Page 1

Fib-R-Dor Fiberglass Doors

Durulite CR1400

Corrosion Resistant Personnel Doors

Page 2

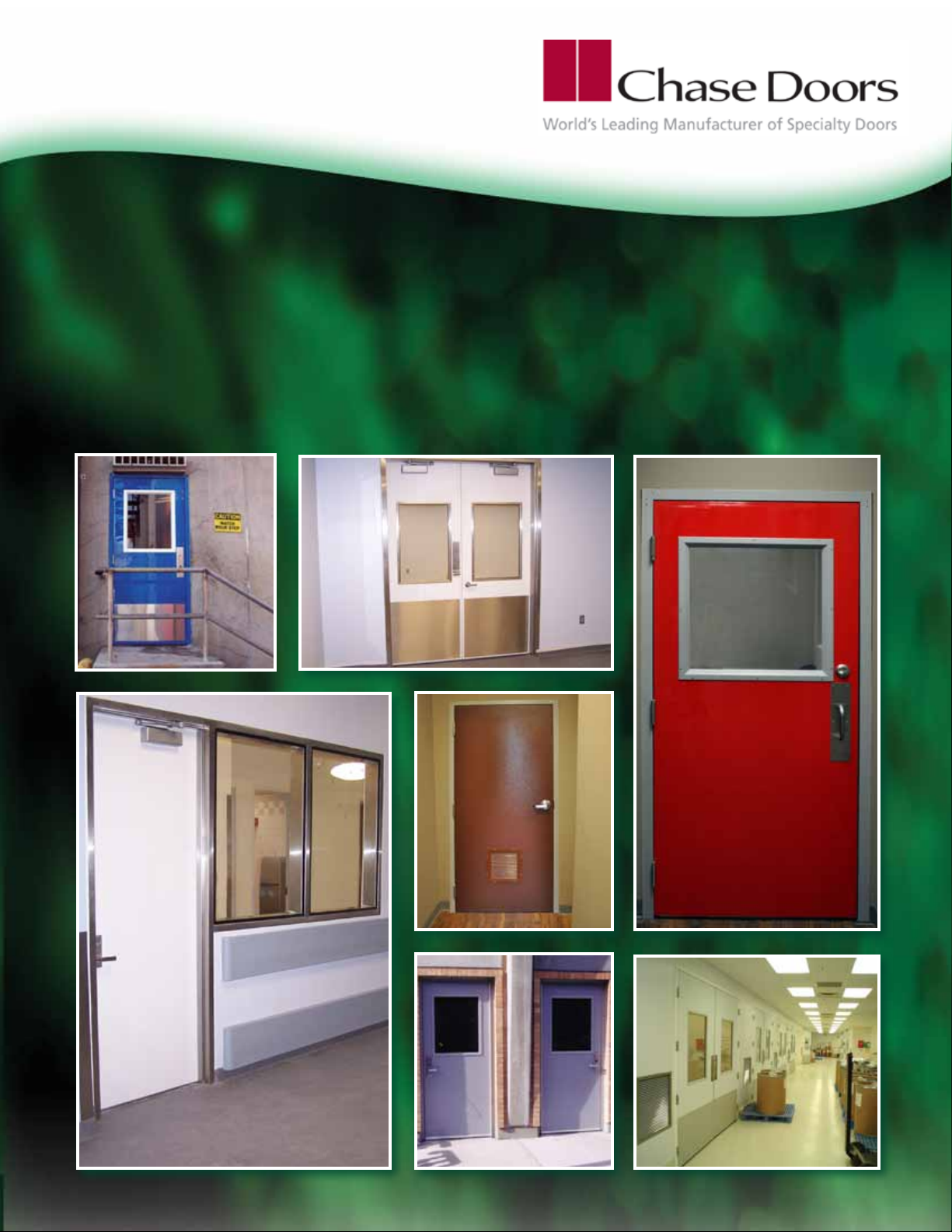

Fib-R-Dor Fiberglass Doors and...

