A5CN – A6 – A8 (Rev. 01/06/2012) ENG 1

Installation and instruction manual,

Pellet stoves

Mod. A5CN – A6 – A8

2 ENG A5CN – A6 – A8 (Rev. 01/06/2012)

DIMENSIONS

AMANDINE, ADELAIDE, ADELE:

ALESSIA, ANTONELLA, AXELLE:

ALEYNA, ARMELLE, ALINE:

A5CN – A6 – A8 (Rev. 01/06/2012) ENG 3

A = 200 mm

B = 300 mm

C = 800 mm

D = 500 mm

E = 300 mm

B

B

A

D C

E

4 ENG A5CN – A6 – A8 (Rev. 01/06/2012)

B

B

A

D C

E

A = 200 mm

B = 300 mm

C = 800 mm

D = 500 mm

E = 300 mm

A5CN – A6 – A8 (Rev. 01/06/2012) ENG 5

B

B

A

D C

E

A = 200 mm

B = 300 mm

C = 800 mm

D = 500 mm

E = 300 mm

6 ENG A5CN – A6 – A8 (Rev. 01/06/2012)

Dear Customer,

Thank you for choosing one product from our range and we hope you will be fully satisfied.

1. All stoves belongs to the A5, A6 and A8 series (product family identification code) have been build with high

gauge steel (up to 3 and 4 mm for the combustion chamber) of the best quality, and materials like vermiculite

(skamolex) for the inner part of the combustion chamber. This gives a clear vision of the stove but also shows a great

heat resistance and allowed us to gain significant levels of heat output as well as very low gas emission levels

2. For the electric and electronic components, the best suppliers on the European market have been selected. The

main board, actually the heart the stove, has been developed by the market leader with over 1.000.000 parts on th e

market.

3. Other components like smoke exhaust motors, pellet loading system and hot air fans have been selected with the

same concept: only the best available on the market. For exemple, for the pre-heater we could use a cheaper

component but we decided to install a double jacket. This gives us the possibility to install the pre-heater right there

in the fireplace, where the pellet is. Why? To get a fast and safe starting of the stove!

4. On the top of all other checks, electric and for single components, we have added the “FINAL FIRE CONTROL”, a

check we already run since over 10 years for all or gas stoves. At the end of the production we do connect and fire all

stoves and thanks to a special electronic control, do simulate all the typical conditions like in your everyday use. In

this way we make 100% sure each single stove is working 100%.

In other words, we have realized the first “noiseless” stove – plus the A5 one that doesn’t have the ventilation fan -:

all A6 and A8 models are fitted with a special function to switch the vent fan off and run the stove like a natural

convention one

You can program the heating in your house but switch the fan off when getting home at the evening and enjoy in

silence the pleasure of the fire.

All models are fitted with the external air inlet in line with the pre-heater. The outside air is getting warmed in the fire

pot but a part is used to keep the glass door clean. This makes the stove tight and ideal to be installed in class A or

BBC houses.

How could we get this result? First of all by choosing reliable top quality components and, last but not least, adopting

a high sophisticated construction technology. Our target hasn’t been the price but the care of the quality. On the top

of that, our 25 years heating system manufacturing experience and a two years intensive developing program of a

French – Italian technical team. The most innovative pellet stove nowadays available on the market is the result.

Our exclusive overpressure valve is your guarantee for safety even when using not approved pellet quality or

chimney which doesn’t work properly.

How to lock and unlock the remote control keypad:

key 7 and right after key 3

.

A5CN – A6 – A8 (Rev. 01/06/2012) ENG 7

Index ENG

1. IMPORTANT INFORMATIONS ERREUR ! SIGNET NON DEFINI.

2. SAFETY ERREUR ! SIGNET NON DEFINI.

3. HANDLING AND STOCKING ERREUR ! SIGNET NON DEFINI.

4. AUTHORIZED FUEL ERREUR ! SIGNET NON DEFINI.

5. NON AUTHORIZED FUELS ERREUR ! SIGNET NON DEFINI.

6. STOVE DESCRIPTION 10

7. INSTALLATION ERREUR ! SIGNET NON DEFINI.

8. LOCATION OF THE STOVE ERREUR ! SIGNET NON DEFINI.

9. THE SMOKESTACK ERREUR ! SIGNET NON DEFINI.

10. CONNECTING TO THE EXISTING SMOKESTACK 12

11. ALLOWED INSTALLATIONS 14

12. NOT ALLOWED INSTALLATIONS (IN ITALY) 15

13. PASSING THROUG FLAMABLE CEILING 15

14. CONNECTING TO THE EXTERNAL AIR INLET 15

15. ELECTRICAL CONNECTION 16

16. REMOTE CONTROL INSTRUCTIONS 17

17. LIST OF MENUS 18

18. MENU 02 - DAY AND TIME SETTING 19

19. MENU 03 - SET WALL THERMOSTAT 19

20. MENU 04 – SELECT LANGUAGE 21

21. MENU 05 – SET ROOM TEMPERATURE PROBE 21

22. MENU 06 – STAND BY OR STOP&GO 22

23. MENU 07 – BEEPER 22

24. MENU 08 – FIRST PELLET LOADING 22

25. MENU 09 – STOVE STATUS 23

26. MENU 10 – SERVICE SETTINGS 23

27. MENU 11 – DEALER SETTINGS 23

28. MENU 12 – FAN ENABLE (ONLY FOR A6 AND A8 MODEL) 23

29. STOVE STARTING 23

30. ROOM TEMPERATURE SETTING 24

31. POWER SETTING 24

32. SWITCHIN STOVE OFF 24

33. REMOTE CONTROL FREQUENCY SETTING 25

34. REMOTE CONTROL LINKING 25

35. HOW TO USE THE REAR CONTROL PANEL (IN EMERGENCY ONLY) 26

36. FIRST STARTING 27

37. MAINTENANCE AND CLEANING 28

38. ELECTRICAL DIAGRAM 29

39. TROUBLESHOOTING 30

40. MOUNTING LATERAL CERAMIC 32

41. GUARANTEE 34

8 ENG A5CN – A6 – A8 (Rev. 01/06/2012)

1. IMPORTANT INFORMATIONS

This instruction manual belongs to the pellet stove and is delivered with it. The stove is delivered with this manual,

the relevant plant booklet and the guarantee form. Please do carefully read this instruction manual before installing

and starting the stove. Save all the a.m. documents because they are integral parts of the stove.

CAUTION: This warning symbol located in various parts of this book, indicates

that if you don’t follow the intructions of what is written, it can cause serious

damages to the product and endanger the safety of those users.

For safety reasons, it is very important to always follow instructions when maintaining the stove.

