Page 1

n

TACHOMETER

C.A 1725

C.A 1727

ENGLISH

User's Manual

11

Page 2

CONTENTS

1. INTRODUCTION ...................................................................... 32

2. DESCRIPTION......................................................................... 32

2.1 TACHOMETER........................................................................................................................ 32

2.2 DISPLAY UNIT........................................................................................................................ 35

3. USE .......................................................................................... 37

3.1 CONTACT -FREE MEASUREMENTS ........................................................................................ 37

3.2 MEASUREMENTS WITH CONTACT........................................................................................ 37

3.3 MEASUREMENTS WITH EXTERNAL INPUT ........................................................................... 38

4. OPERA TION............................................................................. 40

4.1 MEASUREMENT UNITS .......................................................................................................... 40

4.2 MIN/MAX RECORDING ........................................................................................................... 41

4.3 HOLD OF THE DIGIT AL V ALUE ON THE DISPLA Y ................................................................ 42

4.4 SMOOTHING OF THE MEASUREMENT .................................................................................. 43

4.5 MANUAL CHOICE OF RANGE ............................................................................................... 43

4.6 COUNTING (C.A1727 only) ................................................................................................... 44

4.7 RECORDING OF MEASUREMENTS (C.A 1727 only) ............................................................. 44

4.8 ALARMS (C.A 1727 only) ..................................................................................................... 45

4.9 PROGRAMMING (C.A 1727 only) .......................................................................................... 46

4.10 PROCESSING OF THE DATA ON A PC (C.A 1727 only) ........................................................ 50

5. MAINTENANCE ....................................................................... 51

6. CHARACTERISTICS ............................................................... 52

6.1 GENERAL CHARACTERISTICS ............................................................................................. 52

6.2 METROLOGICAL CHARACTERISTICS................................................................................... 53

6.3 CHARACTERISTICS OF THE SENSOR .................................................................................. 55

6.4 CHARACTERISTICS OF THE ADAPTER AND ITS END FITTINGS .......................................... 56

7. TO ORDER............................................................................... 57

3131

Page 3

1. INTRODUCTION

C.A 1725 and C.A 1727 tachometers, specially designed for industrial applications, measure the speed

of rotation of any moving part at a distance or by contact.

CHAUVIN ARNOUX tachometers provide many possibilities in addition to the usual functions:

- Direct reading of the measurement

- Measurement of period, of frequency, of duty cycle, of linear speed

- Measurement by external sensor

- Special functions: smooth, range, hold, etc.

- Dual display: 100,000-point digital and bargraph.

- The C.A 1727 can be parameterized and has a USB link; associated with its specific software, it

provides an extensive range of measurement, acquisition, processing, and data analysis possibilities.

2. DESCRIPTION

2.1 T ACHOMETER

1 Optical sensor

2 key

- Tore last digital value displayed.

- Disable automatic stop.

key on the C.A 1727 only :

- For programming : shift the selection of the active digit or of the decimal point to the right.

3 key

- Smooth the measurements.

key on the C.A 1727 only :

- For programming : increment the active digit.

4 key on the C.A 1727 only :

- Activate the audible and visual alarms.

- Program the alarm thresholds.

5 key on the C.A 1727 only :

- Command recording of the measurements in memory.

key on the C.A 1727 only :

- Program the rate at which the measurements are recorded in memory.

6 USB output connector, on the C.A 1727 only.

7 Connector for external input.

8 Rotary switch.

32

Page 4

9 key on the C.A 1727 only :

- Programming.

- Initialize the program memory .

10 key on the C.A 1727 only :

- Event counter.

key on the C.A 1727 only :

- Program the scale factor : coefficient K.

11 key

- Manual or automatic change of range.

- Extend the measurement range at low frequency.

key on the C.A 1727 only :

- For programming : decrement the digit.

12 key

- Record minima and maxima.

- Disable the buzzer.

key on the C.A 1727 only :

- For programming : shift the selection of the active digit or of the decimal point to the left.

3333

Page 5

34

Page 6

2.2 DISPLA Y UNIT

1 Programming mode, on the C.A 1727 only.

2 Low threshold crossed, on the C.A 1727 only.

3 Full-scale coefficient K, on the C.A 1727 only.

4 Low threshold function, on the C.A 1727 only.

5 Memory write function, on the C.A 1727 only.

6 High threshold function, on the C.A 1727 only.

7 High threshold crossed, on the C.A 1727 only.

8 Rate of recording of measurements function, on the C.A 1727 only.

9 Transmission or reception in progress, on the C.A 1727 only.

10 Flashing indicator of operation of the infrared sensor.

11 Full-scale value of the bargraph (from 2 to 200 x 1000).

12 Analogue display by bargraph.

13 Arrowhead(s) indicating overshoot of end of scale.

14 Speed of rotation - Revolutions per minute

15 Revolutions: count of number of revolutions, on the C.A 1727 only.

16 metres per minute: linear speed.

17 Hertz: frequency.

18 Digital display, 5 digits.

19 Measurements in smoothed values.

20 Frozen display of the last measurement.

21 Recording paused.

22 Device in permanent operation.

23 Battery charge indicator.

24 MIN/MAX recording.

25 Buzzer active indicator.

26 Reading of MAX memory.

27 Measurement range extended to 0.1 Hz.

28 Reading of MIN memory .

29 Disable automatic change of range.

30 Counting function, on the C.A 1727 only.

31 Millisecond: period.

32 Duty cycle.

33 · ft/min: feet per minute - linear speed (in English).

· tr/min: revolutions per minute - speed of rotation.

34 Graduated fixed scale.

35 Measurement by external connector.

36 Optical transmitter in action.

3535

Page 7

36

Page 8

3. USE

3.1 CONTACT -FREE MEASUREMENTS

The contact-free measurement is made by the optical sensor built into the device. This sensor, placed

in the front of the device, comprises a frequency-modulated infrared transmitter.

Before making any measurement, it is necessary to prepare the revolving target of which the speed is

to be determined.

Check that the surface sighted is free of spurious reflections that might be counted in addition to the

pulses from the reflecting adhesive. Proceed as follows: before applying the adhesive used to make

the measurement, turn the target and check that when it is sighted the reading remains at ---. If not, it

will be necessary to cover the entire surface of the target with a mat black medium.

