Page 1

Instructions

for

Use

and

Operation

of

COLPAC®

MASTER

CHILLING

J

UNITS

115

Volt

РМ.

21202

В

Wellness

CHATTANOOGA

GROUP,

By

Design®

INC.

Page 2

Table

i2Menth

EOTEWOTÚ

Precautionary

Instructions

Géneralinformation:

General

Installationie

Maintenance

Trouble:

Technical

Parts

Parts

Parts

Parts

Parts

Parts

Electrical

of

Contents

Warranty.

Le

Instructions

for

Patient

Operating

spera...

Shoaingyx

Specifications

Drawing

List:

Drawing

list:

Drawing

List:

Model

Model

Model

Model

Schematic:

C-2

Model

ED

Model

C-6

oe

Instructions

Smnuyan

ees

ba

..............................

Care

and

2: : 5442

ο

ire

dx

bi,

oz

C-2

..............................

..................................

Gb

ss

40

388

C-6

.............................

.................................

Models

C-2,

utana,

SE a a A o

Comfort

280

messe

..........................

ei

üm 8 miele e 6

ο

ο

ο

gu

ae

fos

ans

C-5

..................

La

ο.

ο

46

nants

sas

ker

Se

TRILLO

and

C-6

aaa

siye

ae

er 8 a

fou

ο

Jags

sek

ber

RE

aa

.............

BD

sasi

şb 2

re

ani

qe

ee

ο.

a

qual

SR

NS

1

2

2

3

4

5

6

7

7

8

9

10

11

12

13

14

Page 3

12

Month

Chattanooga

Unit(s)

for

of

ty

replace

defective

replacement

What

2.

3.

(“Product”)

one

(1)

year

the

Product

period

because

or

repair

Product

This

Warranty

1.

Replacement

approved

Defects

approved

Any malfunction

ranty

period

if

the

malfunction

sonable

Warranty

Group,

during

or

Company

or

damage

Company

and

Inc.

is

free

from

the

the

of a defect

this

Product

is

returned

the

repaired

Does

parts

or

if

the

malfunction

or

necessary

(“Company”)

of

effects

date

of

original

warranty

in

without

to

Product

Not

Cover

or

labor

service

caused

service

failure

failure

agent.

by

agent.

in

maintenance.

warrants

in

material

consumer

period.

material

charge

the

Company

to

the

furnished

labor

furnished

the

Product

or

failure

is

caused

that

the

and

workmanship.

purchase

If

this

Product

and/or

workmanship,

within a period

or

the

consumer's

by

anyone

by

someone

while

is

by

it

is

not

caused

unreasonable

Colpac®

of

this

fails

to

function

of

30

dealer.

residence.

other

in

the

Company

than

other

possession

by a defect

use,

including

C-2,

C-5

This

warranty

Product

Company

days

the

Company,

than

of

in

and

shall

and

extends

during

from

or

material

the

or

the

the

the

dealer

Company,

the

owner

the

failure

C-6

Master

remain

to

one

year

selling

date

on

will

the

dealer

the

dealer

during

or

workmanship

to

provide

Chilling

in

effect

any

owner

warran-

dealer

which

ship

or

or

the

war-

will

the

the

an

an

or

rea-

Company

Some

above

Obtaining

To

obtain

by

the

1. A written

2.

This

to

state.

The

liability

the

warranty

shall

states

limitation

Service

service

following:

claim

The

is

Address:

Phone:

Product

warranty

Company

in

not

be

do

not

allow

or

exclusion

from

claim

made

gives

connection

shall

to

4717

P.O.

Hixson,

(800)

must

does

be

must

Box

you

not

liable

the

Adams

592-7329

void

for

the

Company

be

Company,

489

TN

37343

be

returned

specific

authorize

with

the

and

incidental

exclusion

may

not

or

the

made

Rd.

to

legal

any

sale

of

no

within

the

of

effect.

or

consequential

or

limitation

apply

Company

rights,

person

the

to

you.

selling

written claim

dealer

the

warranty

or

and you

or

Product.

damages

of

incidental

under

should

the

may

representative

Any

this

period

selling

representation

be

dealer

also

to

have

to

property

or

consequential

warranty,

Company

sent

to:

by

the

other

to

create

or

or

the

owner

or

the

owner.

rights

for

agreement

it

which

any

business.

damages,

must

do

selling

other

dealer.

vary

from

obligation

not

contained

so

or

the

abide

If

the

state

or

in

Page 4

Foreword

This

manual

Master

mation.

its

operating

However,

tions

Chilling

To

proper

may

obtain

operation,

the

owing

be

has

been

Units.

maximum

unit.

