CHART Orca MicroBulk CO2 Series Product Manual

Product Manual

Orca™ MicroBulk Delivery System

CO2 Series

Designed and Built by:

Chart Inc.

407 7th Street NW

New Prague, MN 56071 USA

(800) 400-4683

Part Number 21235568 Rev. D

© 2018 Chart Inc.

Product Manual - Orca™ CO2 Series MicroBulk Delivery System

Contents

Revision Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Product Highlights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Product Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Acronyms / Abbreviations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Safety Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Compatibility and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Safety Bulletin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Oxygen Decient Atmospheres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Oxygen Enriched Atmospheres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Nitrogen, Argon & Carbon Dioxide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Personal Protective Equipment (PPE). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Safety — CO2 Specic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Carbon Dioxide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

iii

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Terminology of Cryogenics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Cryogenic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Cryogenic Temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

States of Matter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Saturation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Equilibrium . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Saturation Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Subcool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Two-Phase Liquid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Cavitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Vaporization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Vapor Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Condensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Condensation and the Perma-Cyl® MicroBulk Storage System . . . . . . . . . . . . . . . . . . 10

Stratication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Depressurization Flash Losses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Entrainment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Liquid Growth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Pressure Drop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Modes of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Orca CO2 — First Fill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Fill Orca CO2 from Bulk Tank Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Fill Orca CO2 from Onboard Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Filling Levels - MC-338 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Current Saturation of Liquid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Pressure Build: Heater. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Pressure Build: Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Pressure Delivery: Hose Reel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Pump Delivery: Bulk Hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Receiving Tank Commission: Hose Reel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Table of Contents Product Manual - Orca™ CO2 Series MicroBulk Delivery System

iv

Receiving Tank Commission: Bulk Hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Hydraulic Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Methods to Stop Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Primary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Trailer Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Start Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

End Delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Methods to Stop Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Components & Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Plumbing Cabinet - Roadside . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Plumbing Cabinet - Top Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Plumbing Cabinet - Bottom Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Plumbing Cabinet - Curb Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Plumbing Cabinet - Other Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Anti-Tow Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Ticket Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Bluetooth Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Metering System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Meter Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Dierential Pressure Transmitter (DP Transmitter) . . . . . . . . . . . . . . . . . . . . . . . . 29

RTD - Resistance Temperature Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Flowcom Flow Meter System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Cabinet Power - Truck. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Work Lights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Dash Controls - Truck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Hydraulic System - Truck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Motor and CO2 Pump Rotation Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Grease Fitting Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Pressure Build Heater and Safety Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Trailer System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Top Deck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Roadside Frame Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Overview of Operation Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Error Codes & Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Overview of Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Overview of Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Daily Observation Checks by Operator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Beginning of the Day Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

During PTO (Power Take O) Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

During Deliveries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Weekly Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Plumbing Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Power Take O & Hydraulic System Inspection. . . . . . . . . . . . . . . . . . . . . . . . . .43

Every Three Months Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Electrical Connection Inspection (12V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Every Six Months Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Table of ContentsProduct Manual - Orca™ CO2 Series MicroBulk Delivery System

Tank-to-Frame Mounting Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Carbon Dioxide Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Yearly Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Every Five Year Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Vacuum Integrity Check (as required) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Preventive Maintenance Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Piping Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Truck Electrical System Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Trailer Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Truck Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Trailer Hydraulic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Pressure Build Heater Electrical Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Warranty Statement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Chart Standard Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Chart Purchased Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Major Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Workmanship and Vacuum . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Exclusions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

