Page 1

_fUipoiHgngpv

|

SERVICE

MANUAL

PA

1 1

2.

M

o

d

e

los

Page 2

TABLE

OF

CONTENTS

Introduction...

一

ーー

—

A.

Physical

B.

Principles

C.

Control

D.

Cross

E.

Design

IL

IL

IV.

Typical

A.

B.

Uneven

C.

D.

Trouble

.

Unit

Unit

.

Digital

n=>

D.

Controller

E.

No

F.

Low

G.

Uneven

Recommended

and

of

Principles

Section

Changes

Service

Loss

of

Fluidization

Fluidization

Loss

of

Temperature

Cellex

Spillage

Shooting

is

too

hot

will

not

readout

setting

Fluidization

Fluidization..

Fluidization

Engineering

Operation

Illustration

Reference

Problems

....

and

heat

is

.

...

of a Typical

Control

won't

cool

above

about

different

differs

from

or

Spouting

Tool

Kit

Principles

Table

from

....................

...........

dow:

1079

bed

temperature.

readout

Unit

.

AA

.

GUIA

a

ひひ

ひひ

NY

dv

00

00

00

90

VI.

|

VIL

VII.

Vill.

Heater

Replacing

Instructions

A.

B.

Controller

A.

B.

C.

D.

and

Blower

Motors

Step-by-step

Step-by-step

Design

Temperature

Air

Flow......

Bed

Temperature

Heater

.

The

.

Control & Measurement

.

Parts

.

Parts

.

Fluidotherapy

.

Circuit

MMUDEH>

.

Fluidotherapy

の

Shut

Overall

Placement

List/WEP 1 +

Diagram

and

for

Mounting

Instructions

Calibration

Criteria

Regulator

Down

System

Parts

Wiring

Specifications

Heaters

Measurement

.....

New

Controllers

Instructions

Circuit

.

System

Diagram

WEP 1 +

Controller

List.....

Diagram......

.

Controller

an

Diagram

Page 3

I.

INTRODUCTION

A.

Physical

Ina

Fluidotherapy

medium

air

vided

fluidization,

coming

other

particles

markedly

particles.

viscosity

are

This

the

sion

phase.

almost

variety

is

formed

through

particles.

microscopically

by

the

has

from

The

fluid,

generally

property

body

into

of

these

The

as

freely

of

resistive

and

Engineering

unit,

an

by

uniformly

the

bottom

is

established

rising

unusual

either

fluidized

exhibiting

attributable

permits

the

fluidized

parts

patient

as

of a bed

The

resulting

separated

gas.

This

properties

those

bed

characteristics

submergence

is

very

can

in

water

exercises.

Principles

air-fluidized

distributing

of

finely

state,

by

the

particles

from

"fluidized

which

of

the

gas

or

behaves

to a liquid

bed

much

exercise

and

like a low

state.

of

and

the

suspen-

like a liquid

in

the

can

perform

solid

di-

termed

be-

each

bed”

of

differ

of

the

which

parts

of

bath

a

B.