The

Chattanooga

made

at

prepared

It

contains

read

for

life

and

and

understand

instruction

specifications

Group's

any

time

without

the

owners

efficiency

this

put

forth

policy

obligation

and

operators

on

operation,

from

manual

in

this

of

continuous

on

of

precautions,

you

Colpac

thoroughly

manual

the

were

improvement,

part

of

the

Colpac®

maintenance

C-2,

C-5

and

and

follow

in

effect

Chattanooga

at

changes

Models

C-6

all

the

Group.

C-2,

and

units,

instructions

time

to

these

C-5

and

C-6

parts

infor-

and

to

aid

prior

of

publication.

specifica-

in

to

Precautionary

1.

CAUTION:

2.

CAUTION:

3.

WARNING:

instructions

.

Know

2.

Exercise

3.

Know

loss

4.

Always

5.

Always

tion

Use

perature

the

you

of

becomes

care

Read,

the

ary

Do

Chilling

compartment

Make

trical

codes.

for

chill

characteristics

extreme

patient:

feeling.

have

the

place

one

painful. A warm,

and

judgement

of

the

Colpacs.

limitations

and

not

patient

Instructions

understand

operational

place

Unit.

certain

service

Patient

care

when

use

extreme

inform

or

more

when

and

associated

decals

chemical

This

type

and

refrigeration

that

the

unit

receptacle

Care

of

the

applying

care

you

layers

of

damp

applying

practice

activated

of

conforming

Colpac.

when

if

dampened,

towel

the

with

the

Colpac

installed

and/or

pack

may

system.

is

electrically

and

the

the

Comfort

Colpac.

applying

Colpac

thin

reduces

Colpacs

Precautionary

on

the

instant

break

grounded

to

the

Colpacs

is

too

towel

the

to

infants

Master

units.

and

cold.

Chilling

freeze

cause

applicable

to

between

initial

and

and

Operating

type

corrosive

by

connecting

national

areas

where

the

shock

of

elderly.

Instructions.

Units.

Observe

packs

skin

Constantly

the

in

the

damage

to a grounded

and

the

and

cold

Know

the

caution-

Colpac

to

local

patient

Colpac

Master

the

freezer

elec-

electrical

may

have

if

applica-

application.

check

the

tem-

Exercise

ders,

.

Do

thought

treat

Carefully

and

10.

Tolerance

During

11.

Patient

12.

13.

Treatment

extreme

elbows,

not use

skin tissue

in

the

the

observe

needs

of

of

treatment,

should

time

caution

knees,

Colpac

mind

damage.

your

the

patient.

cold,

frequently

not

should

etc.

in

of

the

first

like

tolerance

sit,

lie

not

when

the

presence

nurse

use

check

or

sleep

exceed

applying

or

therapist

of

the

Colpac

of

heat,

the

on

the

30

minutes.

Colpacs

of

poor

circulation

that

and

will

vary

condition

Colpac.

to

patients

it

is

easier

adapt

from

of

the

with

or

open

to

add

the

method

patient

patient

to

and

thin

skin

wounds.

layers

to

of

application

patient.

the

area

or

“bony”

It

should

terry

being

areas:

shoul-

be a constant

toweling

to

treated.

than

the

tolerance

to

Page 5

General

Listen

Within

individual

are

The

ing,

and

carefully

minutes, a light

Colpacs

shown

initial

time

Colpac

the

re-chilling

out

Information

after

plugging

frost

between

below.

chilling,

of

the

time

unit.

starting

of

Normally a short

unit

covering

the

dividers

the

Colpacs

in

to

from

make

should

in

the

room

will

vary

time

sure

the

compressor

form

on

the

chilling

temperature,

is

chamber

depending

required

goes

into

dividers

will

on

for

in

the

chilling

and

close

the

require several hours.

the

length

re-chilling

of

your

operation

chamber.

lid.

The

various

After

time

in

use

Colpacs.

immediately.

Insert

initial

with

the

Colpacs

chill-

patient

Note:

Care

Always

kept

water.

become

fully

damaged

supply

Remember,

-12°

While

ing

top

of

Colpacs

return

clean

It

torn

and

dealer.

C).