Every plant in the world fights a daily battle

against an age old enemy . . . Corrosion

It’s everywhere you look. Part of the United States is even referred to as the

“Rust Belt”. Huge percentages of annual maintenance budgets are being

used to scrape, paint and replace assets that have fallen victim to corrosion.

These harsh environments are no match against Chase’s Fib-R-Dor

doors and Durulite® CR1400 rotationally molded, cross-linked polyethylene

doors.

Fib-R-Dor and Durulite CR1400 doors are designed for use in extremely

corrosive environments, including pharmaceutical manufacturing, food

processing, water and wastewater treatment, chemical manufacturing,

cleanrooms, oil refineries, theme parks, pulp and paper mills and any other

application where doors are subject to severe corrosive conditions. Fib-R-Dor

and CR1400 doors can also be used as an alternative to stainless steel and

hollow metal doors in schools, institutional and government facilities, saving

thousands of dollars in replacement and maintenance costs.

®

fiberglass

Fib-R-Dor and Durulite CR1400 Advantages:

• Corrosionresistant – monolithic panel design and corrosion resistant

materials ensure long panel life in harsh environmental conditions.

• Cleanablenish – smooth finish is designed for installation in areas

with stringent requirements or frequent washdown.

• Sanitary,seamlessconstruction – no glue, seams or gaps that can

harbor bacteria or cause premature panel failure.

• Pre-nishedpanels – doors ship finished from the factory and do not

require painting. Panel color is throughout the surface of the door.

• Durable,longlastingconstruction – reduces life-cycle cost of the

product and eliminates waste that normally goes into a landfill from

premature product failure.

• Custommanufacturedtoyourexactspecications – your choice of

color, options and sizes.

• ManufacturedtomeetUSDAandFDArequirements.

• Thebestcustomerserviceintheindustry – whether the project is large

or small, we are with you every step of the way and are not satisfied

until you are.

• Superiorwarranty – Chase has been manufacturing doors since 1932;

we stand behind our products before and after they are sold.

