Chatsworth Products Hot Aisle Containment User Manual

Build To Spec Kit

Aisle Containment Solution

User’s Manual

Version 1.0

December 2013

©2013 Chatsworth Products, Inc. All rights reserved. CPI, CPI Passive Cooling, GlobalFrame,

MegaFrame, Saf-T-Grip, Seismic Frame, SlimFrame, TeraFrame, Cube-iT Plus, Evolution,

OnTrac, Velocity and QuadraRack are federally registered trademarks of Chatsworth Products.

eConnect and Simply Efficient are trademarks of Chatsworth Products.

All other trademarks belong to their respective companies. 12/13 MKT-60020-601

techsupport@chatsworth.com

www.chatsworth.com

BTS Aisle Containment Manual, Rev. 1.0 ___ December 2013

Chatsworth Products 2

Contents

INTRODUCTION .......................................................................................................................... 4!

Legal Information ...................................................................................................................... 4!

Warranty .................................................................................................................................... 4!

SAFETY INFORMATION ............................................................................................................. 5!

INTENDED USE ....................................................................................................................... 5!

STORAGE OF COMPONENTS ................................................................................................ 5!

TOOLS REQUIRED FOR ASSEMBLY AND INSTALLATION .................................................. 6!

SITE PREPARATION ............................................................................................................... 6!

UNPACKING ................................................................................................................................ 7!

BUILD TO SPEC KIT – THE AISLE CONTAINMENT DUCT ...................................................... 8!

INTRODUCTION ....................................................................................................................... 8!

COMPONENTS ........................................................................................................................ 8!

ASSEMBLING THE BUILD TO SPEC KIT .............................................................................. 10!

CREATE THE DUCT ........................................................................................................... 12!

CREATE DROP PANELS ................................................................................................... 22!

CREATE AN END FACIA OVER THE DOOR ..................................................................... 25!

FULL HEIGHT CABINET BLANKING PANELS ....................................................................... 27!

INTRODUCTION ..................................................................................................................... 27!

COMPONENTS ...................................................................................................................... 27!

INSTALLATION ....................................................................................................................... 28!

AISLE CONTAINMENT DOOR SYSTEM .................................................................................. 31!

INTRODUCTION ..................................................................................................................... 31!

COMPONENTS ...................................................................................................................... 31!

INSTALLATION ....................................................................................................................... 32!

FLOOR PREPARATION ..................................................................................................... 32!

FLOOR MOUNTING ANGLE INSTALLATION .................................................................... 35!

DOOR FRAME ASSEMBLY ................................................................................................ 36!

DOOR FRAME INSTALLATION .......................................................................................... 41!

DOOR INSTALLATION ....................................................................................................... 49!

BTS Aisle Containment Manual, Rev. 1.0 ___ December 2013

Chatsworth Products 3

AISLE CONTAINMENT FLOOR SEAL KITS ............................................................................ 52!

INTRODUCTION ..................................................................................................................... 52!

FOR GF-SERIES GLOBALFRAME GEN 1 CABINET AND F-SERIES TERAFRAME GEN 3

CABINET ................................................................................................................................. 52!

FOR F-SERIES TERAFAME GEN 2 CABINET ...................................................................... 53!

FOR ALL OTHER CABINETS ....................................................................... 54ACCESSORIES

................................................................................................................................................ 55!

BTS Aisle Containment Manual, Rev. 1.0 ___ December 2013

Chatsworth Products 4

INTRODUCTION

This document is the User’s Manual for CPI Build To Spec Kit Aisle Containment

Solution. It includes basic assembly and installation instructions for the Build To Spec

Kit, Aisle Containment Door Assembly; Full Height Cabinet Blanking Panels and

Cabinet To Floor Sealing Kits, which are used together to create an Aisle Containment

Solution.

Build To Spec Kit Aisle Containment Solution User’s Manual

©2013 Chatsworth Products, Inc. All rights reserved.

Legal Information

The information contained in this guide is subject to change without notice.

Chatsworth Products, Inc. (CPI) shall not be liable for technical or editorial errors or

omissions contained herein; nor is it liable for any injury, loss, or incidental or

consequential damages resulting from the furnishing, performance, or use of this

material and equipment.

Warranty

Chatsworth Products, Inc. (CPI) guarantees manufactured products and each part or

component thereof against all defects in material and/or workmanship. CPI agrees to

remedy any manufacturing defect either through replacement or repair at no charge

provided that the defective unit is returned, transportation prepaid, to the CPI factory.

The warranty extends for a period of one year from the date of installation or initial use,

provided that this period shall not exceed 18 months from the original date of shipment

from the factory.

Any product that has been repaired or replaced shall be similarly warranted on its repair

or replacement for the remaining product warranty period or 90 days from the date of

repair or replacement, whichever expires last.

This warranty does not extend to products that have been subjected to neglect, accident

or improper use, nor to units that have been altered by non-CPI personnel.

No warranties other than those set forth in this section are given or implied with respect

to the products furnished. CPI shall, in no event, be liable for consequential damages,

for loss, damage or expense directly or indirectly arising from the use of the products,

for any inability to use materials or from any other cause.

BTS Aisle Containment Manual, Rev. 1.0 ___ December 2013

Chatsworth Products 5

SAFETY INFORMATION

WARNING: Improper use of this product may lead to serious injury or

death. Read and understand all instructions for proper installation and use

of this product.

WARNING: Installation of aisle containment products may require the use

of ladders, scaffolds, and other climbing tools. Follow all climbing device

procedures and observe all safety and warning precautious.

WARNING: The aisle containment products are heavy and large. This

requires that at least two personnel be used for assembly and installation.

Obtain adequate assistance or hire professional equipment riggers.

WARNING: Depending on the configurations of the deployed system, the

static weight of the duct can result in heavy loads. Consult with the local

building engineer to verify that floor and/or ceiling loading prior to

assembling and installing the structure. Failure to provide adequate

support and anchoring for the frame could result in severe injury of death.

WARNING: Failure to properly support structural members during

assembly colud result in severe injury or death.

WARNING: The aisle containment system is designed to support the

weight of the duct, but is not designed for significant additional loading. Do

not climb on or support heavy items such as cable runways from the

containment structure as doing such could result in severe injury or death.

INTENDED USE

The Build To Spec Kit Aisle Containment Solution should only be used in a restricted

service environment, such as a data center. Use indoors only, in environmentally

controlled areas; do not use outdoors or in harsh environments. Not for use in plenums.

Use this solution for computer server, storage and network equipment. Allow only

qualified service personnel to use this solution.

