Page 1

Page 1

Durulite Evolution XLD360 Installation Instructions

}

DWG # 4002 • DATE: 06-25-08

Preparation

Measure width and height of framed opening and

compare with dimensions given at the time of ordering.

See Figure 1, Page 2 for instructions on testing for a

Square, Level and Plumb Opening.

NOTE: The Durulite® XLD360 doors are constructed

using the dimensions given by the customer when

ordering and are not adapted to fit into a different

sized opening!

Framed openings must meet the dimensions given on

the order received by Chase Doors within the following

tolerances:

SINGLE PANELS

Height: +1/4” -1/4”

Width: +1/4” -1/4”

IMPORTANT: Contact the factory if the dimensions of

your opening do not match the dimensions used for

ordering your panels within the specified tolerances.

DO NOT Continue with installation!

IMPORTANT: ALL CHASE PRODUCTS MUST BE INSTALLED PLUMB AND LEVEL IN A SQUARE OPENING FOR PROPER OPERATION!

Cincinnati OH, and Redmond OR • Phone Toll Free: 1.800.543.4455 • Fax: 1.800.285.0126 • www.chasedoors.com

Cincinnati OH, and Redmond OR • Phone Toll Free: 1.800.543.4455 • Fax: 1.800.285.0126 • www.chasedoors.com

DOUBLE PANELS

Height: +1/4” -1/4”

Width: +1/2” -1/2”

Tools Required

The following tools should be readily available for use

when installing the Durulite® XLD360 Doors:

1) Level

2) Tape Measure

3) Framing Square

4) Phillips Screwdriver

5) Hammer

6) Drill

7) Drill Driver or Rachet

8) 6” Rachet Extension

9) 5/16”, 3/8” & 7/16” Sockets

10) 3/8” Masonry Drill Bit

11) Drill Bits for your application

A] 1/8” Bit for Steel Jambs up to 3/8” Thick

B] 13/64” Bit for Steel Jambs over 3/8” Thick

C] 3/16” Bit for Wood Jambs

D] 5/16” Bit for Drilling and Pinning Lower Hinge

12) 3/16” Allen Wrench (Provided)

13) Center Punch

14) Safety Glasses

It is always recommended that you use protective eye-wear

when installing Chase Doors.

