Page 1

CPX2-173

Rugged Military Grade

6U Rack Mount

17.3-Inch Wide-Screen LCD Display

Technical Reference

22009400A

Revision Preliminary X1

April 11, 2014

Page 2

Warranty The product is warranted against material and manufacturing defects for two years from

date of delivery. Buyer agrees that if this product proves defective Chassis Plans’ is only

obligated to repair, replace or refund the purchase price of this product at Chassis Plans’

discretion. The warranty is void if the product has been subjected to alteration, neglect,

misuse or abuse; if any repairs have been attempted by anyone other than Chassis Plans;

or if failure is caused by accident, acts of God, or her causes beyond the control of Chassis

Plans. Chassis Plans reserves the right to make changes or improvements in any product

without incurring any obligation to similarly alter products previously purchased.

In no event shall Chassis Plans be liable for any defect in hardware or software or loss or

inadequacy of data of any kind, or for any direct, indirect, incidental or consequential

damages arising out of or in connection with the performance or use of the product or

information provided. Chassis Plans’ liability shall in no event exceed the purchase price

of the product purchased hereunder. The foregoing limitation of liability shall be equally

applicable to any service provided by Chassis Plans.

Return Policy Products returned for repair must be accompanied by a Return Material Authorization

(RMA) number, obtained from Chassis Plans prior to return. Freight on all returned items

must be prepaid by the customer, and the customer is responsible for any loss or damage

caused by common carrier in transit. Items will be returned from Chassis Plans via

Ground, unless prior arrangements are made by the customer for an alternative shipping

method

To obtain an RMA number, call us at 858-571-4330. We will need the following

information:

Return company address and contact

Model name and model # from the label on the back of the display

Serial number from the label on the back of the display

Description of the failure

An RMA number will be issued. Mark the RMA number clearly on the outside of each box,

include a failure report for each board and return the product(s) to our San Diego, CA

facility:

Chassis Plans.

10123 Carroll Canyon Road

San Diego, CA 92131

Attn: Repair Department

Page 3

Trademarks “The Original Industrial Computer Source”, “Systems Engineered to Perform” and Chassis

Plans are registered trademarks of Chassis Plans, LLC.

IBM, PC/AT, VGA, EGA, OS/2 and PS/2 are trademarks or registered trademarks of

International Business Machines Corp.

Intel is a registered trademark of Intel Corporation.

MS-DOS and Microsoft are registered trademarks of Microsoft Corp.

All other brand and product names may be trademarks or registered trademarks of their

respective companies.

Liability

Disclaimer This manual is as complete and factual as possible at the time of printing; however, the

information in this manual may have been updated since that time. Chassis Plans

reserves the right to change the functions, features or specifications of their products at

any time, without notice.

Copyright © 2014 by Chassis Plans. All rights reserved.

E-mail: Support@chassisplans.com

Web: www.chassis-plans.com

Chassis Plans

10123 Carroll Canyon Road • San Diego, CA 92131

Phone: (858) 571-4330 • Fax: (858) 571-6146 • Email: Saleseng@chassisplans.com

Page 4

This Page Intentionally Blank

Page 5

Chassis Plans CPX2-173 Technical Reference Index

Table of Contents

Chapter1‐Introduction _______________________________________________________________1

Description _______________________________________________________________________________ 1

Table1–DisplaySpecifications____________________________________________________________________ 1

LCDEnhancements _________________________________________________________________________ 2

Figure1–EMIShieldingEffectivenessofITOCoating __________________________________________________2

Figure2–OpticalStackonLCD____________________________________________________________________ 2

Figure3–ComparisonofReflectionswithandwithoutOpticalBonding ___________________________________3

Figure4–ComparisonwithandwithoutOpticalBonding_______________________________________________ 3

GenesisBasedLCDControllers________________________________________________________________ 4

Figure5–ControllerSpecifications_________________________________________________________________4

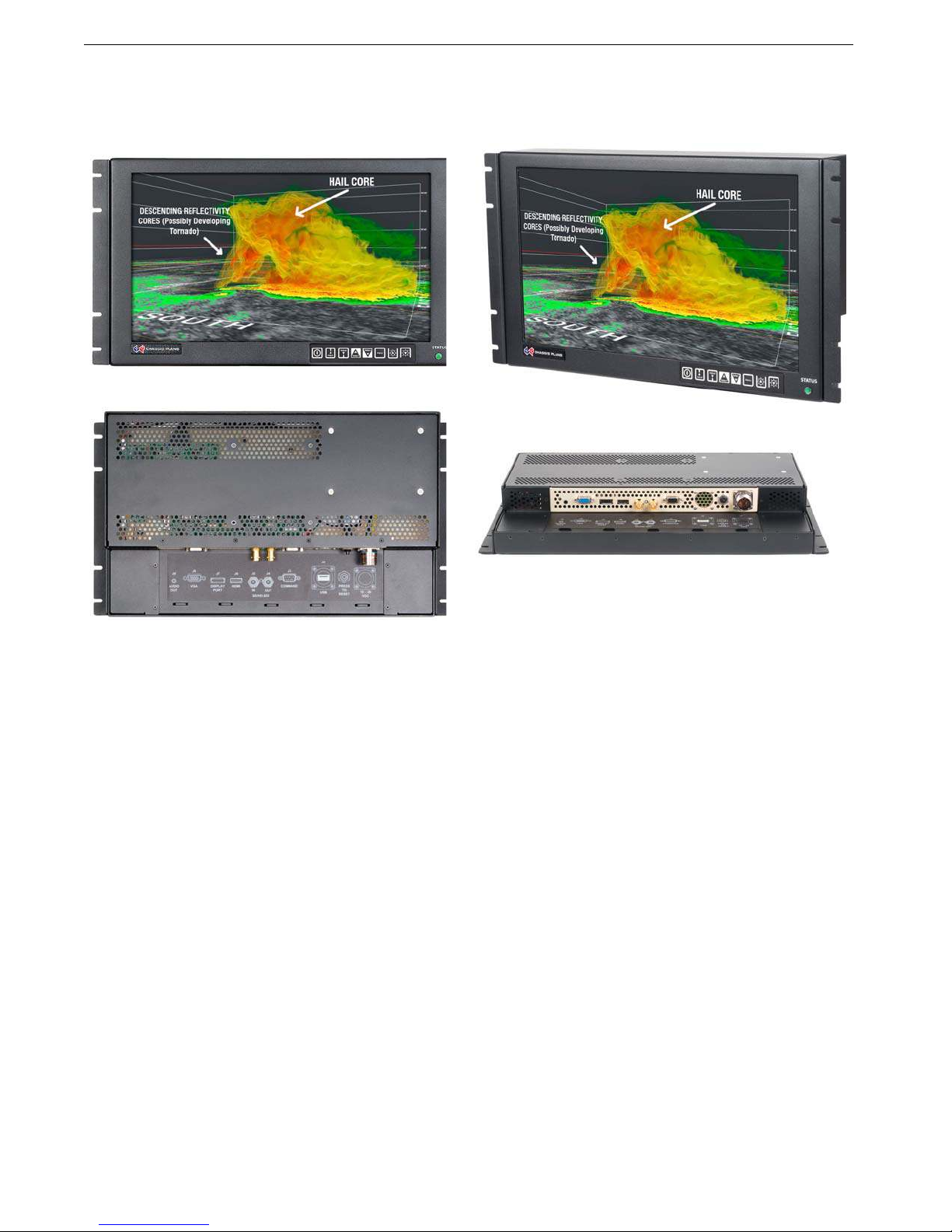

Photos ___________________________________________________________________________________ 5

Specifications______________________________________________________________________________ 6

Enclosure________________________________________________________________________________________ 6

Display__________________________________________________________________________________________6

DisplayEnhancementOptions_______________________________________________________________________ 6

PowerSupplyOptions______________________________________________________________________________ 6

Environmental____________________________________________________________________________________ 6

Table2–Specifications__________________________________________________________________________ 6

Figure6‐CCXOutlineDrawing____________________________________________________________________ 7

Chapter2–PowerSupplyOptions_______________________________________________________9

ACInputPowerSupply______________________________________________________________________ 9

Table3‐ACInputSupplySpecifications_____________________________________________________________ 9

Photo1‐ACPowerSupply _______________________________________________________________________ 9

12VDCInputTransientFilter ________________________________________________________________ 10

Connectors _____________________________________________________________________________________ 10

Photo2‐12VDCInputFrontEndFilter_____________________________________________________________10

MIL‐STD‐704/127528VDCDCInput___________________________________________________________ 11

OperatingSpecifications___________________________________________________________________________ 11

Connectors _____________________________________________________________________________________ 11

EnvironmentalSpecifications_______________________________________________________________________11

Table4‐MIL‐STD‐704PowerSupplySpecifications___________________________________________________11

+/‐48VDCPowerSupply____________________________________________________________________ 12

OperatingSpecifications___________________________________________________________________________ 12

Connectors _____________________________________________________________________________________ 12

ElectricalSpecifications____________________________________________________________________________12

Table5‐48VDCPowerSupplySpecifications ________________________________________________________12

Photo3‐48VDCPowerSupply____________________________________________________________________12

Chapter3–OrderingInformation ______________________________________________________13

PartNumberMatrix ______________________________________________________________________________ 13

ExamplePartNumbers____________________________________________________________________________13

Chapter4‐Installation_______________________________________________________________15

PackageContents________________________________________________________________________________ 15

Table6‐PackageContents ______________________________________________________________________ 15

RackInstallation __________________________________________________________________________ 16

Page 6

Chassis Plans CPX2-173 Technical Reference Index

Figure7‐RackMountingHoleSpacing_____________________________________________________________ 16