Be

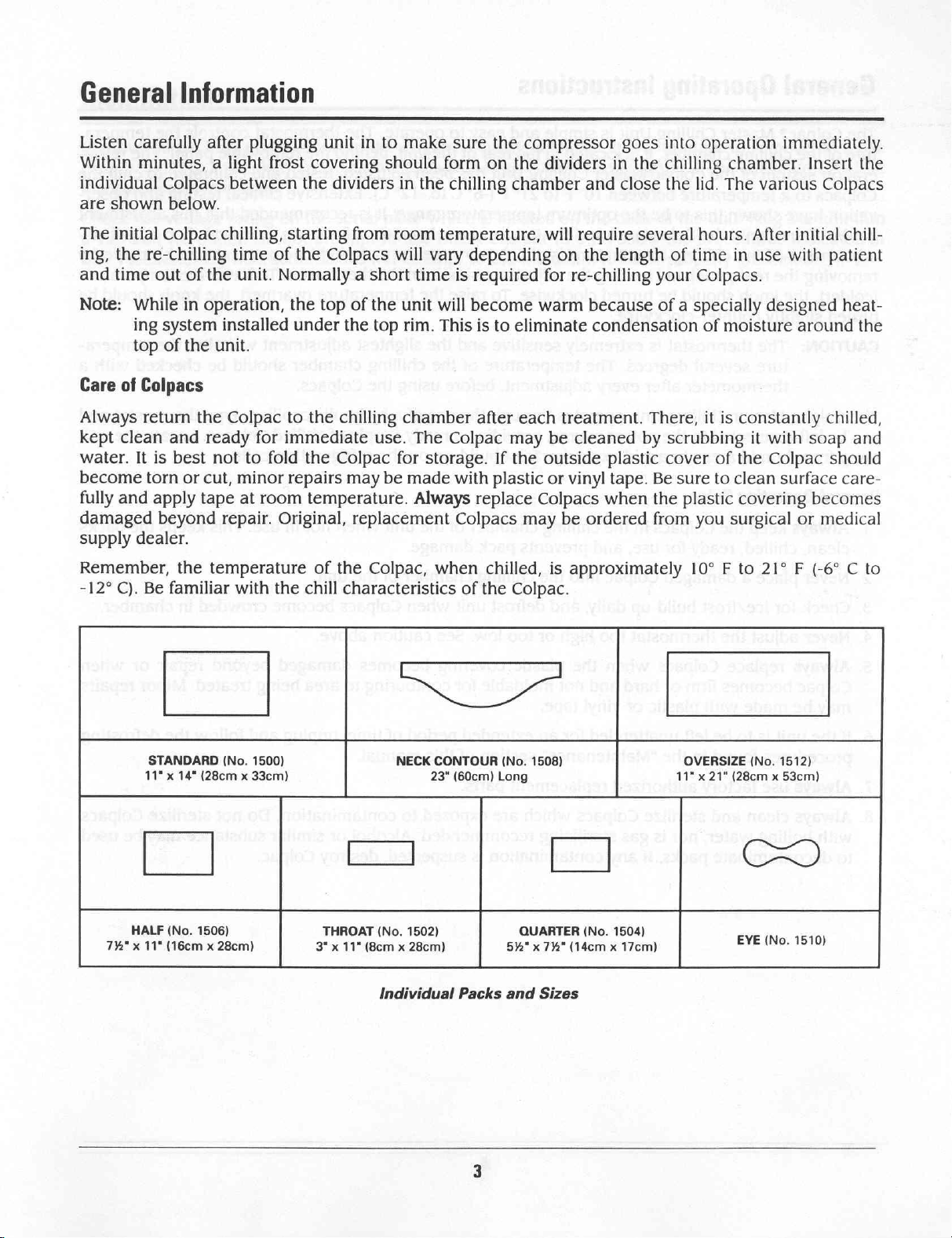

STANDARD

11" x 14"

in

system

of

the

the

and

is

best

or

apply

tape

beyond

the

familiar

(28cm x 33cm)

operation,

installed

unit.

Colpac

ready

cut,

for

immediate

not

to

fold

minor

at

room

repair.

temperature

with

Original,

the

(No.

1500)

the

top

of

under

to

repairs

the

the

chilling

the

Colpac

may

temperature.

replacement

of

the

chill

characteristics

the

unit

top

rim.

chamber

use.

