN

models include steel and

aluminum zero plates

4

Current measurement

Low Battery Indicator

Measurement

mode

Units of

measure

13

8.0 RESOLUTION TABLE

Mils

0- 99.9 mils 0.1 mils

100.0 - 140.0 mils 0.2 mils

Microns (µm)

0 - 999 µm 1 µm

1.000 - 2.498 mm 0.002 mm

2.500 - 3.500 mm 0.005 mm

4

13

Page 5

7.0. SPECIFICATIONS

Range

DCF, DCFN Ferrous: 0 - 140.00 mils (0 - 3500 µm)

DCFN Only Non-Ferrous: 0 - 120.00 mils (0 - 3000 µm)

Accuracy ±0.1 mils (±3µm) or ± 3% of reading

whichever is greater

Resolution Refer To Section 8.0

Display Back-lit, 4-digit alphanumeric

Minimum

Measuring Area 0.5" x 0.5" (13mm x 13mm)

Minimum

Curvature Radius Concave: 0.2" (5mm)

Minimum Substrate Thickness

DCF, DCFN Ferrous: 20 mils (0.5mm)

DCFN Only Non-Ferrous: 2 mils (50 µm)

Calibration Factory calibration, user-set zero calibration,

Statistics Number of readings, mean value, standard

deviation, maximum and minimum reading

based on 99 readings (max).

Operating Temp. 32 °F to 122 °F (0 °C to 50 °C)

Surface Temp. 5 °F to 140 °F (-15 °C to 60 °C)

Storage Temp. -4 °F to 140 °F (-20 °C to +60 °C)

Battery 2x AAA (1.5V)

Dimensions 4.3" x 2" x 1" (110mm x 50mm x 25mm)

Weight 3.2 oz (90 g)

Protection Class IP 52 (proof against dust and dripping water)

Standards DIN, ISO, ASTM, BS

3.0 BASIC OPERATIONS

3.1 On/Off Switch

To turn the gauge on, press the ON/OFF Switch briefly

(see photo on page 3). Press and hold the ON/OFF Switch

for 2 seconds to turn the power off.

Note: The gauge will power off automatically after

90 seconds of non-use.

3.2 Selection of Measuring Units

1. Make sure the gauge is switched OFF.

2. Press and hold the ZERO and STATS keys simultaneously

3. While continuing to hold down the ZERO and STATS

keys, turn the power ON.

3.3 Manually setting the measuring mode

DCFN-3000EZ Only

In some cases, especially with varnish applied to zinc on steel,

it is advisable to manually set the measuring mode—F mode

(Ferrous) for measurements on steel/iron, N mode

(Non-ferrous) for measurements on non-ferrous metals.

Setting the measurement mode

1. Turn the gauge on by pressing the ON/OFF switch.

2. Press the ZERO and STATS keys simultaneously to

change the measuring mode. Each time the keys are

pressed the mode will change.

The display will show the mode selected (see photo,

page 4) using the following abbreviations:

12

7.0. SPECIFICATIONS

Range

DCF, DCFN Ferrous: 0 - 140.00 mils (0 - 3500 µm)

DCFN Only Non-Ferrous: 0 - 120.00 mils (0 - 3000 µm)

Accuracy ±0.1 mils (±3µm) or ± 3% of reading

whichever is greater

Resolution Refer To Section 8.0

Display Back-lit, 4-digit alphanumeric

Minimum

Measuring Area 0.5" x 0.5" (13mm x 13mm)

Minimum

Curvature Radius Concave: 0.2" (5mm)

Minimum Substrate Thickness

DCF, DCFN Ferrous: 20 mils (0.5mm)

DCFN Only Non-Ferrous: 2 mils (50 µm)

Calibration Factory calibration, user-set zero calibration,

Statistics Number of readings, mean value, standard

deviation, maximum and minimum reading

based on 99 readings (max).

Operating Temp. 32 °F to 122 °F (0 °C to 50 °C)

Surface Temp. 5 °F to 140 °F (-15 °C to 60 °C)

Storage Temp. -4 °F to 140 °F (-20 °C to +60 °C)

Battery 2x AAA (1.5V)

Dimensions 4.3" x 2" x 1" (110mm x 50mm x 25mm)

Weight 3.2 oz (90 g)

Protection Class IP 52 (proof against dust and dripping water)

Standards DIN, ISO, ASTM, BS

5

3.0 BASIC OPERATIONS

3.1 On/Off Switch

To turn the gauge on, press the ON/OFF Switch briefly

(see photo on page 3). Press and hold the ON/OFF Switch

for 2 seconds to turn the power off.

Note: The gauge will power off automatically after

90 seconds of non-use.