v

Table of Contents Product Manual - Orca™ CO2 Series MicroBulk Delivery System

vi

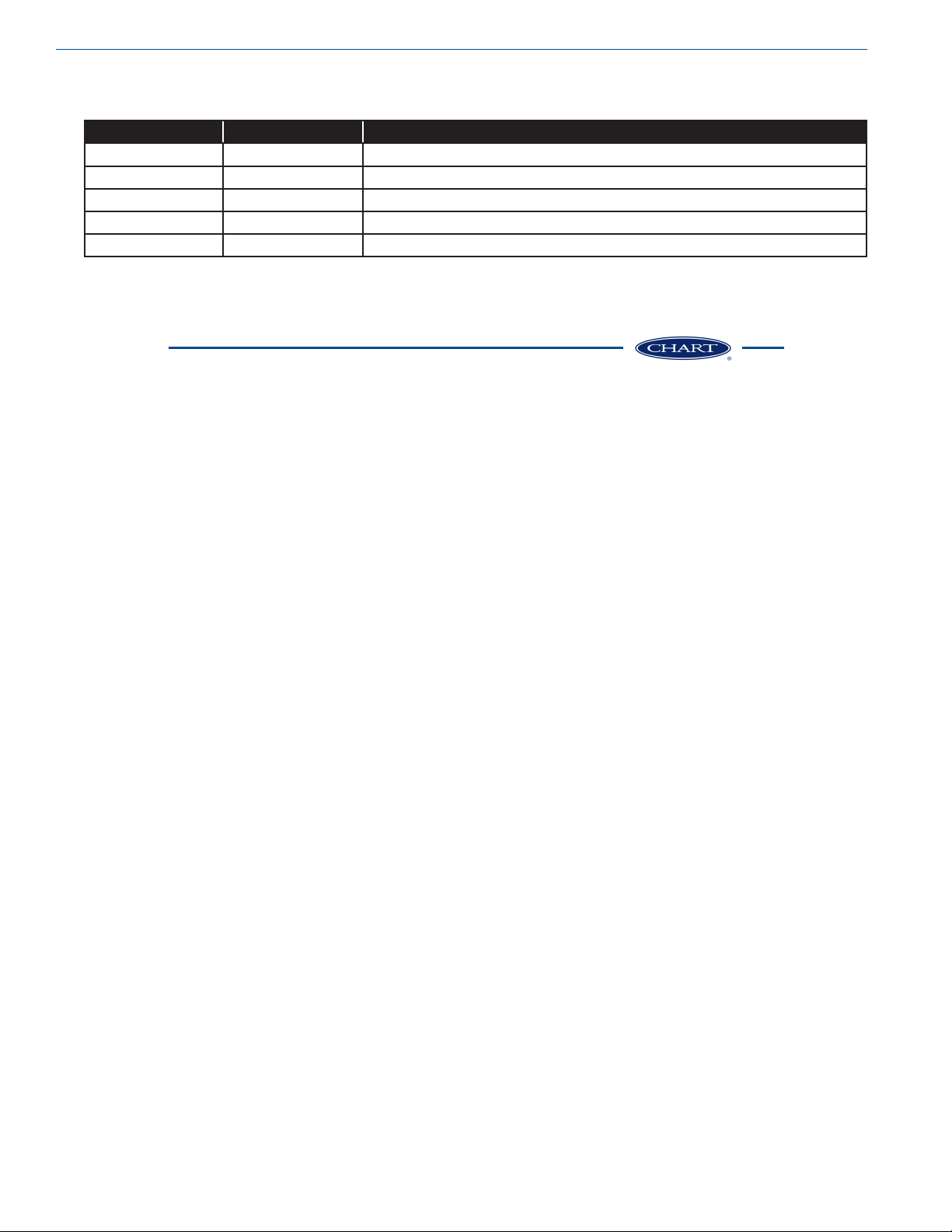

Revision Log

Revision Level Date Description

A 2/21/2018 Original

B 3/8/2018 Added parts and specs update

C 6/18/2018 Specs change, added preventive maintenance log

D 10/15/2018 Inclusion of Trailer components

Product Manual - Orca™ CO2 Series MicroBulk Delivery System

Preface

1

General

Chart’s MicroBulk delivery system has revolutionized the

gas industry by making on-site distribution for smaller

accounts a protable reality. The Orca CO2 Series delivery

unit has been designed to ow up to 500 pounds-per-minute

with minimal pump cooling or product loss under normal

conditions. Fill termination with Sure-Fill eliminates lost

product associated with overlling. In total, the Chart CO2

MicroBulk system increases asset utilization, reduces labor

costs and maximizes distribution eciency.