When the target is correct, apply a reflecting adhesive tape on it, along the longest available radius. On

small targets, the area covered by the adhesive tape must be less than 50% of the total area of the

rotating part.

Start the target turning, aim the front of the device at it, and check that the measurement OK symbol

flashes regularly.

The distance between the sensor and the target must be between 1 and 50cm.

The measurement angle of 30° (15° on either side of the perpendicular to the target) is convenient for

aiming purposes.

During measurements of low speeds, very small movements of the device may make the measurement

unstable: if this happens, we recommend placing the device on a stable support. There is a nut on the

underside of the device for attachment to a tripod or similar support.

3.2 MEASUREMENTS WITH CONTACT

The mechanical adapter and its 3 end fittings allow measurement by contact on a shaft end or on a

surface in linear motion.

It is placed in front of the sighting window of the optical sensor and accepts one of the following 3 end

fittings:

- An elastomer cone with a tip that can be used for shaft end measurements

(minimum diameter: 5mm).

- An elastomer cylinder that can be used for measurements on shafts with flat ends or shafts

smaller than 5mm.

- An elastomer wheel for linear speed measurements (1 revolution of the wheel = 0.1m).

The end fitting must be pressed against the moving part just hard enough to drive it without slippage.

The adapter is attached to the front of the tachometer housing, in front of the sighting window. It

automatically locks in position when pushed home.

- Fitting

To attach the adapter, align the three lugs on the inside of the adapter with the three recesses of the

sighting window of the housing and turn anticlockwise.

- Removal

To remove it, pull the adapter outward until the locking tabs are clear, then turn clockwise.

3737

Page 9

3.3 MEASUREMENTS WITH EXTERNAL INPUT

The device has a 4-contact connector that can be used to connect an external source of which you

wish to measure the speed, the frequency, the period, the duty cycle, etc.

In order to inform the tachometer that the measurement is available on the external input, it is necessary

to short-circuit contacts 1 and 4.

Operation using the external input is indicated on the display unit by the extinction of the transmission

symbol and the display of EXT.

Wiring

Connector of the tachometer 2- measurement input (± 20VC max.)

seen from contact side 3- see below

Connecting 1 to contact 3 makes it possible to adapt the triggering threshold to the nature of the signals.

Contacts 1 and 3 not connected

For operation with 0 - 5V TTL signals.

The triggering threshold is +1.1V (at 1kHz).

To avoid the problems due to noise often present in an industrial environment, the threshold has a

hysteresis of 250mV.

Contacts 1 and 3 connected

For operation with signals balanced with respect to earth.

This function allows direct measurement using a variable-reluctance magnetic sensor or the output of

an alternator.

The triggering threshold is 300mV (at 1kHz), with a hysteresis of 250mV . The residual noise superimposed

on the signal to be measured must be less than 250mV so as not to interfere with the measurement

when the threshold is crossed.

ATTENTION :

The maximum voltage to input no. 2 must not exceed ± 20Vp. The earth of the external input

connected is electrically connected to the earth of the USB digital output.

1- earth

4- to be short-circuited with contact no.1

The external input must be used for the measurement of slow signals, from 0.1Hz. The table below

sums up the characteristics of this input.

38

Page 10

Measurement frequency range from 1Hz to 10kHz

from 0.1Hz to 10kHz in expanded range

Functions available same as optical sensor

Accuracy same as optical sensor

Input impedance ≥ 75kΩ

Balanced signals mode 300mV ± 90mV at 1kHz

Thresholds 600mV ± 160mV at 10kHz

Hysteresis 250mV ± 80mV

TTL signals mode 1.1V ± 150mV to 1kHz

Thresholds 2.2V ± 300mV to 10kHz

Hysteresis 250mV ± 80mV

Maximum voltage ± 20V peak

Acceptable overload (1second) 250Vrms

Example of DUTY CYCLE Measurement on EXTERNAL INPUT

When the external input is used, the FRB connector provided with the device must be connected to the

source of the signal to be measured, then to the connector marked EXT.

Consider a signal like the one shown in the figure below:

Here, the frequency of the signals is given by the formula :

1

f =

T

T = 5 x 1ms = 5ms

1

so f = = 200Hz

5.10

-3

3939

Page 11

The duty cycle is given by :

t

Duty =

or, in %. Duty % = x 100

Here, we have :

1

t1 + t

2

t

1

t1 + t

2

3

Duty % = x 100 = 60%

3 + 2

To make this measurement with the C.A 1725 or C.A 1727 tachometer, you must:

1) Check the amplitude of the input signal to the device. This serves to determine what threshold

must be set. Here, the amplitude is greater than +1.1 V, so contacts 1 and 3 of the FRB

connector must not be interconnected.

2) Switch the tachometer on by setting the rotary switch to "%".

3) The display unit indicates directly the result mentioned above.

If there is no reading on the display unit, check that the amplitude of the signal to be measured is above

the triggering threshold.

4. OPERATION

4.1 MEASUREMENT UNITS

The table below indicates the display capacity for each function.

Function Display

tr/mn or RPM 60.000 to 99999

m/mn (K = 0.1) 6.0000 to 99999

ft/mn (K = 0.328) 19.680 to 99999

Hz 1.0000 to 9999.9

Period (ms) 0.1000 to 999.99

Duty cycle % 0.1 to 99.9

Counter 0 to 99999

In a measurement extended to 0.1Hz using the Ext input, the minimum values are divided by 10.

On/Off function:

If this function is not overridden when the device is switched on (see below), the device is switched

off automatically if one of the following has not occurred during the last 5 minutes:

- Press of a key,

- Or change of setting of the rotary switch,

- Or interrogation of the digital output.

Before switching off automatically, the tachometer emits an audible beep.

40

Page 12

Special functions :

The following special functions are obtained when a key is kept pressed when the device is switched

on:

KEY FUNCTION

No key pressed Switched on for 5 minutes

Switched on for an indefinite duration

appears on the display unit

Switched on without buzzer

The symbol does therefore not appear

Initialization of all values contained in the program memory.

The display unit indicates „Init“

Measurement down to 0.1Hz

SLOW lights on the display unit.

4.2 MIN / MAX RECORDING

The recording function can be used to store the minimum and maximum values of the measurements.