All the local, regional, National and European regulations have to be satisfied when using

this stove.

The packaging does protect your stove. However, during transport, the stove could get damaged. Therefore, we

kindly ask you to carefully check the stove and its components. A damaged stove - or in case of missing component

– should not be installed. Please get immediately in touch with your dealer.

2. SAFETY

Attention: the glass is very hot !!!! Do not leave kids near the stove!!!

Do not leave curtains, clothes, dish closes, furniture or other material on or near to the stove. Do respect the safety

distances.

After installing the stove let it burn at an average power (power 3).

Ventilate the room and carefully supervise the stove. During this time, all paints and assembling material will dry out.

The light smoke that could develop will rapidly fade away.

Regular maintenance and cleaning are essentials for the stove proper working and lasting. Check for craked or

broken glasses. In case, replace immediately.

Your stove has been developed for using a well defined fuel. Specification for the ideal fuel is shown in the next

chapter. In case of use of different or not allowed fuels, your stoves can get shortly damaged.

The remote control does integrate a probe and you can set the desired temperature for the room where the remote is

located. The range is 7 to 8 meters depending on the architecture of the building. We suggest not placing it close to

the stove. All side walls and the top of the stove are getting very hot. Do not leave there the remote because it will be

damaged.

Always use original parts for the guarantee. It is not allowed to modify in any way the stove.

Basic safety rules:

General Indications:

- Never use water for extinguishing a stove.

- The glass and other parts of the stoves are extremely hot and could be very dangerous for kids

- Through the glass, there is a radiant heat, don’t put flammable materials, heat sensitive objects or people at less

than 80 cm by 180°.

- Don’t leave flammable materials near to the stove.

- Never run the stove when the ashtray is out

- When cleaning the ash tray and burning pot, put all rests in a metallic container and wait at least 48 hours before

discarding it in order to prevent fire cases.

After sale service

We recommend you to always order only original spare parts directly supplied by the stove manufacturer otherwise

the guarantee will decline.

The manufacturer is not responsible for maintenance and cleaning operations made unaccordingly with this manual.

A5CN – A6 – A8 (Rev. 01/06/2012) ENG 9

3. HANDLING AND STOCKING

The cardboard/wood package has been designed to protect the

stove but cannot be stocked outside or in very damp places. It

must be exposed to the elements, otherwise some components

or the stove itself could get damaged and the guarantee will

decline. As stoves have some fragiles parts like glasses and

electronic components, it should be handled following few basic

rules:

Lift and lay down the stove gently. In case you use a two wheels

trolley or when transporting upstairs, always take the stove at the

side opposite to the glass (which is identified by a sticker). The

glass is always placed on the sticker side.

.

4. AUTHORIZED FUEL

Pellet is produced with wood rests from clean wood machining like sawmills, furniture manufacturing or new wood

from forest culture. All these 100% vegetable materials are dried and pressed into the pellet form without adding any

kind of glue or chemical. We do approve to be used in our stoves all pellets that satisfy the European regulation EN

14961-2. All the approved pellets must carry the following logo:

New logo since 2011

Typical specifications for the approved fuel:

.caloric capacity (in MJ/kg) (2*)

. ≥ 17,6 MJ/kg

.caloric capacity (in KWh/kg) (2*)

≥ 4,9 KWh/kg

.caloric capacity (in Kcal/kg) (3*)

≥ 4.223 Kcal/kg

..density

..1,12 kg/dm3

..water content

..mass. 10,0 %

..ash content

..mass. 0,5 %

..length

..mass. 30 mm

..diameter

5- 6 mm

..thin material (rests)

..mass. 2,3% (1*)

..composition

..natural wood

If using a low quality fuel, the stove could possibly work not properly and can lead the guarantee to decline.

The uses of low quality pellet leads to:

- Shorter cleaning intervals

- Higher fuel consumption

- Lower output

- Glass getting quickly dirty

- Fire pot and exhaust smoke connection will clog up rapidly

5. NON AUTHORIZED FUELS

All pellet types that doesn’t satisfy the a.m. indications..

10 ENG A5CN – A6 – A8 (Rev. 01/06/2012)

6. STOVE DESCRIPTION

Remote control

Flap door for

charge pellet

Protection grid

Fire pot

Air-glass cleaning

Fire pot support

Ashtray

Flap door inspection

lower smoke chamber

Inner glass ceramic

Closing door

Door

Charge pellet in fire pot

Interior in skamolex

Convection air outlet

Overpressure security valve

Handle opening door

Make sure the power supply is always available

Rear control panel

Room temperature probe

Wall thermostat connecting

Air inlet for combustion

(chose one of two solutions)

Fuses

Electrical connection

On / Off switch

Smoke piping

Starting resistance

A5CN – A6 – A8 (Rev. 01/06/2012) ENG 11

IMPORTANT: ALL PICTURES AND DRAWINGS LISTED IN THE MANUAL ARE

ONLY INFORMAL. THE INSTALLATION MUST TO BE CONFORM TO THE LOCAL

AND NATIONAL REGULATIONS FOR INSTALLATION.

Before installing the stove please check as follows:

- The chimney has to be correctly designed for exhaust gases and must satisfy the requirements for the stove

- The distance between stove and flammable materials has to be respected

- The wall back to the stove must satisfy the regulations in force and manufacturer’s recommendations

- The external air intake must be the right size and connected to the stove

- Floor capacity is enough related to stove weight

8. LOCATION OF THE STOVE

If the stove is located on a flammable floor (i.e. parquet), you will have to protect it against radiant heat and

eventually some combustion rests with appropriate non flammable materials (steel, marble, tiles etc.).

Minimum distances to be respected are shown below and in the first page of this manual:

If scaffoldings are placed over the stove, a minimum distance of 50 cm from the stove itself and from the chimney

has to be respected. A distance of min 50 cm between the chimney and heat sensitive building elements like facing,

beams or wooden ceilings, etc. must be respected

Keep all flammable materials like wooden furniture, curtains, carpets and

flammable fluids at least 80 cm from the stove when operating).

9. THE SMOKESTACK

Each stove should be only connected to a single chimney. The chimney pipe must be built in a proper way to

facilitate cleaning and inspection. All chimneys and connection piping must be identified by an approved tag showing

all typical data in accordance with local and national regulations in force.

MIN 50 cm

MIN 50 cm

12 ENG A5CN – A6 – A8 (Rev. 01/06/2012)

Smoke evacuation system components designation example:

Temperature class (es: T400 minimum, T450-T600 suggested)

The smokestack temperature class should not be lower than the maximum exhaust gasses temperature declared by

the stove manufacturer.