2

www.fibrdor.com / www.chasedoors.com

Page 3

Durulite CR1400 Corrosion Resistant Doors

Stop Corrosion with Fib-R-Dor

and Durulite CR1400 Doors

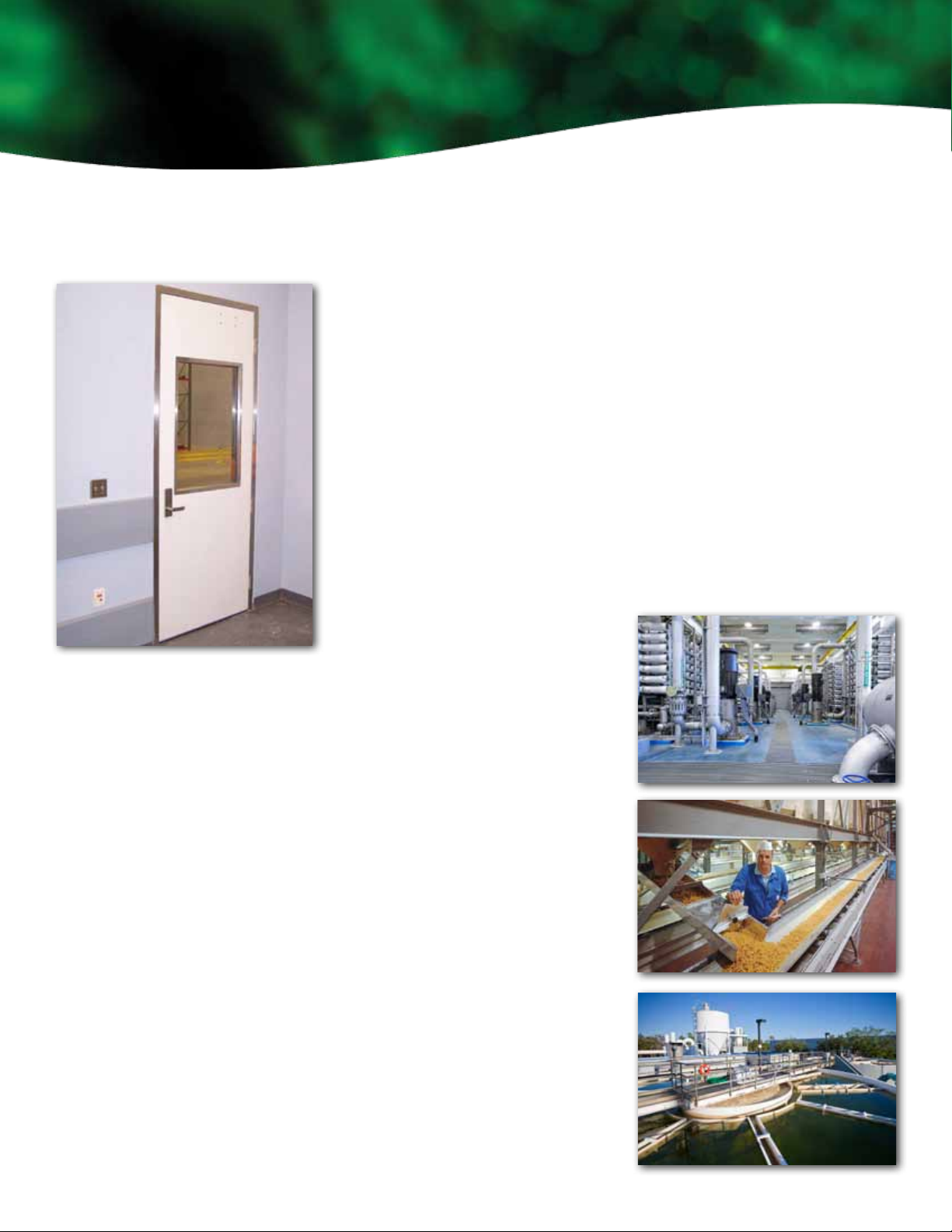

Our customers demand durability, performance and ease of

maintenance. Fib-R-Dor and Durulite CR1400 door systems

utilize premium materials, hardware and accessories,

ensuring an attractive, dependable door that will stand

up in the worst atmospheric conditions. Neither Fib-R-Dor

nor Durulite CR1400 doors will ever need to be painted as

the color is molded into the door and both can be cleaned

easily with soap and water or washed down with stringent

cleaners.

Every Fib-R-Dor and Durulite CR1400 door system is custom

manufactured to meet your precise specifications. Our inhouse engineering team and customer service department

check every order before sending it to production, making

sure the specifications exactly meet the application

requirements. Our experienced production team includes

crafts people that are cross trained to perform a variety

of duties, ensuring that the door systems meet customer

demand with minimal interruption.