Pressing the key switches the device into recording mode. The RECORD and symbols

are displayed. The automatic switching off function is disabled.

MIN value

Initially, the value store is OL (OVER LOAD). When the key is pressed, the value displayed

is stored in the MIN register.

Whenever a value below the value storedd in the register is measured, it is transferred to the MIN

register and 1kHz audible beep is emitted.

MAX value

The value stored at the start is zero. A measured value greater than the value stored in the register

leads to an update.

Each time the content of the MAX memory is modified, a 2 kHz audible beep is emitted.

Reading of the MIN/MAX memories

The values contained in the MIN and MAX registers can be displayed by successive presses

on .

The circular display indicates in turn the MAX, the MIN and the current measurement value.

Recording continues during the reading; the bargraph indicates the instantaneous measurement.

NB: if the "SMOOTH" function is activated, the MAX and MIN are determined from the smoothed values.

Stopping the MIN/MAX recording function

The recording function is stopped either by a long press on the key or by turning the switch.

Remark : The MIN/MAX functions is not available in counting mode.

4141

Page 13

4.3 HOLD OF THE DIGIT AL V ALUE ON THE DISPLA Y

HOLD memory

MAX memory

HOLD

RECORD PAUSE MAX RECORD PAUSE

Instantaneous

measurement

MIN memory

RECORD PAUSE

MIN RECORD

PAUSE

MIN MAX

MIN MAX

MIN MAX

MIN MAX

By a brief press on the HOLD key (when not in programming mode).

Pressing HOLD freezes the digital display on the last measurement displayed; the bargraph continues

to indicate the instantaneous measurement value. The display indicates HOLD. Pressing the HOLD key

again restores the display of the instantaneous measurements, and HOLD disappears from the display

unit.

in the „MIN/MAX“ recording mode

When the key is pressed while RECORD is displayed :

- The HOLD and P AUSE symbols are displayed.

- Recording stops and the values contained in the MIN and MAX memories are the last values

before .

- The digital display unit indicates the last measurement value, or else the MIN or MAX value if the

device was reading them back.

- The bargraph continues to indicate the current measurement.

Pressing the key again causes the recording of the MIN and of the MAX to resume :

- The HOLD and PAUSE symbols remain displayed.

- The display unit indicates the measurement in progress or the content of the MIN/MAX memory

being read back.

- The device is once again in MIN/MAX mode, but the memories have not been reset and they

contain the MIN and MAX values present before the .

When the HOLD and RECORD - PAUSE symbols are displayed, it is always possible to display, in a

circular manner, the values in the memories and the instantaneous measurement value, by brief

presses on the

.

The bargraph always indicates the current measurement value.

Whatever display is in progress :

- A brief press on the key restores recording without resetting the memories.

- A long press on the key stops recording.

42

Page 14

Application :

When the tachometer is used in a place where it is difficult or impossible to read the display unit, the

HOLD function can be used in conjunction with MIN/MAX recording to store the minimum and maximum

values reached.

4.4 SMOOTHING OF THE MEASUREMENT

Pressing the key starts the smoothing of the measurement (SMOOTH displayed). The digital

value indicated is then the sliding average of the last 10 measurements (approximately 5 seconds).

The bargraph always indicates the instantaneous measurement.

In MIN/MAX recording, if the SMOOTH symbol is displayed, the values recorded are the smoothed

values.

Activating or deactivating the SMOOTH mode during MIN/MAX recording cancels the MIN and MAX

values already stored.

Remark: The SMOOTH function has no effect on the counting function.

4.5 MANUAL CHOICE OF RANGE

When the device is switched on, or during a change of function, the device automatically selects the

most appropriate measurement range. Each function has 4 or 5 ranges, except for the duty cycle

function (2 ranges).

In automatic operation, the digital display unit has a display capacity of 20,000 points and the possible

full-scale values of the bargraph are 2, 20, 200, 2000, 20,000, and 200,000.

In the automatic mode, the digital display unit switches to a higher range when

20,000 points is reached.

A first brief press (<2 s) on the key freezes the current measurement range. RANGE

appears on the display unit. The digital indicator then has a display capacity of 100,000 points.

Each new press on the key switches both displays (bargraph and digital) to the next

higher range. From the highest range (20,000) the key switches the device to the 2 range.

To exit from the manual range change mode, press the key for more than 2 seconds.

Remark:

If the measurement value exceeds the display capacity, the display unit indicates OL and the range

overshoot arrow appears to the right of the bargraph.

ATTENTION :

The functions described in the paragraphs that follow are available only on the C.A 1727.

4343

Page 15

4.6 COUNTING (C.A 1727 ONL Y)

Press the COUNT key to switch the device into the event counting mode. COUNT appears on the display

unit and the measurement units are changed (see table below).

Measurements mode COUNT mode

tr/min rev (revolution)

m/min m (metre)

RPM REV (revolution)

ft/min ft (foot)

Hz /

ms /

Duty % /

The Hz, ms, and % symbols disappear. There is no longer a measurement unit displayed; the device

simply counts the number of pulses received.

A press on the key stops the counting. A second press causes the counting that was

paused to resume.

When 99,999 events are reached, the display changes to OL.

To exit from the counting mode, simply press the key again. The counter is reset by 2

successive presses on the key.

Remarks:

- As standard, the device counts metres or feet, with a measurement resolution equal to the circumference

of the end fitting used, 0.1m or 0.328ft. This resolution can be changed by changing the value of K.

- In the counting mode, the recording, change of range, and smoothing functions are not available.

4.7 RECORDING OF MEASUREMENTS (C.A 1727 ONL Y)

The key can be used to record the value displayed.

- with HOLD :

The record will be the last value displayed, preceded by HOLD.

- with MIN/MAX recording :

When the device is in recording mode (RECORD, MIN or MAX on the screen), the PRINT command

records the MIN, the MAX and the current measurement.

- with record MIN MAX + HOLD :

In this mode (RECORD - PAUSE and HOLD symbols displayed), the PRINT command records the

following four parameters:

- The HOLD value

- The value contained in the MIN register

- The value contained in the MAX register

- The current measurement value.