For all appliances (appliances for home heating burning wooden pellet as fuel – requirements and testing procedure)

temperature class lower than T400 are not allowed. In any case always check the stove data sheet for technical

details but temperature Txxx should be at least 50 °C higher than the maximum smoke temperature.

Pressure class (smoke tightness) N

Since all smokestacks must work in depression, the pressure class will be N = negative

By the end a smokestack showing this tag is perfect to fit a pellet stove: T450N1D2GXX

Soot fire resistance class G

All smokestacks connect to appliances burning solid fuel must be soot fire resistant; the designation letter will

therefore be G followed by the distance in millimeters (XX) (as per UNI EN 1443) from flammable materials. The

chimney has to be built in accordance with the local and national regulations in force.

10. CONNECTING TO THE EXISTING SMOKESTACK

The connection to the existing smokestack has to fulfill the the local and national regulations in force. Piping with

classification “O” and minimum distance in millimeters xx is allowed and ensures that in case of soot fire all

connecting piping will be fully replaced in order to restore the original conditions. Please make sure only 3 direction

changing of maximum 90° and a 4 meters horizontal segment are allowed (check following examples) .

Example with 2 bends 90° Example with 3 bends 90° (maximum allowed)

The stove can be connected to an existing smokestack only after carefully checking it. If the smokestack doesn’t

show the approved tag, a registered chimneysweeper has to certify it.

Metal chimney

Regulation ID number

Temperature class (as per UNI EN 1443)

Pressure class N, P or H (as per UNI EN 1443)

Moisture resistance class (as per UNI EN 1443)

Corrosion resistance class (as per UNI EN 1443)

Soot fire resistance class G or O Followed by the distance from flammable materials

EN 1443 T400 N1 D 2 G50

1

2

3

m

a

x

1

,

5

m

1

2

3

1

2

m

a

x

4

m

i

n

c

l

i

n

a

t

i

o

n

>

3

%

i

n

c

l

i

n

a

t

i

o

n

>

3

%

A5CN – A6 – A8 (Rev. 01/06/2012) ENG 13

When connecting to non isolated smokestacks, draught problems can occur. It is however forbidden to connect the

stove to the smokestack with a diameter bigger than 200 millimeters (in the case slot - a 100 / 150 millimeter pipe up

to 4 meters or a 150 / 180 millimeters one over 5 meters of smokestack height). Always follow the local and national

regulations in force.

CONNECTOR T WITH CAP

A HERMETIC CLOSING

CONNECTOR

ø 80 > ø 100

ø 80mm

ø 100mm

STOVE

INSULATING

CONNECTOR T

CONNECTOR T

CLEANING

DIRECTION

CLEANING

DIRECTION

M

a

x

4

m

(

m

i

n

.

3

%

)

CLEANING DIRECTION

ø 100 mm

min.

CHIMNEY

TCONNECTOR

Ø 80mm

INSULATING

Ø 180mm MAX

Ø 100mm MIN

INSERTING

OF A TUBE

INSPECTION

COVER

NOT INTEGRATED FLUE

DUCTING WITH

CLOSING FLANGE

CLOSING FLANGE IN HERMETIC

STAINLESS STEEL OR ALUMINATE

OUTDOOR AIR SUPPLY

WITH GRATE NO PACKABLE

DUCTING

EXISTING

FLUE

14 ENG A5CN – A6 – A8 (Rev. 01/06/2012)

11. ALLOWED INSTALLATIONS

Smokestack diameter has to be adequate to its height as is the following sketches.

The use of insulated smokestacks is recommended in all the following cases:

- All outside smokestacks.

- When getting through non heated attics or mansards

- Very long segments (over 4 meters) inside the apartment.

INSULATING

INSULATING

CLEANING

DIRECTION

M

a

x

4

m

(

m

i

n

.

3

%

)

CLEANING DIRECTION

CLEANING

DIRECTION

OK

M

a

x

4

m

(

m

i

n

.

3

%

)

CLEANING DIRECTION

NO

CLEANING DIRECTION

OK

Ø 80 mm

MAX 3 meters

Ø 100 mm

MAX 6 meters

Ø 150/180 mm

MAX 15 meters

INSULATING

INSULATING

A5CN – A6 – A8 (Rev. 01/06/2012) ENG 15

Following sketches are wall exhaust examples for the countries where it is allowed.

12. NOT ALLOWED INSTALLATIONS (In Italy)

1) Two or more stoves connected to the same smokestack.

2) Stove and fireplace connected to the same smokestack.

For all other countries, respect all local and national regulations in force.

13. PASSING THROUG FLAMABLE CEILING

Be very careful when getting through walls, ceilings or roofs made of flammable materials.

The high smoke temperatures can start a fire. Always respect the safety distances of your

local and national regulations in force.

14. CONNECTING TO THE EXTERNAL AIR INLET

The air inlet diameter should be not less than 60 millimeters and the maximum piping length is 1 meter and one 90°

bend. The stove is fitted as standard with a 80 millimeters connection. In this case, the maximum length can be 1,5

MIN 2 meters

MIN 1,5 meters

INSULATED

PIPE

Inclination > 3%

Length < 3 m

16 ENG A5CN – A6 – A8 (Rev. 01/06/2012)

meters and one 90° bend. When connecting the stove with an external air inlet, you will get an exceptional level of

comfort and operation softness. The stove will properly burn even in case you can’t connect it to an external air inlet

but getting the combustion air from the inside of the room.

15. ELECTRICAL CONNECTION

Check that the wall plug is in accordance to the stove electrical requirements: 230V/50Hz e 400Watt. Make sure that

the electrical cord doesn’t get in touch with any hot part of the stove and doesn’t run over the smoke connection, that

a proper earth is available and a proper circuit breaker is fitted. In case of irregular power supply (normally in remote

or mountain areas), do not worry, your stove is protected with two 5X20 4A STD between the main switch and the

cord plug on the rear panel. Check the fuses before installing the stove.

A5CN – A6 – A8 (Rev. 01/06/2012) ENG 17

16. REMOTE CONTROL INSTRUCTIONS

The remote control works up to a maximum distance of 8 meters and allows you

operating your pellet stove.

› Button 1 - Navigation

To reduce temperature and power output and scrolling down worth the menu.

› Button 2 - Navigation

To increase temperature and power output and scrolling up worth the menu.

› Button 3 - ON-OFF and BACK

Hold for 3 seconds for switching the stove on and off. Press once for getting back into

the menu till home page.

› Button 4 - ROOM TEMPERATURE SETTING

Press for entering the room temperature setting menu with buttons 1 and 2.

› Button 5 - POER OUTPUT SETTING

Press for entering the power output level 1 to 5 setting menu with buttons 1 and 2.