Principles

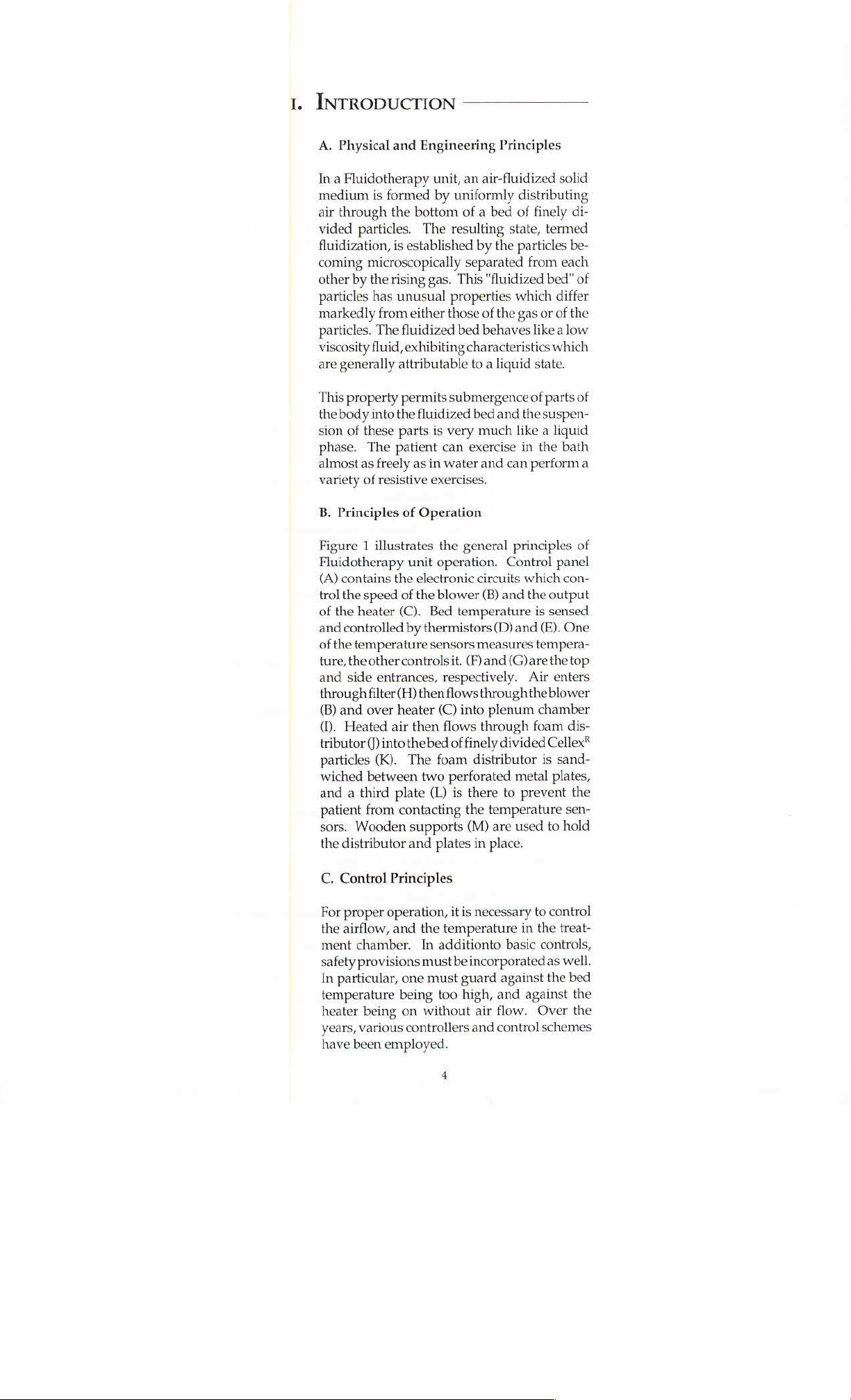

Figure 1

Fluidotherapy

(A)

contains

trol

the

of

the

heater

and

controlled

of

the

temperature

ture,

theothercontrolsit.

and

side

through

(B)

and

(D.

Heated

tributor

particles

wiched

and a

third

patient

sors.

Wooden

the

distributor

C.

Control

For

proper

the

airflow,

ment

chamber.

safety

provisions

In

particular,

temperature

heater

years,

have

various

been

of

Operation

illustrates

unit

the

electronic

speed

of

the

(C).

Bed

by

thermistors

sensors

entrances,

filter

(H)

then

over

heater

air

then

(J)

into

the

bed

(K).

The

between

from

being

two

plate

(L)

contacting

supports

and

Principles

operation,

and

the

In

mustbeincorporated

one

must

being

on

without

controllers

employed.

the

general

operation.

blower

temperature

(F)

respectively.

flows

(C)

into

flows

of

finely

foam

perforated

is

there

the

(M)

plates

it

is

temperature

additionto

guard

too

high,

principles

Control

circuits

(B)

and

(D)

measures

and

(G) are

through

plenum

through

divided

distributor

to

temperature

are

in

place.

necessary

basic

against

and

air

flow.

and

control

and

metal

used

of

panel

which

con-

the

output

is

sensed

(E).