44

Page 16

- with SMOOTH

Digital measurement > low threshold

(LO AL)

No action

Digital measurement < high

threshold (HI AL)

No action

Digital measurement < low threshold

Continuous buzzer at 1

kHz

Display of

Digital measurement > high

threshold

Continuous buzzer at 4

kHz

Display of

If the value of LO AL is greater than the value of HI AL, this

operation is reversed. The buzzer is triggered (at 2 kHz) in the

central zone between the HI AL and LO AL values.

The value recorded is then the smoothed value, when this function is displayed (SMOOTH).

For the entire duration of recording of the information, the PRINT and COM symbols are displayed.

When the Scanning function is programmed (see "Recording Interval"), pressing the key

starts the measurement recording cycle according to the interval programmed. The SCAN symbol is

displayed and remains displayed for the entire duration of the scanning operation. PRINT and COM are

displayed each time data are transmitted to the memory.

A second press on the key interrupts the scanning; the last data are transmitted and the

SCAN, PRINT , and COM symbols go of f.

Further presses on the key alternately start and stop the function.

4.8 ALARMS (C.A 1727 ONL Y)

When thresholds have been programmed, a brief press on the key activates detection of the

croosing of these thresholds by the measurement.

The or symbol is displayed, or both, according to the type of threshold programmed.

The operation of the device is summed up in the table below.

If no threshold value has been programmed, an audible beep is emitted when the key is

pressed and the command is not accepted.

To stop the Alarm function, press the key again.

4545

Page 17

4.9 PROGRAMMING (C.A 1727 ONL Y)

The device lets you program four values to define:

- A low alarm threshold (LO AL).

- A high alarm threshold (HI AL).

- A multiplier coefficient (K).

- A recording interval (SCAN).

A press on the key switches the C.A 1727 into programming mode; PRGM is displayed.

In the programming mode, the C.A 1727 no longer makes measurements; the bargraph is off, the optical

transmitter is off.

The functions of the keys become those indicated in yellow above each key.

Functions of the keys in Functions of the keys in

measurement mode pogramming mode

Shift left

Shift right

Increment active digit

Decrement active digit

Program scanning

Program threshold

Program coefficient K

Procedure

The explanations below describe the procedure to follow to program the various memories of the

C.A 1727. These stages are common to all functions: scanning, thresholds, and coefficient K.

The "Alarm thresholds" to "Recording interval" paragraphs describe the features specific to each function.

Before switching the C.A 1727 to programming mode, you must choose, on the rotary switch, the

function of which you wish to program the values.

Pressing the key displays the PRGM symbol, switches off the bargraph, and displays "-----".

The second stage is choosing the function to be programmed, by pressing

the: ; or key.

The digital display unit then indicates the value contained in the memory , or "-----" if nothing has yet been

programmed (when programming for the first time, or if the last programming disabled this function). At

the same time, the left-hand digit (or dash) flashes.

Programming is on 100,000 points (0 to 99,999), and there are 5 possible positions of the decimal point

for the alarm thresholds (the decimal point is fixed for K and the SCAN interval has no decimal point).

A value is entered in memory as follows:

A/ writing of all digits of the desired value, without taking account of the decimal point.

B/ positioning of the decimal point.

46

Page 18

A/ Writing of a number without a decimal point:

When the dashes are displayed, pressing a horizontal shift key replaces the dashes by zeros, by the

value previously recorded, or by the extreme value possible compatible with the function. The value of

the active digit (flashing) is incremented or decremented by pressing the

key, respectively. Increasing a digit from 9 to 0 automatically increments the digit (or digits) to the left of

it, while decreasing a digit from 0 to 9 automatically decrements the digit (or digits) to the left of it.

Example :

1. Display

2. Key

3. Display

If during the incrementation or decrementation operations the maximum display capacity is exceeded,

the display unit reverts to displaying five dashes.

The and keys are used to shift the active digit (flashing), the one to be programmed,

to the left or to the right, respectively.

When the left-hand digit is active, pressing the key causes the appearance of the five

dashes or of the value previously recorded in memory.

Validation is effected by pressing the key or another programming key (e.g. SCAN).

Validating "-----" stops and cancels all programming.

B/ Positioning of the decimal point:

To activate the decimal point, you must press the

Pressing the key again activates the shifting of the decimal point. The and/

key until the right-hand digit flashes.

or .

or key can then be pressed to set the dcimal point to desired position.

Example :

1. Display

2. Key

3. Display

4. Key

5. Display

When the decimal point is located on the left or right side of the display unit, pressing

the or key, respectively, causes the appearance of „-----“.

4747

Page 19

To return the decimal point to the display unit, simply press the or key, depending

on whether the decimal point exited on the left or right, respectively. Because there are five possible

positions of the decimal point, the resolution of the programming may be finer than the resolution of the

measurement. When this is the case, the crossing of the alarm thresholds is still determined according

to the true measurement resolution.

To exit from the programming mode, and to validate:

Either press the . You leave the programming mode and PRGM goes off.

- Or switch to another programming function by pressing , or key.

- Or turn the switch to any other position except "OFF". The device then returns to measurement

mode (switching to "OFF" disables validation and entails the loss of the current values; the

values previously recorded remain valid).

The information contained in memory is read back in the same way as it is programmed, except that

the , , and keys must not be used.

Alarm thresholds (C.A 1727 only)

Two thresholds can be set. To program these values, press the key when in programming

mode.

A first press on the key results in the display of and lets you program the low threshold.

A second press on the key validates the low threshold (LO AL), displays and lets you

prigram the high threshold (HI AL).

When a threshold is programmed and the ALARM function is activated, the corresponding symbol

appears on the display in measurement mode and the measured value is compared to this value at all

times. An overshoot of the threshold results in the display of the corresponding symbol and activates

the buzzer (see the use of this function in the "ALARM" section).

When one or both alarm thresholds have been programmed and activated, it or they appear on the

bargraph in reverse video (with respect to the measurement): black if the deviation is below the

threshold, white if the deviation is above the alarm threshold, flashing (4 Hz) if the measurement is

equal to the threshold value.

Coefficient K (C.A 1727 only)

Coefficient K is a multiplier applied to the raw measurement value in order to obtain a display that can

be used as is.

Examples:

- Programming of a gearbox ratio. This makes it possible to display, directly, the output speed of

a reduction gear while measuring the input speed.

- Flow measurements. A flow meter delivers one pulse every 2 m3. Setting a coefficient of K =

2 makes the reading in Hz equal to the flow rate in m3 per second. The COUNT function delivers,

in addition, the total volume that has flowed through the pipe.