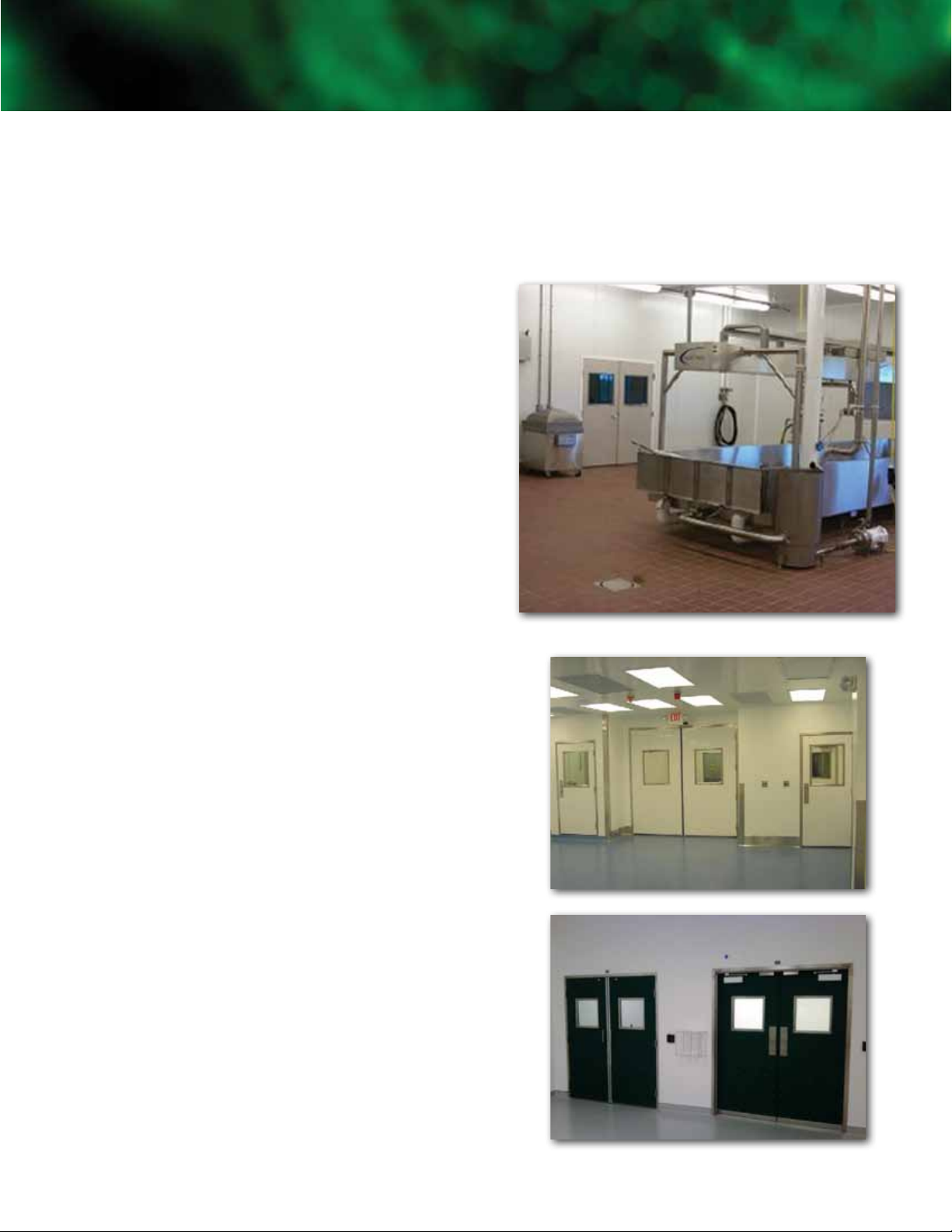

Fib-R-Dor Fiberglass Door Systems

Fib-R-Dor utilizes a combination of unique manufacturing

techniques and fiberglass technology to create a panel

that is beautiful, cleanable and durable. Fib-R-Dor products

are FDA and cGMP compliant, and are designed for use in

facilities that require regular cleaning with harsh chemicals.

Fib-R-Dor door systems are designed for use on interior and

exterior applications, and can be equipped with virtually any

hardware configuration required. Fib-R-Dor door systems

are available with up to 90 minute fire labels, are certified

to meet the Florida Building Code Standards, and have far

surpassed the ANSI One Million Cycle Test.

Durulite CR1400 Corrosion Resistant Door Systems

In high abuse interior applications, consider the Durulite

CR1400 corrosion resistant door system. The CR1400 is

impervious to acids, petroleum products, animal fats and

cleaning solvents, and will take a punch like no other door

system. The door panel is constructed using rotational

molding technology, creating a one-piece outer skin of high

density, cross-linked polyethylene. The interior core is ultrahigh density urethane foam. This combination results in a

panel that will absorb impact and perform well in the most

difficult conditions.

800.FIBRDOR or 800.342.7367

3

Page 4

Fib-R-Dor’s Unique Manufacturing Process

Fib-R-Dor utilizes a unique “outside-in” manufacturing

process, creating a highly durable panel with no seams,

gaps or potential failure points. Designed for use in

facilities that require regular cleaning with harsh chemicals,

the seamless construction eliminates particulate “catch”

points that make traditional doors difficult to sanitize. The

entire exterior of the door panel is molded fiberglass with a

permanent bond to the core material, ensuring a beautiful,

durable, low maintenance door that will last an extremely

long time. Fib-R-Dor fiberglass door color is a molded gel

coat finish, so it will never corrode, need to be painted or

discolor like steel and aluminum doors.