STORAGE OF COMPONENTS

All system components should be stored indoors only in environmentally controlled

areas. Do not store outdoors. Do not expose to harsh or humid areas.

BTS Aisle Containment Manual, Rev. 1.0 ___ December 2013

Chatsworth Products 6

TOOLS REQUIRED FOR ASSEMBLY AND INSTALLATION

The following tools are required to assemble the Build To Spec Kit and Aisle Containment

Doors. Additional tools may be required depending on site-specific requirements.

Tool

Application

Mitre saw with metal/aluminum cutting blade

For cutting frame components

Jig/reciprocating saw with metal cutting blade

For cutting corner brackets

Utility Knife or Flute Cutter

For cutting poly panels/bulb seal

Straight edge or Guardian Knife Guide*

For cutting poly panels/bulb seal

#2 Phillips screwdriver or bit for drill/driver

Assembly, BTS Kit

#3 Phillips screwdriver or bit for drill/driver

Assembly, Door

8 mm socket and open end wrench

Assembly, Door

10 mm socket and open end wrench

Assembly, Door

13 mm socket and open end wrench

Assembly, Door

Ladders

Installation

Levels

Installation

Drill, bits

Installation

*For best results when cutting corrugated plastic sheet use specialized cutting tools, like

the Guardian Knife Guide by Saw Trax Mfg. Inc.

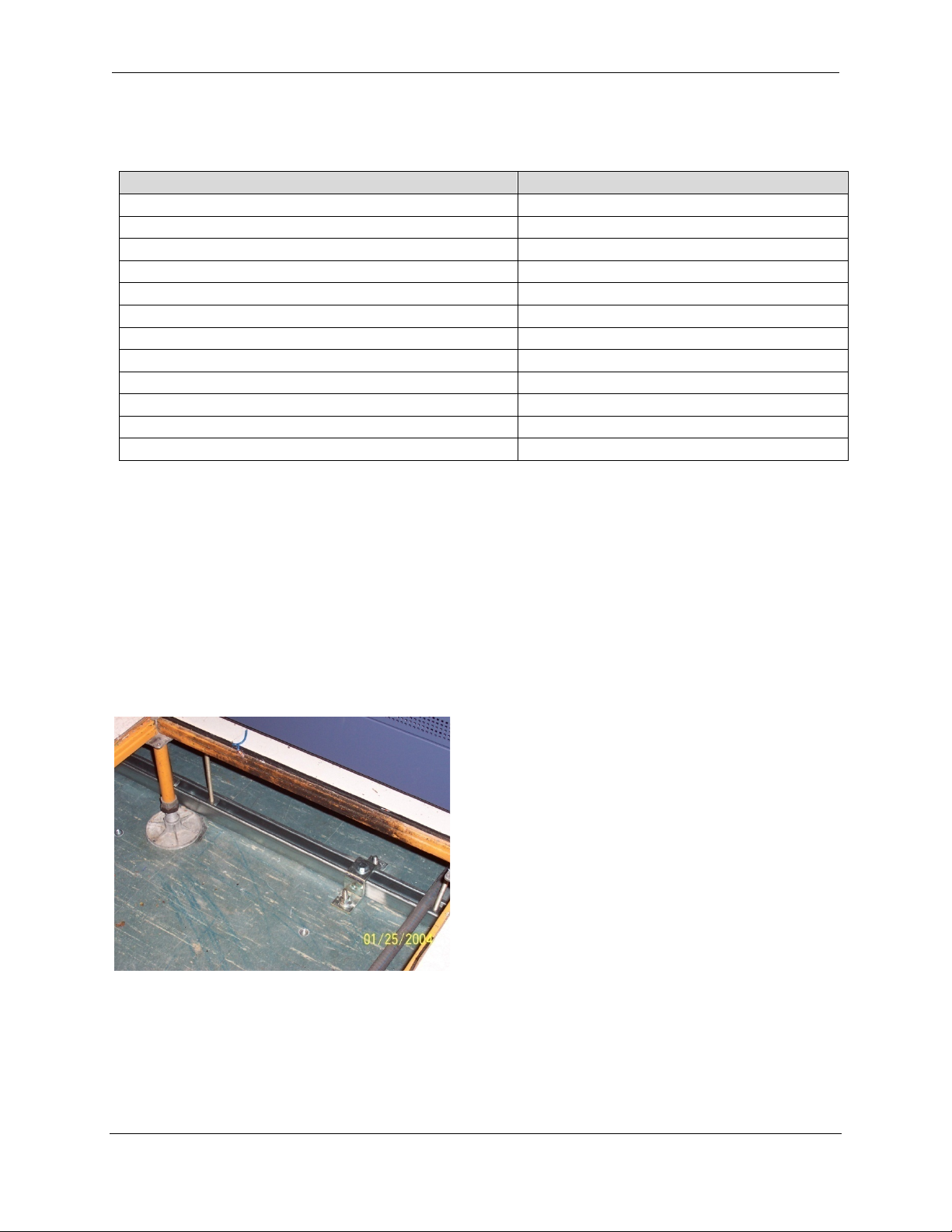

SITE PREPARATION

Floor

In an access floor installation, ensure that the floor is strong enough to support the fully

populated computer cabinets, and the additional weight of the Build To Spec Kit (aisle

containment duct) and Aisle Containment Door Systems. If required, add subfloor

bracing to provide the proper support for equipment.

Subfloor bracing.

Ceiling

If supporting from threaded rod, ensure that the ceiling is strong enough to support the

Build To Spec Kit (aisle containment duct). Threaded rod used to support the duct

should only be used to support the duct.

BTS Aisle Containment Manual, Rev. 1.0 ___ December 2013

Chatsworth Products 7

UNPACKING

The containment system components are packaged in separate crates. Inspect the

components for damage as they are unpacked. If any damage is observed, contact your

distributor or CPI Customer Service.

CAUTION: Aisle containment components are heavy. Use a

minimum of two (2) people to unpack and remove components from

the pallet.

1. Components are packaged in protective crates. The upper crate will need to be

removed to access the components. Carefully remove the mounting screws from the

steel plates that tie the upper and lower crate. The upper crate will need to be lifted

and set aside.

CAUTION: The upper crate is heavy. Use a minimum of two (2)

people to remove.

2. Individual component pieces will be individually wrapped with foam. The foam

should be used to provide protection when the components are staged on the floor

prior to assembly. Use a utility knife to cut any tape. Be careful not to allow the knife

to contact the components as this causes damage.

RECYCLABLE MATERIALS: CPI uses only recyclable materials in all

of its containment packaging. Please save packaging for later use or

dispose of properly. All wood components of CPI pallets have been

properly treated to comply with the pest-free certifications required by

foreign countries.