3.2 Selection of Measuring Units

1. Make sure the gauge is switched OFF.

2. Press and hold the ZERO and STATS keys simultaneously

3. While continuing to hold down the ZERO and STATS

keys, turn the power ON.

3.3 Manually setting the measuring mode

DCFN-3000EZ Only

In some cases, especially with varnish applied to zinc on steel,

it is advisable to manually set the measuring mode—F mode

(Ferrous) for measurements on steel/iron, N mode

(Non-ferrous) for measurements on non-ferrous metals.

Setting the measurement mode

1. Turn the gauge on by pressing the ON/OFF switch.

2. Press the ZERO and STATS keys simultaneously to

change the measuring mode. Each time the keys are

pressed the mode will change.

The display will show the mode selected (see photo,

page 4) using the following abbreviations:

12

5

Page 6

Ferr — indicates Ferrous Mode.

Non-Ferr — indicates Non-Ferrous Mode.

AUTO FN — indicates Auto-Select Mode.

3.4 Total Reset to Factory Defaults

1. Switch the gauge off.

2 Press and hold the ZERO key. At the same time, turn on

the power using the ON/OFF switch

3. An acoustic signal will sound, all statistical values will

deleted and the factory settings µm, calibration, and

AUTO FN (DCFN-3000EZ only) will be activated.

3.5 Battery Replacement

3000EZ gauges use 2x AAA alkaline batteries. When battery

power becomes low, the BATTERY INDICATOR will begin

to flash. The gauge will continue to operate, but the batteries

should be replaced as soon as possible. When battery power is

depleted, the Battery Indicator will remain

on continuously,

indicating that less

than 60 seconds of

power remains before

the gauge will shut off.

Battery Indicator

6.1 Clearing the statistical values:

To clear the statistical values, momentarily press and release

the ON/OFF switch. A value of zero will be shown in the

number or measurements field “n” confirming that the stored

statistical values have been cleared.

6

Ferr — indicates Ferrous Mode.

Non-Ferr — indicates Non-Ferrous Mode.

AUTO FN — indicates Auto-Select Mode.

3.4 Total Reset to Factory Defaults

1. Switch the gauge off.

2 Press and hold the ZERO key. At the same time, turn on

the power using the ON/OFF switch

3. An acoustic signal will sound, all statistical values will

deleted and the factory settings µm, calibration, and

AUTO FN (DCFN-3000EZ only) will be activated.

3.5 Battery Replacement

3000EZ gauges use 2x AAA alkaline batteries. When battery

power becomes low, the BATTERY INDICATOR will begin

to flash. The gauge will continue to operate, but the batteries

should be replaced as soon as possible. When battery power is

depleted, the Battery Indicator will remain

on continuously,

indicating that less

than 60 seconds of

power remains before

the gauge will shut off.

11

6.1 Clearing the statistical values:

To clear the statistical values, momentarily press and release

the ON/OFF switch. A value of zero will be shown in the

number or measurements field “n” confirming that the stored

statistical values have been cleared.

6

11

Page 7

6.0. ONLINE STATISTICS DISPLAY

Every time a measurement is

take, a pair of statistical values

appear in the lower part of the

display, as shown at right.

For example:

n = 12 x = 2.8 mils

(n = number of measurements ; x = average)

Each time the STATS key is pressed, the number of measurements

and a different statistical value will appear, allowing the user to

easily scroll through statistics menu in the following sequence:

Press n = number of measurements; x = average

Press n = number of measurements s = standard deviation

Press n = number of measurements max = maximum reading

Press n = number of measurements min = minimum reading

You can pre-select a required pair of values by means of the STATS

key, for example n = 12 s = 0.1 mils, and have it displayed during

the entire measurement data recording process.

Note: After the stistical values are deleted, or before new

measurments are made, the display will show:

n = 0 x = mils

Important: If a series of measurements is meant to be statistically

evaluated, the old statistical values must be deleted

before starting a new series of measurements.