› Button 6 - Not in use

Not in use.

› Button 7 - MENU and OK

Press for entering the main menu than use buttons 1 and 2 for scrolling; press button

7 again for entering the desired sub menu.

Press to confirm selection (OK).

› Display

All the needed information are displayed (the aboce schema represents the starting

screen):

If no buttons are pressed for 30 seconds after switching on the stove the remote

control enters the stand-by status and the display goes off. Press any button to

reactivate.

To lock or unlock the keyboard: button 7 and button 3 in rapid sequence.

The remote control is supplied with a wall rest.

Do not place the remote control near the stove or close to other heat sources. For best

results, we suggest to locate it at a height of 150 centimeters. The maximum operating range of 8 meters from the

stove depends on architectonical barriers (walls). The remote control should be handled with care and not exposed

to the weather (sun, rain). The control is fitted with AAA cells (included). Change batteries every year or when low.

Remove the cover on the backside to access the battery location. Please dispose flat batteries properly. In case of

doubts, check with your local recycling center.

When programming the stove using the remote control, the clock stops, so if you use

with the remote control for a long time, you will find that the display not indicate more

the exact time. The clock goes programmed every time you use for a long time with the

remote control.

TOLERANCE INDICATOR OF TEMPERATURE ON THE REMOTE CONTROL is + or - 3 ° C

18 ENG A5CN – A6 – A8 (Rev. 01/06/2012)

17. LIST OF MENUS

After switching the remote control on (press button3 ),

Access the different menus for programming the stove:

Press button 7 to access the main menu (MENU 1 on the display)

Press button 1

and 2

to scroll all menus 1 to 12

When selected the desired menu, press button 7 to confirm.

Confirm the different options (OK) with button 7 .

To exit the menus and getting back to main menu, press button 3

.

.

MENU 01

ADJUST BLOWER

Disabled menu.

MENU 02

SET CLOCK

> Day (Monday – Sunday)

> Hours (00 – 24)

> Minutes (00 – 59)

> Date (01 – 31)

> Month (1 – 12)

> Year (00 – 99)

MENU 03

SET THERMOSTAT

> Week setting (ON/OFF)

> Start program – 1

(OFF, 00:00 – 24:00)

> Stop program – 1

(OFF, 00:00 – 240:00)

10 minutes interval

MENU 04

SET LANGUAGE

> Italian ITA

> French FRE

> English ENG

> German DEU

MENU 05

SET PROBE

> Inside probe

> Remote control probe

MENU 06

STAND-BY

> On

> Off

MENU 07

BUZZER

> On

> Off

MENU 08

STARTING LOAD

To be used by the starting

only

MENU 09

STOVE STATUS

Close menu.

All indication on stove

status are given

MENU 10

SERVICE SETTINGS

Code access menu for

qualified service use only

MENU 11

DEALER SETTINGS

Code access menu for

qualified dealer use only

MENU 12

SET FAN

> On

> Off

For models A6/A8 only

MENU 01

ADJUST

BLOWER

MENU 02

SET

CLOCK

MENU 03

SET

CHRONO

MENU 04

SELECT

LANGUAGE

MENU 05

SELECT

FEELER

MENU 06

MODE

STAND-

MENU 07

MODE

BUZZER

MENU 08

LOAD

INITIAL

MENU 09

STATE

STOVE

MENU 10

SETTINGS

TECHNIC

MENU 11

SETTINGS

CLIENT

MENU 12

ENABLE

BLOWER

A5CN – A6 – A8 (Rev. 01/06/2012) ENG 19

18. MENU 02 - DAY AND TIME SETTING

1) From main

menu…

2) Press button

7 for accessing

menus

3) Menu 01 is

displayed

4) Press button

2 for scrolling all

menus

5) Show menu

02

6) Press button

7 for entering

the menu

7) Display the

week day

(Monday –

Sunday)

8) Press button

2 to change the

day

9) Press button

7 to confirm

10) Display the

time (00 – 24)

11) Press button

2 for changing

the time

12) press button

7 to confirm

13) Display

minutes (00 –

59)

14) Press button

2 to set minutes

15) Press button

7 to confirm

16) Day date is

displayed (01 –

31)

17) Press button

2 for changing

date

18) Press button

7 to confirm

19) display

month (01 – 12)

20) Press button

2 to set month

21) Press button

7 to confirm

22) Year is

displayed (00 –

99)

23) Press button

2 for changing

year

24) Press button

7 to confirm and

then button 3.

19. MENU 03 - SET WALL THERMOSTAT

This program enables you setting a fire or power off interval for each week day. You can schedule up to 4 different

on/off programs. The following example shows a typical program for a family with children. On/OFF intervals are set

to satisfy the school time table of the children as well as the week end warm requirements when the whole family is

remaining home.

Monday

Tuesday

Wednesday

Thursday

Friday

Saturday

Sunday

PROG 1 : from 5h00 to 9h00

PROG 2 : from 18h00 to 23h00

PROG 3 : from 13h00 to 23h00

PROG 4 : from 9h00 to 23h00

Attention: before programming the CRONO function, you have to set day, date and time (menu 02 - SET TIME).

14 :34

28.5 P-1

OFF

MENU 01

ADJUST

BLOWERS

MENU 02

SET

CLOCK

MENU 02

SUNDAY

DAY

10

MENU 02

TIME

CLOCK

: 09

MENU 02

MINUTES

CLOCK

23

MENU 02

DAY

CLOCK

10

MENU 02

MONTH

CLOCK

11

MENU 02

YEAR

CLOCK

20 ENG A5CN – A6 – A8 (Rev. 01/06/2012)

MENU 03 - SET WEEK THERMOSTAT

1) From main

menu…

2) Press button

7 for accessing

menus

3) Menu 01 is

displayed

4) Press button

2 for scrolling all

menus

5) Show menu

03

6) Press button

7 for entering

the menu

7) Program

on/off displayed

8) Press button

2 for enable

program (ON)

9) Press button

7 to confirm

10) Starting time

program 1 is

displayed but

disabled (OFF)

11) Press button

2 for enables

the program

(ON)

12) Starting time

program 1 is

displayed

13) Press button

2 for changing

starting time (10

minutes steps)

14) In this

example starting

time at 05:00

AM is shown

15) Press

button7 to

confirm starting

time

16) Switch off

time program 1

is displayed but

disabled (OFF)

17) Press button

2 for enables

the switch off

time

18) Program 1

switch off time is

displayed

19) Press button

2 for changing

switch off time

(10 minutes

steps)