Page 2

Page 2

Durulite Evolution XLD360 Installation Instructions - Continued

}

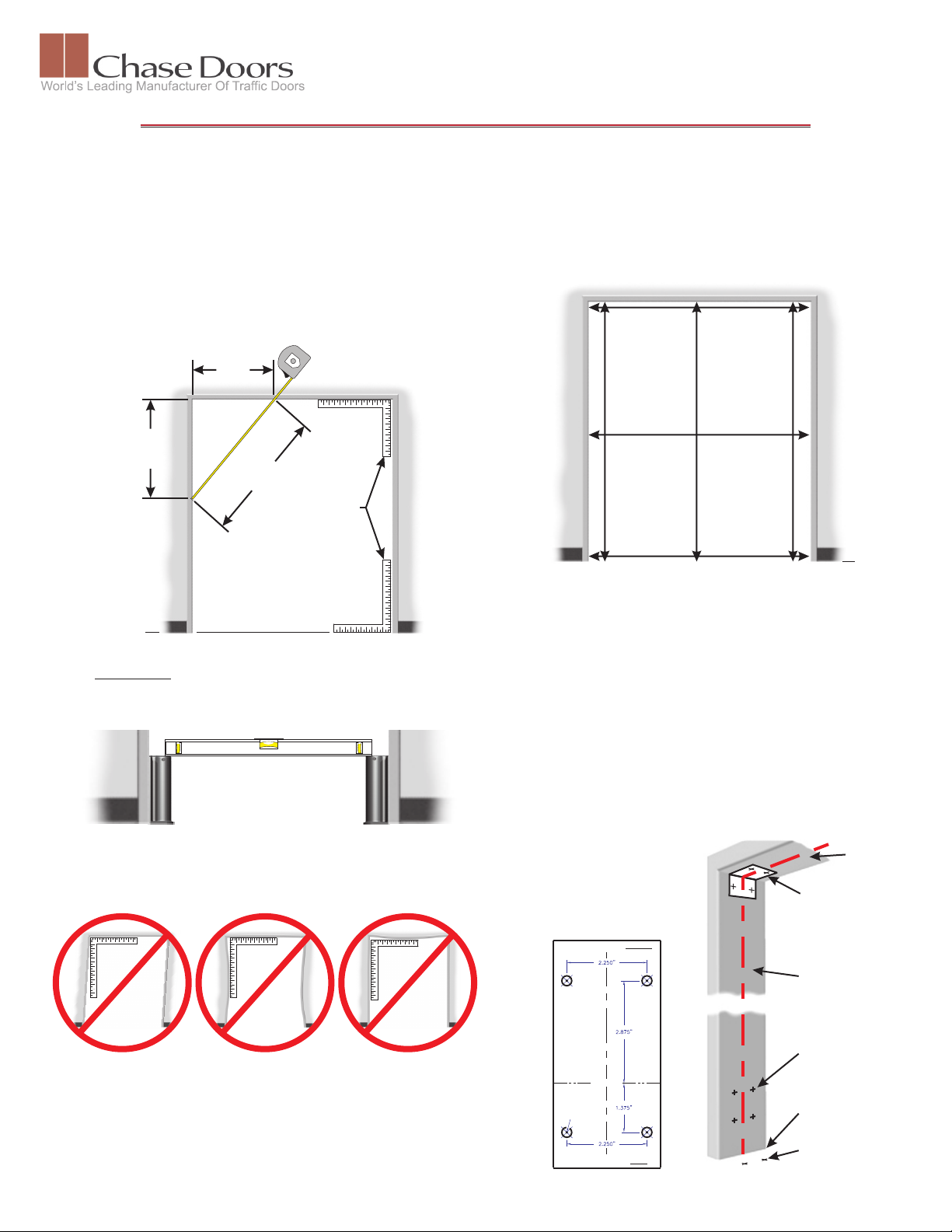

Checking for Square & Plumb Frame

You can check the Upper and Lower Corners of your opening with

a Framing Square, See Figure 1. If you do not have access to a

square then you can use what is commonly known as the “3, 4, 5

Method”.

To Perform the 3, 4, 5 Method (Refer to Figure 1):

Begin by measuring out horizontally from the corner and make a

slight mark at 3’ (Measurement # 1).

From the same corner measure down vertically and make a mark

at 4’ (Measurement # 2).

If the Frame is Square then the measurement between the two

marks (Measurement # 3) will be 5’. If the measurement is not 5’,

then your frame is not square and your doors may not work

properly.

Measurement # 1

3’

Measurement # 2Measurement # 2

4’

Measurement # 3

5’

Framing Square

DWG # 4002 • DATE: 06-25-08

Measuring Your Frame

There are commonly 6 Points of Measurement to assure that your

frame is square, See Figure 3.

If any of these measurements vary by more than 1/4” the doors will

not work properly.

NOTE: The use of any shim material to correct your opening

may cause gaskets to not seal properly. Longer Gaskets may be

available, contact the factory for assistance.

F.F.L.

Figure 1- A

IMPORTANT: If you are installing double panels, it is extremely

important that the Jamb Guards be level with one another for

proper operation, see Figure 1 - B. Un-level floors may require

shims (provided) to be placed under one Jamb Guard.

Doors Must Be Installed Level

for Proper Operation!

Figure 1- B

If any of the conditions in Figure 2-A apply to your opening and

are out of tolerance by more than what is defined in Figure 2-B,

then you will have to rework or replace the frame before installing

Chase Doors.

Figure 3

F.F.L.

Before You Begin Installation

Remove door panel from container. Do NOT remove lumber that binds

the upper and lower hinges together at this time, See Figure 5 - Page 3.

Locate the Hardware Fasteners, Top Seal and Upper Hinge Template. If

any of these items are missing please contact the Customer Service

Department at Chase Doors.

Installing the Durulite XLD360

1)

Locate the Upper Hinge Template, See Figure 4-A. Fold Template

at 90° as indicated on the template. Place template in upper most

corner of Frame and center with jamb & header as shown in

Figure 4-B. Secure with tape. Place a center punch at the center

point of the circles indicated on the template and strike the center

punch with a hammer. Remove the template from the frame and

drill holes at the marks with the appropriate sized bit indicated on

the template.

NOTE: You may need to adjust

your template if there is a Fillet

Weld in the corner of the Jamb.

Measurements on template are

taken from the face of the Jamb

& the face of the Header.