ConnectingtheDisplay_____________________________________________________________________ 17

StandardControllerRearPanelConnections ___________________________________________________ 17

Photo4–StandardControllerRearPanelI/O________________________________________________________ 17

Table7‐RearPanelConnections–StandardController _______________________________________________ 17

AdvancedControllerRearPanelConnections___________________________________________________ 18

Photo5‐AdvancedHD/SDIControllerRearPanelI/O_________________________________________________18

Table8‐RearPanelConnections–AdvancedHD/SDIController ________________________________________18

Chapter5‐Operation________________________________________________________________19

LCDFrontPanelControls ___________________________________________________________________ 19

Table9‐FrontPanelControls____________________________________________________________________ 19

StandardControllerOSDMenus _____________________________________________________________ 20

AdvancedHD/SDIControllerOSDMenus______________________________________________________ 25

AppendixA –DisplaySerialControlProgramming_______________________________________27

RS‐232Serialcontrol_______________________________________________________________________ 27

ControllerSerialControlFunctions ___________________________________________________________ 27

Table10‐StandardControllerCommandstoImplementSwitchMountControlButtons _____________________ 27

Table11‐StandardControllerParameterSetting‐Immediate,Relative,ResetandQuery____________________28

Table12‐StandardControllerOtherControl________________________________________________________38

Table13‐HextoASCIIConversionTable ___________________________________________________________40

AppendixB–AutoColorGain__________________________________________________________41

ImageB‐1–AutoColorGainExample______________________________________________________________ 41

AppendixC–DVI‐DversusDVI‐IConnectors______________________________________________42

Overview________________________________________________________________________________ 42

Connectors_______________________________________________________________________________ 42

AppendixD–EthernetNetworkConnection ______________________________________________43

ConnectinganetworkporttoCPX2‐173_______________________________________________________ 43

GettheIPaddressusingDHCP_______________________________________________________________ 44

WebConsole_____________________________________________________________________________ 44

IPLocator________________________________________________________________________________ 44

ImageD‐1–IPLocatorScreenShow_______________________________________________________________ 44

Networkconfiguration_____________________________________________________________________ 44

ImageD‐2–NetworkDropDown_________________________________________________________________ 44

ImageD‐3–NetworkConfigureSettings ___________________________________________________________ 45

ConnecttoasingleCPX2‐173________________________________________________________________ 45

TableD‐1–RemoteControl______________________________________________________________________45

ImageD‐4–IPAddressLocator___________________________________________________________________ 46

ImageD‐5–IPAddressSettingandEnable__________________________________________________________ 46

ConnecttomultipleCPX2‐173_______________________________________________________________ 46

TableD‐2–RemoteControl______________________________________________________________________46

ImageD‐6–DHCPTableScreenshot_______________________________________________________________47

ImageD‐7–NATFowardingScreenshot____________________________________________________________47

Page 7

Chassis Plans CPX2-173 Technical Reference Chapter 1 - Introduction

Chapter 1 - Introduction

Description

The CPX2-173 is a military-grade high-performance 6U rack mount or panel mount LCD display offering 1920 x

1080 wide-screen high-definition resolution. The CPX2-173 is designed to meet Mil-Std 901D and MIL-STD810G and includes a solid milled aluminum front panel, lightweight 5052-H32 aluminum construction and locking

stainless hardware throughout. The CPX2-173 is ideal for mounting in a transit case for adverse environments

that would destroy lesser displays.

Two versions offer standard brightness or hi-bright for sunlight visibility.

Contrast Ratio 600:1 600:1

Viewing Angle (L/R/U/D) 80º 80º

Response Time 40ms 40ms

Brightness 400 cd/m2 1000 cd/m2

Backlight LED LED

Native Resolution 1920 x 1080 1920 x 1080

Aspect Ratio 16:9 16:9

Table 1 – Display Specifications

The displays are high-performance, long life TFT LCD’s offering a maximum native wide-screen resolution of

1920 x 1080. The displays offer optional optically bonded anti-reflective overlay glass. In addition, an optional

laminated 1.1mm soda lime glass with an ITO conductive EMI filter and an additional 1.1mm soda lime glass

overlay with anti-reflective (AR) coating. Both glass components are optically bonded to each other, and to the

front of the display, for superior viewing clarity and overall ruggedness. A 6mm copper bus bar surrounds the

entire glass stack-up and provides consistent grounding. A contrast ratio of approximately 1300:1 is delivered

with this ITO/Anti-Reflective glass stack-up. The front surface is an oleophobic anti-reflective coating resistant to

fingerprints.

The displays offer 16.7 million colors (True Color). The displays provide multiple signal input options including

aRGB, DVI-D, HDMI, Display Port, HD-SDI, NTSC, S-Video and Composite Video, depending on the controller.

The displays offer a choice of high quality advanced scaling controllers with a Genesis chipset. These are

specifically ruggedized controllers offering as standard conformal coating with high shock/vibration and

temperature extreme tolerances as well as long life product availability for assured delivery throughout multi-year

programs.

The Standard Controller offers DVI-D, VGA (aRGB), HDMI, NTSC, S-Video and CVS with an option for

Component (YCbCr) input. In addition, the Standard Controller supports Picture-In-Picture (PIP) and Picture-ByPicture.

The Advanced HD-SDI Controller offers VGA (aRGB), HDMI, Display Port, HD-SDI and 3G HD-SDI.

The display is only 6U (10.47-inches) high offering significant rack space savings. It can be rack mounted, panel

mounted, or mounted using a VESA adapter via the included VESA hole pattern on the rear of the unit. It is only

3.2-inches deep and power and signal cables exit down so as to not increase depth requirements.

As with all Chassis Plans products, a wide variety of custom options can be configured per customer or

application specific requirements. Contact your Sales Engineer to discuss your particular requirements.

CPX2-1731

Standard

CPX2-1732

Hi-Bright

Page 1

Page 8

Chassis Plans CPX2-173 Technical Reference Chapter 1 - Introduction

LCD Enhancements

Chassis Plans starts with Grade A Industrial Quality LCD panels selected for optical performance, high reliability

and long product life cycle. In order to not only ruggedize the LCD, but to also enhance the mechanical, optical

and EMI properties of the finished unit, as an option, Chassis Plans optically bonds one 3mm anti-reflective or

two layers of coated 1.1 mm soda-lime float glass to the front of the LCD panel. The first layer is coated with an

Indium Tin Oxide (ITO) coating with a surface resistivity of <13.5 ohms/sq. See Figure 1 for attenuation values.

50

45

40

35

30

25

20

30MHz 75MHz 100MHz 150MHz 200MHz 300MHz 500MHz 700MHz 1000MHz

15"LCD

17"LCD

19"LCD

Figure 1 – EMI Shielding Effectiveness of ITO Coating

There is a Copper conductive buss bar that wraps around the edge of the glass to facilitate conduction from the

ITO coating to the front surface of the laminated structure to make a complete electrical shield around the face of

the LCD. See Figure 2 for details.

Copper Buss Bar

AR Coating

O ptical Ind ex

Matching

Adhesive

Soda Lime Float G lass

ITO Co ating

LCD Panel

And

Backlight

LCD Frame

Figure 2 – Optical Stack on LCD

The second layer of glass is coated with an Oleophobic Anti-Reflective (AR) coating which matches the index of

refraction of air to eliminate surface reflections. These layers of coated glass are bonded together with an index

matching optical adhesive to eliminate internal reflections caused by the index of refraction mismatch between

the soda lime glass and air. This eliminates over 95% of unwanted glare from the screen. Please see Figure 3

below for more details.

Page 2

Page 9

Chassis Plans CPX2-173 Technical Reference Chapter 1 - Introduction

Without Optical Bonding

Or AR Coating

With Optical Bonding

And AR Coating

4.5%

4.5%

4.5%

4.5%

4.5%

Reflected

Light

Total

22.5%

0.3%

0.1%

0.1%

0.1%

0.1%

Reflected

Light

Total

0.7%

Figure 3 – Comparison of Reflections with and without Optical Bonding

The resulting structure in conjunction with the CPX2-1732 Hi-Bright 1000nit panel has greatly enhanced optical

characteristics in high ambient light conditions. The optical adhesive used is a silicone RTV and offers other

benefits mechanically to the LCD as well. The adhesive remains pliable and therefore acts as a shock

absorbing medium for the front of the LCD. Together with the additional layers of glass provides a very rugged

composite structure. Another benefit is that should breakage actually occur the shards of glass will be retained

together to prevent injury to personnel. The adhesive also prevents any condensation from building up in the air

gap between the layers of glass which would cause fogging of the display. Finally, the added mass bonded to

the front of the LCD display adds a thermal conduction path to help dissipate the heat generated in the

backlights themselves.

By eliminating the majority of reflected light, the apparent contrast improves making the display more readable in

high bright situations. An alternative to improving the contrast is to increase the back light levels to overpower

the reflected light. The downside to this approach is the higher power requirements and higher heat generated

by the backlights.

Photo Courtesy of

GDS Clearview

Figure 4 – Comparison with and without Optical Bonding

Page 3

Page 10

Chassis Plans CPX2-173 Technical Reference Chapter 1 - Introduction

Genesis Based LCD Controllers

The LCD Controller is a key component in any display

system and no expense has been spared in specifying the

Standard Controller and Advanced HD-SDI Controller

Genesis controllers. These are long life revision

controlled military grade components. The Genesis chip

set is the current gold standard for LCD controllers.

The controllers support 3x8-bit 16.7 million colors at up to

1920 x 1200. Refresh rates of 60Hz for WUXGA and

UXGA with higher refresh rates for lower resolutions

available. Computer input signals of VGA, SVGA, XGA,

SXGA, WXGA, UXGA and WUXGA are supported.