The

for

be

made

Always

Colpac,

ED

NECK

will

become

This

is

after

Colpac

storage.

with

replace

Colpacs

when

CONTOUR

23"

chilled,

of

the

(60cm) Long

warm

to

eliminate

each

may

If

the

outside

plastic

or

Colpacs

may

Colpac.

(No.

1508)

because

condensation

treatment.

be

cleaned

plastic

vinyl tape. Be

when

be

ordered

is

approximately

of a specially

of

moisture

There,

by

the

from

it

is

scrubbing

cover

of

sure

to

plastic

you

10° F to

OVERSIZE

11" x 21"

clean

surgical

(28cm x 53cm)

constantly

it

the

covering

(No.

designed

with

Colpac

surface

21° F (-6° C to

heat-

around

chilled,

soap

should

care-

becomes

or

medical

the

and

1512)

HALF

11"

x

7%"

(No.

1506)

x

(16cm

28cm)

THROAT

3"

ss

11"

x

ba]

(No.

1502)

28cm)

x

(8cm

Individual

Packs

QUARTER

x

5%"

and

(14cm

732"

Sizes

(No.

1504)

17cm)

x

CO

(No,

EVE

1510)

Page 6

General

The

Colpac®

ture

of

the

chilling

eration

Colpacs

vation

not

adjustment

removing

(colder),

turned

system

to a temperature

have

be

altered

the

the

slightly

Operating

Master

shown

until

of

rear

knob

Chilling

chamber.

of

the

Colpac

between

this

to

be

the

Colpac

the

chilling

panel

should

counter-clockwise.

temperature

and turning

be

Instructions

Unit

is

It

is

located

Master

the

optimum

unit

turned

simple

Chilling

10° F to

and

the

clockwise.

and

easy

in

the

rear

Unit

21° F (-6° C to

temperature

the

Colpacs

is

absolutely

adjustment

To raise

to

operate.

of

the

unit,

has

been

-12°

range.

have

been

necessary. A slight

knob

on

the

The

behind

adjusted,

C).

Extensive

It

is

used

the

thermostat.

temperature

thermostat

the

removable

tested

recommended

for

and

clinical

some

time,

adjustment

To

(warmer),

controls

the

panel.

calibrated

testing

that

this

and

then only

can

be

lower

the

the

temperature

knob

tempera-

The

refrig-

to

chill

the

and

obser-

adjustment

if

any

made

should

by

be

CAUTION:

The

Colpac

can

be

left

away

from

General

1.

Always

clean,

Never

N

Check

O

Never

Always

AUS

Colpac

may

6.

If

the

procedures

7.

Always

The

thermostat

ture

several

thermometer

Master

connected

humid

Operating

keep

chilled,

place a damaged

for

adjust

replace

becomes

be

made

unit

use

Chilling

areas

Rules

the

Colpacs

ready

ice/frost

the

thermostat

Colpacs

firm

with

is

to

be

found

factory

is

extremely

degrees.

after

every

Unit

to

the

power

to

avoid

in

for

use,

Colpac

build-up

when

or

hard

plastic

left

in

authorized

or

unattended

the

“Maintenance”

sensitive

The

temperature

adjustment,

operates

source,

excessive

the

chilling

and

prevents

into

the

daily,

and

too

high

the

plastic

and

not

vinyl

tape.

for

replacement

and

the

of

the

before

through

providing a ready

frost

build-up

chamber

pack

chilling

defrost

or

too

low.

covering

moldable

an

extended

section

parts.

using

the

use

of

the

damage.

chamber

unit

when

See

for

contouring

period

of

this

slightest

chilling

of a hydraulic

supply

on

the

unit

of

Colpacs

caution

becomes

of

manual.

adjustment

chamber

the

Colpacs.

of

chilled

refrigeration

when

time,

the

unit.

above.

damaged

to

not

become

area

unplug

will

should

capillary

in

being

type

Colpacs.

coils.

use.

This

crowded

beyond

treated.

and

follow

alter

the

be

checked

thermostat

Locate

keeps

in

chamber.

repair

Minor

the

tempera-

with

a

and

the

unit

the

packs

or

when

repairs

defrosting

8.

Always

with

to

clean

boiling

decontaminate

and

water,

packs.

sterilize

nor

Colpacs

is

gas

If

any

which

sterilizing

contamination

recommended.

are

exposed

is

suspected,

to

contamination.

Alcohol

or

similar

destroy

Colpac.