One

tempera-

the

top

Air

enters

theblower

chamber

foam

dis-

Cellex*

is

sand-

plates,

prevent

in

against

the

sen-

to

hold

to

control

the

treat-

controls,

as

well.

the

bed

the

Over

the

schemes

4

Page 4

IH

Cross

sectional

view

fluidotherapy

Figure

of a typical

1

unit.

A

=

С

1973-1978

1978-1982

1982-1985

1985-

Motor

Control

Dayton

Low

Circuit

Low

Circuit

Low

Circuit

Model

Hysteresis

Hysteresis

Hysteresis

4X797

Triac

Triac

Triac

Heater

Control

(On-Off)

Duty-cycle

Duty-cycle

Duty-cycle

Fenwall

Modulated

Modulated

Modulated

Thermostat

Control

Control

Control

Timer

Dayton

Dayton

Electronic

(button

Electronic

(membrane

Model

Model

Module

control)

Module

2E270B

2E270B

switches)

Safety

features

Snap-Disc

Grainger 2 E634

Temperature-sensing

thermistor

if

bed

Low-current

on

which

low

Snap-Disc

located

Circuit

from

pletely

Snap-Disc

heater.

blower

completely

is

on.

cuts

under

is

above

motor

cuts

motor

at

to

being

off

Circuit

from

Pressure

off

power

blower

controller

prevent

Thermostat,

(in

bed)

cuts

off

heater

140ºF.

sensing

off

current.

Thermostat

heater.

turned

when

Thermostat

being

off

heater

blower

com-

heater

to

prevent

turned

when

sensor

if

pressure

falls

to

circuit

at

is

at

heater

which

ambient.

on.

Other

Changes

1973-1986

Until

1978,

solder

connectors

have been

connecti

ions

were

employed.

em]

loyed.

From

1978

to

1985,

spade

connectors were

used.