Video inputs of NTSC, PAL and SECAM are optionally

available. DVI inputs supports up to 1920 x 1080

WUXGA 60Hz signals.

These ruggedized military grade controllers are rated for

operating at -40 to +80 deg C, use low mass tantalum

capacitors for maximum vibration and shock tolerance

and are conformal coated for extreme ruggedness. The

coating is silicone resin conformal coating.(MOD) DEFSTAN 59/47 Issue 4 &UL QMJU2 compliant

MTBF for the controllers is in excess of 150,000 to

200,000 hours.

Figure 5 – Controller Specifications

Page 4

Page 11

Chassis Plans CPX2-173 Technical Reference Chapter 1 - Introduction

Photos

Connector details dependent on installed controller

Page 5

Page 12

Chassis Plans CPX2-173 Technical Reference Chapter 1 - Introduction

y

Specifications

Enclosure

6U (10.47”) x 3.2” deep

Front Panel milled 5052 aluminum alloy

Body made of 5052-H32 aluminum alloy

All stainless steel hardware

All self-locking pressed in fasteners where

appropriate

Powder coat black, medium texture, for ruggedness

Other colors optionally available

Designed to Mil-Spec Standards to Satisfy Military,

Industrial and Commercial Requirements

Compact Enclosure for Limited Depth Installation

Weight: 9.7lbs (depending on model & features)

Display

17.3" Wide-Screen TFT LCD 1920 x 1080

Display Colors: 16.7 Million

Response Time: 40ms Typical

Viewing Angle: 80 deg

Contrast Ratio: 600:1 typical native

Brightness: 400cd/m2 standard (CPX2-1731),

1000cd/m2 enhanced daylight visibility (CPX2-

1732)

Pixel Pitch: 0.1989mm x 0.1989mm

Pixel Arrangement: R.G.B Stripe

Display Enhancement Options

3mm smudge-resistant anti-reflective coated soda

lime float glass,bonded to the LCD panel with

optical index matched adhesive

Laminate of 1.1mm smudge-resistant anti-reflective

coated soda lime float glass panel and a 1.1 mm

ITO coated glass panel(<12.5Ω/sq) grounded via

a copper buss bar, bonded to the LCD panel with

optical index matched adhesive

Power Supply Options

AC Input

100 to 260VAC, auto selecting

47-66 HZ

12VDC Input Transient Filter

Line transient protection for 12VDC vehicular

applications

Mil-Std-1275A DC/DC Converter

True 1275 compliance for military 28VDC

nominal vehicle inputs

18 to 36VDC input

48VDC DC/DC Converter

36 to 75VDC Input

Isolated Inputs for +/- input levels

See the appropriate power supply section for complete

power suppl

specifications.

Table 2 – Specifications

Environmental

(Designed to meet or exceed)

Altitude

High Temperature

Low Temperature

Humidity

Blowing Sand and Dust

Transport Vibration

Bench Handling Shock

10,000 ft. Operational,

30,000 ft. Storage

MIL-STD-810, Method 500.5

70°C Operational, 70°C Storage

MIL-STD-810, Method 501.5

0°C Operational, -20°C Storage

MIL-STD-810, Method 502.5

5-95%, Non-condensing

MIL-STD-810, Method 507.5

Procedures I and II

MIL-STD-810, Method 510.5

US Highway Truck and Air Transport

MIL-STD-810, Method 514.6

Procedure VI, 20G @ 11ms

MIL-STD-810, Method 516.6

Page 6

Page 13

Chassis Plans CPX2-173 Technical Reference Chapter 1 - Introduction

Figure 6 - CCX Outline Drawing

Page 7

Page 14

Chassis Plans CPX2-173 Technical Reference Chapter 1 - Introduction

This Page Intentionally Blank

Page 8

Page 15

Chassis Plans CPX2-173 Technical Reference Chapter 2 – Power Supply Options

Chapter 2 – Power Supply Options

AC Input Power Supply

The AC Input Power Supply is a 65W Medical Grade “Brick” style power supply. The output is provided with a

circular mil connector for connecting to the LCD Keyboard Drawer. The input accepts a standard IEC 320 plug.

A bracket is provided to securely mount the supply in a rack.

Alternate AC supplies are available as required by the application or environmental requirements.

INPUT

Voltage 100-240VAC

Current 2.0A @ 100VAC

Frequency 50-60Hz

Input Connector 3-Pin IEC 320 Receptacle

OUTPUT

Total Regulation < +/- 5%

Set Point Accuracy < +/- 3% @ 60% Load

Hold-up Time >12mS @ Full Load,

115VAC

Over Voltage Protection Built-in

Over Current Protection Built-in

Short Circuit Protection Pulsing mode, auto

recovery

SIZE

L X W X H 5.07” X 3.06” X 1.35”

Weight 1.2 lbs

Table 3 - AC Input Supply Specifications

ENVIRONMENTAL

Operating Temperature 0 to 50°C

Storage Temperature -40 to +85°C

SAFETY

cTUVus

UL 60601-1

CSA C22.2 No. 601.1-M90

CB per IEC 60601-1

CE marked to LVD

Class I

EMI/EMC

Emissions CISPR11 and FCC Part 15, Class B

EN61000-3-2, -3

Immunity EN61000-4-2, -3, -4, -5, -6, -9, -11

Photo 1 - AC Power Supply

Page 9

Page 16

Chassis Plans CPX2-173 Technical Reference Chapter 2 – Power Supply Options

12VDC Input Transient Filter

The CPX2-173 display consoles require nominal +12VDC at 40W for operation. An EMI line filter is provided to

limit EMI emissions and to provide a small measure of input filtering.

For operation from unregulated 12VDC (+/-10%) such as in a vehicular or marine environment, front end

transient filtering is required to suppress potentially damaging spikes from large inductive loads in the DC circuit

(starters, etc.).

The xxx 12VDC Input Transient Filter provides an input Transient Protection as well as inductive and capacitive

filtering to suppress large input transients. A bridge rectifier provides reverse connection protection. A circuit

breaker provides for failure protection and allows the power to be disconnected.

Connectors

Input Connector MS3102A-10SL-3P (MIL-C-5015)

Mating Input Connector MS3106A-10SL-3S (Straight)

MS3108A-10SL-3S (Right Angle)

Pinouts Pin A – Positive

Pin B – Negative Input

Pin C – N/C

Output Connector MS3102A-10SL-3S (MIL-C-5015)

Mating Output Connector MS3106A-10SL-3S (Straight)

MS3108A-10SL-3S (Right Angle)

Pinouts Pin A – Positive

Pin B – Negative

Pin C – N/C

Photo 2 - 12VDC Input Front End Filter

Page 10

Page 17

Chassis Plans CPX2-173 Technical Reference Chapter 2 – Power Supply Options

MIL-STD-704/1275 28VDC DC Input

The ‘C’ option 28VDC Mil-Std-704/1275 DC Input is an internal power supply providing true 704/1275 input

specifications allowing reliable operation from nominal 28VDC input mains in a military environment. This supply

meets Mil-Std-704A and Mil-Std-1275A (100V for 50mS).

Operating Specifications

Input Voltage 18-36VDC

Output Voltage 12.0VDC

Output Current 5A

Output Power 75W

Electrical Specifications

Efficiency 81%

Isolation 200VDC, Input to

Output and Input to Case

EMI Filtering Mil-Std-461E,

CD101 and CE102 on the input

Operating Temperature -40°C to +85°C

Storage Temperature -55°C to +100°C

Connectors

Input Connector MS3102A-10SL-4P

(MIL-C-5015)

Mating Input Connector MS3106A-10SL-4S

(Straight)

MS3108A-10SL-4S

(Right Angle)

Pinouts Pin A – Positive

Pin B – Negative

Pin C –N/C

Output Connector MS3102A-10SL-3S

(MIL-C-5015)

Mating Output Connector MS3106A-10SL-3S

(Straight)

MS3108A-10SL-3S

(Right Angle)

Pinouts Pin A – Positive

Pin B – Negative

Pin C– N/C

Table 4 - MIL-STD-704 Power Supply Specifications

Environmental Specifications

Pressure-Altitude Per MIL-STD-810F,

Method 500.4, Procedure I

and II

High Temperature Per MIL-STD-810F,

Method 501.4, Procedure I

and II

Low Temperature Per MIL-STD-810F,

Method 502.4, Procedure I

Humidity Per MIL-STD-810F,

Method 507.4, Procedure I

Fungus Per Mil-Std-810F, Method

508.5, Procedure I

Salt Fog Per Mil-Std-810F, Method

509.4, Procedure I

Sand and Dust Per Mil-Std-810F, Method

510.4, Procedure I and II

Explosive Atmosphere Per Mil-Std-810F, Method

511.4, Procedure I

Acceleration Per MIL-STD-810F,

Method 513.5, Procedure I

and II

Vibration Per MIL-STD-810F,

Method 514.5, Procedure

I, Category 1, 4, 7 thru 14

and 16 thru 21

Shock Per MIL-STD-810F,

Method 516.5, Procedure

I, IV

Page 11

Page 18

Chassis Plans CPX2-173 Technical Reference Chapter 2 – Power Supply Options

+/-48VDC Power Supply

The xx 48VDC Input Converter provides universal isolated 48VDC input, either positive or negative input. Thus

it can be used in a data center with centralized power of +48VDC as well as a central office with -48VDC mains.

The system is provided in a rack mountable case with military grade circular connectors.