3. After the all of the components have been unpacked, locate the hardware kit and

inspect the product for concealed damage. If any damage to the aisle containment

solution is observed, contact your distributor or CPI Customer Service.

BTS Aisle Containment Manual, Rev. 1.0 ___ December 2013

Chatsworth Products 8

BUILD TO SPEC KIT – THE AISLE CONTAINMENT DUCT

INTRODUCTION

The Build To Spec Kit from Chatsworth Products, Inc. (CPI) includes various

components that are field fabricated to create a single duct over the contained aisle.

The duct isolates and guides exhaust air from the contained aisle back to the air

handlers as part of a closed return system. The duct can be supported from the ceiling

or from the tops of cabinets. Clear polycarbonate panels allow light to enter the

contained aisle. Use Aisle Containment Door Assemblies (ordered separately) on each

end of the contained aisle. Use Full Height Blanking Panels (ordered separately) to fill

any gaps from missing cabinets or uneven rows. If cabinets vary in height, use

Universal Bulb Seal (ordered separately) on drop panels cut from extra panel material to

seal the gaps.

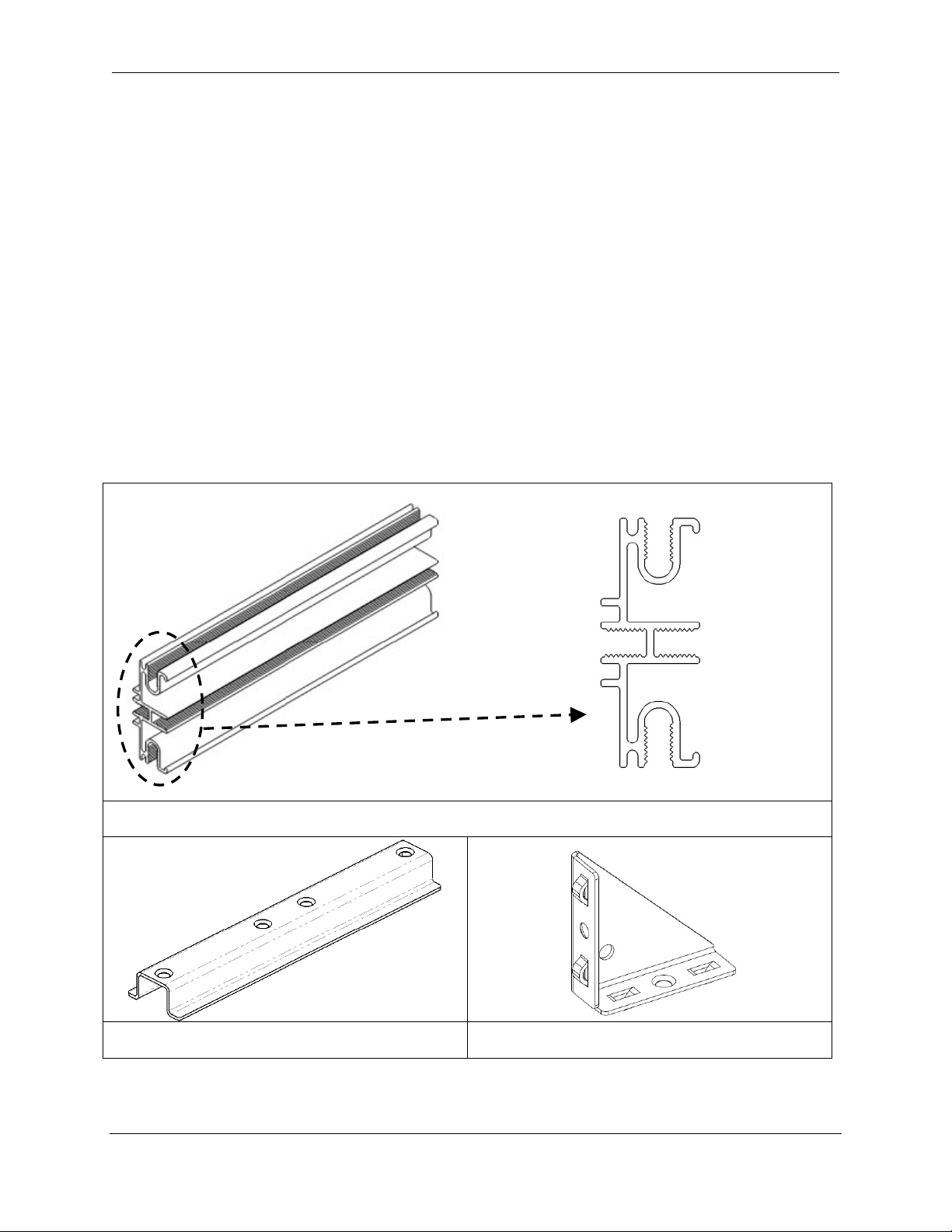

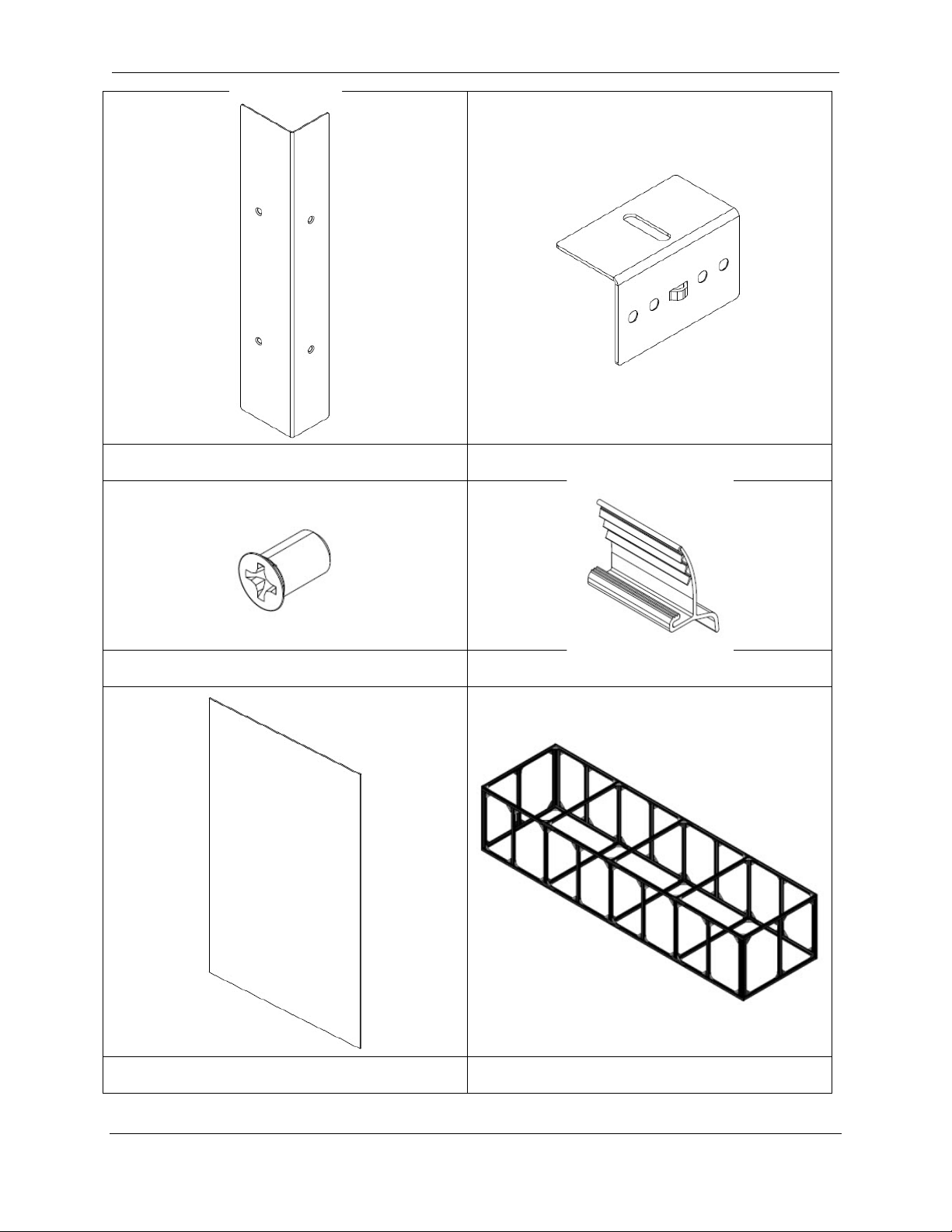

COMPONENTS

The basic components included with each Build To Spec Kit are illustrated below and

on the next page.

Extrusion, 94”L (2387 mm)

Use to build structure of the duct

Joiner Gusset

Use to splice Extrusion for longer duct

Plate Gusset

Use to splice corners/intersections

Inside

Containment

Outside

Containment

BTS Aisle Containment Manual, Rev. 1.0 ___ December 2013

Chatsworth Products 9

Corner Cover

Use to reinforce outside corners

Mounting Bracket

Use to attach duct to ceiling or cabinets

Screws

Use to assemble Gussets and Extrusion

Panel Clamp

Use to secure Panels against Extrusion

Polycarbonate Panels

48” (1219 mm) W x 96” (2438 mm) L

Build To Spec Kit Assembled

Kits are available in several sizes.

BTS Aisle Containment Manual, Rev. 1.0 ___ December 2013

Chatsworth Products 10

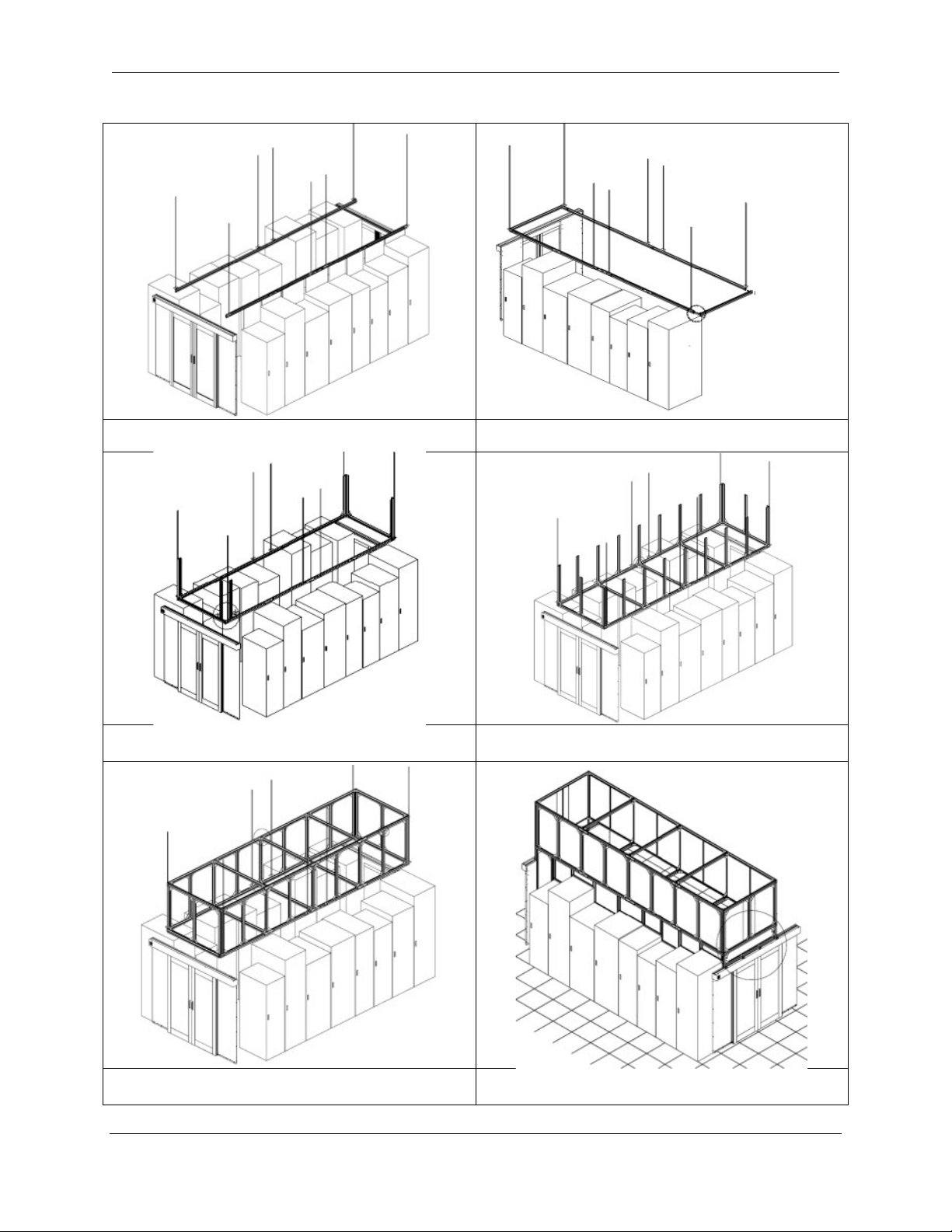

ASSEMBLING THE BUILD TO SPEC KIT - The following sections cover recommended

assembly and installation methods. Use alternate methods or order of assembly as required.