The Door Edge Advantage

The unique panel manufacturing technique is one of the

key differences offered by Fib-R-Dor when it comes to panel

durability. All Fib-R-Dor panels have a molded fiberglass

edge that is chemically welded to the door skins, making

it up to 3 times stronger than tubular or channel door

designs. Competitors use glue to attach the face sheets to

tubes or channels, resulting in a potential separation point

over time. The Fib-R-Dor method of permanently welding

the edge of the door to the skins creates a one-piece

exterior shell that will not peel, separate or delaminate.

The Door Frame Advantage

By design, the Fib-R-Dor pultruded frame system

conforms to industry standards in shape and

installation methods. The durable, corrosion resistant

frame is constructed with FRP pultruded material in

performance with Steel Door Institute standards. The

corners are mitered with no exposed fasteners for a

clean finish. Additional reinforcement can be added

if required by the application or to accommodate

specialty hardware. A variety of configurations and

mounting options are also available, allowing Fib-RDor products to be installed on concrete, brick, block,

foam panel, drywall and tilt-up wall systems.

Installation is Fast and Easy

All Fib-R-Dor panels are CNC machined to fit

perfectly in their matching frames. Fib-R-Dor panels

are made to Steel Door Institute dimensions and

standards, making installation of Fib-R-Dor door

systems fast and easy. As a door system that battles

rust, corrosion, fire and hurricanes, Fib-R-Dor is an

extremely valuable component in a wide range of

markets and applications!

4

www.fibrdor.com / www.chasedoors.com

Page 5

Beauty Meets Durability

Designed for quality and dependability, every Fib-R-Dor door system is custom manufactured to the exact

specifications of each job. Fib-R-Dor door systems can be ordered with windows, passage/locksets, door closers,

panic devices, push/pull handles, kick plates, louvers, flush bolts, astragals, bottom sweeps and weather-stripping.

Even special colors and textures can be produced.

Fib-R-Dor Features:

• Door Surface – Requires no painting or finishing, the mirror-

smooth gel coated fiberglass panels are constructed with impact

resistant, premium grade resins. The resin is reinforced with handlaid glass fibers that are integrally molded creating a corrosion

resistant, one-piece seamless exterior surface. The gel coat finish

is so beautiful that no one would ever know the punishment it

can withstand from harsh corrosive elements such as chemicals,

cleaning agents, repeated washdowns, saltwater and even severe

weather. Standard colors are white, gray, brown and tan in a high

gloss or pebble finish. Optional colors are also available, please

contact factory.

• Door Core – Fib-R-Dor is available with a variety of cores

including polypropylene honeycomb, end grain balsa, urethane

foam and gypsum for fire rated doors. (Seeimagesbelow)

• Door Edge – Multiple layers of pigmented resin are chemically

welded to the face sheets, creating a monolithic one-piece

exterior. Standard nominal thickness is 3/8”. This design combined

with steel reinforcement plates buried beneath the fiberglass

at hinge locations easily supports the weight of the door. Door

edges are CNC machined for an accurate fit and smoothness.

• Hinges – Full mortise stainless steel hinges are standard.

Continuous hinges, hospital hinges and other specialty hinges are

available.

• Frame – A variety of frame options including pultruded fiberglass

and stainless steel are available. Fib-R-Dor offers several common

fiberglass frames for installation on most wall conditions including

insulated panel walls. In addition, stainless steel frames can be

manufactured to your specific jamb requirements.

Polypropylene Honeycomb

is lightweight and extremely

durable, and is commonly used

as a core for doors installed in

pharmaceutical applications.

800.FIBRDOR or 800.342.7367

End Grain Balsa provides superior

strength, and is recognized as one of the

most versatile core materials for sandwich

construction. This closed cell material is

non-absorptive, and extremely strong

with an 11 lb. density rating. Balsa is also

an environmentally friendly, ecological

resource core material.