Operating Specifications

Input Voltage 36-75VDC

Output Voltage 12.0VDC

Output Current 10A

Output Power 120W

Connectors

Input Connector MS3102A-14SL-7P

(MIL-C-5015)

Mating Input Connector MS3106A-14S-7S

(Straight)

MS3108A-14S-7S

(Right Angle)

Pinouts Pin A - Positive

Pin B – Negative

Output Connector MS3102A-10SL-3S

(MIL-C-5015)

Mating Output Connector MS3106A-10SL-3S

(Straight)

MS3108A-10SL-3S

(Right Angle)

Pinouts Pin A – Positive

Pin B – Negative

Pin C– N/C

Table 5- 48VDC Power Supply Specifications

Electrical Specifications

Efficiency 92%

Isolation 1500VDC, Input to

Output and Input to

Case

EMI Filtering Mil-Std-461E,

CD101 and CE102 on

the input

Operating Temperature -40°C to +85°C

Storage Temperature -55°C to +125°C

Photo 3- 48VDC Power Supply

Page 12

Page 19

Chassis Plans CPX2-173 Technical Reference Chapter 3 – Ordering Information

Chapter 3 – Ordering Information

Part Number Matrix

CPX2-173[M][ME][S][P])

(M) Standard or Hi-Bright Monitor

1 – Standard 600 cd/m2

2 – Hi-Bright 1,000 cd/m2

(ME) LCD Surface Enhancements

A – Bonded EMI Filter and AR cover glass

B – Standard w/ no screen enhancements

C - Bonded 3mm AR coated cover glass

E - Bonded USB Resistive touch screen

(S) Video Signal Inputs

D4 – Includes VGA, DVI-D, HDMI, Component, Composite

G1 - VGA, Dispay Port, HDMI, Component, Composite, HD-SDI

(P) Power Supply Option

N – No supply provided. Operates from nominal 12VDC +/-5%

A – AC input, universal 100-260VAC, 50/60Hz

B – 12VDC Front End Transient Filter

C – 28VDC Mil-Std-704 Military Grade

D – 12VDC for connection to Chassis Plans Chassis Power Plug

E – +/-48VDC, Vicor Module Military Grade

F – AC input, universal 100-260VAC, 400Hz

Example Part Numbers

CPX2-1731BD4A – Standard brightness. No LCD enhancements. VGA/DVI/HDMI input. AC Power.

CPX2-1732CG1C – Hi-Bright display brightness. Anti-reflective LCD enhancement. Enhanced HD/SDI

controller. 28VDC input power.

Page 13

Page 20

Chassis Plans CPX2-173 Technical Reference Chapter 3 – Ordering Information

This Page Intentionally Blank

Page 14

Page 21

Chassis Plans CPX2-173 Technical Reference Chapter 4 - Installation

Chapter 4 - Installation

Package Contents

Part Description Quanty

LCD Keyboard Assembly 1

Power Supply 1 (if P/S spec’d in part number)

Power Supply Rack Bracket 1 (if P/S spec’d in part number)

Rack Ruler 1

Rack Slide Hardware Kit (General Devices) 1

Cable Tie, 7-9/16” Long 8

Velcro Tie, Black 6

Cage Nuts 8

Manual, LCD User, CD 1

Manual, LCD Quick Start Guide 1

Checklist 1

DVI Cable, 6-Foot 1

VGA Cable, 6-Foot 1

USB A-A Cable, 6-Foot 1

PS/2 Keyboard/Mouse Cable, 6-Foot 2

Table 6 - Package Contents

Notes:

1. Power Cord Kit – For the AC input supplies, a standard 6-foot North American IEC-320 power cord is

provided. For the DC input supplies, a kit is provided with a mating Mil Circular connector, backshell,

and pins allowing the user to fabricate an appropriate cable for the intended application. For volume

orders, Chassis Plans can provide pre-fabricated power cables per the end use specifications.

Page 15

Page 22

Chassis Plans CPX2-173 Technical Reference Chapter 4 - Installation

Rack Installation

To mount the CPX2-173 in a rack, it is first important you identify the correct holes to mount to. Please see the

following illustration. Note that a ‘U’ starts between the holes that are ½” apart. One very common problem is

trying to install into the wrong holes.

Because there are multiple styles of racks, it is not possible to provide detailed instructions on mounting the

equipment. However, there are general instructions at

for rack installation which should help.

http://www.chassis-plans.com/PDF/Rack_Slide_Use.pdf

Figure 7 - Rack Mounting Hole Spacing

Chassis Plans offer free Rack Rulers to assist in installing equipment into racks. You should have received one

with your order. To request more, fill out the short form at

and we’ll send you as many as you want. These are invaluable for installing systems into racks.

http://www.chassis-plans.com/form_rack_ruler.html

Page 16

Page 23

Chassis Plans CPX2-173 Technical Reference Chapter 4 - Installation

r

t

t

t

t

t

t

t

Connecting the Display

The CPX2-173 provide for two controllers with rear panel details provided below.

Standard Controller Rear Panel Connections

The Standard Controller provides for DVI and VGA inputs. In

addition, the rear of the display provides for Keyboard and

Pointing Device outputs plus a Circular Mil connector for power

connection. If you have purchased a KVM option, then the

KVM control cable connector will be present. The sealed

keyboard with built-in pointing device offers universal output

providing USB and PS/2 outputs for the keyboard and ‘mouse’

devices.

The Standard Controller offers the following features:

Inputs:

Analog RGB: 60Hz at WUXGA, UXGA

75Hz at SXGA, WXGA, XGA, SVGA, VGA

With auto detect of Digital Separate Sync,

Sync-On-Green & Composite Sync. Auto detects VGA-WUXGA, interlaced & non-interlaced

DVI-D/HDMI: 60Hz at WUXGA

75Hz at SXGA, WXGA, XGA, SVGA, VGAImage Scaling: Up / down scaling to fit input to

native panel resolution of 1280x1024.

Video: NTSC /PAL/SECAM (Interlaced), Composite Video, S-video, SD Component (YCbCr),

HD Component (YPbPr)

Image Control: Brightness, Contrast, Saturation, Hue, Frequency, Phase, Color temperature, Image

position, Hue, Gamma.

Other Features: Auto picture setup, Auto RGB calibration, Auto source seek, OSD timeout, OSD position,

Input source select, OSD menu lock, Direct key for brightness level adjustment.

Photo 4 – Standard Controller Rear Panel I/O

Legend Function Connecto

VGA aRGB Inpu

Display Port Display Port Inpu

HDMI HDMI Inpu

SDI Input HD/SDI Inpu

Reclocked SDI Outpu

RS232 Control Port RS232 Remote Control DB9 Female

Touch Screen Touch Screen Output USB USBFTV22G (Optional)

12VDC Power Input Power, 12VDC +/-5% Circular Mil N/S 3102A-10SL-3P

Circuit Breaker Power Interruption Push to reset

Table 7 - Rear Panel Connections – Standard Controller

HD/SDI Reclocked Outpu

Page 17

HD15 Female

Display Por

HDMI

BNC

BNC

Page 24

Chassis Plans CPX2-173 Technical Reference Chapter 4 - Installation

r

t

t

t

t

t

t

t

Advanced Controller Rear Panel Connections

The Advanced Controller provides for HD/SDI, VGA

analog, HDMI, Display PortComposite and S-Video

video inputs. The Advanced Controller also supports

Picture-In-Picture (PIP) allowing a video input

(Composite or S-Video) image to be laid on top of

either a VGA or DVI input. In addition, the rear of the

display provides for Keyboard and Pointing Device

outputs plus a Circular Mil connector for power

connection. If you have purchased a KVM option,

then the KVM control cable connector will be present.

The Advanced HD/SDI Controller offers the following

features:

Inputs:

Analog RGB: 60Hz at WUXGA, UXGA, SXGA, WXGA, XGA, SVGA, VGA With auto detect of Digital

Separate Sync,Sync-On-Green & Composite Sync. Auto detects VGA-WUXGA, interlaced &

non-interlaced

HDMI 1.3: 60Hz at WUXGA, UXGA, SXGA, WXGA, XGA, SVGA, VGA, 1080p, 1080i, 720p, 576p, 480p

Display: 60Hz at WUXGA, UXGA, SXGA, WXGA, XGA, SVGA, VGA, 1080p, 1080i, 720p, 576p, 480p

Port 1.1a

SDI: 576i50 (PAL), 480i60 (NTSC), 720p60/59.94/50 (4:2:2), 1080i60/59.94/50 (4:2:2),

1080p60/50 (4:2:2)

Features: Image Up-Scaling, Image Down-Scaling, Auto picture setup, Auto RGB calibration, Auto

source seek, OSD timeout, OSD position, OSD menu rotation, OSD transparency, select

input source, Volume control, On board temperature reporting

Image Control: Brightness, Contrast, Sharpness, Color, Clock, Phase, Color temperature, Image position,

Gamma

VGA

Display

Port

HDMI

SDI

Reclocked

Output

SDI

Input

RS232

Control

Port

Touch

Screen*

Circuit

Breaker

Power

Photo 5 - Advanced HD/SDI Controller Rear Panel I/O

Legend Function Connecto

VGA aRGB Inpu

Display Port Display Port Inpu

HDMI HDMI Inpu

SDI Input HD/SDI Inpu

Reclocked SDI Outpu

RS232 Control Port RS232 Remote Control DB9 Female

Touch Screen Touch Screen Output USB USBFTV22G (Optional)

12VDC Power Input Power, 12VDC +/-5% Circular Mil N/S 3102A-10SL-3P

Circuit Breaker Power Interruption Push to reset

Table 8 - Rear Panel Connections – Advanced HD/SDI Controller

HD/SDI Reclocked Outpu

Page 18

HD15 Female

Display Por

HDMI

BNC

BNC

Page 25

Chassis Plans CPX2-173 Technical Reference Chapter 5 – Operation & OSDs

Chapter 5 - Operation

LCD Front Panel Controls

The On Screen Display (OSD) is adjusted as follows:

1. Press the Menu Button located on the front of the monitor.

2. Use the buttons described below to maneuver around the Menu.

3. Select the desired OSD Menu from the Menu Screen Shots below to make the desired adjustment(s).

4. Press the Menu button to exit out of the OSD Menu when complete or wait for the OSD window to

automatically close as set by the OSD Time Out setting.