20) In this

example switch

off time at 09:00

AM is shown

21) Press

button7 to

confirm switch

off time

22) First week

day Monday

with program 1

is displayed

23) Press button

2 for enabling

(ON) program 1

for that day

24) Press button

7 to confirm and

start

programming

the next day

25) repeat all

points from 23)

to 24) for each

single day of the

week…

26) …after

Sunday,

program 2 will

be displayed

27) repeat all

points from 11)

to 25) for the

remaining 3

programs

28) When

finished press

button 3 to

confirm

29) Press button

3 to exit back to

menus

2

mere tasto 7 per

confermare e

14 :34

28.5 P-1

OFF

MENU 01

ADJUST

BLOWERS

MENU 03

SET

CHRONO

OFF

MENU 03

CRONO

WEEKLY

OFF

MENU 03

START

PROG-1

00 00

MENU 03

START

PROG-1

05 00

MENU 03

START

PROG-1

OFF

MENU 03

STOP

PROG-1

00 00

MENU 03

STOP

PROG-1

09 00

MENU 03

STOP

PROG-1

OFF

MENU 03

MONDAY

PROG-1

OFF

MENU 03

START

PROG-2

A5CN – A6 – A8 (Rev. 01/06/2012) ENG 21

MENU 03 - WALL THERMOSTAT ENABLING AND CONNECTING

1) From main

menu…

2) Press button

7 for accessing

menus

3) Menu 01 is

displayed

4) Press button

2 for scrolling all

menus

5) Show menu

03

6) Press button

7 for entering

the menu

7) Program

displayed but

disabled (OFF)

8) Press button

7 to confirm

8) Press button

3 to back to the

menu

9) Connect to

the plug on

stove’s rear

panel ….

10) … by mean

of two wires

as….

11) … wall

thermostat

electrical

diagram

20. MENU 04 – SELECT LANGUAGE

This menu allows selecting the desired language among Italian (ITA) which is the default selection, English (ENG),

French (FRE) and German (DEU)

.

1) Select menu

04 (button 7 and

then button 2)

2) Press button

7 to enter the

menu

3) The selected

language is

displayed ENG

(English)

4) Press button

2 for selecting

the desired.

5) Press button

7 to confirm.

6) Press button

3 to back the

menu.

21. MENU 05 – SET ROOM TEMPERATURE PROBE

This menu allows switching the desired room temperature probe on selecting between the remote control probe

(REMOTE) and the one located on the stove’s rear panel (INTERN). As default we suggest using the remote control

probe.

1) Select menu

05 (button 7 and

then button 2)

2) Press button

7 to enter the

menu

3) Probe in use

INTERN or

REMOTE is

displayed

4) Press button

2 to select the

desired probe.

5) Selected

probe INTERN

or REMOTE is

displayed

6) Press button

7 to confirm and

button 3 to back

to the menu

14 :34

28.5 P-1

OFF

MENU 01

ADJUST

BLOWER

S

MENU 03

SET

CHRONO

OFF

MENU 03

CRONO

WEEKLY

MENU 04

SELECT

LANGUA

GE

MENU 04

ENG

LANGUA

GE

MENU 05

SELECT

FEELER

Menu 0 5

INTERN

PROBE

Menu 0 5

REMOTE

PROBE

22 ENG A5CN – A6 – A8 (Rev. 01/06/2012)

22. MENU 06 – STAND BY or STOP&GO

This menu allows choosing between two functions:

- ON: after few minutes when the set room temperature has been reached the stove switch off and will automatically

switch on again by room temperature decreasing 2 to 3°C (is safety requirements are satisfied).

- OFF (default and suggested setting): when the set room temperature has been reached the stove doesn’t switch off

but continue burning at the minimum thermal output; by room temperature decreasing 2 to 3°C the stove will

automatically increase its thermal output.

1) Select menu

06 (button 7 and

then button 2)

2) Press button

7 to enter the

menu

3) The OFF or

ON setting will

be displayed

4) Press button

2 to select the

setting.

5) Press button

7 to confirm

6) Press button

3 to back to the

menu

23. MENU 07 – BEEPER

This menu allows to enable (ON) or disable(OFF) the confirmation “beep” for all remote control operations.

1) Select menu

07 (button 7 and

then button 2)

2) Press button

7 to enter the

menu

3) The OFF or

ON setting will

be displayed

4) Press button

2 to select the

setting.

5) Press button

7 to confirm

6) Press button

3 to back to the

menu

24. MENU 08 – FIRST PELLET LOADING

This menu allows filling the feeding screw when first loading pellet into the relevant fuel tank.

Attention: this program should be run when first starting the stove or when the pellet tank goes empty

(maintenance, clearing, run out of pellet) otherwise the stove will not start because of lake of fuel in the fire pot. This

operation can only be done when the stove is cold.

.

1) Select menu

08 (button 7 and

then button 2)

2) Press button

7 to enter the

menu

3) The OFF

setting will be

displayed

4) Press button

1 for loading

pellet

5) After 90” the

feeding screw

will stop

6) Press button

7 to confirm and

button 3 to back

to the menu

MENU

06

MODE

STANDBY

OFF

MENU 06

MODE

STANDBY

MENU 07

MODE

BUZZER

ON

MENU 07

MODE

BUZZER

MENU 08

LOAD

INITIAL

OFF

MENU 08

P1 TO

LOAD

90’’

21.0 P - 1

LOAD

INITIAL

A5CN – A6 – A8 (Rev. 01/06/2012) ENG 23

25. MENU 09 – STOVE STATUS

This menu gives advanced information on the stove status and has to be use by dealer’s authorized personnel only.

.Here are the matches of the state indicated on the display:

STATUS 0 = STOVE OFF

STATUS 1 = STOVE ON

STATUS 2 = STOVE WAS ON HOLD or HOLD FIRE BURNOUT

STATUS 3 = FIRE PRESENT

STATUS 4 = STOVE WORK

STATUS 5 = BURNER CLEANING

STATUS 6 = FINAL CLEANING

STATUS 7 = STOVE WAS WAITING FOR COOLING FROM STAND-BY

STATUS 8 = ALARM WAS ACTIVE IN STOVE

STATUS 9 = STOVE WAS IN MEMORY ALARM

26. MENU 10 – SERVICE SETTINGS

To be entered by trained service center technicians only (password required).

27. MENU 11 – DEALER SETTINGS

To be entered by trained dealer technicians only (password required).

28. MENU 12 – FAN ENABLE (only for A6 and A8 model)

Allows selecting one of two options:

- ON fan enabled.

- OFF fan disabled (fan goes however automatically on in case of overheating – over 250 °C – in order to cool the

stove down within safety parameters, than the fan goes automatically off).

1) Select menu

12 (button 7 and

then button 2)

2) Press button

7 to enter the

menu

3) The OFF or

ON setting will

be displayed

4) Press button

2 to select the

setting.