Step 1: Join Extrusions to form the bottom, sides of the

duct and support from ceiling or top of cabinets.

Step 2: Level the sides and connect the ends to

form the bottom of the duct.

Step 3: Cut and install vertical supports at

each corner.

Step 4: Cut and install cross braces and intermediate

vertical supports.

Step 5: Cut and install the frame and cross braces at the

top of the duct.

Step 6: Cut, fit and install the panels. You may also

need to add drop panels and end fascias.

BTS Aisle Containment Manual, Rev. 1.0 ___ December 2013

Chatsworth Products 11

BTS Aisle Containment Manual, Rev. 1.0 ___ December 2013

Chatsworth Products 12

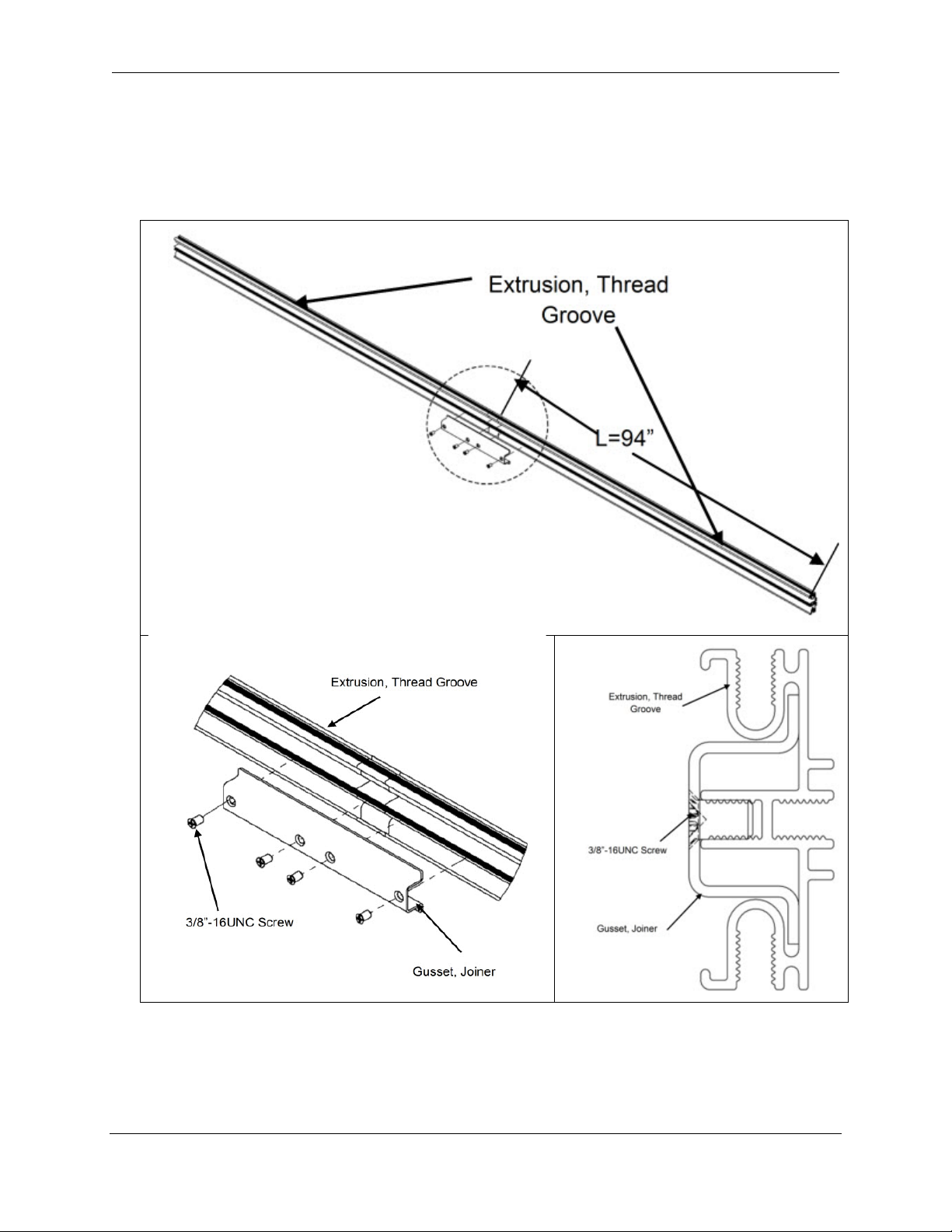

CREATE THE DUCT

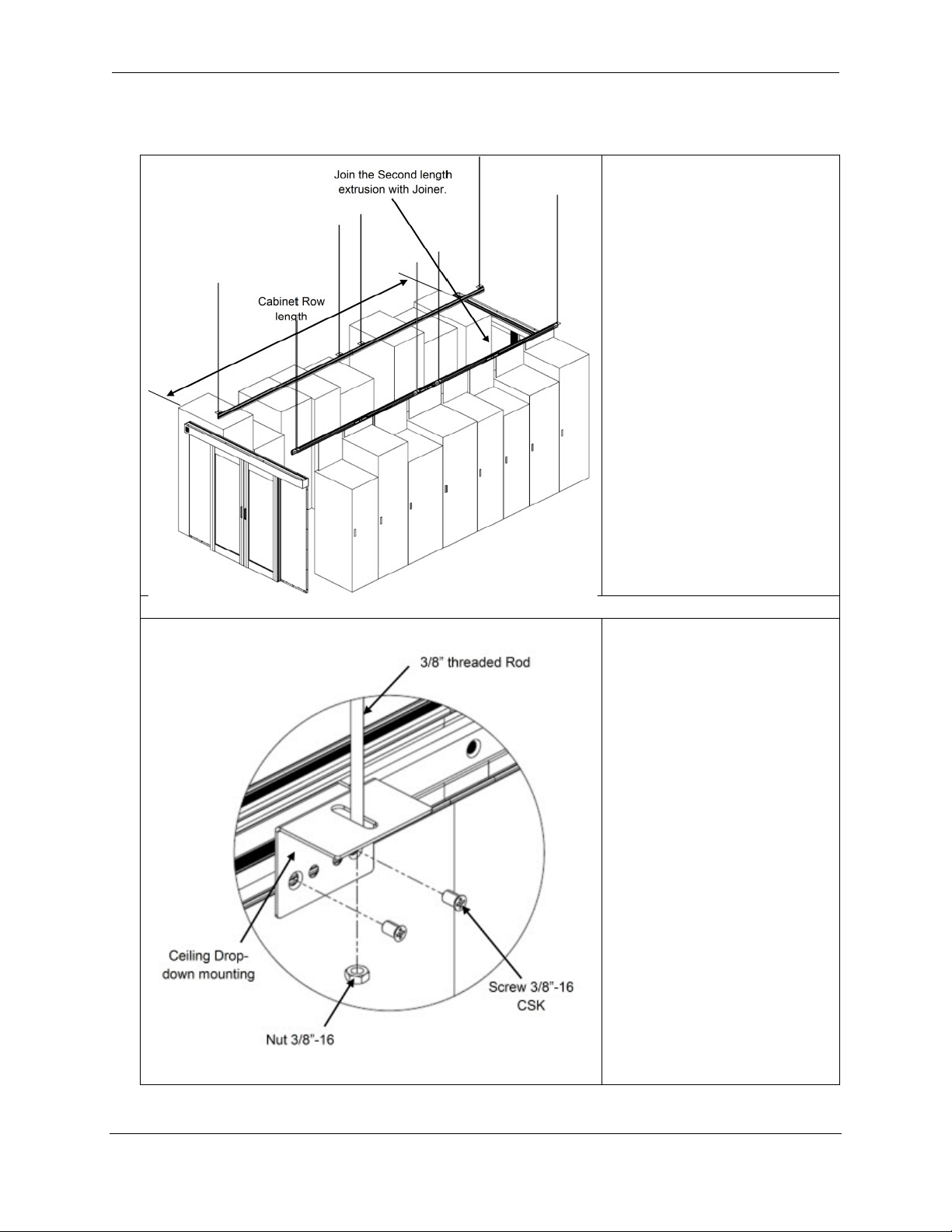

1. Assemble Extrusions to make the two long sections for the bottom of the duct.

If cabinet row length is greater than 94” (2387 mm), join extrusions together using