Since

1986,

modular

Page 5

|

|

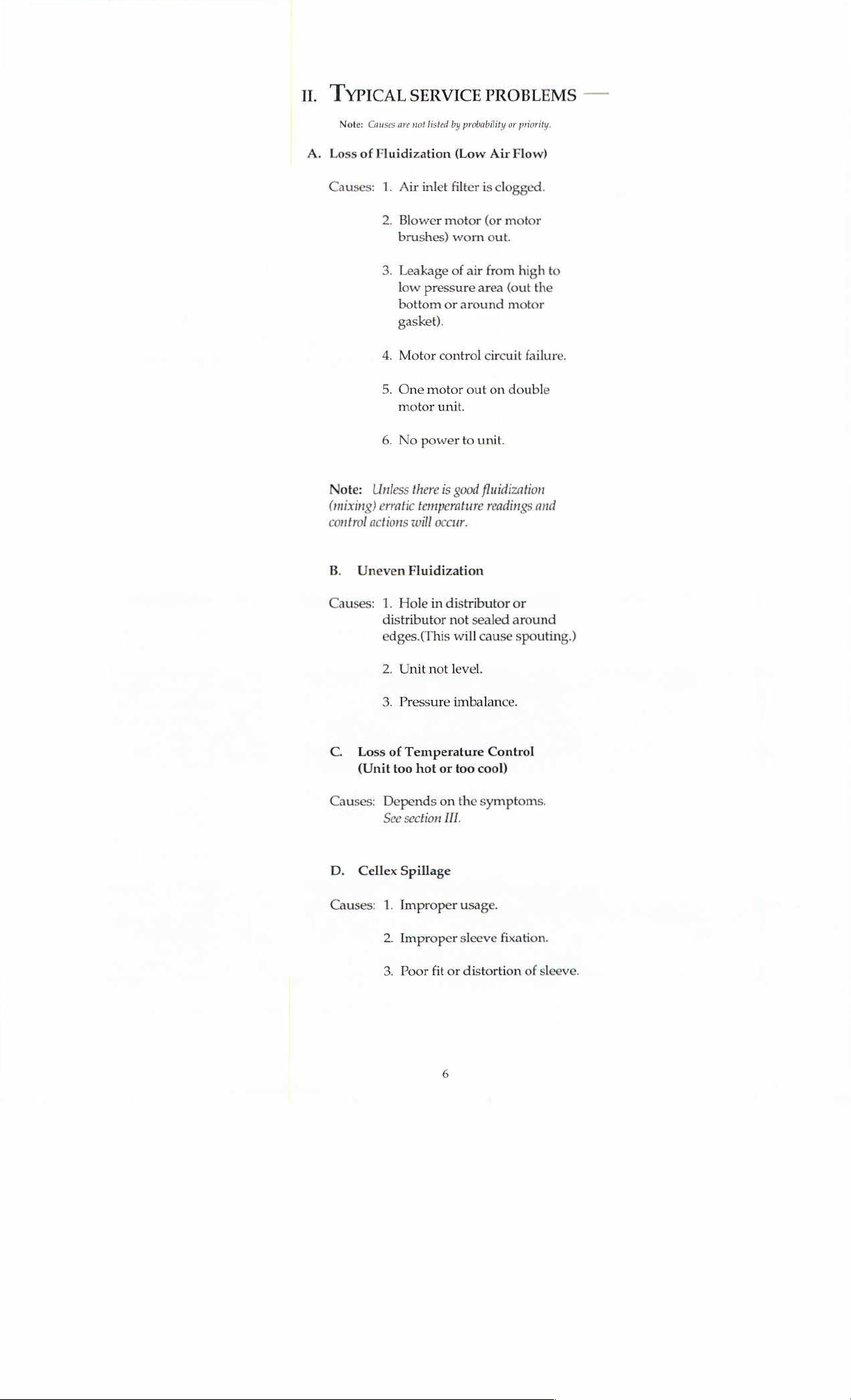

II.

A.

TYPICAL

Note:

Causes

Loss

of

Fluidization

SERVICE

are not

listed

PROBLEMS

by

probability

(Low

or

priority.

Air

Flow)

—

Causes:

Note:

(mixing)

control

B.

Unless

erratic

actions

Uneven

1.

Air

inlet

2.

Blower

brushes)

3.

Leakage

low

pressure

bottom

gasket).

4.

Motor

5.

One

motor

motor

6.

No

power

there

temperature

will

occur.

Fluidization

filter

motor

worn

of air

area

or

around

control

out

unit.

to

unit.

is

good

fluidization

is

clogged.

(or

motor

out.

from

high

(out

motor

circuit

failure.

on

double

readings

to

the

and

Causes:

C.

Loss

(Unit

Causes:

D.

Cellex

Causes:

1.

Hole

in

distributor

distributor

edges.(This

2.

Unit

3.

Pressure

of

Temperature

too

Depends

See

section

Spillage

1.

Improper

2.

Improper

3.

Poor

not

hot

fit

or

on

not

will

level.

imbalance.

III.

or

or

sealed

around

cause

Control

too

cool)

the

symptoms.

usage.

sleeve

fixation.

distortion

spouting.)

of

sleeve.

Page 6

ur.

TROUBLE

When

receiving a service

1.

If

the

LED

2.

That

there

caused

SA

How

(under

=

.

That

.

That

warmup).

Some

A.

by

long they

heavy

the

air

the

unit

typical

PROBLEM:

SHOOTING

display

is

poor

scenarios,

is

functioning

good

fluidization

fluidization).

have

had

use,

motor

filters

are

clean.

is

at

steady

and

Unit

is

-

call,

it

is

(because

the

unit,

brushes

state

(because

diagnoses

too

hot,

useful

(this

and

will

are:

and

won't

to

ascertain:

means

wear

the

poor

temperature

how

long

out

in

transients

cool

unit

has

since

about

can

occur

down

power).

control

the

last

one

can

service

year).

during

be

Condition:

Diagnosis:

Condition:

Possible

Condition:

