Page 1

Saino Fire SlidingDoors

Pharmaceutical Doors

Industrial Sliding Doors

Page 2

Chase Doors

plus yea

Since 1899, the Saino brand has been a

recognized leader in the industrial door market.

Saino brand sliding fi re and pharmaceutical doors, manufactured by Chase

Doors have earned a reputation as high quality products that are reliable,

durable and competitively priced. Chase offers the most comprehensive line

of specialty door systems available for pharmaceutical, food processing and

industrial applications. From modular construction manual sliding door systems

to microprocessor controlled automated barrier systems, we’ll design a system

to suit your needs. Saino doors can be used in both single slide and center

parting applications with up to 4 hour UL labels making them acceptable for

most applications requiring fi re barriers. Chase is the only manufacturer that

has the ability to provide a fi re door with a 12” headroom clearance. Let us put

100 plus years of experience to work for you.

UL & FM labeled fi re doors designed for

use in washdown applications

“Smart” Microprocessor drive systems with a

broad range of capabilities

Process room doors with fl ush

panel construction

A wide variety of panel fi nishes including

stainless steel, fi berglass, Kydex and Polyethylene

Pre-assembled, casing mounted drive

systems for simplifi ed fi eld installation

2

Page 3

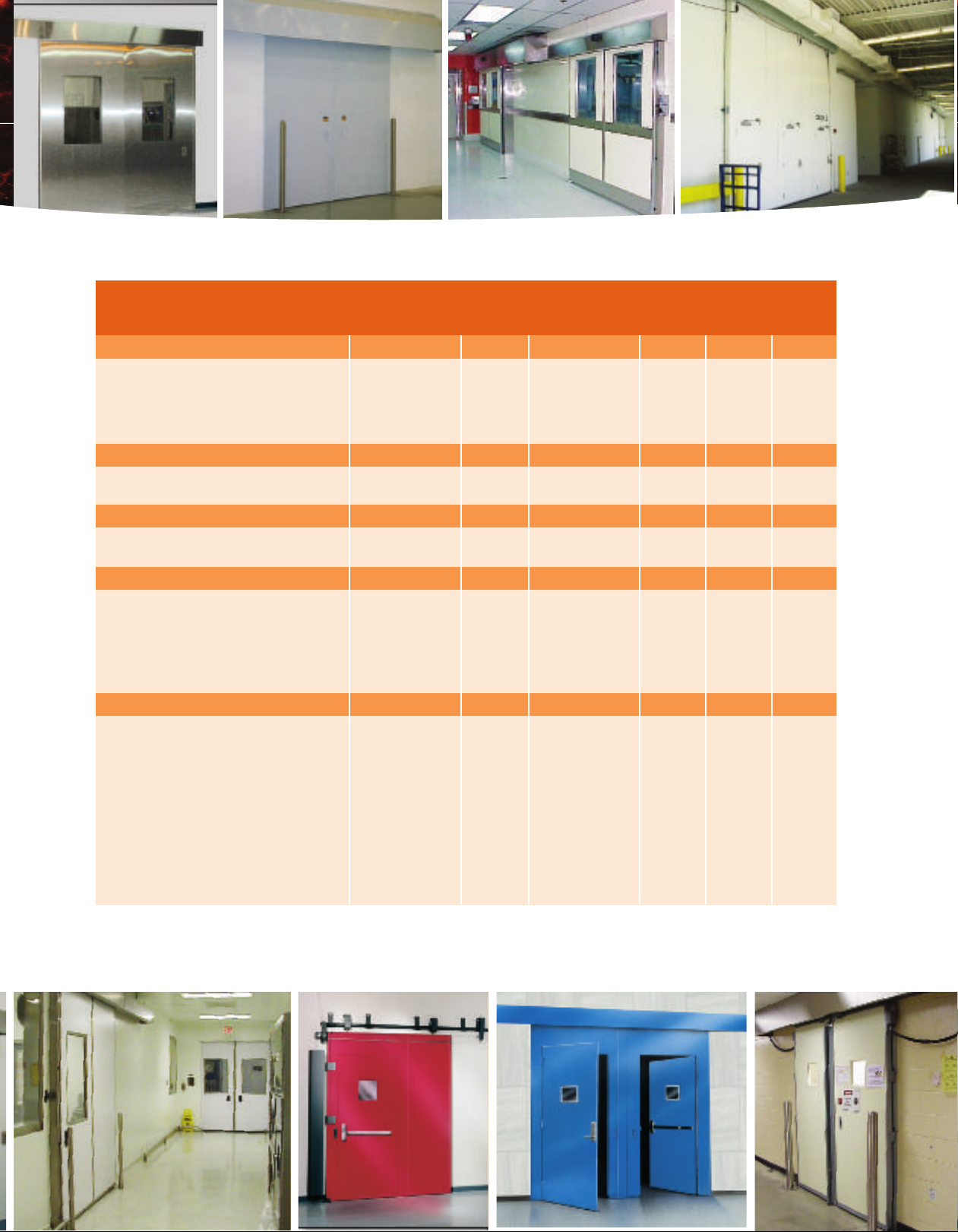

Models

1000 - 4000 50000 1100 - 3100 61000 67000 73000

Type of Door / Application

Fire Door X X

Industrial Service Door X X

Pharmceutical Door X X X X

Clean Room Door X X X X

Food Processing Door X X X X

Mounting Options

Casing Mounted X X X X

Direct Wall Mount X X

Door Configuration

Single Slide X X X X X X

Center Parting X X X X X X

Available Door Finish

Stainless Steel X X X X X

Galvanized X X X X

Prime Painted X X X X

Cross-linked Polyethylene

Kydex X

Fiberglass X

Most Popular Options

Operator X X X X X X

Pass Doors X X X X

Vision Panels X X X X X X

Track Hoods X X X X X X

Perimeter Gasketing X X X X X X

Reel Closing Systems X X

Control Speed Closing X X X X X X

Locking Devices X X X X X X

Spark Proof Hardware X X

Monorail Cutouts X X

Temperature Rise Rating X X

Page 4

Saino Fire and Service Doors

Listed and Labeled Construction

Saino Fire Doors can be rated for openings that require up to a 4-hour label. Saino

Fire Doors are UL approved and FM available. Temperature rise labels are also

available, providing an added level of safety in areas where personnel are present.

All Saino listed and labeled operators comply with ANSI standards.

Multi-Purpose Door

All Saino Door Systems can be automated, allowing the door to be used as a

functional door system as well as a fi re door. This two-in-one feature reduces

the cost of providing multiple door systems in a single opening and insures that

the door will be operational in the unlikely event of a fi re. All Saino fi re door

operators are listed and labeled for use as an automatic closure device. Automated

fi re doors can be connected to a central fi re system, increasing personnel safety

and minimizing potential damage caused from fi res.