5) Press button

7 to confirm

6) Press button

3 to back to the

menu

29. STOVE STARTING

After having correctly installed the stove do as follows for starting it:

- fill the stove’s pellet tank up

- run the first pellet loading program (MENU 08) at first starting only.

- follow this procedure:

1) Press red

button 3 for 3

seconds

2) START will

be displayed.

3) After some

10” “LIGHTERWAIT“ will be

displayed.

4) After some 1’

“LOAD PELLET”

will be

displayed.

5) After some 3’

“FIRE WAIT” will

be displayed.

6) After some 4’

“FLAME LIGHT”

will be displayed

MENU 12

ENABLE

BLOWER

ON

MENU 07

ENABLE

BLOWER

14 :00

28.5° P-1

START

14 :00

28.5° P-1

LIGHTER

WAIT

14 :01

28.5° P-1

load

PELLET

14 :04

28.5° P-1

FIRE

WAIT

14 :08

28.5° P-1

FLAME

LIGHT

24 ENG A5CN – A6 – A8 (Rev. 01/06/2012)

7) After some 2’ “WORK” will be displayed; this means the stove is correctly working and the burning is constant.

Now you can set both room temperature and thermal output. The fan will automatically start when the heat

exchanger temperature will reach the correct level. When the stove is in use CLEANING CRUCIBLE will be

displayed after each hour burning and will automatically disappear after the self clearing procedure being performed.

.

30. ROOM TEMPERATURE SETTING

Desired room temperature can be set.

When room temperature value being reached the stove switches in the modulation status and “WORK MODULAT”

will be displayed.

1) Press button

4 to enter the

temperature

menu

2) Set

temperature is

displayed

3) Press button

1 for decreasing

temperature

4) Press button

2 for increasing

temperature

5) Press button

7 to confirm

6) Press button

3 to back to

main menu

31. POWER SETTING

Desired power level can be set (from 1 to 5). Much higher the selected power level, much quicker the stove will reach

the set room temperature.

1) Press button

4 to enter the

temperature

menu

2) Set power is

displayed

3) Press button

1 for decreasing

power

4) Press button

2 for increasing

power

5) Press button

7 to confirm

6) Press button

3 to back to

main menu

32. SWITCHIN STOVE OFF

When you switch the stove off by pressing red button 3, the switching off procedure will start, but both fan and smoke

fan will work till the safety stove temperature will be reached.

1) Press and

hold red button

3 for some 3’’

2) “CLEANING

FINAL” will be

displayed

3) After some

20’ stove goes

completely off.

14 :10

28.5° P1

WORK

20°

SET

TEMP

ROOM

03

SET

POWER

14 :15

28.5° P-1

CLEANI

NG

FINAL

14 :34

28.5° P1

OFF

A5CN – A6 – A8 (Rev. 01/06/2012) ENG 25

33. REMOTE CONTROL FREQUENCY SETTING

For avoiding transmission failures in case of radio controller appliances being located near to the stove changing the

remote control frequency is needed (default 0) following the procedure:

1) Press at

same time

buttons 1 and 2

and keep for

some seconds

2) “CHOOSE

UNIT 0” will be

displayed.

3) Press button

2 to select the

radio code: 0, 1

2, or 3

4) Switch the

stove off by

mean of the

main switch

located on the

rear stove’s

panel

5) Switch the

stove on by

mean of the

main switch

located on the

rear stove’s

panel

6) Press red

button 3

7) “UNIT 1

LOADED” (or

unit 0 or 1 or 2

or 3) will be

displaye

8) After some

10” the remote

control switches

back to main

menu

34. REMOTE CONTROL LINKING

In case radio data transmission between remote control and stove doesn’t work properly (high electromagnetic

pollution) it is possible linking the remote control with a dedicated cable (to be ordered as option).

Attention: when linking the remote control to the stove via the cable, batteries must be removed because the

needed power is supplied from the stove.

OIO

I

CHOOSE

UNIT 0

UNIT 1

LOADED

14 :34

28.5° P-1

OFF

26 ENG A5CN – A6 – A8 (Rev. 01/06/2012)

35. HOW TO USE THE REAR CONTROL PANEL (in emergency only)

The rear control panel is designed to be used in emergency cases only, (i.e. remote control failure or loosing

remote)) The heart of the system is the remote control. For this reason, only 2 functions can be operated from the

real panel: on/off and power output setting on steps 2 or 5. It is not possible setting the room temperature.

› Button 3 - On / Off

To switch the stove on: press button for some 3 seconds till the relevant led lights green

To switch the stove off: press button for some 3 seconds till the relevant green led starts

flashing . When the self clearing procedure will be finished it goes out.

› Covering led

This led confirms the remote control transmission has been correctly covered.

› Alarm Led

This led lights on when a failure has been detected. The remote control is necessary to

display the failure that did occur. In case the stove went out of pellet press and keep

button 3 to reset the alarm till red led goes off and green led starts flashing. In all other

cases, do not start the stove but call for service.

› Button 2 - Power output 5

Allows setting the power output on level 5.

Press and keep button 2 for 3 seconds till the relevant led light yellow .

› Button 1 - Power output 2

Allows setting the power output on level 2.

Press and keep button 1 for 3 seconds till the relevant led light yellow .

A5CN – A6 – A8 (Rev. 01/06/2012) ENG 27

36. FIRST STARTING

Fill the tank up with pellet before starting the stove. Remember that the feeding screw is empty and a longer time is

needed when first starting the stove. Run the relevant menu.

When first starting the stove, you can feel bad smells in the room (it’s due to the burning of protection greases

used during production procedure). Do ventilate the room and do not stay in till smells cannot be felt. In order to

supply you with the best possible product, al paints are water based and no harmful thinners are used.

SWITCHIN ON

- Check the cord being connect to the wall plug and for the right voltage.

- Check for the main switch on the rear panel being on ON position.

- Check safety fuse being properly working.

- Check the pellet tank being loaded with a sufficient quantity of pellet for the programmed time of heating.

- Check the remote control working properly and batteries being charged.

- Check day and date settings on the remote control.

- Check the safety flap being properly closed.

- Check the ashtray being properly located in the stove.

- Check the fire pot grid being properly located.

- Check the door being properly closed

FUEL LOADING

- Swing the flap door located on the upper panel up.

- Cut a corner of the bag of and let pellet slowly flow into the tank. Check for any object accidentally being

packed with the pellet.

- Fire alert: do absolutely not leave some pellet on the hot parts of the appliance particularly on the top panel.

- Pellet is packed in plastic or paper bags. Do carefully stock it to allow humidity from damaging it.