Urethane Foam has excellent

insulating qualities, plus it

is known for sound control,

low permeability and helps

to prevent mold and mildew

growth.

5

Page 6

Fire Rated Doors

When fire rated doors and

frames are required, Fib-R-Dor

has the solution. Fib-R-Dor

fire rated door systems meet

and exceed both neutral and

positive pressure fire rated

labels. Available with 20, 30, 45,

60 and 90 minute labels.

Neutral Pressure Fire Doors

Fib-R-Dor corrosion resistant door systems are available with 20, 30, 45, 60 and

90 minute labels and meet the Underwriters Laboratories, Inc. “Standard for

Fire Tests of Door Assemblies, UL 10B” and UL 305 Standard for Safety “Panic

Hardware”.

When doors are tested under the neutral pressure testing method, the test

chamber is vented so the neutral plane is above the door. This scenario does

not allow pressure to build-up in the room, so air actually enters the room

around the door edges, reducing the chance of flames igniting the outside

door and surface.

Positive Pressure Fire Doors

Fib-R-Dor corrosion resistant door systems are also available with 20, 30, 45, 60

and 90 minute labels by Warnock-Hersey with UBC 7-2-1997 and UL 10c NFPA

252 for positive pressure fire rated doors.

Under positive pressure, the test is performed with the neutral plane 40”

above the floor. This method causes hot gases to be forced out around the

edge of the door, making it easier for flames to transfer to the outer door

and surface. To prevent flames from transferring, Fib-R-Dor fire door utilizes

intumescent seals. Intumescent seals expand under heat, filling the gap

between the door and frame. The intumescent seals can be molded in during

the manufacturing process or applied on the surface of the door.

6

www.fibrdor.com / www.chasedoors.com

Page 7

Storm Rated Doors and Certifications

Fib-R-Dor fiberglass door systems meet Florida building code approval, ASTM standard for Airblast Loading and

GSA test for Dynamic Overpressure Loadings. Plus at 2 million and counting, Fib-R-Dor has far surpassed the ANSI

One Million Cycle Test!

Fib-R-Dor door systems meet and

exceed the stringent requirements

of the Florida Building Code (FBC),

International Residential Code

(IRC), and the Texas Department

of Insurance for hurricane rated

openings. The International Building

Code (IBC) and International

Residential Code (IRC) are the

model codes for the 2007 Florida

Building Code and the soon to be

adopted 2010 Florida Building Code.

Contained within the building code

are specific sections relating to

design pressure calculation, testing

and evaluation of products to be

used in hurricane prone regions.

Chapter 16 of the Florida Building Code stipulates that the wind loads on every building be determined in

accordance with ASCE 7. ASCE 7 determines design pressures for components and cladding used on building

envelopes based on parameters such as geographic location, wind speed, importance of the building use and

location of the opening on the building and size of the opening.

ASTM E1886/1996 is a standard that was created to ensure that products installed in coastal regions will provide

adequate protection against the extreme weather conditions that are common with a hurricane. To meet the ASTM

E1886/1996 standard, the door system must act as a barrier to water, maintain structural integrity under high wind

conditions, including cycling from extreme positive to extreme negative pressures, and pass a “missile test” where a

projectile is fired at the door panel at a high rate of speed.

Fib-R-Dor “FBC Series” is approved for use in the State of Florida under

Florida Product Approval # FL14551 and meets the following codes:

ASTM Test

ASTM E1886 - Impact testing by missile and cyclic

pressure differential test

ASTM E1996 - Large missile impact testing

ASTM E330 - Wind load testing of windows and

doors by static air pressure difference

ASTM E331- Water penetration testing

ASTM E283 - Air leakage testing by air pressure

differences

ASTM D635-03 - Rate and extent of burning test

ASTM D1929-96 - Ignition temperature test

ASTM D2843-99 - Smoke density from burning test

Cycle Test

ANSI A250.4-2001 - Acceptance criteria for physical

endurance for steel doors, frames, frame anchors and

hardware reinforcement

Airblast Loading

ASTM F 1642-04 - Standard test method for Airblast

Loading

GSA-TS01-2003 - US General Service Administration

standard test method for Dynamic Overpressure

Loadings

800.FIBRDOR or 800.342.7367

7

Page 8

Durulite CR1400 Utilizes Rotational

Molding Technology

Chase Doors invented the roto-molded door in 1976. Since that time, we have sold over a half million rotationally

molded doors and our manufacturing process is second to none. The Durulite CR1400 utilizes the rotationally

molded manufacturing process and is extremely durable.