Pressing the key in the PRGM mode lets you program the value of coefficient K.

When a coefficient other than the initial value has been programmed, the symbol K appears on the

display unit in the measurement mode. The digital display and the bargraph then both apply multiplier

coefficient K.

48

Page 20

The K symbol can be made to disappear only by reprogramming the original value of coefficient K (see

the table below).

The programming of K is limited to values between 99.999 and 0.010. No other values are accepted.

Measurement Counting Original K

K in tr/mn K in revolutions 1

K in m/min K in m 0.1

K in RPM K in REV 1

K in ft/min K in ft 0.328

K in kHz, ms, % K in pulse count 1

Programming a coefficient K does not change the maximum measurement and display limits (0.1 to

10,000Hz and 0 to 99,999 points).

The table below indicates the frequency limits as a function of the programmed value of coefficient

K (it is assumed that the external input connector is used). Beyond these limits, the display indicates

"OL" for an overshoot and "-----" for an undershoot.

Measurement unit Programmed coefficient K

MAX input freq., 9999.9Hz 1000Hz

giving a MAX

display of 99999pts 99999pts

Hz

MIN input freq., 0.1Hz 0.1Hz

giving a MIN

display of 0.0010pts 9999pts

MAX input freq., 10.000Hz 16.666Hz

tr/min or RPM giving a MAX

display of 6000.0pts 99999pts

MIN input freq., 0.1Hz 0.1Hz

m/min giving a MIN

display of 0.0600pts 59999pts

Measurement unit Programmed coefficient K

MAX input freq., 10000Hz 50.8Hz

ft/min giving a MAX

display of 19800pts 99999pts

MIN input freq., 0.1Hz 0.1Hz

1ft = 0.3048cm giving a MIN

1m = 3.281ft display of 0.1980pts 196.86pts

0.01 99.999

0.033 32.81

4949

Page 21

Recording interval (C.A 1727 only)

The scanning function is used to make measurements at a preset rhythm and automatically record the

results. It is possible to store up to 4000 points.

This function is programmed by pressing the key in PRGM mode. The SCAN symbol is

displayed.

The value programmed is the number of seconds between two successive records. The limits are 10

seconds minimum and 99,999 seconds maximum (approximately 27 hours).

In measurement mode, recording is started (stopped) by pressing the key; the display of the

PRINT and SCAN symbols confirms that recording is in progress (see "RECORDING").

If the recording interval exceeds five minutes, the optical transmitter of the device is switched off

between measurement ( symbol off on the display unit), then switched back on 2 seconds before

the next measurement.

The automatic stop function of the C.A 1727 is disabled for the duration of the scanning function. The

symbol is displayed.

4.10 PROCESSING OF THE DA T A ON A PC (C.A 1727 ONL Y)

TACHOGRAPH software can be used for two-way management of the data contained in the C.A 1727.

It allows the acquisition, processing, and analysis of the measurements made by the C.A 1727

tachometer, and the transfer of result s files to the hard disc of a PC. It can be used to translate them into

a format compatible with EXCEL, to allow the end user to perform any desired digital processing of the

results. It allows the transfer and display of the programming parameters of the device.

Digital processing of the results, such as calculation of the mean value, of the integral (position), or of

the derivative (acceleration), and the corresponding display in graph form are included in the

TACHOGRAPH software.

The editing functions available in the graph window are:

- Addition of Min + text1, addition of Max + text2, rename the graph.

The display functions available for each graph are:

- Parameterizing of the scale, of the colours, addition of the grid (reticule), of two cursors, of a key

with display of the delta between the cursors, of the Zoom + and - function.

The parameterizing functions for the start of acquisition are:

- Parameterizing of the RS232 communication interface, of the Scan or rate of reading of the

measurement, of the recording thresholds, of the alarms.