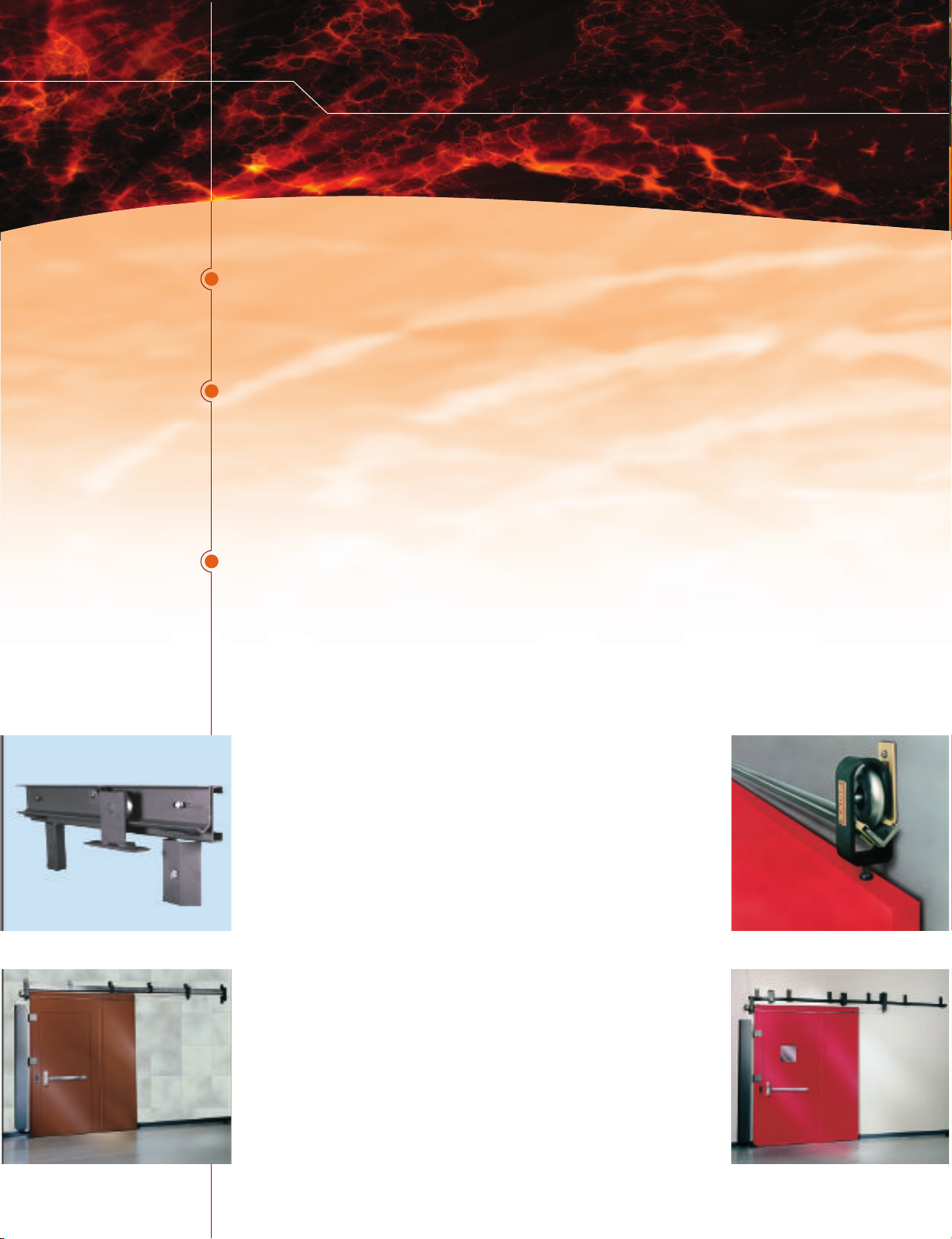

STEL Track for Model 50000 Series

Standby Battery Closing System

Saino automated fi re door systems come complete with a self-contained, standby

power supply that is approved under UL 228 and UL 924 as tested for critical

components. The closing system allows a horizontal sliding door system to be used

as an approved means of egress in many applications. Saino sliding fi re doors can

also be equipped with pass doors including multiple doors for double egress.

Saino Sliding Fire Door

Models 1000, 2000, 3000 & 4000

Panel Construction – All models incorporate modular panel

construction with either Kraft honeycomb or calcium silicate

core material. Calcium silicate offers a 250°, 30 minute

temperature rise rating. Both cores are securely bonded to 18

gauge cold rolled face sheets and 18 gauge interior channels,

making the panel inherently strong and durable. Doors are

available in single slide or center parting confi gurations, and

can be manual or motorized.

Surface Finish – The standard door ships prime painted with

galvanized or stainless steel fi nishes available upon request.

Hardware - All hardware is UL labeled. The patented Easy

Roll Track System gives Model 3000 & 4000 the lowest friction

of any fi re door on the market. The door system can be

motorized without additional track hardware. Models 1000 &

2000 use economical box track hardware, providing a simple

solution for a manual sliding door.

Easy Roll

TM

Model 1000 Model 4000

4

Page 5

Saino Casing Mounted Fire Door

Model 50000

Casing mounted fi re doors are an excellent choice for applications with

high usage and where appearance is important. The casing mounted

design provides adequate spacing on both sides of the panel to

install surface-mounted hardware for handicap access while allowing

a portion of the weight of the door to be transferred to the fl oor.

Standard features include a 20 minute to 4 hour rating, low headroom

track system, concealed binders and full perimeter gasketing.