Do

not

sterilize

substance

may

Colpacs

be

used

Page 7

Installation

Remove

pieces

the

of

drain

all

packing

paper

valve

and

is

closed.

material

other

packing

inside

material

the

Colpac®

which

chilling

chamber.

might

otherwise

It

is

important

plug

the

to

drain!

remove

Make

all

loose

certain

that

Check

a

the

the

voltage

120

Volt

“Precautionary

AC

rating

outlet.

Do

Instructions”.

on

not

the

serial

attempt

Do

plate

to

not

which

use

Direct

attempt

is

Current

to

use

located

the

unit

on

the

(D.C.).

if

it

back

Follow

is

not

of

the

unit.

the

procedures

properly

Plug

the

indicated

grounded.

unit into

in

Page 8

Maintenance

Care

of

Unit

The

Colpac®

maintain

ed

to

the

Master

the

proper

electrical

Chilling

Colpac

outlet,

providing a ready

Unit

is

equipped

temperature

with a hydraulic

evenly

supply

in

the

chilling

of

chilled

capillary

chamber.

Colpacs.

type

The

thermostat

unit

may

be

in

order

left

connect-

to

Periodically,

are

crowded

when

Defrosting

Dust

periodically

panel.

this

1.

Disconnect

2.

Raise

warm

3.

Attach

panel.

4.

Open

n

Allow

before

Close

Plug

ea

Clean and

9.

Close

and

Always

occurs

Unit

chamber

water

extension

bottom

unit

the

bottom

unit

chamber

lint

to

the

accumulated

and

insertion

and

the

unit

lid

may

be

drain

drain

to

defrost

unit

is

started

drain

back

into

return

will

insure

disconnect

Colpacs

lid — chilling

accumulate

highest

or

the

inside

from

its

and

remove

poured

hose

valve.

completely.

again.

valve

the

and

power

to

efficiency.

power

frost

in

removal

of

the

power

Colpacs.

over

to

the

detach

source.

the

chilling

sequence

on

the

before

the

chilling

of

the

packs

tank

wiped

source.

Leave

the

refrigeration

valve,

All

condenser

The

cleaning

located

excess

extension

chamber.

begins

condenser

chamber

becomes

dry

with a clean

lid

open

coils

beneath

water

drain

again.

fins

of

the

condenser.

will

build

difficult.

to

speed

to

speed

chilling

must

be

removed

hose.

the

refrigeration

may

be

reached

up

to a point

The

units

should

towel

or

cloth.

defrosting. A small

defrosting.

chamber,

from

unit.

by

removing

behind

the

This

where

be

chilling

must

be

the

the

Colpacs

defrosted

amount

rear

access

chamber

removed

rear

access

of

Replacing

1.

Remove

Remove

do

Remove

a

Remove

a

Remove

a

To

reinstall,

After

ga

ing

nut

Thermostat

plate.

bushing

packing

brass

rubber

installation,

with

nut.

in

nut.

washer.

reverse

seal

silicone

Thermostat

bushing

procedure.

top

of

nut.

pack-

sealant.

Installation

Page 9

Trouble

SYMPTOM

A.

Unit

plugged

packs

not

B.

Packs

too

C.

Packs

too

Shooting

POSSIBLE

in

but

chilled.

cool.

warm.

1.

2.

3.

4.

5.

1.

2.

1.

CAUSE

Breaker

circuit

Thermostat

functioning.

Fan

Compressor

Refrigerant

Thermostat

low.

Thermostat

Thermostat

for

electrical

off.

not

motor

failure. | 3.

failure.

leak.

set

failure.

set

too

too

SUGGESTED

1.

Turn

breaker

2.

Replace

Replace

4.

Contact

5.

Contact

1.

Adjust

Thermostat.

2.

Replace

1.

Adjust

themostat.

SOLUTION

on.

thermostat

motor.

factory.

factory.

Thermostat.

Technical

Type

Amount

Test

Pressures,

Normal

Operating

high.

2.

Thermostat

3.

Power

failure.

failure.

Specifications

Rated

Rated

of

of

Voltage:

Frequency:

Current: 4 Amps

Horsepower:

Refrigerant:

Refrigerant:

All

Models:

Temperature,

All

Models:

115V

60

Hz

1/5

R-134A

C-2,

C-5,

C-6,

High,

Low,

-12°C

+10º F to

2.

3.

11

oz.

11

oz.

12.5

oz.