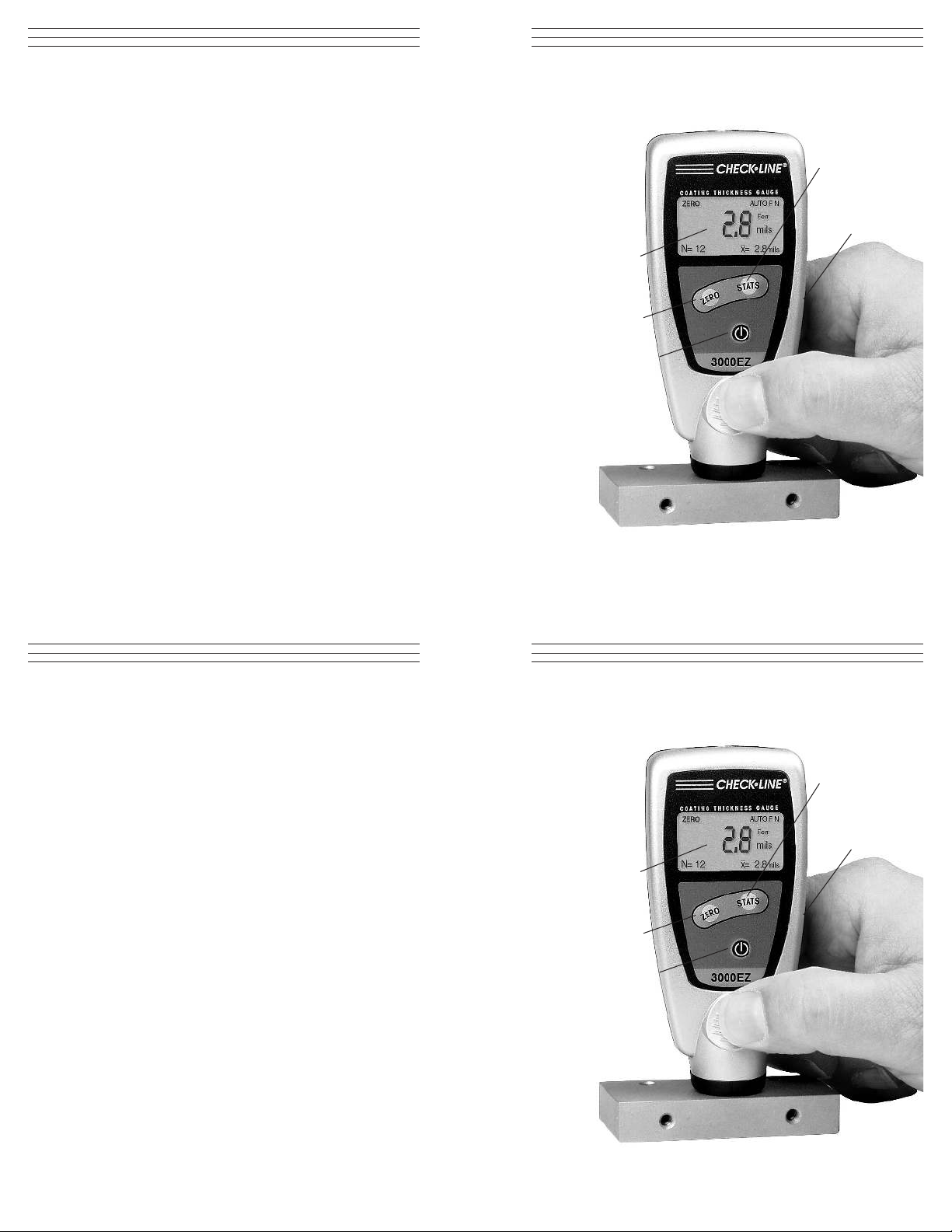

4.0 MEASURING USING FACTORY CALIBRATION

1. Press the ON/OFF switch to turn

the gauge on.

2. If the ZERO icon does not appear

in the upper left corner of the

display, the preset factory

calibration is activated.

If the ZERO icon does appear, it

indicates that a Zero Procedure

has been performed. See Clearing

a Zero Setting, Section 5.2 before

continuing.

3. Place the gauge on the test object and read the measurement. Lift

the gauge off of the test object by at least 1 inch (2.5 cm) before

taking another reading.

Note: Using the factory calibration, you can immediately carry out

measurements on flat and slightly curved surfaces. On strongly

curved or rough parts it is recommended that a ZERO procedure

be performed (see section 5.0).

DCFN-3000EZ Only: The DCFN-3000EZ automatically recognizes

whether the base material is a ferromagnetic steel or a non-ferrous

metal and will display the correct reading.

10

6.0. ONLINE STATISTICS DISPLAY

Every time a measurement is

take, a pair of statistical values

appear in the lower part of the

display, as shown at right.

For example:

n = 12 x = 2.8 mils

(n = number of measurements ; x = average)

Each time the STATS key is pressed, the number of measurements

and a different statistical value will appear, allowing the user to

easily scroll through statistics menu in the following sequence:

Press n = number of measurements; x = average

Press n = number of measurements s = standard deviation

Press n = number of measurements max = maximum reading

Press n = number of measurements min = minimum reading

You can pre-select a required pair of values by means of the STATS

key, for example n = 12 s = 0.1 mils, and have it displayed during

the entire measurement data recording process.