Panel Construction – Model 50000 is ruggedly constructed with 12

gauge welded channels and 18 gauge surface welded face sheets. The

standard core material is fi berglass. A 14 gauge perimeter capping

channel encloses the panel and eliminates surface-mounted fasteners.

The Pre-mounted casing system reduces installation time and improves

the sealing capability of the door system. Pass door panic devices can

be mortised for use on the wall side of the fi re door, allowing for

double egress.

Surface Finish – The standard door ships prime painted with

galvanized or stainless steel fi nishes available upon request.

Hardware - All hardware is UL listed and labeled. The 50000 is

equipped with a standard weight type closing system, 7 gauge header

casing and STEL track system. The STEL track system is an excellent

alternative for low headroom applications. This door system is

designed to provide years of trouble free service in high frequency

applications. Like all Saino fi re door systems, the 50000 can be motor

operated.

Saino Sliding Service Doors

Models 3100 & 1100

Chase manufactures non-labeled Saino Sliding Service Door Systems

to the same high standards that are maintained for fi re door systems.

Models 3100 and 1100 offer options that will satisfy almost any nonlabeled sliding door application, including warehouse doors, doors

with high wind load, or wall openings that provide access to oversized

manufacturing equipment.

Both models incorporate modular panel construction with a resin

impregnated Kraft honeycomb core securely bonded to 18 gauge cold

rolled face sheets and 18 gauge interior channels. The Model 3100 is an

excellent choice for high use applications requiring easy operation. The

track door system can be motorized without additional track hardware.

The 3100 uses the patented Easy Roll hardware system, offering the

lowest friction of any service door. The Model 1100 is an economical

manual sliding door system. Heavy-duty hardware is available for large

openings or motorized doors.