Power: Turns the Unit On and Off

Adjust ▲:

o Hot Key 1 Increase

o When the cursor is not showing in

sub menus, moves selection right

between top tabs.

o Cursor showing in sub menus,

adjusts setting up.

o Cursor on sub-sub menu (►

showing), enters sub-sub menu.

(See Select ▲ below to escape).

o Toggles Off to On

Adjust ▼:

o Hot Key 1 Decrease

o When the cursor is not showing in

sub menus, moves selection left

between top tabs.

o Cursor showing in sub menus,

adjust setting down

o Toggles On to Off

Select ▲:

o Hot Key 2 Increase

o Moves the cursor up.

o When in a sub-sub menu,

repeatedly press to move to the

previous menu level. (See Adjust ▲

above)

Select ▼:

o Hot Key 2 Decrease.

o Moves the cursor Down.

Menu

o Opens or closes the OSD menu

o See Note 1 below for additional

information.

Brightness ▲:

o Increases the screen brightness.

Brightness ▼:

o Decreases the screen brightness.

Green Normal Operation

Red Power On but no input signal

Off No power or display turned off

Hot Keys

Hot Keys are defined in the Utility/Hot Key menu and allow single

button access to the defined function.

Adjust ▲ and ▼ - Hot Key 1 Up and Down

Select ▲ and ▼ - Hot Key 2 Up and Down

Display Auto Adjust

Pressing Auto/Exit will perform a auto display adjustment

when in aRGB mode. This automatically adjusts the Phase

and Clock for the est displayed image.

To save your changes, press the front panel Menu button.

Alternatively, changes are saved if no buttons are pressed and

the OSD times out returning back to the display.

Notes On the Menu Buttons –

1. The Menus are context sensitive in that only adjustments

pertaining to the selected input will be displayed. For

example, if DVI is selected for the input, then items such

as Hue will not be adjustable.

2. Pressing the Menu button returns to the previously

opened menu.

Notes on Hot Keys -

1. Hot Keys allow single button selection of a function.

2. Definition of the Hot Keys is set in the Utility menu.

Thus, for example, if the Adjust keys are set up for Input

Source, pushing the Up button rolls Up through the Input

Sources and pushing the Down button rolls Down

through the Input Sources.

3. The Hot Keys display in the upper left of the screen when

pushed.

Note on Factory Default –

1. Under the Utilities Menu, a selection is available to return

the board setting to the factory defaults.

Table 9 - Front Panel Controls

Page 19

Page 26

Chassis Plans CPX2-173 Technical Reference Chapter 5 – Operation & OSDs

Standard Controller OSD Menus

Page 20

Page 27

Chassis Plans CPX2-173 Technical Reference Chapter 5 – Operation & OSDs

Page 21

Page 28

Chassis Plans CPX2-173 Technical Reference Chapter 5 – Operation & OSDs

Page 22

Page 29

Chassis Plans CPX2-173 Technical Reference Chapter 5 – Operation & OSDs

Page 23

Page 30

Chassis Plans CPX2-173 Technical Reference Chapter 5 – Operation & OSDs

Page 24

Page 31

Chassis Plans CPX2-173 Technical Reference Chapter 5 – Operation & OSDs

Advanced HD/SDI Controller OSD Menus

Page 25

Page 32

Chassis Plans CPX2-173 Technical Reference Chapter 5 – Operation & OSDs

Page 26

Page 33

Chassis Plans CPX2-173 Technical Reference Appendix A – Display Serial Control Programming

Appendix A – Display Serial Control Programming

Both LCD controllers provide for remote serial RS232 control through the rear panel Control Port as shown

below. The Standard Controller also provides for control through an Ethernet port. The following command set

remains the same for Ethernet control as compared to Serial control.

RS-232 Serial control

Baud rate 2400, 8 bits, 1 stop bit and no parity

1

7

6

Mating connector : DB9 Female

Mating face of

RS-232 DB9 Male

54

3

9

8

PIN# Description

2 RS-232 Rx Data

3 RS-232 Tx Data

5 Ground

Controller Serial Control Functions

The OSD functions are controlled through the following RS-232 commands.

The RS-232 program can be custom-tailored to fit the application or it can be used as provided by Chassis

Plans on request. Please contact Chassis Plans for additional information.

Note: Not all Serial Control functions are supported in the Advanced HD/SDI controller. In the following

table, functions not supported for the Advanced HD/SDI Controller are indicated with a ‘*’ in the Function

column.

Table 10 - Standard Controller Commands to Implement Switch Mount Control Buttons

Function Command Description Acknowledge (if

enabled)

OSD Menu

Lock

Menu 0xf7 Menu button pressed Button equivalent

Select-down

button

Select-up

button

Right/+ button 0xfc Right/+button pressed Button equivalent

Left/- button 0xfd Left/- button pressed Button equivalent

0xf6 OSD menu Lock Off / OSD

Button equivalent

menu Lock On

0xfa Select down button

Button equivalent

pressed

0xfb Select up button pressed Button equivalent

Page 27

Page 34

Chassis Plans CPX2-173 Technical Reference Appendix A – Display Serial Control Programming

y

Table 11 - Standard Controller Parameter Setting - Immediate, Relative, Reset and Query

Function Command Description Acknowledge (if enabled)

Volume control -

left+right channel

Volume control -

on/off (mute)

Brightness control 0x81,

Contrast control -

all channels

Saturation control* 0x83,

Hue control* 0x84,

Phase (tuning)

control

Image H position 0x86,

0x80, “a” | “A”,

nn | “+” | “-” |

“r” | “R” |

“?”

0x80, “m” | “M”,

“0” |

“1” |

“r” | “R” |

“?”

nn | “+” | “-” |

“r” | “R” |

“?”

“m”

“n”

“i” , ss, nn

“o”, ss,

0x82, “a” | “A”,

nn | “+” | “-” |

“r” | “R” |

“?”

“m”

“n”

“i ” , ss, nn

“o”, ss,

nn | “+” | “-” |

“r” | “R” |

“?”

“m”

“n”

“i” , ss, nn

“o”, ss,

nn | “+” | “-” |

“r” | “R” |

“?”

“m”

“n”

“i” , ss, nn

“o”, ss,

0x85,

nn | “+” | “-” |

“?”

nnnn | “+” | “-” | “?”

Set audio (L+R) volume =

value/increment/decrement

Reset

Quer

Disable audio output.

Enable audio output.

Reset

Query

Set brightness =

value/increment/decrement

Reset

Query Current Source

Maximum query *1

Minimum query *1

Set, Source, value *1

Query, Source *1

Set all contrast =

value/increment/decrement

Reset

Query

Maximum query *1

Minimum query *1

Set, Source, value *1

Query, Source *1

Set color =

value/increment/decrement

Reset

Query

Maximum query *1

Minimum query *1

Set, Source, value *1

Query, Source *1

Set tint =

value/increment/decrement

Reset

Query

Maximum query *1

Minimum query *1

Set, Source, value *1

Query, Source *1

Set dot clock phase =

value/increment/decrement

Query

Set img_hpos =

value/increment/decrement

Query

volume

Range : “0””0”-“1””E”

Default : “0””F”

“0” - audio off (muted).

“1” - audio on.

Brightness.

Range : “4””E”-“B””2”

Default : “8””0”

ss - reference by Input main

select(0x98)

Contrast

Range : “1””C”-“E””4”

Default : “8””0”

ss - reference by Input main

select(0x98)

PAL/NTSC color (In video mode

only )

Range : “0””1”-“F””F”

Default : “8””0”

ss - reference by Input main

select(0x98)

NTSC tint (In NTSC mode only)

Range : “5””3”-“9””F”

Default : “7””9”

ss - reference by Input main

select(0x98)

Dot clock phase.

(In PC mode only)

Image horizontal position.

(In PC mode only)

# - Function in ARGB mode only

* - Implemented only in standard controller. Not applicable to Advanced HD/SDI Controller.

Page 28

Page 35

Chassis Plans CPX2-173 Technical Reference Appendix A – Display Serial Control Programming

Image V position 0x87,

nnnn | “+” | “-” |

“?”

Sharpness 0x8a,

nn | “+” | “-” |

“r” | “R” |

“?”

Frequency 0x8b,

nnnn | “+” | “-“ |

“?”

Scaling Mode* 0x8c,

“0” | “1” | “2” | “3” |

“9” | “A” |

“B” | “C” | “D” |

“r” | “R” |

“?”

OSD H position 0x90,

nnn | “+” | “-” |

“r” | “R” |

“?”

OSD V position 0x91,

nnn | “+” | “-” |

“r” | “R” |

“?”

OSD

Transparency*

OSD menu

timeout

Select OSD

Language*

Input main select 0x98,

0x92,

n | “+” | “-” |

“r” | “R” |

“?”

0x93,

nn | “+” | “-” |

“r” | “R” |

“?”

0x95,

n |

“r” | “R” |

“?”

nn | “+” | “-” |

“r” | “R” |

“?”

Set img_vpos =

value/increment/decrement

Query

Set sharpness =

value/increment/decrement

Reset

Query

Set frequency =

Value/increment/decrement

Query

Set graphic image scaling mode

=

value

Reset

Query

Set osd_hpos =

value/increment/decrement

Reset

Query

Set osd_vpos =

value/increment/decrement

Reset

Query

Set OSD transparency =

value/increment/decrement

Reset

Query

Select menu timeout =

value/increment/decrement

Reset

Query

Select language =

English, Chinese,…

Reset

Query

Select input main =

PC or VIDEO or next available

Reset

Query

Image vertical position.