Chart oers the complete MicroBulk CO2 delivery system as

a solution to reliably and eortlessly manage a diverse range

of applications. The Orca CO2 Series delivery unit oers

fast, reliable and accurate on-site delivery to Perma-Max and

Carbo Series storage vessels or small bulk tanks. The Perma-

Max line oers the widest range of sizes and piping options

and the greatest exibility with accommodations for indoor

and outdoor installation.

Product Highlights

• Fast on-site lling of the Perma-Max storage system

• Fast-lling of Carbo-Max and Carbo-Mizer

• Flowcom® Flow Meter System

• National Institute of Standards & Technology (NIST)

and California Weights and Measures approved metering

system

• Large cabinet with removable access panels for ease of

maintenance and servicing

Product Manual

The CO2 Series Product Manual is designed to be used in

conjunction with Orca CO2 Series models. It should be

thoroughly read and understood by anyone who operates

or is exposed to this equipment. If there are any questions

regarding the operation of the tank, contact Chart’s Technical

Service division at 1-800-400-4683.

The safety requirements for operating the tank and handling

or transporting extremely cold liquid products are shown in

the Safety section. It is imperative that all persons having

contact with the Orca delivery system become thoroughly

familiar with all maintenance, safety precautions, and

procedures contained in this product manual.

The Introduction section discusses the general features of the

tank and the theory of operation.

For detailed information on how to operate the Orca system,

refer to the Operations section. Here are various lling,

pressure dispense and pump dispense instructions.

The Components & Systems section contains photos and

descriptions of all working parts of the Orca system.

The Troubleshooting section will become an invaluable tool

for answering various possible questions that may arise while

using the Orca system.

Reference the Preventive Maintenance section for a schedule

of maintenance to follow to keep your Orca system running

smoothly.

Please refer to the Specications section for a complete

listing of part numbers, drawings and other technical

information.

• Pressure transfer for small delivery

• Optional pump transfer for bulk deliveries; pump can also

be used to ll Orca CO

• Calibrated meter system with no moving parts for

minimal maintenance

• Vessel designed with robust inner support system for

rugged road conditions

• Stainless steel plumbing with stainless steel and brass

valves for long service life and reliability

• Stainless steel inner vessel eliminates damage due to

icing

2

Preface Product Manual - Orca™ CO2 Series MicroBulk Delivery System

2

Terms

Throughout this manual safety precautions will be designated

as follows:

Warning! Description of a condition that

can result in personal injury or

death.

Caution! Description of a condition that

can result in equipment or

component damage.

Note: A statement that contains information

that is important enough to emphasize or

repeat.

Acronyms / Abbreviations

The following acronyms / abbreviations are used throughout

this manual:

ASME American Society of Mechanical Engineers

BAR Metric Unit of Pressure

BARG Metric Unit of Gauge Pressure

CGA Compressed Gas Association

CO

2

DOT Department of Transportation

NER Normal Evaporation Rate

GAWR Gross Axle Weight Rating

GPM Gallons Per Minute

GVWR Gross Vehicle Weight Rating

LAR Liquid Argon

LN2/LIN Liquid Nitrogen

Carbon Dioxide

LOX Liquid Oxygen

LPM Liters Per Minute

MAWP Maximum Allowable Working Pressure

NIST National Institute of Standards and Tech.

NPSH Net Positive Suction Head

OEM Original Equipment Manufacturer

PB Pressure Builder

PN Part Number

PSI Pounds per Square Inch

PSIA Pounds per Square Inch Absolute

PSIG Pounds per Square Inch Gauge

PSID Pounds per Square Inch Dierential

PTO Power Take-O

RV Relief Valve

RTD Resistance Temperature Device

SS Stainless Steel

VAC Voltage - Alternating Current

VDC Voltage - Direct Current

VFD Variable Frequency Drive

Product Manual - Orca™ CO2 Series MicroBulk Delivery System

Safety — General Orca

3

Safety Summary

While every possible safety precaution has been taken to

ensure safe operation and maintenance of the Orca CO

Series delivery system, it is imperative that all persons

having contact with the Orca delivery system become

thoroughly familiar with all maintenance, safety precautions,

and procedures contained in this product manual. If for any

reason any part or parts of this manual become confusing

or the information provided is not completely understood

contact a Technical Service Representative at Chart Inc.