Possible

Condition:

Possible

PROBLEM:

Diagnosis:

Diagnosis:

Diagnosis:

Lowest

There

this.

ture

Lowest

Lowest

temperature

is

nothing

Use

at

below

temperature

Inlet

Leak

Too

Motor

temperature

Wrong

Same

Heater

Temperature

Controller

Bad

temperature

LM324

IC

Unit

will

not

is

wrong.

lower

motor

105°F

is

required.

is

air

screen

(recycle)

hot

in

room

almost

above

temperature

as

110°F

light

burned

above

110°F,

out

temperature

sensor)

or

SC150D

#2

heat

above about

105°F

(with

Motor

setting

about

dirty

around

worn

heat

110°F

motor

out

120°F

reading

diagnoses

out

heater

of

calibration

sensor

Triacs

heater

alone

in

cooler

(with

(with

heater

light

won't

(verify

have

failed

107°F

off,

can

room,

heater

off,

go

by

switching

account

if

tempera-

off)

out

for

Condition:

Possible

Condition:

Possible

Heater

Diagnoses:

Heater

Diagnoses:

light

not

on

(Post

1985

failed

or

has

Temperature

Control

(Post

motor

light

Heater

Thermal

Fuse

Fuse

circuit

1982

failed

on

failure

snap-disc

failure

holder

Model)

been

disconnected.

sensor

calibration

Models)

broken

Pressure

failure

Low-current

sensor

incorrect

failure

safety

cutoff

switch

circuit

on

Page 7

PROBLEM:

Digital

bed

readout

temperature

temperature

is

different

from

Condition:

Possible

Diagnoses:

PROBLEM:

Condition:

Diagnoses:

PROBLEM:

Condition:

Possible

Condition:

Possible

Diagnoses:

Diagnoses:

Bed

temperature

Most

thermometers

SF,

also

depends

discrepancy

limb

immersion,

Controller

shows

Small,

Recalibration

No

fluidization--

Power

No

power

set

at,

different

or

large

temperature

required

to

motor

Motor

brushes

Poor

connection

to

motor

Motor

fuse

Motor

controller

was

measured

are

the

temperature

on

the

depth

is

more

than

and

recalibrate.

for

example

temperature

offsets

motor

off

worn

of

motor

failure

with

thermometer

only

accurate

measured

of

immersion.

5%,

verify

115°F,

but

wires

to 2-

If

the

by

readout

PROBLEM:

Condition:

Possible

PROBLEM:

Condition:

Possible

Diagnoses:

Diagnoses:

Low

fluidization

Motor

is

good

Air

Adjustable

high--See

Uneven

High motor

distribution

Distributor

Airflow

leak

in

speed

must

bottom

resistor

II.

A.

or

spouting

needs

be

adjusted-See

of

in

to

be

unit

or

motor

resealed

around

circuit

too

II.

В.

motor

Page 8

RECOMMENDED

Mm

Phillips

Very

Allen

ON

Digital

Adjustable

Wire

Fuses-15A,

Silicone

Thermometer

SONATA

10.

Knife

11.

Camper

12.

Motor

screw

small,

slottedscrew

wrench

multimeter

wrench

cutter,

crimper,

120V

and/or

tape,

brushes,

TOOL

driver

(.050"

size

(amps,

(or

stripper

scissors

masking

gasket,

KIT

driver

for

removing

volts,

wrench

tape

motor

(for

trim

ohms)

set)

pot

adjustments)

knobs

on

faceplate)

WARNING:

Unplug

service

Turning

insure

work.

your

the

unit

the

safety.

before

unit

off

any

will

VI.

not

HEATER

Heaters

'Finstrip'

Heater

'Finstrip'

Blower

Lamb

thru 2 inch

Blowers

Lamb

Three

REPLACING

Motors:

cabinet.

motors.

Connect

housing

mounting

gaskets

AND

for

Models

air

heaters,

for

Model

heater,

motor

for

#116309-00 1 stage,

orifice.

for

Model

#116312.00,

motors

required

To

access

Motors

Pull

motor

new

motor

and

install

hole

and

if

necessary.