(In PC mode only)

Sharpness.

(Video Mode Source only)

Range : “F””4”-“0””C”

Default : “0””0”

Graphic mode H active size (in

pixels)

Image expansion on/off.

“0” – 1:1

“1” – fill screen

“2” – fill to aspect ratio

“9” – 4:3

“A” – 16:9

“B” – 16:10

“C” – 2.35:1

“D” – 2:1

OSD horizontal position.

Range : “0””0”-“F””F”

Default : “8””0”

OSD vertical position.

Range : “0””0”-“F””F”

Default : “8””0”

OSD transparency.

“0” – ON

“1” - OFF

OSD menu timeout value.

“0””0” – Continuous.

value – Round up to nearest

available step.

if value > max available step, set

it to the max available step.

Range : “0””5”-“3””C”

Default : “0””A”

“0” – English.

“2” - French

“3” – Spanish

“6” - German

“8” – Chinese

Main selected.

“0x41,0x31” ARGB

“0x42,0x31” Composite*

“0x42,0x32” Composite2*

“0x43,0x31” S-video*

“0x43,0x32” S-video2*

“0x44,0x31” Component*

“0x44,0x32” Component2*

“0x45,0x31” HDSDI

“0x45,0x32” HDSDI2

“0x46,0x31” DVI

“0x48,0x31” HDMI

“0x48,0x31” Display Port

Page 29

Page 36

Chassis Plans CPX2-173 Technical Reference Appendix A – Display Serial Control Programming

Auto Source Seek*

0x99,

nn ,

“0” |

“1” |

“?” |

”o”

Set Auto source enable = *1

Source

Disable/ Enable

Query

Valid Source query

“nn” =

“0x41,0x31”- ARGB

“0x42,0x31”- Composite

“0x42,0x32”- Composite 2

“0x43,0x31”- S-video “0x43,0x32”S-video 2 “0x44,0x31”Component “0x44,0x32”Component 2 “0x45,0x31”HDSDI “0x45,0x32”- HDSDI2

“0x46,0x31”- DVI “0x48,0x31”

HDMI

Source Layout*

0x9a,

n |

“r” |

“R” |

“?”

Select source layout = Single,

PIP, PBP, PBPT Reset,

Query

Query:

“0”- Single

“1”- Picture in Picture (PIP) “2”Picture by Picture (PBP) “3”Picture by Picture Tall

(PBPT)

Video System

(Composite, Svideo and

Component Only)*

GAMMA value

select

Auto power off*

0x9b,

“0” |

“1” |

“2” |

“3” |

“r” |

“R” |

“S” |

“s”|

“?”

0x9d,

n |

“r” |

“R”

“?”

0x9f,

“0” |

“1” |

“r” |

“R” |

“?”

Set video system =

Auto/NTSC/PAL/SECAM Reset

Video State Query

Query

Select GAMMA value = Value

Reset

Query

Set power down option = On/Off

Reset

Query

Query

“0” – Auto.

“1” – NTSC_M_358 “2” –

PAL_N_443 “3” – SECAM

“4” – NTSC_M_443 “5” PAL_M_358 “7” – PAL_M_443 “9”

– PAL_N_358

GAMMA value:

“0” – 1.0, “1” – 1.6

“2” – 2.2, “3” – User Defined

“4” – 1.7, “5” – 1.8, “6” – 1.9, “7” –

2.0, “8” – 2.1, “9” – 2.3, “A” – 2.4,

“B” – 2.5, “C” – 2.6,

“D” – 0.6, “E” – 0.7, “F” – 0.8, “G”

– 0.9, “H” – 1.1, “I” – 1.2, “J” – 1.3,

“K” – 1.4, “L” – 1.5

“0” – Off. “1” – On.

Hotkey 1*

0xa0,

“1”, n

|

“r” |

“R” |

“?”

Set Hotkey 1= Value

Reset

Query

Page 30

“1” – volume.

“2” – brightness. “3” – contrast.

“4” – colour.

“5” – input source. “7” – zoom

“8” – freeze

“9” – PIP

“B” – No function

“D” – PIP Swap

“E” – Aspect Ratio

“G” – Hue

“H” – Backlight

“I” – Auto Picture Setup

Page 37

Chassis Plans CPX2-173 Technical Reference Appendix A – Display Serial Control Programming

Hotkey 2*

Runtime counter*

PIP brightness

control*

PIP contrast

control*

PIP H position* 0xa4,

PIP V position* 0xa5,

PIP window size

select*

PIP source select*

0xa0, “2”,

n |

“r” | “R” |

“?”

0xa1,

nnnnn |

“r” | “R” |

“?”

0xa2,

nn | “+” | “-” |

“r” | “R” |

“?”

0xa3,

nn | “+” | “-” |

“r” | “R” |

“?”

nnn | “+” | “-” |

“r” | “R” |

“?”

nnn | “+” | “-” |

“r” | “R” |

“?”

0xa6,

nn |

“r” | “R” |

“?”

0xa7,

n |

“r” | “R” |

“?”

Set Hotkey 2 =

value

Reset

Query

runtime counter value =

nnnnn (* 0.5 hour)

Reset

Query

Set PIP window brightness =

value/increment/decrement

Reset

Query

Set PIP window contrast =

value/increment/decrement

Reset

Query

Set PIP_hpos =

value/increment/decrement

Reset

Query

Set PIP_vpos =

value/increment/decrement

Reset

Query

Select PIP window size =

PIP window size value

Reset

Query

Select input main =

Video source value

Reset

Query

“1” – volume.

“2” – brightness.

“3” – contrast.

“4” – colour.

“5” – input source.

“7” – zoom

“8” – freeze

“9” – PIP

“B” – No function

“D” – PIP Swap

“E” – Aspect Ratio

“G” – Hue

“H” – Backlight

“I” – Auto Picture Setup

Runtime = nnnnn.

PIP window brightness.

Range : “4””E”-“B””2”

Default : “8””0”

PIP window contrast.

Range : “1””C”-“E””4”

Default : “8””0”

PIP window horizontal position.

Range : “0””0””0”-“0””6””4”

Default : “0””5””5”

PIP window vertical position.

Range : “0””0””0”-“0””6””4”

Default : “0””1””4”

Main selected.

PIP off if “nn” = “0””0”.

“0””0”~”1””2”

“0””0” ~ “1””2”

“1””9” : Size by Size

“1””A” : Size by Size Tall

Main selected.

0x40 0x30 : PIP OFF

0x41, 0x31 : ARGB

0x42, 0x31 : Composite

0x43, 0x31 : S-video

0x44, 0x31 : Component 1

0x45, 0x31 : HDSDI 1

0x46, 0x31 : DVI

0x42, 0x32 : Composite 2

0x43, 0x32 : S-video 2

0x44, 0x32 : Component 2

0x45, 0x32 : HDSDI 2

“0x48,0x31” HDMI

Zoom level* 0xa8,

nnnn | “+” | “-” |

“r” | “R” | “?”

Set Zoom level =

value/increment/decrement

Reset

Query

Zoom level.

Min : 0x30 0x30 0x30 0x30

(Default)

Max : 0x30 0x30 0x41 0x33

Page 31

Page 38

Chassis Plans CPX2-173 Technical Reference Appendix A – Display Serial Control Programming

Zoom H position* 0xa9,

nnnn | “+” | “-” |

“r” | “R” |

“?”

Zoom V position* 0xaa,

nnnn | “+” | “-” |

“r” | “R” |

“?”

Horizontal Size* 0xad,

nnn | “+” | “-” |

“r” | “R” |

“?”

Vertical Size* 0xb0,

nnn | “+” | “-” |

“r” | “R” |

“?”

Horizontal Pan* 0xb1,

nnn | “+” | “-” |

“r” | “R” |

“?”

Vertical Pan* 0xb2,

nnn | “+” | “-” |

“r” | “R” |

“?”

Colour

temperature select

0xb3,

n |

“r” | “R” |

“?”

Set Zoom_hpos =

value/increment/decrement

Reset

Query

Set Zoom_vpos =

value/increment/decrement

Reset

Query

Set horizontal size for

Aspect Size =

value/increment/decrement

Reset

Query

Set Vertical Size for Aspect

Size =

value/increment/decrement

Reset

Query

Set horizontal pan position

for Aspect Size =

value/increment/decrement

Reset

Query

Set Vertical pan position for

Aspect Size =

value/increment/decrement

Reset

Query

Select colour temperature =

value

Reset

Query

Zoom window horizontal

position.

Default : 0x30 0x30 0x30 0x30

The min and max values will

change depends on input

resolution.

Zoom window vertical position.

Default : 0x30 0x30 0x30 0x30

The min and max values will

change depends on input

resolution.

Scalar horizontal stretch

PAL(576i) / NTSC (480i) :

Min : 0x30 0x30 0x30 (Default)

Max : 0x30 0x46 0x30

Scalar vertical stretch.

PAL(576i) / NTSC (480i) :

Min : 0x30 0x30 0x30 (Default)

Max : 0x30 0x46 0x30

Scalar horizontal pan position

PAL(576i) / NTSC (480i) :

Assume max H-Size & max Vsize :

Min : 0x46 0x38 0x38

Max : 0x30 0x37 0x38

Default : 0x30 0x30 0x30

The min and max values will

change depends on different

value of H-Size, V-Size and input

resolution.