5

Page 6

Pharmaceutical Doors

Pharmaceutical process areas, food manufacturing and clean rooms have specifi c requirements that

many door systems can not meet. Environmental control, cleanability with harsh chemicals and high tech

automation are required to insure product quality and manufacturing effi ciency. All Chase door systems are

built with these requirements in mind. Chase doors are designed to comply with entrapment and egress

codes as well as local and national building standards.

Chase Pharmaceutical Door Systems incorporate modular design with the latest technology, insuring that

all door systems are both functional and cost effective. Every system is designed and manufactured to meet

your exact requirements. Features including fl ush panel construction, sloped track hoods, sloped or fl ush

window frames and a concealed lower door guide system insure that all Chase pharmaceutical door systems

are both beautiful and functional. All Chase doors can be operated manually or be equipped with a variety

of drive systems including microprocessor controlled operators that can be connected to process control

or monitoring equipment. Manual door systems can be equipped with an automatic closing system that

provides a positive closure at controlled speeds, insuring effective environmental control and personal safety.

DuruSlide

The 67000K door is fabricated using a 16 gauge

internal welded steel tube framework, allowing

the panels to be manufactured to virtually any

size. The standard core is resin impregnated Kraft

honeycomb with optional urethane insulation

available. The panel fi nish is impact resistant Kydex

that has a high gloss fi nish and meets UL 94V, 5v

and FAR 25.853a for fi re retardancy. Available in 14

colors. Consider the 67000K for large size openings

and areas that have high positive or negative

air pressure.

™

67000K

DuruSlide

The 67000F Fiberglass Door Systems utilize a unique

“outside-in” manufacturing process with one

piece fi berglass face sheets that are permanently

bonded to an internal core and perimeter tube

®

frame. This process creates a highly durable panel

with no seams, gaps or potential failure points

ensuring beauty, durability and long panel life.

The gel coated FRP 1/8” thick skin has a smooth

and cleanable fi nish that requires no painting or

maintenance. All edges are protected by stainless

steel capping channels, creating an attractive

appearance and durable design.

6

™

67000F

Page 7

Model 73000

Designed for installations requiring the highest sanitary standards, the

Model 73000 sliding pharmaceutical door system incorporates fully

fl ush panel design making the door system beautiful and easy to clean.

Standard features on the 73000 include sloped stainless steel hood, no

surface fasteners, double pane vision panels, integrated gaskets and

casing mounted fl oor guides.

TEP Track System

Quiet and Dependable

Model 67000 and 73000 door

systems operate on the TEP track

system, which is designed to

provide years of smooth, troublefree service. This track system,

combined with permanently

lubricated trolleys provides

virtually “silent” operation and

minimal resistance. The compact

TEP system requires the least

head room of any industrial door

system. Pre-mounted

components minimize field

assembly time and reduce the

possibility of installation errors.

The “intelligent” microprocessor

control system constantly

monitors the door’s operation

and position, ensuring maximum

control and efficiency.

The door is constructed with 18 gauge stainless steel face sheets bonded to resin impregnated Kraft honeycomb

core and 16 gauge internal tubing. The stainless steel face sheets wrap around the door, eliminiating particulate

“catch points” that make traditional doors diffi cult to sanitize. A closed end sloped stainless steel trackhood allows

for easy cleaning and resists particle buildup. Multi-pane vision panels fi t fl ush into the door panel eliminating

sloped window frames and surface fasteners required on most window systems. Recessed pull handles are fl ush on

both sides of the door.

Traditional capping channels that must be fastened to competitor’s door panels have been eliminated, as

have extrusions to hold perimeter gaskets in place. All gaskets fi t into keyways in the door panel, and are fi eld

replaceable.

Optional motor operation is achieved using a microprocessor controlled drive system with encoder. Standard

electronic reversing eliminates surface mounted reverse edge devices and the wiring required. Standard

control features allow interlocking, full and partial open and remote door status confi rmation. Durability, low

maintenance requirements and ease of cleaning make the 73000 the choice for pharmaceutical processors!

7

Page 8

Other Specialty Door Products from

Chase Doors

Strip DoorsBug & Bird Screen Doors Cold Storage Doors

Impact Traffic DoorsCorrosion-Resistant

Personnel Doors

Chase Industries, Inc. / Cincinnati, OH / Redmond, OR / 800.543.4455 / 513.860.5565 / fax 800.245.7045

www.chasedoors.com

Kydex is a registered trademark of Klerdex

In our continuing effort to improve our products, some specifications

or descriptions may change. We reserve the right to make such

changes without notice or recourse.

Fiberglass Door

Systems

Brochure #SBPH 0611 Printed in U.S.A.

Loading...

Loading...