- When loading pellet, make sure the bag doesn’t touch hot parts of the stove.

- Check for sawdust in the pellet tank. Vacuum clean weekly.

At stove starting the loading of pellet into the fire pot takes some minutes; during this time the firing

resistance is activated. Usually combustion starts after some 5 to 6 minutes. When the smoke gas

temperature is getting the minimum temperature level the smoke probe transmits to the operating system all

the components are properly working. Now the stove switches to normal burning mode. In the contrary an

error message will be displayed on the remote control (check for error messages).

TURNING STOVE OFF

Press button 3 on/off but do not disconnect the power cord.

The smoke fan and the fan (when fitted) will continue working till the stove will cool down to a safety level.

28 ENG A5CN – A6 – A8 (Rev. 01/06/2012)

37. MAINTENANCE AND CLEANING

Before making any kind of maintenance or cleaning intervention the stove must be switched off, cold and be

disconnected from power supply

For keeping your stove efficient following maintenance and clearing operation must be performer.

Every day cleaning

In order to obtain the best performance from your stove and prolong as much as possible it trouble free working life

you should perform obligatorily every day some simple and quick operations as follows:

1) Ashtray: take it

completely out and empty

ash in a metal can. Wait at

least 48 hours before

discarding for preventing

fire danger.

2) Fire pot: take it

completely out and empty

ash in a can.

3) Protection grid: vacuum

clean all pellet and ash

rests.

4) Glass: clean the glass

with a soft cloth in

combination with our

specific glass cleaner

PULISCI VETRI. Make

sure air adduction slots

being free and clean

Every year:

- Combustion chamber

- Lower smoke chamber

- Smoke fan

- Connection pipe to the smokestack

- Fan if fitted

- Air intake

- Vacuum clean the back side and all electric/electronic components

- Smokestack

Call for a trained serviceman to let all smoke internal connection as well as the smoke fan case to be

cleaned. All mechanical and electronic components will be carefully checked. Our partners located all over

Europe will provide you with the right professional maintenance service.

Smokestack cleaning:

- It is compulsory to call a professional chimney sweeper for brushing the smokestack once a year, or at least

every 1000 kg of pellet but not later than 2 years.

- A cleaning & inspection certificate has to be issued and it will be valid for stove maintenance service as well

as for your home assurance.

- Always check the stove being perfectly working and all gaskets not being worn. All smokestack connections

must be tight and the whole mechanic not being damaged.

A5CN – A6 – A8 (Rev. 01/06/2012) ENG 29

38. ELECTRICAL DIAGRAM

M

M

M

ALP

ALC ALF

thermostat

additional

probe

ambient

+-

230V

Ground

fan smoke

cochlea

main

interchange

electrical resistance

yellow / green

Blue

Pink

White

White

Violet

Green

Gray

Brown

Red

Gray

Orange

Orange

ALF = Safety thermostat General

ALC = Pressure

ALP = Safety thermostat

probe

smoke

fan smoke

Red

Blue

White

Red

Black

30 ENG A5CN – A6 – A8 (Rev. 01/06/2012)

39. TROUBLESHOOTING

Error messages on the remote control display

Trouble: combustion doesn’t start.

Cause: - pellet feeding screw empty.

- Not enough primary air (combustion) because of dirtiness (lack in maintenance)

- Check for the starting resistance

- Check for pellet quality

- check for overpressure switch, could be off because of dirty smoke outlet. Could a

sign the smoke extractor doesn’t work properly

- Check for the safety thermostat.

Solution: check for pellet in the tank. In case you couldn’t slear the problem call for technical

service.

Problem: the stove is far too hot.

Cause: smokestack could be obstructed.

- Canvas or different objects laid on the stoves

- Stove has been installed in a niche without proper

ventilation

- Remote control temperature probe failure

- On board temperature probe failure

Solution: detect the causes. To quit the error signal follow the procedure

1) Unscrew protection cup 2) press safety thermostat button 3) screw the protection

up

Problem: depression hasn’t been build up into the stove.

Cause: - check for all pressure switch connections and the static pressure intake working

properly.

- Check the door being closed and all gaskets not being damaged.

- Check the overpressure flap located on the top of combustion chamber being closed.

- Check all smoke exhaust connection piping and the smokestack (it must be properly

connected and clean).

Solution: go carefully through the a.m. possible causes. If it doesn’t solve the problem, call for

technical service.

Problem: the smoke exhaust fan doesn’t work.

Cause: check all the electrical connections and the wiring to the encoder.

Solution: If it doesn’t work call for technical service.

MANCA

TA

SAFETY

THERMAL

FAILURE

DEPRESS

FAN

FAILURE

NO

LIGHTING

A5CN – A6 – A8 (Rev. 01/06/2012) ENG 31

Problem: pellet doesn’t start burning into the fire pot.

Cause: - Check for pellet tank being loaded.

- Check for loading screw motor not being blocked.

- Check for loading screw not being staged.

- Check the main board.

Solution: go carefully through the a.m. possible causes. If doesn’t solve the problem, call for

technical service.

Problem: refer to smoke probe wiring

Cause: - check the temperature probe.

- check the smoke probe being correctly positioned at the correct depth.

Solution: go carefully through the a.m. possible causes. If doesn’t solve the problem, call for

technical service.

Problem: the stove doesn’t copy the remote control.

Cause: - check the main switch on stove’s rear panel being ON.

- check fuses (4A) located near the main switch and on the electronic board .

Solution: go carefully through the a.m. possible causes. If it doesn’t solve the problem, call for

technical service.

Problem: stove is getting overheated

Cause: - Stove hasn’t been correctly located.

- Smoke piping is staged.

- Combustion chamber is not properly cleaned.

Solution: let the Every Year Cleaning be performed by authorized trained professionals. If it

doesn’t work properly, call for technical service.