Scalar vertical pan position

PAL(576i) / NTSC (480i) :

Assume max H-Size & max Vsize :

Min : 0x46 0x38 0x38

Max : 0x30 0x37 0x38

Default : 0x30 0x30 0x30

The min and max values will

change depends on different

value of H-Size, V-Size and input

resolution.

Main selected.

“0” – 9500K.

“1” – 8000K.

“2” – 6500K.

“3” – 5000K

“4” - User

Page 32

Page 39

Chassis Plans CPX2-173 Technical Reference Appendix A – Display Serial Control Programming

Red level for

selected colour

temperature

0xb4,

nn | “+” | “-” |

“r” | “R” |

“?”

“m”

“n”

“i” , ss, c, nn

“o”, ss, c

Set the level of the red channel

for the selected colour temp. =

value/increment/decrement

Reset

Query

Maximum query *1

Minimum query *1

Set, Source, Temperature

Group, value *1

Query, Source *1

Red level for selected colour

temperature.

Range : “9””C”-“F””F” Default :

“E””C”

c – reference by Color

Temperature

ss - reference by Input main

select(0x98)

Green level for

selected colour

temperature

Blue level for

selected colour

temperature

Graphic horizontal

resolution enquiry*

Graphic vertical

resolution*

Graphic horizontal

sync frequency

enquiry*

Graphic vertical

sync frequency

enquiry

OSD status

enquiry*

Display Video

Source Select*

0xb5,

nn | “+” | “-” |

“r” | “R” |

“?”

“m”

“n”

“i” , ss, c, nn

“o”, ss, c

0xb6,

nn | “+” | “-” |

“r” | “R” |

“?”

“m”

“n”

“i” , ss, c, nn

“o”, ss, c

0xb7 Horizontal resolution (in pixels)

0xb8

0xb9

0xba

0xbb Status of OSD

0xbc,

“?” |

“0” |

“1”

Set the level of the green

channel for the selected colour

temp. =

value/increment/decrement

Reset

Query

Maximum query *1

Minimum query *1

Set, Source, Temperature

Group, value *1

Query, Source *1

Set the level of the blue channel

for the selected colour temp. =

value/increment/decrement

Reset

Query

Maximum query *1

Minimum query *1

Set, Source, Temperature

Group, value *1

Query, Source *1

in 3 digit hex number

Vertical resolution (in lines) in 3

digit hex number

Horizontal sync frequency (in

units of 100Hz) in 3 digit hex

number

Vertical sync frequency (in units

of Hz) in 3 digit hex number and

1 char

Display Video source select

Query

Name of video source not

displayed.

After switching to a new video

source, the name of the video

source is displayed for 5

seconds.

Green level for selected colour

temperature

Range : “9””C”-“F””F”

Default : “E””C”

c – reference by Color

Temperature

ss - reference by Input main

select(0x98).

Blue level for selected colour

temperature.

Range : “9””C”-“F””F”

Default : “E””C”

c – reference by Color

Temperature

ss - reference by Input main

select(0x98).

“nnn” = horizontal resolution

“nnn” = vertical resolution

“nnn” = horizontal frequency

“nnnn” = vertical frequency

nnn = 3 digit hex

c= “i” or “p”

interlace or Progressive

0xba added the interlace(i)

or Progressive(p) feedback.

“0” – OSD turned off

“1” – OSD turned on

“2” – Text Overlay on

“3” – Display Mark on

“4” – Screen Marker on

“0” – Disabled.

“1” – Enabled.

Page 33

Page 40

Chassis Plans CPX2-173 Technical Reference Appendix A – Display Serial Control Programming

OSD turn off* 0xbd Turn off the OSD. “0” – fail.

“1” – successful.

Set gamma data

for user defined

gamma curve*

Query External

Memory*

Query Revision

Number*

Backlight control 0xe0,

Backlight On/Off 0xe1,

Color

Monochrome

mode selection

(Output Channel

Select)*

PIP Swap* 0xe3 Swap Main and PIP source "0" - Fail.

Backlight D/A /

PWM*

0xbf, mm, c, “?”

0xbf, “R” | “r”

0xbf, mm, c, nn

0xcb, “2” Check External Menory 24c256 “0” – Not Installed

0xcb, “3” Read Revision Number “nn” = Revision number

nn | “+” | “-” |

“R” | “r” |

“?”

“0” | “1” |

“R” | “r”

”?”

“S” | “s”

0xe2

“0” | “1” | “2” | “3” |

| “4” | “5” | “6” |

“R” | “r”|

”?”

0xe5

“0” | “1” |

“R” | “r”

”?”

Query gamma data for color c

index mm ( c = 0 for color Red,

c=1 for color Green,

c=2 for color Blue)

Set user gamma curve to linear

Set gamma data for color c

index mm. (If c= 3, then gamma

data for red, green & blue will be

set at the same time.)

Set Backlight =

value/increment/decrement

Reset

Query

Backlight Off / Backlight On

/Status

Off/

Blue Only/

Red Only/

Green Only/

Blue Mono/

Red Mono/

Green Mono/

Set : PWM or D/A

Reset

Query

“nn” = gamma data

“1”

“nn” = gamma data

“1” – Installed

“?” – Not Support

Backlight.

Range:

D/A : “0””0” ~ “1””6”

100Hz : “0””0” ~ “8””A”

120Hz : “0””0” ~ “7””3”

140Hz : “0””0” ~ “6””3”

160Hz : “0””0” ~ “5””6”

180Hz : “0””0” ~ “4””D”

200Hz : “0””0” ~ “4””5”

220Hz : “0””0” ~ “3””E”

240Hz : “0””0” ~ “3””9”

260Hz : “0””0” ~ “3””5”

280Hz : “0””0” ~ “3””1”

300Hz : “0””0” ~ “2””E”

320Hz : “0””0” ~ “2””B”

340Hz : “0””0” ~ “2””8”

360Hz : “0””0” ~ “2””6”

380Hz : “0””0” ~ “2””4”

400Hz : “0””0” ~ “2””2”

420Hz : “0””0” ~ “2””0”

440Hz : “0””0” ~ “1””F”

“0” – Backlight Off

“1” – Backlight On.

“?” – Backlight On/Off Query

“S”|”s” – Backlight Status Query

“0” – Off

“1” – Blue Only

“2” – Red Only

“3” – Green Only

“4” – Blue Mono

“5” – Red Mono

“6” – Green Mono

"1" - Successful.

“0” – PWM

“1” – D/A

Page 34

Page 41

Chassis Plans CPX2-173 Technical Reference Appendix A – Display Serial Control Programming

Backlight PWM

Frequency*

Backlight Invert* 0xe7

Red Offset for

selected colour

temperature*

0xe6,

nnn | “+” | “-” |

“R” | “r” |

“?”

“0” | “1” |

“R” | “r”

”?”

0xe8,

nn | “+” | “-” |

“r” | “R” |

“?”

“m”

“n”

“i” , ss, c, nn

“o”, ss, c

Green Offset for

selected colour

temperature*

0xe9,

nn | “+” | “-” |

“r” | “R” |

“?”

“m”

“n”

“i” , ss, c, nn

“o”, ss, c

Blue Offset for

selected colour

temperature*

0xea,

nn | “+” | “-” |

“r” | “R” |

“?”

“m”

“n”

“i” , ss, c, nn

“o”, ss, c

PIP Window Blend

Level*

0xed,

nn | “+” | “-” |

“R” | “r” |

“?”

Set Backlight PWM Frequency =

value/increment/decrement

Reset

Query

Set On or Off

Reset

Query

Set the Offset of the red channel

for the selected colour temp. =

value/increment/decrement

Reset

Query

Maximum query *1

Minimum query *1

Set, Source, Temperature

Group, value *1

Query, Source *1

Set the Offset of the green

channel for the selected colour

temp. =

value/increment/decrement

Reset

Query

Maximum query *1

Minimum query *1

Set, Source, Temperature

Group, value *1

Query, Source *1

Set the Offset of the blue

channel for the selected colour

temp. =

value/increment/decrement

Reset

Query

Maximum query *1

Minimum query *1

Set, Source, Temperature

Group, value *1

Query, Source *1

Select PIP Transparency Level

PIP Transparency value

Reset

Query

+/- 20Hz

Value

100Hz : “0”,”6”,”4”

120Hz : “0”,”7”,”8”

140Hz : “0”,”8”,”C”

160Hz : “0”,”A”,”0”

180Hz : “0”,”B”,”4”’

200Hz : “0”,”C”,”8”

220Hz : “0”,”D”,”C”

240Hz : “0”,”F”,”0”

260Hz : “1”,”0”,”4”

280Hz : “1”,”1”,”8”

300Hz : “1”,”2”,”C”

“0” – Off

“1” – On

Red Offset for selected colour

temperature.

c – reference by Color

Temperature

ss - reference by Input main

select(0x98)

Green Offset for selected colour

temperature.

c – reference by Color

Temperature

ss - reference by Input main

select(0x98)

Blue Offset for selected colour

temperature.

c – reference by Color

Temperature

ss - reference by Input main

select(0x98)

PIP Transparency

“0”F” = 6.25% “0”E” = 12.5%

“0”D” = 18.75% “0”C” = 25%

“0”B” = 31.25% “0”A” = 37.5%

“0”9” = 43.75% “0”8” = 50%

“0”7” = 56.25% “0”6” = 62.5%

“0”5” = 68.75% “0”4” = 75%

“0”3” = 81.25% “0”2” = 87.5%

“0”1” = 93.75% “0”0” = 100%.

Page 35

Page 42

Chassis Plans CPX2-173 Technical Reference Appendix A – Display Serial Control Programming

PIP Window Auto

Off*

ScreenMarker*

CenterMarker*

AspectMarker*

“0xee”, “0x41”

“0” |”1”

“?”