the Joiner Gusset and (4) Screws as shown below.

Note:

• The flat side of the extrusion faces the inside of the containment/duct (see page 8).

• The Joiner Gusset faces the outside of the containment/duct.

BTS Aisle Containment Manual, Rev. 1.0 ___ December 2013

Chatsworth Products 13

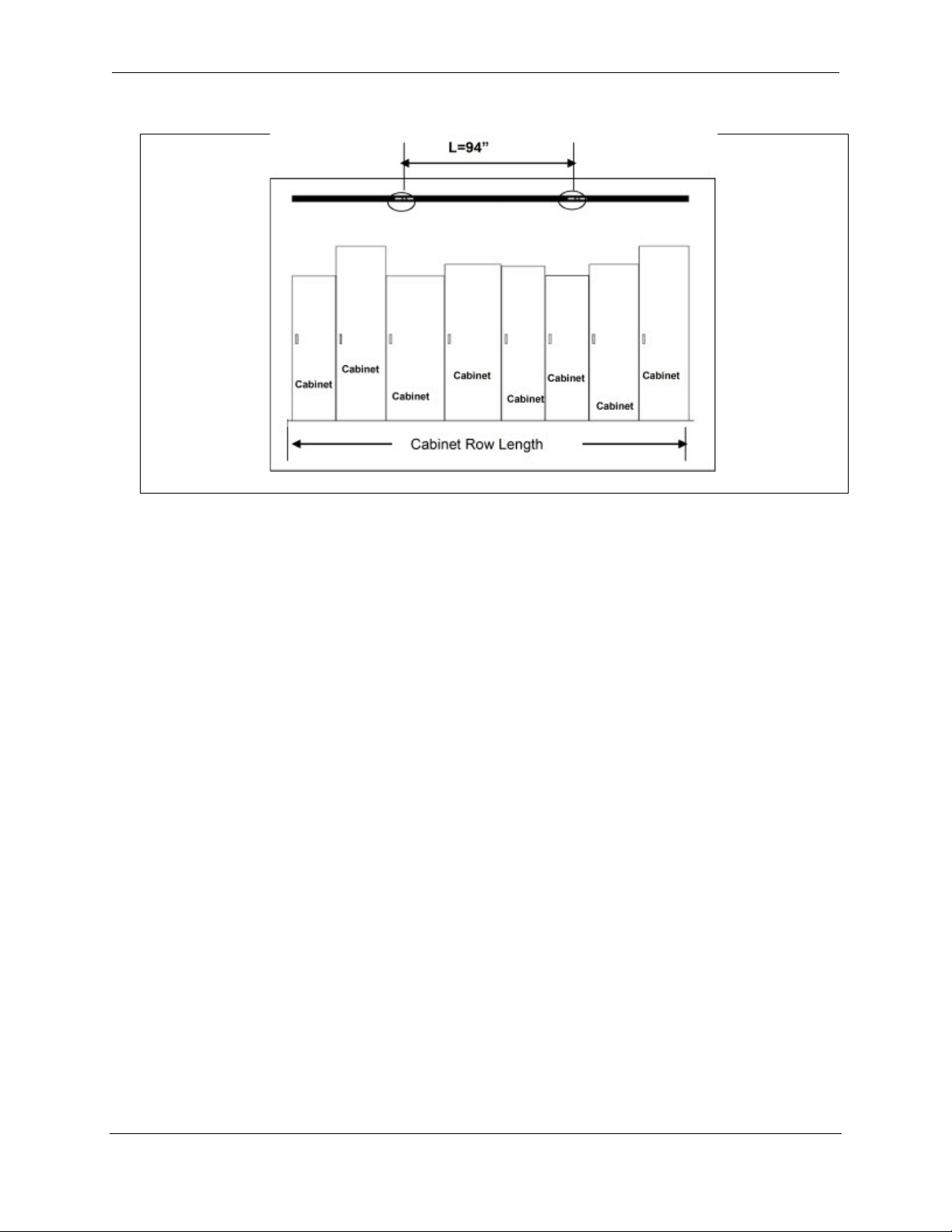

2. Cut the extrusions to match the Cabinet Row Length.

If cabinet row lengths are uneven, cut Extrusions to match the longest row length.

Consider the addition of future cabinets also. Open space at the end of the row can

be filled with a Full Height Blanking Panel (sold separately, see page 26).

BTS Aisle Containment Manual, Rev. 1.0 ___ December 2013

Chatsworth Products 14

3. Use Mounting Brackets to attach extrusions to the ceiling or to the tops of cabinets.

• Position the extrusions

so Gusset Joiners

face the outside of the

containment/duct.

• Mounting brackets

attach to the outside of

the containment/duct.