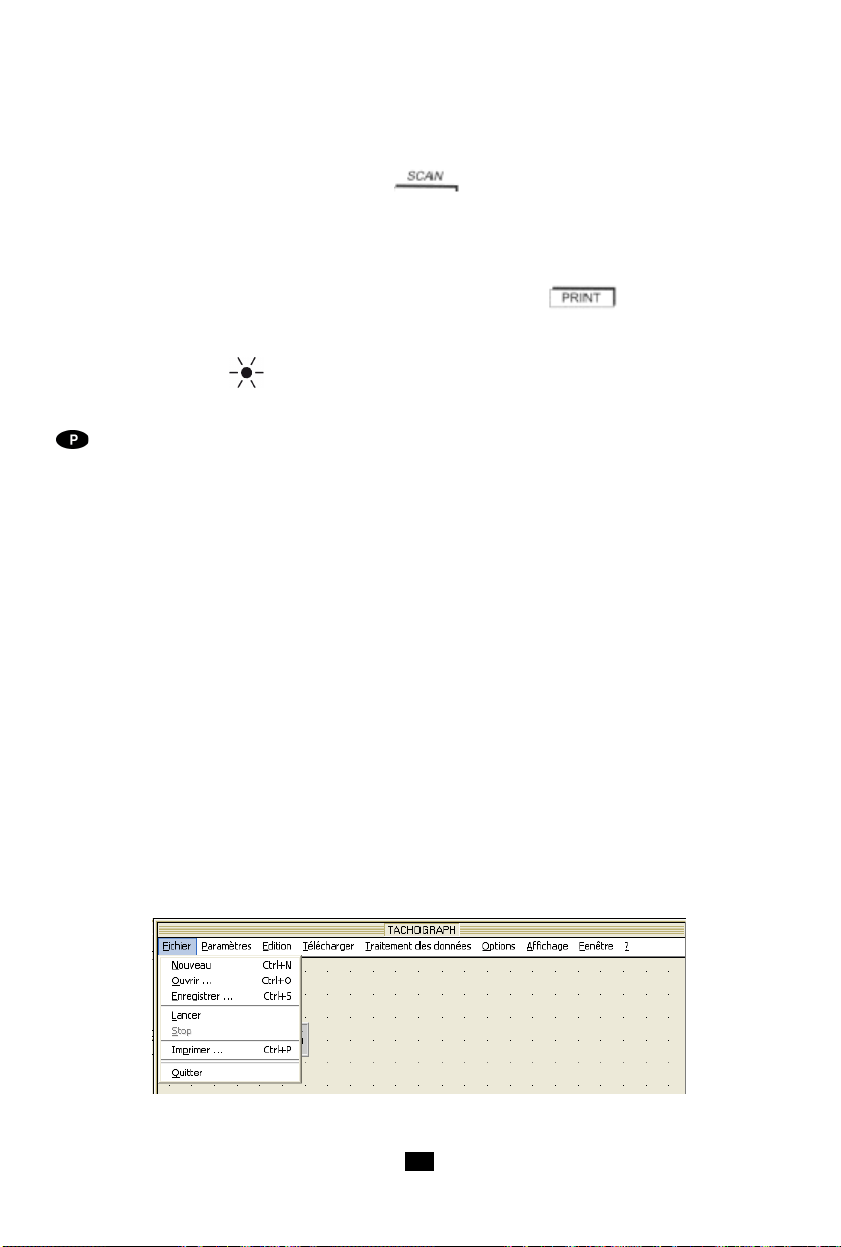

Example of menu on the screen of the PC: The File menu

50

Page 22

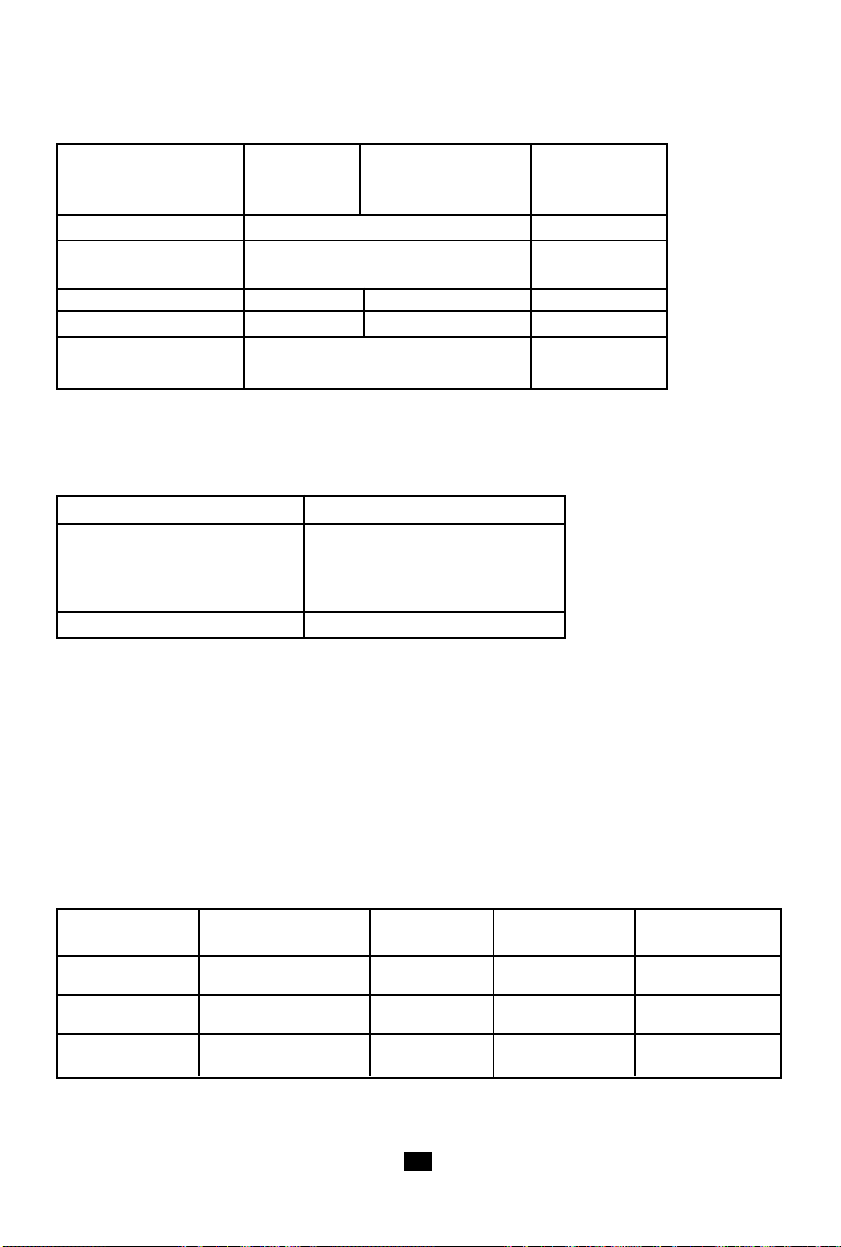

Example of menu on the screen of the PC : The help menu (?)

5. MAINTENANCE

The tachometer requires no special maintenance other than changing the battery and cleaning the

housing.

- Adjustments

The device has no internal adjustments. Measurement accuracy is ensured by a highly stable crystal

oscillator.

- Cleaning the housing

Clean with a cloth moistened with soapy water, then plain water.

A dirty sighting window can severely impair the sighting characteristics, making any measurement

impossible or unstable.

- Cleaning the mechanical kit

Clean with a cloth moistened with soapy water, then plain water.

The use of alcohol or of another solvent might irreversibly damage the mechanical adapter by degrading

its lubrication.

- Replacement of the battery

When the battery symbol appears on the display unit, the battery must be replaced.

Set the switch to "OFF".

- Open the battery compartment, located on the back of the device. Unscrew the screw using a tool

(coin, etc.)

- Remove the battery and insert a new one in its place, taking care with the polarity. Use a 6LF22 or

similar alkaline battery.

- Close the cover of the compartment and tighten the screw moderately.

- Storage

For extended periods of non-use, we recommend removing the battery from the device and storing it

separately.

- Metrological check

Like all measuring or testing devices, the instrument must be checked regularly.

This instrument should be checked at least once a year. For checks and calibrations, contact one of our

accredited metrology laboratories (information and contact details available on request), at our Chauvin

Arnoux subsidiary or the branch in your country.

5151

Page 23

- Repair

For all repairs before or after expiry of warranty, please return the device to your distributor.

- Warranty

Our warranty is valid, except as otherwise expressly stipulated, for twelve months, counting from the

date on which the equipment is made available (extract from our General Terms of Sale, communicated

on request).