“0xee”, “0x42”

“0” |”1”

“0xee”, “0x43”

“0” |”1”

“0xee”, “0x44”

“0” |”1”

Auto Off / Auto On

Query

Screen Marker Off / Screen

Marker On

Center Marker Off / Center

Marker On

Preliminary

4:3 /16:9

“0”- Off

“1”- On

“0”- Off

“1”- On

“0”- Off

“1”- On

“0”- 4:3

“1”- 16:9

Marker

Background

Transparency*

Safe Area Marker*

IR Lock*

Light Detector*

Safe Area Marker

Enable*

Aspect Marker

Enable*

Display real time

clock**

“0xee”, “0x45”

“0” |”1” |”2” |”3”

“0xee”, “0x47”

“0x53”~”0x63”

“0xee”, “0x48”

n | “0” | “1” |

“r” | “R” |

“?”

“0xee”, “0x4A”

“0” | “1” |

“R” | “r”

”?”

“S” | “s”

“0xee”, “0x4B”

“0” |”1”

“0xee”, “0x4C”

“0” |”1”

“0xee”, “0x4D”

“0” |”1”

Preliminary

0% /25%/50%/95%

Preliminary

80%~99%

IR Lock Disable / IR Lock

Enable

Reset

Query

Light Detector Off / Light

Detector On

Light Detector On/Off Query

Light Detector Value Query

Safe Area Marker Off / Safe

Area Marker On

Aspect Marker Off / Aspect

Marker On

Real Time Clock Display Off /

Real Time Clock Display

“0”- 0%

“1”- 25%

“2”- 50%

“3”- 95%

“36”, “33”- 99%

“36”, “32”- 98%

“36”, “31”- 97%

“36”, “30”- 96%

“35”, “46”- 95%

“35”, “45”- 94%

“35”, “44”- 93%

“35”, “43”- 92%

“35”, “42”- 91%

“35”, “41”- 90%

“35”, “39”- 89%

“35”, “38”- 88%

“35”, “37”- 87%

“35”, “36”- 86%

“35”, “35”- 85%

“35”, “34”- 84%

“35”, “33”- 83%

“35”, “32”- 82%

“35”, “31”- 81%

“35”, “30”- 80%

“0” – IR Lock Disable

“1” – IR Lock Enable

“0” –Light Detector Off

“1” –Light Detector On.

“?” – Light Detector On/Off

Query “S”|”s” –Light Detector

Value Query 0x00~0xFF

“0”- Off

“1”- On

“0”- Off

“1”- On

“0”- Off

“1”- On

Static IP or DHCP

mode switching***

Custom Sizing*

“0xee”, “0x70”

“A””0” |”A””1”

0xef,

“0” | “1” | “2”

”?”

Select Static IP or DHCP mode Static IP: 0xee 0x70 0x41 0x30

DHCP : 0xee 0x70 0x41 0x31

Custom sizing selection :

Overscan / Normal / Custom

Query

Page 36

“0” – Overscan

“1” – Custom / Underscan

“2” – Normal

Page 43

Chassis Plans CPX2-173 Technical Reference Appendix A – Display Serial Control Programming

Function Command Description Acknowledge (if enabled)

Send Display

Mark*

e.g Send

Display Mark

RS232 Code:

“0xF1 0x53

Clear Display

Mark*

e.g Clear Display Mark RS232*

Code: “0xF1 0x43” Return

Code: “0xF1 0x43 0x31”

Display Mark

Horizontal

Position*

e.g Set Display Mark Horizontal Position*

RS232 Code: “0xF1 0x48 0x30 0x31”

Return Code: “0xF1 0x48 0x30 0x31 0x30 0x31”

Display Mark

Vertical

Position*

0xF1,

”S” |

”0x21” | ”0x40”

”0x60” | ”0x7E”

Return “1”

0xF1,

”C”

Return “1”

0xF1,

|”H” |”ss”|

Return “nn”

0xF1,

|”V” |”ss”|

Return “nn”

“S” = “0x53 or 0x73”

ASCII “0x21,0x40,0x60,0x7E”

Return “ 0x31”

“C” = “0x43 or 0x63”

Return “ 0x31”

“H” = “0x48 or 0x68”

-----------------------------------------“nn” = “0x30,0x30~0x46,0x46”

“V” = “0x56 or 0x76”

-----------------------------------------“nn” = “0x30,0x30~0x46,0x46”

“S” – Send Command

“Text” – Character

“1” - successful.

“C” – Clear command

“1” - successful.

“H” – Horizontal Position command

“ss” – Set Horizontal Position number

“nn” – Return Position number

“V” – Vertical Position command

“ss” – Set Vertical Position number

“nn” – Return Position number

e.g Set Display Mark Vertical Position*

RS232 Code: “0xF1 0x56 0x30 0x31”

Return Code: “0xF1 0x56 0x30 0x31 0x30 0x31”

Display Mark

Background

Transparency*

Set Display Mark background Transparency value is 8*

RS232 Code: “0xF1 0x42 0x38”

Return Code: “0xF1 0x42 0x38 0x38”

OSD menu

lock

0xF1,

|”B”|”N”|

Return “n”

0xf6,

n | “0” |

“1” | “r” |

“B” = “0x42 or 0x62”

Set Transparency command

-----------------------------------------“N” = “0x30~0x46”

Transparency Value

(Rang 00~0F)

OSD menu lock Off/ On

Reset

Query

“B” - Transparency command

“N” – Transparency Value

“n”- Return Value

0x00 =opaque

“0” – OSD menu lock Off

“1” – OSD menu lock On

Page 37

Page 44

Chassis Plans CPX2-173 Technical Reference Appendix A – Display Serial Control Programming

Table 12 - Standard Controller Other Control

Function Command Description Acknow ledge (if enabled)

Select RS-232

acknowledge

Auto-setup 0xc3

Command

availability

Auto-calibration 0xc5

Freeze frame* 0xc6, “0” | “1” Unfreeze / freeze frame

Soft Power On/Off* 0xc8,

Query video input

status*

0xc1, “0” | “1” | “2” |

“3”

0xc4, n

“0” | “1” |

“?”

0xc9

Disable/enable command

acknowledge.

Start auto-setup of current

vmode.

Check whether a command is

available.

Start auto-calibration of gain

of the RGB amplifier.

Soft power

off/on

query

Query the status of the primary

& pip status

“0” – acknowledge disabled.

“1” – acknowledge enabled.

“2” – serial command disabled.

“3” –serial command enabled.

“0” – fail.

“1” – successful.

“0” – not available.

“1” – available.

“0” – fail.

“1” – successful.

“0” – unfreeze.

“1” – freeze.

“0” – Turn off the LCD power and

backlight. Turn off memory

controller, Power down DVI

Power down ADC, Power

down Fclk PLL

“1” – Turn on the unit

“nn,nn” = input status

“nn,xx” digit = primary status:

“0”,”0” : invalid

“A”,”1” ARGB

“B”,”1” Composite

“B”,”2” Composite 2

“C”,”1” S-video

“C”,”2” S-video 2

“D”,”1” Component

“D”,”2” Component 2

“E”,”1” HDSDI

“E”,”2” HDSDI 2

“F”,”1” DVI

“H” “1” HDMI

“xx,nn”= PIP input status:

“0”,”0”: invalid

“A”,”1” ARGB “B”,”1”

Composite “B”,”2”

Composite 2 “C”,”1”

S-video “C”,”2” Svideo 2 “D”,”1”

Component “D”,”2”

Component 2 “E”,”1”

HDSDI

“E”,”2” HDSDI 2

“F”,”1” DVI

“H” “1” HDMI

Page 38

Page 45

Chassis Plans CPX2-173 Technical Reference Appendix A – Display Serial Control Programming

Video de-interlace

method*

0xca,

“0” | “1”

“r” | “R”

“?”

De-interlace mode

Reset

Query

“3” ”1”- enable AFM

“3” ”0”- disable AFM

“4” ”1”- enable TNR

“4” ”0”- disable TNR

“5” ”1”- enable MADI

“5” ”0”- disable MADI

“7” ”1”- enable DCDi

“7” ”0”- disable DCDi

Query BIOS

version

0xcb, “0” Read BIOS version

BIOS version “VV.YY.ZZ”

VV = V0 or E0,

V0 = Release version

E0 = Engineering Sample

YY= Version Number

ZZ= Customer Number

Query PCBA

number

Reset to Factory

Defaults

Reset to Factory

Defaults with

0xcb, “1” Read PCBA number “nnnnn” = PCBA number

SVX-1920= “41721”

0xce

Reset all parameters to

“1” – successful.

default value

0xcf

Reset all parameters for all

“1” - successful.

video modes to default value

(color temp) *

Saved Calibrated

default*

Load Calibrated

default*

0xd7

0xd8

Saving all parameters to user

default value

Loading all parameters to

user default value

“1” - successful.

“1” - successful.

“0” - not successful

“E” – Checksum Error

Wide Screen

Mode Selection*

ScreenMarker*

0xd9,

“0” | “1”| “2”

“r” | “R”

“?”

“0xee”, “0x42”

“0” |”1”

Wide Screen Mode

Reset

Query

Screen Marker Off / Screen

“0” – Normal Mode

“1” – 1280x768

“2” – 1366x768

“0”- Off

“1”- On

Marker On

CenterMarker* “0xee”, “0x43”

“0” |”1”

AspectMarker*

“0xee”, “0x44”

“0” |”1”

Marker

Background

“0xee”, “0x45”

“0” |”1” |”2” |”3”

Transparency

Safe Area Marker*

“0xee”, “0x46”

“0x53”~”0x63”

Center Marker Off / Center

Marker On

Preliminary

4:3 /16:9

Preliminary

0% /25%/50%/95%