• Support extrusions on

both sides of Joiner

Gussets and close to

the ends of the duct.

• Space brackets

approximately every

48” (1200 mm) of

span.

• Use 3/8” threaded rod

to support the duct

from the ceiling as

shown.

• When cabinets are the

same height, you can

support extrusion(s)

directly from the tops

of cabinets.

• Flip the Mounting

Bracket and use a 3/8”

hex bolt to attach the

extrusion directly to

the tops of cabinets.

• Hardware for ceiling or

cabinet attachment is

not included.

BTS Aisle Containment Manual, Rev. 1.0 ___ December 2013

Chatsworth Products 15

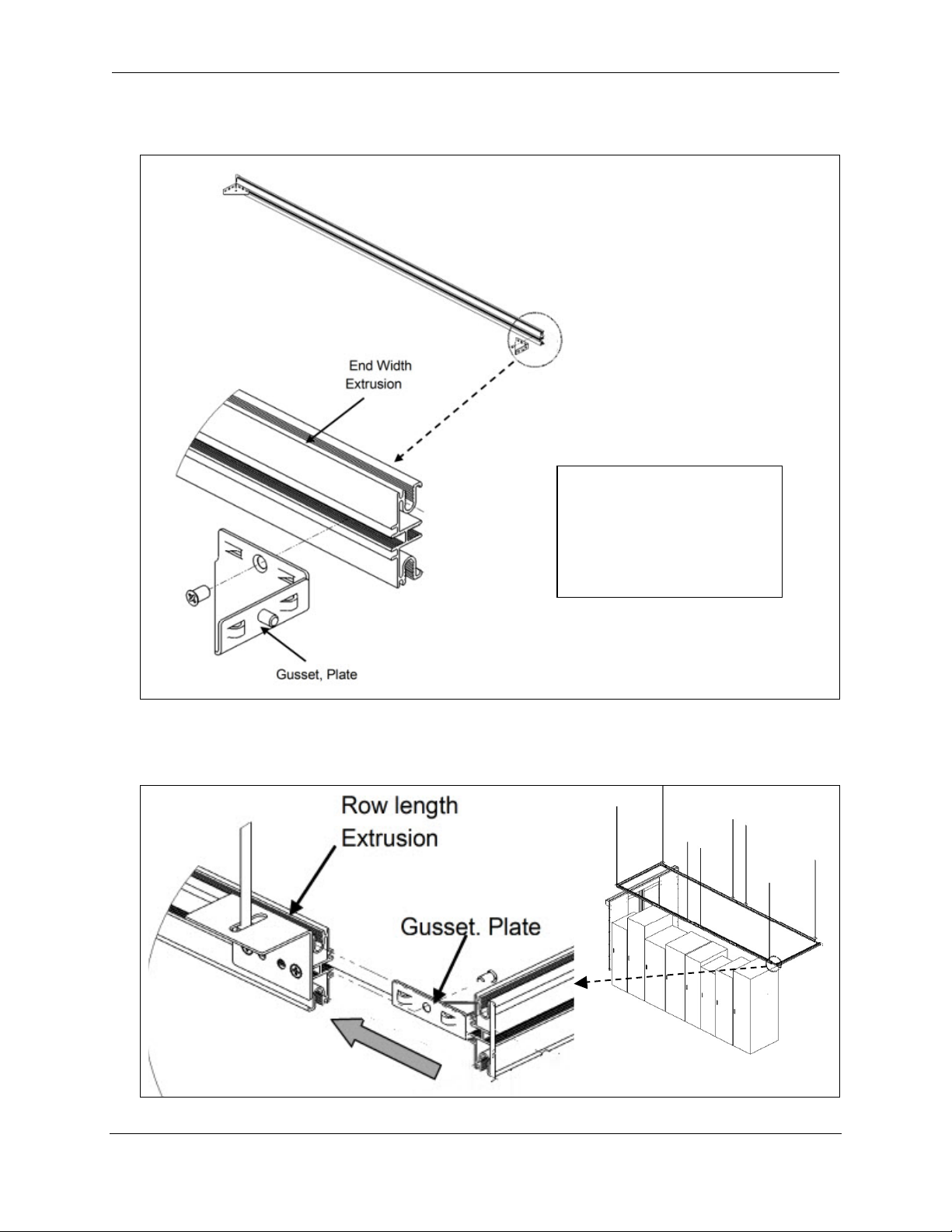

4. Cut extrusions to cap the ends of the duct and attach with Plate Gussets as shown

below. Note the orientation of the Extrusion; the Plate Gusset goes inside the duct.

5. Attach the extrusions to the ends of the duct with the Plate Gussets. Note the

orientation of the Extrusion; the Plate Gusset goes inside the duct.

The flat side of the

Extrusion faces the inside

of the containment. The

curves face the outside of

the containment/duct.