TAPE THIS EDGE TO HEADER

Upper Hinge

Template

Jamb

Header

Figure 2- A

Framed openings must meet the dimensions given on the order

received by Chase Doors within the following tolerances:

SINGLE PANELS

Height: +1/4” -1/4”

Width: +1/4” -1/4”

DOUBLE PANELS

Height: +1/4” -1/4”

Width: +1/2” -1/2”

Figure 2- B

CENTER LINECENTER LINE

JAMB & HEADER

CENTER THIS LINE WITH

3/8" Thick & Over, USE: 13/64" Drill Bit

For Steel Jambs

For Wood Jambs

Up To 3/8" Thick, USE: 1/8" Drill Bit

Use: 3/16" Drill Bit

DRILL BIT SIZES

FOLD UP 90°

MARK @ CENTER

OF HOLES

TAPE THIS EDGE TO JAMB

For Steel Jamb

For Wood Jamb

Use: 1/4" X 1" TEK Screw

Use: 1/4" X 2" HW Screw

FASTENERS

Figure 4-A Figure 4-B

Use 8” Jamb

Guard for

Template

Finished Floor

Line

Mark & Drill for

Anchor Bolts

Page 3

Page 3

Durulite Evolution XLD360 Installation Instructions - Continued

}

Installing the Durulite XLD360 Continued

Carefully remove the 1 X 4 wood

2)

member that holds the upper &

lower hinges in place, beginning

with the fasteners at the Top.

Remove the fasteners from the

lower jamb guard and remove the

Lower Hinge system from the

panel.

NOTE: If the Upper Hinge

Assembly should come apart

before installation refer to page 4

for assistance in reassembling

the hinge. The hinge must have

all parts listed on page 4 to work

properly. If any part is damaged

or missing call the factory

immediately.

Remove 1 X 4 Wood Member

from the Back of the Door

Assembly and discard. Begin

disassembly by removing

the Fasteners that secure the

Top Hinge Assembly.

Locate and remove the Lower Jamb Guard (See Figure 6) from

3)

the hinge assembly. Place the Jamb Guard on the floor at the

lower corner of the jamb, See Figure 6.

NOTE: If a flooring material is to be added later you will need

to make the proper vertical adjustments prior to marking and

drilling the mounting holes. Before marking and drilling holes

for mounting the hardware, double check opening height with

the opening height used when placing order. If there are any

variations your panels may not work properly. Please contact

factory for assistance if your opening differs from the opening

measurements used to order panels.

Center the Jamb Guard with the Jamb as seen in Figure 6.

Secure the Jamb Guard to jamb and floor with tape.

Use a Center Punch and Hammer to mark the center of the

mounting holes on the jamb as done in the previous step.

Check to see that the jamb guard has not moved before

marking each hole.

Figure 5

DWG # 4002 • DATE: 06-25-08

Mark the center point of the holes at the base of the jamb guard

for inserting floor anchors.

Remove Jamb Guard from jamb and set aside.

Use the same drill bit on the jamb as required in the previous step.

You will need a 3/8” Masonry Bit to drill for the Floor Anchors.

Once all the mounting holes have been marked and drilled,

4)

reassemble the hinge system by lifting the door panel and placing

the spine onto the cam as shown in Figure 7.

Figure 7

Stand the door panel up and slide into the opening as near to the

5)

mounting holes as possible.

Carefully remove the Retaining Screw from the upper hinge

assembly using a phillips screwdriver, See Figure 8.

Keep Fingers away from the top of the hinge!

Line up the upper and lower hinges with the mounting holes.

Begin with the Top Hinge and insert and firmly tighten the

appropriate fasteners for your jamb material. Insert fasteners into

the jamb guard and firmly tighten.

Insert floor anchors as instructed on Anchor Package.

Finished Floor

Line

CENTER LINECENTER LINE

Figure 6

Header

Jamb

Use 8” Jamb

Guard for

Template

Mark & Drill for

3/8” Anchor Bolts

Figure 8

IMPORTANT NOTE

THE JAMB GUARD MUST BE PINNED FOR PROPER OPERATION!

Through Jamb Guard

The “Pinning” Process and Step 6 of

Loosen the Setscrews that have been installed in the Lower Jamb

Guard, See Figure 9. Set the door to the center position and firmly

these instructions has been removed.

tighten the setscrew on one side of the Jamb Guard. Open door

These doors are now “Pinned” in the

enough to give you access to the center setscrew and tighten firmly.

Make sure that the door is still in the centered position. Remove the

setscrew on the side and Drill a 5/16” hole completely through the

Jamb Guard and Aluminum Cam, See Figure 9. Use a hammer and

gently tap the 5/16” Roll Pin supplied with your hardware, through the

hole until the end is Flush with the outside edge of the Jamb Guard.

and Aluminum Cam

factory. This will not allow for any

centering adjustment at the Cam and

Hinge. Any centering adjustments

must be made using shims behind

the Hinge/Jamb Guard and the

Upper Hinge Bracket. If your doors

do not close at the center of the

Drill 5/16” Hole

opening, place shims as needed to

Completely

Jamb

Guard

Knurled Point

Setscrew

bring the leading edges of the doors

together.