The process starts by placing a specific amount of colored

plastic resin into an aluminum mold. The mold is then closed

and attached to a long arm on an automated molding

machine. The mold first moves into an oven chamber and

then slowly spins on two axis, causing resin to melt and

adhere to the inside of the hot mold. After the proper

amount of “cooking time,” the mold swings to the next

station where air is used to cool down the mold, allowing

the material to set as it continues to spin–assuring an even

wall thickness. When it is completely cooled, it swings to

the original station where the mold is opened and a hollow

door shell is removed. The rotational speed, heating and

cooling times are all controlled throughout the process.

The end result is a seamless, one piece high density crosslinked polyethylene door shell that is naturally resilient and

is impervious to acids, petroleum products, animal fats and

cleaning solvents.

Large oven used to “cook” Durulite CR1400 doors.

After cooling is complete, the hollow panel is

put into a hydraulic press where it is injected

with NON-CFC urethane foam, which completely

fills the cavity inside the hollow door shell. The

foam provides a variety of benefits, including

thermal insulating characteristics and increased

shock absorbency. The Durulite CR1400 will retain

an attractive appearance in the most difficult

conditions.

8

www.fibrdor.com / www.chasedoors.com

Page 9

Attractive, Durable and Maintenance Free

The Durulite CR1400 door is

designed for use in heavy duty

interior applications that require

durability, corrosion resistance

and ease of maintenance in a door

system. Every Durulite CR1400 is

custom manufactured to the exact

specifications of each opening.

Durulite CR1400 doors can be ordered

with windows, passage/locksets,

door closers, panic devices, push/pull

handles, kick plates, louvers, astragals,

flush bolts, bottom sweeps and

weather-stripping.

CR1400 Features:

• Door Surface – Seamless panel construction makes

this door ideal for washdown applications. The sanitary

surface never needs painting and cleans easily with soap

and water. Available in 14 standard colors.

• Door Panel – Constructed with a 1/8” thick outer skin

of cross-linked polyethylene with an ultra high density,

NON-CFC urethane foamed-in-place core. The panel

can retain its properties from -40°F to 150°F continuous

service and 170°F intermittent service with temperature

differences of up to 40°F. The overall thickness of the

panel is 1-3/4”, yet weighs only 3.66 pounds per square

foot, making it lightweight and easy to open.

• Gasketing – All doors come standard with a replaceable

bottom sweep, and are available with a drop down seal.

Full perimeter gasketing is also available.

• Hinges – Optional high quality stainless steel hinges

mount the CR1400 securely to the frame and provides

years of service.

• Window – CR1400 door systems can be equipped with

a variety of window configurations, including single

and double pane units. Various glazing types and frame

materials are available.

• Insulation – The CR1400 has excellent insulation

qualities with an EcoMate foamed-in-place NON-CFC

urethane core. Ecomate insulation is designed to be

environmentally friendly; it was awarded VOC (Volatile

Organic Compound or SMOG) Exempt Status by the EPA.

800.FIBRDOR or 800.342.7367

9

Page 10

Fib-R-Dor & CR1400 Door Options

Hinges

We offer heavy duty 4-1/2” x 4-1/2” full mortise stainless steel ball bearing

hinges with non removable pins. Continuous hinges, hospital hinges and other

specialty hinge systems are available. Fib-R-Dor and CR1400 doors will accept

virtually any hollow metal type door hinging system. Hinge locations can be set

to custom locations or to match any manufacturer’s locations.