BTS Aisle Containment Manual, Rev. 1.0 ___ December 2013

Chatsworth Products 16

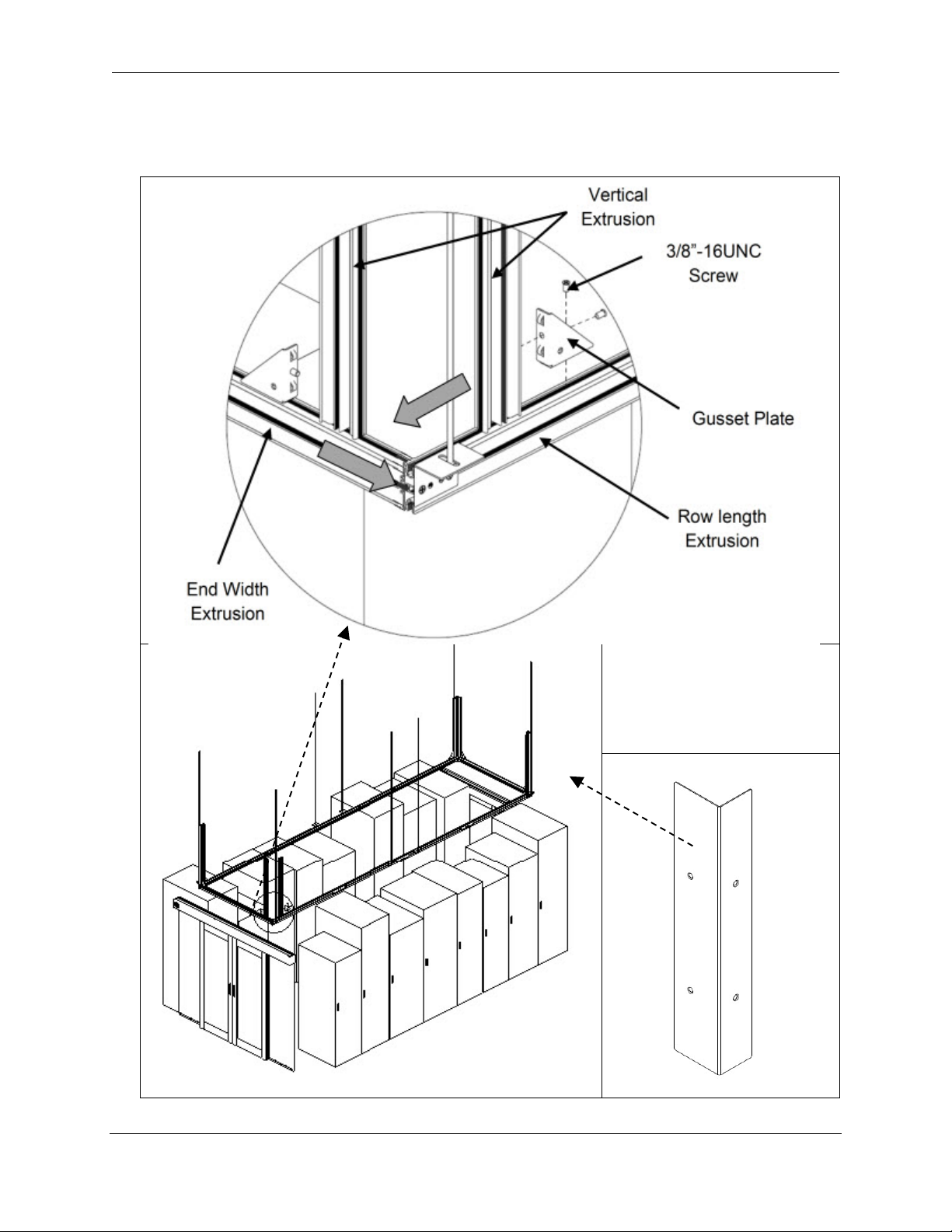

6. Cut two vertical extrusions per corner. Each vertical extrusion should be 3.25” (83

mm) less than the cabinet to ceiling distance to allow space for the top of the duct

frame. Attach the extrusions in the corners with Plate Gussets as shown below.

• After the duct frame is

complete, you will

attach Corner Covers

around the outside of

the corner extrusions.

BTS Aisle Containment Manual, Rev. 1.0 ___ December 2013

Chatsworth Products 17

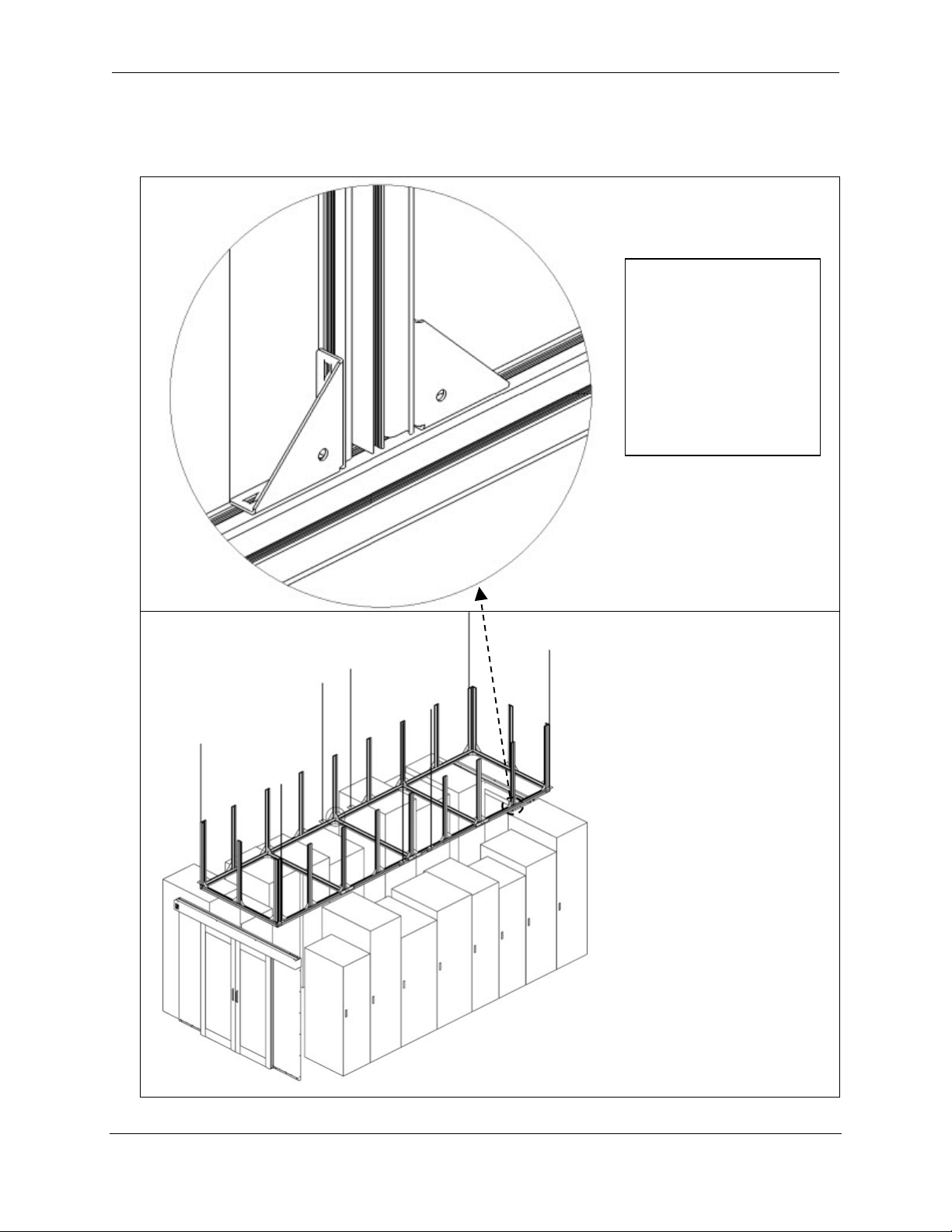

7. Add vertical extrusions every 48” (1200 mm) or at a smaller even interval across the

length of the duct. Use two gussets with two screws each to secure each vertical

extrusion as shown below. The flat side of the extrusion faces the inside of the duct.

This view is from the

outside of the

containment/duct.

The flat side of the

extrusions face the

inside of the

duct/containiment.

Loading...

Loading...