Knurled Point

Setscrew

Figure 9

Page 4

Page 4

21

19

22

22

21

19

21

21

19

19

10

21

21

21

21

}

15

2

2

4

13

20

DWG # 4002 • DATE: 06-25-08

Locate the Top (Header) Seal, See Figure 10. Remove paper backing from tape.

7)

9

10

10

11

10

10

18

2

18

2

3

18

Locate centerline of header. Center the top seal between the upper hinge

brackets and press firmly to header.

Insert fasteners for every hole in the base of

Tape

the top seal and tighten firmly. Some

Trimming may be required. Trim as needed

for proper seal.

2”

Top Seal

End View

NOTE: The fasteners included for your

Top Seal are self tapping and do not

require a pilot hole. However if you are

installing to a Hard Steel Frame it may

be easier to drill a 1/8” pilot hole at the

hole locations in the base of the top seal

then insert the fasteners.

DESCRIPTION

Durulite XLD360

Care & Maintenance

The XLD360 Hinge was

designed to be Maintenance

Free.

Door panels may be washed

with detergent, either

sponged or sprayed on.

Dishwashing detergent mixed

with water at 1/50 works well.

For dirtier areas, commercial

cleaners can be used. On

white yellow or sand colored

doors bleach may be used to

remove difficult stains. In

areas where greasy or

extremely dirty conditions are

encountered, it may be

necessary to use a steam

pressure wash (use

detergent). Dry and apply a

plastic treatment such as

ARMOR-ALL, to the panel

and gaskets.

Wash the window area with

mild soap and dry with a soft

cloth. Do Not Use Solvents,

Bleach or Petroleum

Products on Windows.

ITEM

1

2

3a

3b

4

5

6

7

8

9

10

11

12

13

14

15

16a

16b

17

18

19

20

21

22

23

Figure 10

XLD360 Hinge Parts List

QTY

12

1

8

1

1

1

1

1

1

2

2

8

1

1

2

2

1

1

1

2

4

6

1

4

2

DURUS #

D10HWDK8JG

D09FS01247

D10ALDKPSP

D10ALDKPSL

D10GS178A

D10HWDKLSH

D10HWDKUSH

N/A

D09ALBTCAM

D09PPTPSLV

D09FS01253

D10HWXLDSP

D10HW028SP

D09PPTPPLG

D09PPLWCAM

D10HWDKTLB

D10ALDKSSP

D10ALDKSSL

D08FS01125

D09FS01246

D09HW5524

D05GS16779

D09FS01248

DO9FS01245

D0MFS02098

8” Jamb Guard

3/8 - 16 Button Socket

Primary Spine (96”)

Primary Spine (108”)

Spine Gasket

Lower Spine Holder

Upper Spine Holder

Attached to Item #6

Aluminum Cam

UHMW Sleeve (Black)

1 ½” O.D. Fender Washer

5” Spring, Ø0.250” Wire

5” Spring, Ø0.280” Wire

UHMW Top Plug

UHMW Cam

Top “L” Bracket

Secondary Spine (96”)

Secondary Spine (108”)

3/8 - 16 Knurled Setscrew

3/8 x 1” Flat Cap Screw

Steel Insert

Back Gasket

5/16 - 18 Button Socket

3/8” X 1 ½” Lag

1-3/4” X 3/16” Roll Pin

Durulite Evolution XLD360 Installation Instructions - Concluded

6

7

10

10

12

10

13

21

19

16

21

19

22

22

21

2

2

21

17

14

17

8

5

17

23

XLD360 Hinge System

Durulite XLD360 Troubleshooting Guide

Problem Possible Cause Solution

18

14

8

2

2

23

Doors Do not Return

1) A. Loose cam in lower hinge.

to Center

B. Excessive negative air flow.

C. Un-level floor.

2)

Doors Stand Open Firmly Tighten the 3 Setscrews in

A. Loose cam in lower hinge.

B. Un-level floor.

Firmly Tighten the 3 Setscrews in

the Lower Jamb Guard.

Add Washers to Upper Hinge

Assembly.

Trim Bottom Gasket or Shim

the Lower Jamb Guard.

Trim Bottom Gasket or Shim

Contact Information

1

Cincinnati, Ohio

Corporate Headquarters

Manufacturing and Customer Service

Toll Free: 800.543.4455

Phone: 513.860.5565

Fax: 800.245.7045

International Sales Phone: 513.603.2931

International Sales Fax: 513.860.0933

Redmond, Oregon

Manufacturing and Customer Service

Toll Free: 800.543.4455

Phone: 541.923.8787

Fax: 800.285.0126

Loading...

Loading...