Hardware Options

*Durulite CR1400 Standard Colors

(Fromlefttoright)White, Choc. Brown,

Med. Brown, Beige, Cloud Gray, Metallic Gray,

Forest Green, (Secondrow) Black, Red, Navy,

Burgundy, Royal Blue, Cadet Blue, Jade

*Fib-R-Dor Standard Colors

White, Gray, Brown and Tan

*Contactfactoryforadditionalcolorsandexact

colormatch.

The Fib-R-Dor and CR1400 doors can be

equipped with virtually any hardware that is

available on a standard hollow metal door:

• Chrome and stainless finish passage and

locksets

• Stainless steel push/pull handles, dead

bolts

• Surface or flush bolts

• Panic device – either a rim, mortise or

surface mounted vertical rod device

• Protective edge caps and stainless impact

plates are available.

Lite Kits

Optional windows are clear, polycarbonate or a variety of glass products including

laminated, tempered or wire reinforced. Windows are available in an array of

sizes. On the CR1400 doors, the glazing is set in your choice of stainless steel or

two-piece injection molded, low profile PVC frames. The stainless steel frames can

either be surface mounted or flush mounted for pharmaceutical applications.

Fib-R-Dor has three standard kits with no miters or fasteners on one side, which

creates a seamless frame that is easy to clean and used for security

features. Optional stainless steel lite kits are also available.

Adjustable Door Closers

Adjustable closers with corrosion resistant finishes are available for use

with Fib-R-Dor and CR1400 doors and can be mounted on the push or

pull side of the door. Closers can be equipped with time delay or hold

open option.

10

www.fibrdor.com / www.chasedoors.com

Page 11

Fib-R-Dor & CR1400 Door Frame Options

Chase offers both pultruded fiberglass frames and stainless steel frames. Either frame can be butt mounted or

wrapped for most wall conditions, including insulated panel walls. The frames are available with a variety of

mounting systems. Fib-R-Dor products can be installed on any type of wall construction, including concrete, brick,

block, foam panel, drywall and tilt-up wall systems. Stainless steel frames can be manufactured to your specific

jamb requirements.

Fiberglass Frames

Fiberglass frames are constructed of

1/4” thick, fiberglass material with

reinforced, mitered corners. Fiberglass

frames are available in 4” wide (single

rabbet) or 5-3/4” wide (double rabbet)

profiles. Reinforcements are placed

inside the frame for installation of the

door hardware.

Stainless Frames

Manufactured for any wall thickness,

stainless frames can ship K.D. (knock

down), face welded or fully welded.

Standard type 304 stainless and

optional type 316 material is available.

Single or double rabbet frames can be

manufactured for walls as narrow as

3” or as wide as 12”.

Fib-R-Dor and CR1400 frames are available in a variety of styles and profiles and adapts to all types of wall

constructions, including steel, wood and CMU. Whether you require a fire rated frame, storm rated frame, variable

frame or standard frame, we can provide a frame for your specific application. Additional frames available, please

contact factory.

4” Single Rabbet

4”

5 3/4” Variable Frame

5 3/4”

Up to 10”

2”

800.FIBRDOR or 800.342.7367

2”

2”

11

Page 12

Other Specialty Door Products from

Chase Doors

Cold Storage Doors

Sliding Fire Doors and

Pharmaceutical Doors

Flexible and Impact Traffic Doors

Strip Doors and

PVC Roll Goods

Vinyl and Insect Doors

Industrial Curtains

World’s Leading Manufacturer of Specialty Doors

Chase Industries, Inc. / Cincinnati / Redmond / North Little Rock

www.chasedoors.com / www.fibrdor.com

For Fib-R-Dor Fiberglass Doors, please call 800.342.7367 / 501.758.9494 Fax: 501.758.9496

For Durulite CR 1400 and all other door products, please call 800.543.4455 / 513.860.5565 Fax: 800.245.7045

In our continuing effort to improve our products, some specifications or descriptions may change. We reserve the right to make such changes without notice or recourse.

Brochure # FIBCR1400 1211

Loading...

Loading...