BLOWER

110, 111, 113, 114, 210,

900

watts @ 120

211M.

1900

watts © 240

Models

SPECIFICATIONS

volts.

110,

111,

Flo-through,

211M.

roughly

MOTORS

the

are

motor

replace

115

for

Model

motor,

located

from

mounting

wires

into

in

motor

cubic

211M.

AND HEATERS

remove

behind

connectors.

mounting

bracket.

220.

volts.

113, 114, 115,

roughly

feet

per

the

screws

faceplate.

hole

and

hole.

Test

90

minute

Remove

unplug

Put

the

Make

motors

210,

attaching

220.

cubic

feet

thru a 2

faceplate

motor

connectors

gaskets

sure

motor

for

in

air

per

minute

inch

orifice.

bracket

on

place

is

centered

leaks

and

to

above

wires.

in

motor

adjust

in

Heater--Wood

cord

and

remove

screws.

bottom

Fiberglass

After

and

check

units

Units:

Toaccess

the

bottom.

mounting,

for

air

should

Heater

make

sure

leaks.

be

returned

the

heater,

is

heater

turn

located

does

to

factory

unit

in

metal

not

for

onits

air

touch

cabinet

heater

side

opposite

duct

secured

wall.

Replace

replacement.

power

by

two

Page 9

vu.

INSTRUCTIONS

STEP

STEP

STEP

STEP

The

calibration

STEP

STEP

1

2

3

4

new

controller

1

2

FOR

Unplug

Remove

abox,

Remove

Labeleachas

the

from

Reconnect

NOTE: A Polaroid

procedure

Place

access

no

Turn

clockwise).

(faceplate,

unit

screws

stool,

each

old

controller

faceplate.

each

is

now

follows:

controller

both

wires

can

blower

straight

MOUNTING

from

AC

from

faceplate,

or

small

table

of

the

wires

you

take

it

from

Replace

of

the

picture

can

also

hooked-up,

on a box,

the

controls,

short

circuit

control

Turn

knob

TEMPERATURE

up).

outlet.

under

and

cables

off.

You

the

unit.

with

new

cables

and

help

if

used

and

must

stool,

and

the

against

to

low

NEW

then

faceplate

should

CONTROLLER

remove

from

now

Remove

to

board,

original

controller.

wires

to

the

in

conjunction

or

small

circuit

the

position

with

be

calibrated.

table

board.

p.c.

board.

(faceplate,

CONTROL

faceplate.

rest

controller

one

at a time.

beable

to

controller

new

controller.

wire

labels

The

so

that

Be

sure

knob

一

Place

on.

remove

you

can

that

counter-

to

115°

STEP

STEP

STEP

STEP

3

4

5

6

Place

thermometer

Plug

in

the

unit.

up

to

give

good

ning.

Allow

the

unit

thermometer.

lightis

flashing

is

on

when

the

Allow

the

unit

temperature

115°,

slightly

adjust

longer

for

at

with

adjust

trim

shorter

trim

pot

duration.

least

ten

into

the

treatment

Push

treatment

fluidization.

torun

until

it

reaches

Adjust

to

trim

on

and

off

light

is

on.

run

forabout

the

thermometer.

pot

R20

duration;

R20

so

that

Repeat

STEP

pot

(about

so

if

the

minutes.

bed

button.

Unit

should

115°,

R20

on

p.c.

50%

on,

10

minutes

If

the

that

the

heater

the

temperature

heater

6,

until

light

the

of

the

unit.

Turn

blower

now

be

on

as

measured

board

until

the

50%

off).

The

more,

then

check

temperature

light

is

is

below

is

on

for a slightly

unit

remains

control

and

run-

with

the

heater

heater

bed

is

above

on

for

115°,

at

115°

a

10

Page 10

Atthis

mains

The

degrees.

STEP

STEP

STEP

VIII.

point,

the

temperature

is

to

calibrate

unit

should

The

1

2

3

still

procedure

Adjust

(on

measured

Putsome

vibration

Reattach

CONTROLLERDESIGNCRITERIA

A.