Note: After the stistical values are deleted, or before new

measurments are made, the display will show:

n = 0 x = mils

Important: If a series of measurements is meant to be statistically

evaluated, the old statistical values must be deleted

before starting a new series of measurements.

7

4.0 MEASURING USING FACTORY CALIBRATION

1. Press the ON/OFF switch to turn

the gauge on.

2. If the ZERO icon does not appear

in the upper left corner of the

display, the preset factory

calibration is activated.

If the ZERO icon does appear, it

indicates that a Zero Procedure

has been performed. See Clearing

a Zero Setting, Section 5.2 before

continuing.

3. Place the gauge on the test object and read the measurement. Lift

the gauge off of the test object by at least 1 inch (2.5 cm) before

taking another reading.

Note: Using the factory calibration, you can immediately carry out

measurements on flat and slightly curved surfaces. On strongly

curved or rough parts it is recommended that a ZERO procedure

be performed (see section 5.0).

DCFN-3000EZ Only: The DCFN-3000EZ automatically recognizes

whether the base material is a ferromagnetic steel or a non-ferrous

metal and will display the correct reading.

10

7

Page 8

5.0 PERFORMING A ZERO PROCEDURE

To obtain more accurate measurements on strongly curved or rough

parts, you should carry out the ZERO Procedure on a similar curved

reference piece without coating.

1. Press the ZERO key. ZERO flashes in the display.

2. Place the gauge on the bare surface several times. Lift the gauge

off of the surface by at least 1 inch (2.5 cm) between placements.

3. Press ZERO key again. The display shows ZERO

4. You can now carry out additional measurements.

Note: Zeroing is required if the convex radius of curvature

• is smaller than 1.2” (30mm) on steel parts,

• is smaller than 2.4” (60mm) on non-ferrous metal parts.

5.2 Clearing a zero setting and restoring factory

calibration

If the ZERO icon is shown on the display after switching

on (see top photo below), a custom calibration is activated.

To clear the custom setting:

1. Press the ZERO key twice. The ZERO icon disappears.

The factory calibration is active.You can now take

measurements using the factory calibration.

5.1 Checking accuracy

The foil standard included in the complete kit can be used

together with the suppled zero plates (Fe or Al) to check the

accuracy of the gauge. After zeroing, the measured thickness

of the foil will be displayed within the tolerance of the foil

plus the gauge accuracy.

8

5.0 PERFORMING A ZERO PROCEDURE

To obtain more accurate measurements on strongly curved or rough

parts, you should carry out the ZERO Procedure on a similar curved

reference piece without coating.

1. Press the ZERO key. ZERO flashes in the display.

2. Place the gauge on the bare surface several times. Lift the gauge

off of the surface by at least 1 inch (2.5 cm) between placements.

3. Press ZERO key again. The display shows ZERO

4. You can now carry out additional measurements.

Note: Zeroing is required if the convex radius of curvature

• is smaller than 1.2” (30mm) on steel parts,

• is smaller than 2.4” (60mm) on non-ferrous metal parts.

Custom calibration active

Custom calibration cleared

9

5.2 Clearing a zero setting and restoring factory

calibration

If the ZERO icon is shown on the display after switching

on (see top photo below), a custom calibration is activated.

To clear the custom setting:

1. Press the ZERO key twice. The ZERO icon disappears.

The factory calibration is active.You can now take

measurements using the factory calibration.

5.1 Checking accuracy

The foil standard included in the complete kit can be used

together with the suppled zero plates (Fe or Al) to check the

accuracy of the gauge. After zeroing, the measured thickness

of the foil will be displayed within the tolerance of the foil

plus the gauge accuracy.

8

Custom calibration active

Custom calibration cleared

9

Page 9

OI502

CHECK•LINE

BY ELECTROMATIC

Coating Thickness Gauges

DCF-3000EZ AND DCFN-3000EZ

®

CHECK•LINE

INSTRUMENTS

®

ELECTROMATIC

E Q U I P M E N T C O., I N C.

600 Oakland Ave., Cedarhurst, NY 11516–U.S.A.

TEL: 516-295-4300

•

FAX: 516-295-4399

www.checkline.com

Operating Instructions

OI502

CHECK•LINE

BY ELECTROMATIC

Coating Thickness Gauges

DCF-3000EZ AND DCFN-3000EZ

®

CHECK•LINE

INSTRUMENTS

®

ELECTROMATIC

E Q U I P M E N T C O., I N C.

600 Oakland Ave., Cedarhurst, NY 11516–U.S.A.

TEL: 516-295-4300

•

FAX: 516-295-4399

www.checkline.com

Operating Instructions

Loading...

Loading...