The warranty does not apply following:

- inappropriate use of the equipment or use with incompatible equipment;

- modifications made to the equipment without the explicit permission of the manufacturer's

technical staff;

- work done on the device by a person not approved by the manufacturer;

- adaptation to a particular application not anticipated in the definition of the equipment or not

indicated in the operating instructions;

- damage by shocks, falls, or floods.

6. CHARACTERISTICS

6.1 GENERAL CHARACTERISTICS

- Device: Tachometer with optical sensor, external input, and USB input / output (C.A 1727 only).

- Functions: Measurements of rpm, m/min, Hz, ms, and duty cycle.

- Recording : 4000 points, recording interval from 10 to 99 999s.

- Housing: Polycarbonate, sensor lens made of methacrylate.

- Dimensions: 21 x 72 x 47mm

- Mass: Approximately 250g.

- Tightness: IP51 as per standard IEC 60529 (Ed 92).

- Electromagnetic compatibility: In conformity with EMC requirements as per NF EN 61326-1 (Ed

- Safety: in conformity with IEC 61010-1 Ed.2 2001

- Power supply:

- Environment:

97) + A1 (Ed 98) + A2 (Ed 2001)

- 6LF22 or equivalent 9V alkaline battery.

- Mean battery life: - 250 5-minute measurements with optical sensor.

- 600 5-minute measurements with external input.

- Storage: -20 to +70°C / 95% RH max without condensation.

- operation: 0°C to +55°C / 90% RH without condensation.

52

Page 24

6.2 METROLOGICAL CHARACTERISTICS

- Reference conditions

Quantity of influence Reference conditions Tolerances

Ambient temperature 23°C ± 3k

Relative humidity 45% to 75% HR

Ext. magnetic field < 40A/m to 50 or 60Hz

Electric field < 1V/m to 50 or 60Hz

Battery voltage 9V ± 0,5V

Use in the reference range

- Optical sensor: matte target (one that produces no measurement in rotation without reflecting adhesive).

- External connector: standardized 0 - 5V TTL signal.

- RPM function

Range * rpm 6.0000 10.000 100.00 1000.0 10000

- - - - -

9.9999 99.999 999.999 9999.9 99999

Resolution 0.0006tr/min 0.0006tr/min 0.0006tr/min 0.0006tr/min 0.0006tr/min

Accuracy 1.10-4 of reading ± 6 points

Measurement time 11s > t > 7s 7s > t > 1s 1s > t > 1s < 0,5s

Stability ± 6 points

* from 6 to 60rpm: usable only with the external input. Use up to 10,000rpm with the mechanical adapter.

- HZ function

At frequencies above 10kHz (upper limit of the range of use), the device may indicate erroneous values.

Range * Hz 0.1000 10.000 100.00 1000.0

- - - -

9.9999 99.999 999.99 9999.9

Resolution 0.0004Hz 0.004Hz 0.04Hz 0.4Hz

Accuracy 4.10-5 of reading ± 4 points

Measurement time 11s > t > 0,5s < 0,5s

Stability ± 4 points

* from 0,1 to 1Hz : usable only with the external input.

5353

Page 25

- Linear speed function

Mechanical adapter with wheel 3.1813cm in diameter giving K = 0.1 for m/min and K = 0.328 for ft/

min.

Range* m/min 0.60000 10.000 100.00 1000.0 10000

- - - - -

9.9999 99.999 999.99 9999.9 59999

Range ft/min 1.9680 10.000 100.00 1000.0 10000

- - - - -

9.9999 99.999 999.99 9999.9 59999

Resolution 0.0006m/min 0.006m/min 0.06m/min 0.6m/min 6m/min

0.0006ft/min 0.006ft/min 0.06ft/min 0.6ft/min 6ft/min

Accuracy not 1.10-4 of reading ± 1 resolution step in m/min

counting sensor 3.10-4 of reading ± 1 resolution step in ft/min

Measurement time 1 1s>t>1,1s 1,1s>t>0,5s < 0,5s

Stability ± 1 resolution step

Accuracy of 3.10

-3

the sensor

* from 0.6 to 6m/min and above 999.99m/min (from 1.968 to 19.680ft/min and above 3200ft/min),

usable only with the external input.

- Period meter function

Range * ms 9999.9 999.99 99.999 9.9999

- - - -

1000.0 100.00 10.000 0.1000

Resolution 0.3ms 0.03ms 0.003ms 0.0005ms

Accuracy 1.10-4 of reading ± 5 points

Measurement 11s>t>1,5s 1,5s>t>1,5s 11s>t>1,5s 11s>t>1,5s

Stability ± 1 resolution step

* from 100.0 to 9999.9ms : usable only with the external input.

54

Page 26

- Duty cycle function

Range % *9999.9 999.99 99.999

- - -

1000.0 100.00 10.000

Resolution 0.1% 1%

Accuracy 0.1% of full scale from 0.2Hz to 50Hz 1% of full scale

0.2% of full scale from 50Hz to 125Hz

Frequency range 0.2 to 125Hz 1 to 125Hz 125 to 500Hz

Measurement time 6s>t>0,5s 1,5s>t>0,5s < 0.5s

Stability ± 1 point from 0.2Hz to 50Hz ± 1 point

± 2 points from 50Hz to 125Hz

* Usable only with the external input.

- Event counter function

Measurement range from 0 to 99999 events

from 1Hz to 10kHz

Counting frequency from 0.1Hz to 10kHz with

range external input in

Accuracy of count ± 1 event

expanded range

6.3 CHARACTERISTICS OF SENSOR

- Measurement conditions

- Optical sensor

Reflecting area: from 10 to 90% of the area of the target.

Surface of the target: in the absence of the reflecting adhesive, the device must not be able to make a

measurement.

Measurement distance: from 1 to 50cm. The maximum distance is valid for a reflecting adhesive tape

having an area of at least 10cm².

Measurement angle: ± 15° from the perpendicular to the reflecting surface.

- variation in the range of use

Quantity of Limit of the range Quantity Typical variation Max. variation

influence of application influenced

Ambient -10 to + 70°C Any quantity ± 30ppm ± 50ppm

temperature measured

Humidity 10% to 90% HR Any quantity < 1.10-5 not significant

Power supply 7 to 10V Any quantity not significant

without condensation measured

measured

5555

Page 27

- optical sensor

Transmission wavelength: 890 nm.