Temperature

B.

Air

flow:

Thisis

volume

flow,

controller

the

digital

be

running,

follows:

trim

pot

Controller)

control

shows

with

the

nail

polish,

from

slowly

faceplate

over

controllable

to

the

maximum

has

temperature

and

the

on

Module A (see

'115'.

thermometer.

or

glyptol

turning

to

cabinet.

the

range:

over

the

required

been

calibrated,

readout.

bed

temperature

Figure

3)

until

This

should

on

the

the

一

trim

trim

一

be

the

pots

pots.

一

105°F < T < 130°F.

range

from

minimal

for

violent

bed

and

all

thatre-

should

一

be 115

the

readout

temperature

to

prevent

一

fluidization

activity.

the

一

C. © Bedtemperature

digitally

D.

Heatershut-down:

fluidization.

displays

measurement:

bed

temperature

The

heaters

The

measuring

over

are

disabled

the

system

range

in

case

measuresand

from

100°F

of

insufficient

to

130°F.

bed

11

Page 11

THE

OVERALL

SYSTEM

Figure 2 shows

final

system.

‘a

separate

is a phase-controlled

to

the

motor,

The

heater

control

maintains

heaters

cycle,

The

switch,

(event

The

temperature

temperature

with

put

The

controls

found

duty

less

continuous

the

switches.

on

with a fixed

other

shutting

of

inadeguate

circuitry

an

associated

controls a pulse

output

the

that

cycle,

than

duty

cycle

the

block

The

motor

block

of

the

control

temperature

and

part

controller

of

heater

the

operating

ten

heat

circuit

One

off

with a variable

time

of

the

circuit

down

bed

which

dependent

amplifier,

the

pulse

switch.

heaters,

in

seconds,

output

of

the

control

AC

acts

diagram

control

system.

voltage

control

by

the

air

is

current

width

width

with

recycle

have a smooth,

proportional

circuit

Its

output

applied

has a pair

switch

switching

recycle

as a feedback

composed

period.

acts

asa

safety

heaters

in

flow.

source,

whose

modulator.

modulator

It

has

controlled

periods

signal.