NO

PELLET

FEELER

EXHAUST

OUT OF

FIELD

HOT

EXHAUST

32 ENG A5CN – A6 – A8 (Rev. 01/06/2012)

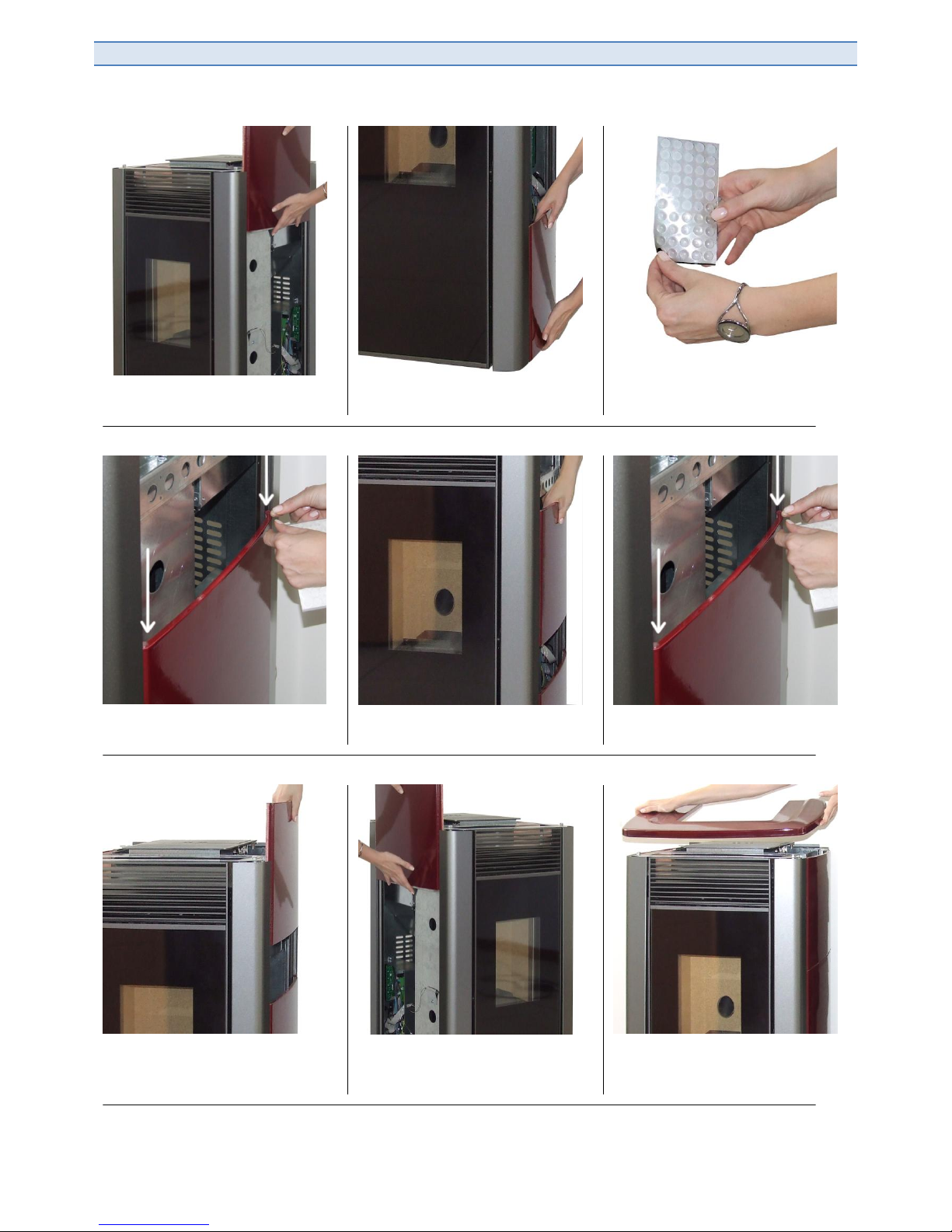

40. MOUNTING LATERAL CERAMIC

The ceramics are provided disassembled to avoid breakage during transport and assembly of the stove. Handle with

great care to avoid damages on the ceramics. Below the procedure for mounting the corners and the cover of the

stove ALESSIA, ANTONELLA, AXELLE:

1) Place the first ceramic corner into

the stove guides.

2) Guide the corner up to the

support bottom.

3) Remove two silicone rubber from

the packaging ...

4) Paste the rubber at either end of

the angle ceramic.

5) Place the second angular

ceramic.

6) Repeat steps 1 through 5 for the

other side.

7) Place the rear cover by inserting

the two pins in the holes on the

uprights of the stove.

8) Paying attention to the hands,

place the cover on the front where it

will be held in place by magnets

adjustable in height.

9) Open the cover of load pellet and

lock the cover to the rear uprights

with bolts supplied.

A5CN – A6 – A8 (Rev. 01/06/2012) ENG 33

Below the procedure for mounting the sides and top of the ceramic heater Aleyna, Armelle, ALINE:

1) Place the first ceramic side into

the stove guides.

2) Guide the ceramic side up to the

support bottom.

3) Remove two silicone rubber from

the packaging ...

4) Paste the rubber at either end of

the lateral ceramic.

5) Place the second side ceramic. 6) Paste the rubber at either end of

the lateral ceramic.

7) Insert the third ceramic side with

caution.

8) Repeat steps 1 through 5 for the

other side of the stove.

9) Place the top cover in support of

the structure.

34 ENG A5CN – A6 – A8 (Rev. 01/06/2012)

41. GUARANTEE

8.1 – Lasting

The stove is covered by a 2 years guarantee with the exception of all wear and tear components, vermiculite and

gaskets. Guarantee starts from delivery date – purchasing date if bought from a reseller – but stated on the relevant

bill that must always be enclosed.

The guarantee does cover for the time of 2 years all production, components and materials mistakes. All the

damages parts will be checked by our technicians and in case of need substituted free of charge.

8.2 – Validity

The buyer states he went carefully through this installation and instruction manual. The guarantee does only apply to

appliances that have been correctly installed in accordance with the local and national regulations in force

8.3 – Exclusions

8.3.1 wear & tear and refractory components

Al gaskets on door and inspection flaps as well as vermiculite components into the combustion chamber are

considered as wear & tear parts. The guarantee does therefore cover those components for a period of 1 year

starting from delivery date.

8.3.2 Glass

All standard and screened ceramic glasses are eluding from the guarantee.

8.3.3 all ceramic components are handmade. Small marks or differences in color cannot be considered as failures

but a plus being the sign are made one by one as per a centuries old ceramic tradition.

8.3.4 General

All travelling, transport, man craft, packaging, disassembling and down time of the stove rising from the stove repair

in guarantee time are at customer charge.

All components not belonging to the stove but connected to the stove itself, i.e. electronic equipments, are not

covered by the guarantee and are out of our responsibility but not part of the appliance.

In case of using non approved fuels, the guarantee will expire and will not cover all related damages

Guarantee will not be applied in the following cases:

If the installation and assembling is not being done by us, we cannot be responsible for any kind of damage to

people and/or objects due to an incorrect installation, violating the regulations in force.

The guarantee will not be applied to appliances which havn’t been used in the proper way or for different purposes: if

component have been modified, , in case of any kind of modification non expressly approved in written by the

manufacturer, in case of cleaning with aggressive thinners or acids able to damage the finishing and decoration on

the appliance.

A5CN – A6 – A8 (Rev. 01/06/2012) 35

Loading...

Loading...