Luminous power transmitted: depends on sighting distance ;

at 1cm => 0,5mW/cm²

at 50cm => 2mW/cm .

Minimum luminous power received: 10µW/cm2.

Ratio of reflecting area to target area: > 5%.

Detection distance: from 1 to 50cm.

Sighting angle from the perpendicular to the target: 0° ± 15°.

6.4 CHARA TERISTICS OF THE ADAPTER AND ITS END FITTINGS

- Mechanical adapter

End fittings: elastomer, Shore hardness 80

Pressure exerted on the moving part: between 2 and 40N.

Maximum speed: 10,000rpm.

Life: approximately 1,000 hours at 3,000rpm at a pressure of 20N.

- Conical end fitting accessory

This end fitting is used for a measurement by contact on the shaft end of a system in rotation.

It is an elastomer cone (max. diameter 15mm) that fits onto the output shaft of the adapter, with quick locking.

Minimum measurement shaft diameter: 5mm.

- Cylindrical end fitting accessory

This end fitting is used for a measurement by contact on the shaft end of a system in rotation.

It is an elastomer cylinder that fits onto the output shaft of the adapter, with quick locking.

It is used to measure the speeds of shafts larger than 5mm in diameter or having flat ends.

- End fitting accessory with wheel

This end fitting is used to measure a linear speed by direct contact with the moving part.

It is a rigid elastomer wheel that fits onto the output shaft of the adapter, with quick locking.

Diameter of the wheel: 30.183mm.

Circumference of the wheel: 10cm ± 0.1mm.

56

Page 28

7. TO ORDER

TACHOMETER C.A 1725 .......................................................................P01174810

- Delivered in its carrying case with 1 FRB F connector, 1 9V battery, 1 set of 15 strips of retroreflecting

film (length 0.1 m), 1 instruction manual on CD-ROM, and one Guide to getting started (printed).

ACCESSORY OF THE C.A 1725

- Mechanical accessories kit ............................................................................................. P01174902

comprising 1 mechanical adapter, 1 calibrated wheel, 1 conical end fitting, 1 cylindrical end fitting.

SPARES FOR THE C.A 1725

- End fittings (set of 3) ....................................................................................................... P01174903

comprising 1 calibrated wheel, 1 conical end fitting, 1 cylindrical end fitting.

- 9V battery ........................................................................................................................ P01100732

- Retroreflecting film (15 0.1ms strips) .............................................................................. P01101797

- FRB F connector .............................................................................................................. P01101785

TACHOMETER C.A 1727 .......................................................................P01174830

Delivered in its carrying case with 1 FRB F connector, 1 9V battery, 1 set of 15 strips of retroreflecting

film (length 0.1 m), 1 instruction manual on CD-ROM, T ACHOGRAPH software on CD-ROM and a Guide

to getting started (printed).

ACCESSORIES OF THE C.A 1727

- Mechanical accessories kit ............................................................................................. P01174902

comprising 1 mechanical adapter, 1 calibrated wheel, 1 conical end fitting, 1 cylindrical end fitting

- Software of TACHOGRAPH ............................................................................................ P01174835

- USB-A cable <--> USB-B .................................................................................................P01295293

SPARES OF THE C.A 1727

- End fittings (set of 3) ....................................................................................................... P01174903

comprising 1 calibrated wheel, 1 conical end fitting, 1 cylindrical end fitting.

- 9V battery ........................................................................................................................ P01100732

- Retroreflecting film (15 0.1ms strips) .............................................................................. P01101797

- FRB F connector .............................................................................................................. P01101785

5757

Page 29

02 - 2010

Code 692670A00 - Ed.2

DEUTSCHLAND - Chauvin Arnoux GmbH

Straßburger Str. 34 - 77694 Kehl / Rhein

Tel: (07851) 99 26-0 - Fax: (07851) 99 26-60

ESP AÑA - Chauvin Arnoux Ibérica SA

C/ Roger de Flor N° 293, Planta 1

08025 Barcelona

T el: 93 459 08 11 - Fax: 93 459 14 43

ITALIA - Amra SpA

Via Sant’Ambrogio, 23/25 - 20050 Bareggia di Macherio (MI)

T el: 039 245 75 45 - Fax: 039 481 561

ÖSTERREICH - Chauvin Arnoux Ges.m.b.H

Slamastrasse 29/2/4 - 1230 Wien

Tel: 01 61 61 961-0 - Fax: 01 61 61 961-61

SCANDINAVIA - CA Mätsystem AB

Box 4501 - SE 18304 TÄBY

Tel: +46 8 50 52 68 00 - Fax: +46 8 50 52 68 10

SCHWEIZ - Chauvin Arnoux AG

Einsiedlerstraße 535 - 8810 Horgen

T el: 044 727 75 55 - Fax: 044 727 75 56

UNITED KINGDOM - Chauvin Arnoux Ltd

Unit 1 Nelson Court - Flagship Square-Shaw Cross Business Park

DEWSBURY - West Yorkshire - WF12 7TH

T el. : 01628 788 888 - Fax : 01628 628 099

MIDDLE EAST - Chauvin Arnoux Middle East

P.O. BO X 60-154 - 1241 2020 JAL EL DIB (Beirut) - LEBANON

Tel: (01) 89 04 25 - Fax: (01) 89 04 24

CHINA - Shanghai Pu-Jiang - Enerdis Instruments Co. Ltd

3 F , 3 rd Building - N° 381 Xiang De Road - 200081 SHANGHAI

T el: +86 21 65 21 51 96 - Fax: +86 21 65 21 61 07

USA - Chauvin Arnoux Inc - d.b.a AEMC Instruments

200 Foxborough Blvd. - Foxborough - MA 02035

T el: (508) 698-2115 - F ax: (508) 698-2118

http://www.chauvin-arnoux.com

190, rue Championnet - 75876 PARIS Cedex 18 - FRANCE

Tél. : +33 1 44 85 44 85 - Fax : +33 1 46 27 73 89 - inf o@c hauvin-arnoux.fr

Export : Tél. : +33 1 44 85 44 86 - Fax : +33 1 46 27 95 59 - export@chauvin-arnoux.fr

142

Loading...

Loading...