of

the

of

the

duty

the

of

out-

been

of

to

is

a

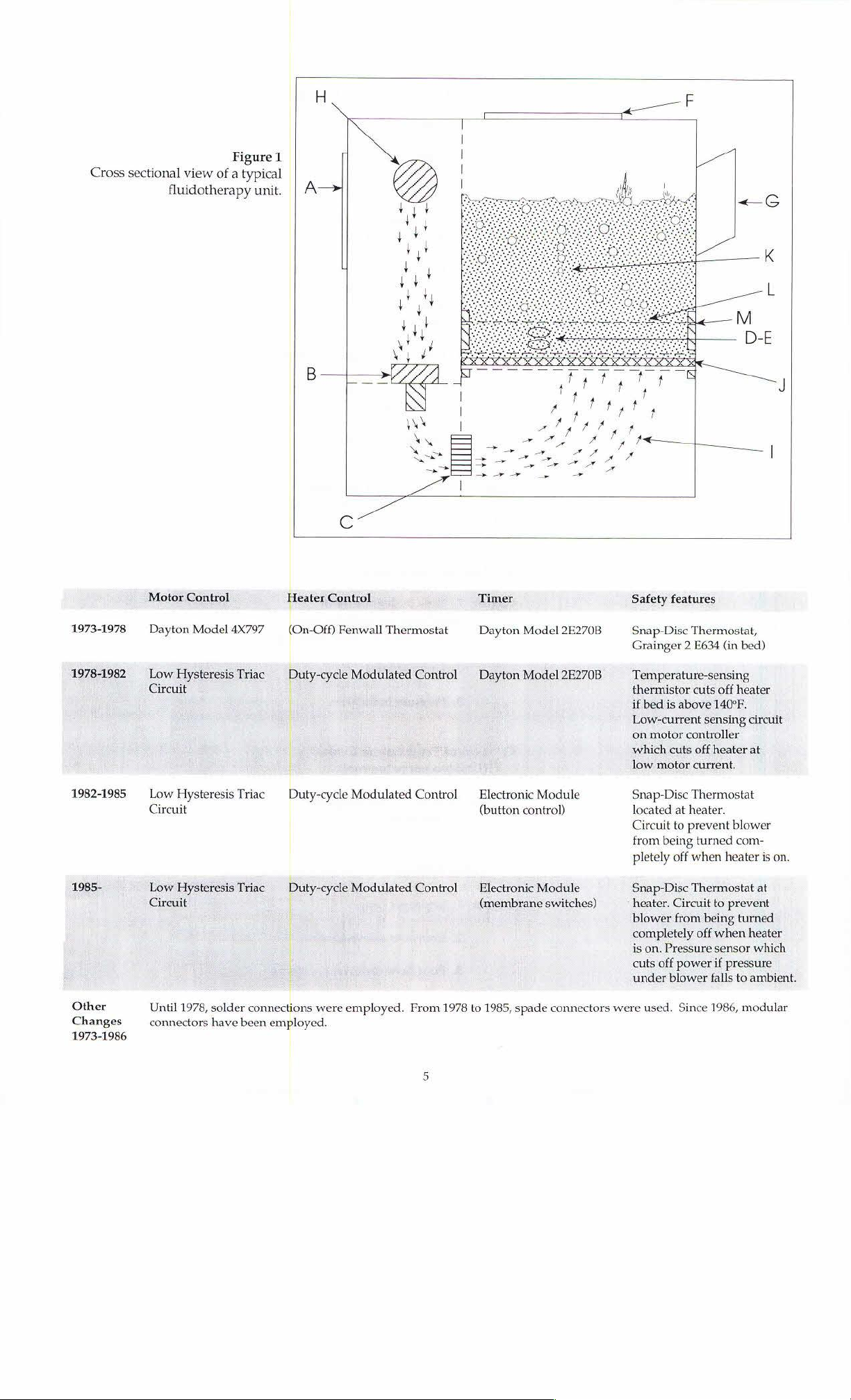

The Control

Measurement

Figure

and

System

2

|

HEATER

+

SENSOR

REFERENCE]

BED

T

SENSOR

da

=

DI

CONTROL

HEATER

INHIBIT

———>

ICOMPARATORI

HEATER

SWITCH

|

Wolor

HEATER

PULSE

WID'

=

MODULATOR

=

PRESSURE

SWITCH

Page 12

e

19

00094

a

1a

=

1760.24

901

van

Cie

|

α[ρος»]

END

94 SH

Ù

[0

l

iq

コー

F

ή

g”

18

1 ‘

nen

.

az,

|

PHA

018

64

tal

Lee)

vnnaow

eo

+

Hu

Tu

y

ae

“Sam

sui

gu

E

SNole

)

za

eu

au

|

eo

L

se

|

S

ΒΝΟ

ΗΟΕΟΟΝ

E

019

|

019

IR

H

Go

özi

>

|

tra

[E]

ni

elo

Be

Figure

Parts

3

Placement

Diagram

13

*

CN3

is

located

on

Module A in

latest

style

PCB.

Page 13

CONTROLLER

CIRCUITRY

eragy

DATE:

2

01702792

pe

T

15:07:

oroe57664。

«ο

[SHEET

€

03

Re

OF

os

WEP=1+

SCHEMATIC

Figure

Circuit

4

Diagram

WEP1+

Controller

18

Shea ovat

2)

er

Page 14

JosussoujJsu」

[|

lojluoo

JaleaH

]

=.

Josuasouay

oe

|

Aejdsiq

I

UOIAS

9JnSS9Jd

(siluAW)

laJineN

Е

0102

1900

生

|IGJIu590

F

İM

JoJo

EN)

JeleaH

3503

7

이

이

0503

1816

하 1

seigld

uoHndu1SIQ

Figure

Fluidotherapy

5

Wiring

Diagram

19

Loading...

Loading...