235

psi

150

psi

to

-6°C

+21°F

Replace

Check

circuit.

thermostat.

electrical

Page 10

Parts

Drawing:

Model

C-2

14

Page 11

Parts

List:

Model

C-2

1

20500

3

20042

4

21282

5

21635

6

21983

7

20514

8

22219

9

22220

10

|‘

21373

11

12

13

14

15

16

17

18

Note:

21259

22121

4228

22409

22420

22955

20237

60286

Whenever

always

of

the

include

unit.

THERMOSTAT,

LAMP,

Pilot

CORD

SET,

HOSE,

BACK

DOOR,

HANDLE,

LID,

Assembly

STOP,

S-C

VALVE,

CASTER,

COMPRESSOR,

THERMOMETER,

COIL

COVER,

COIL

COVER,

COIL

COVER,

HANDLE,

LATCH,

ordering

serial

Resale

Light

w/J28G

Nylon,

5/8" x 12",

Sub-Assembly

Lid,

Resale

3.625" x 16.75"

Boiler

Drain,

3”

EY4520,

13.5" x 22.75",

Sub-Assembly

Middle,

Decorative,

Door,

Rear

parts

number

Coupled,

1/2"

ID,

7/16-20 x 1/2"

BM2A528-1

Dial

Aluminum

12"

(not

shown)

or

corresponding

which

M-F

Chrome

Outside

is

located

一

一

一

一

一

一

一

一

一

睛

一

一

一

一

下

about

on

the

unit,

back

Page 12

Parts

Drawing:

Model

C-5

10

Page 13

Parts

List:

1

3

20042

4

5

6

7

8

9

10

11

12

22121

13

14

15

16

17

18

20500

21282

21635

22457

20514

22297

22300

21373

21259

22461

22462

22956

20237

60286

4228

Model

THERMOSTAT,

LAMP,

Pilot

CORD

SET,

HOSE,

Nylon,

DOOR,

Rear,

HANDLE,

LID,

Assembly

STOP,

S-C

VALVE,

Boiler

CASTER,

COMPRESSOR,

THERMOMETER,

COIL

COVER,

COIL

COVER,

COIL

COVER,

HANDLE,

LATCH,

Door,

C-5

Resale

Light

w/J286

5/8” x 12”,

Complete

Lid,

Resale

3.625" x 16.75"

Drain,

1/2”

3”

EY4520,

Decorative,

7/16-20 x 1/2”

BM2A528-1

Dial

Outside

Sub-Assembly

Middle,

Rear

Aluminum

12”

(not

shown)

Coupled,

ID,

Chrome

M-F

1

1

1

1

1

1

1

1

1

4

1

1

1

1

E

3

À

2

|

1

Note:

Whenever

always

of

the

include

unit.

ordering

serial

parts

number

or

corresponding

which

is

located

about

on

the

nit,

hack

11

Page 14

Parts

Drawing:

Model

C-6

e

9

12

Page 15

Parts

List:

1

20500

3

20042

4

21282

5

21635

6

23008

20514

7

8

22348

9

22352

10

1

12

13

14

15

16

17

18

21373

21260

22121

23021

23022

22954

20237

60286

4228

Model

THERMOSTAT,

LAMP,

Pilot

CORD

SET,

HOSE,

Nylon,

DOOR,

Rear,

HANDLE,

LID,

Assembly

STOP,

S-C

VALVE,

Boiler Drain,

CASTER,

COMPRESSOR,

THERMOMETER,

COIL

COVER,

COIL

COVER,

COIL

COVER,

HANDLE,

LATCH,

Door,

C-6

Resale

Light

w/J28G

5/8" x 12”,

Complete

Lid,

Resale

3.625" x 16.75"

1/2"

3”

EY4520,

Decorative,

7/16-20 x 1/2"

BM2A528-1

Dial

Outside

Sub-Assembly

Middle,

Rear

Aluminum

12”

(not

shown)

Coupled,

ID,

M-F

Chrome

dial

ni

mp

mm

NO

Note:

Whenever

always

of

the

include

unit.

ordering

serial

parts

number

or

corresponding

which

is

located

about

on

the

unit,

back

13

Page 16

Electrical

Schematics:

Models

Compresi

iti

bl

Thermostat

C-2,

IU

C-5,

Heating

一

fic

C-6

나

Element

EL

qi

|

ヒーーーー

lh

14

Page 17

1-800-592-7329

Wellness

CHATTANOOGA

GROUP,

By

INC.

Design®

Loading...

Loading...