1-800-400-4683 before proceeding with the operation or

repair of the vessel.

2

Compatibility and Cleaning

Always keep the Orca delivery system clean and free from

grease and oil. Use care when cleaning with high-pressure

water or steam cleaning equipment. DO NOT direct the

cleaning nozzle into the electronic components. When

replacing components, use only parts which are considered

compatible with liquid oxygen. Do not use regulators,

ttings, or hoses, which were previously used in compressed

air or carbon dioxide environments. Use only oxygen

compatible sealants on threaded connections. All new joints

should be leak tested with an oxygen compatible leak test

solution at a minimum of 35 psig. Failure to comply with

these instructions may result in serious personal injury,

death, or damage to the container.

Caution! Before removing any parts or

loosening of ttings empty the

cryogenic container of liquid

contents and release any vapor

pressure in a safe manner.

External valves and ttings

can become extremely cold.

Personnel must wear protective

gloves and eye protection

whenever removing parts or

loosening ttings. Failure to do

so may result in personal injury

due to the extreme cold and tank

pressure. Accidental contact of

liquid gases to skin or eyes may

cause a freezing injury similar to

a burn.

Warning! If cryogenic liquid or cold boil-

o gas contacts a worker’s skin

or eyes, the aected tissues

should be promptly ooded or

soaked with tepid water (105-

115°F; 41-46°C). DO NOT USE

HOT WATER. A physician should

examine cryogenic burns that

result in blistering or deeper

tissue freezing promptly.

Warning! Do NOT use open ame in or

around the plumbing cabinet.

Use warm water if thawing of

components is necessary.

Safety Bulletin

Portions of the following information are extracted from

Safety Bulletin SB-2 from the Compressed Gas Association,

Inc. Additional information on oxygen, nitrogen, argon, and

cryogenics is available from the CGA at www.cganet.com.

Cryogenic containers, stationary or portable, are from time

to time subjected to assorted environmental conditions of

an unforeseen nature. This safety bulletin is intended to call

attention to the fact that whenever a cryogenic container

is involved in any incident whereby the container or its

safety devices are damaged, good safety practices must be

followed. The same holds true whenever the integrity or

function of a container is suspected of abnormal operation.

Good safety practices dictate the contents of a damaged or

suspect container be carefully emptied as soon as possible.

Under no circumstances should a damaged container be left

with product in it for an extended period of time. Further, a

damaged or suspect container should not be relled unless

the unit has been repaired and re-certied.

Incidents which require that such practices be followed

include: highway accidents, immersion of a container in

water, exposure to extreme heat or re, and exposure to most

adverse weather conditions (earthquake, tornadoes, etc.) As a

general rule, whenever a container is suspected of abnormal

operation, or has sustained actual damage, good safety

practices must be followed.

Safety Product Manual - Orca™ CO2 Series MicroBulk Delivery System

4

In the event of known or suspected container vacuum

problems (even if an extraordinary circumstance such as

those noted above has not occurred), do not continue to use

the unit. Continued use of a cryogenic container that has a

vacuum problem can lead to embrittlement and cracking.

Further, the carbon steel jacket could possibly rupture if the

unit is exposed to inordinate stress conditions caused by an

internal liquid leak.

Prior to reusing a damaged container, the unit must be

tested, evaluated, and repaired as necessary. It is highly

recommended that any damaged container be returned to

Chart for repair and re-certication.

The remainder of this safety bulletin addresses those adverse

environments that may be encountered when a cryogenic

container has been severely damaged. These are oxygen

decient atmospheres, oxygen enriched atmospheres, and

exposure to inert gases.

Oxygen Decient Atmospheres

Warning! Nitrogen, argon and carbon

dioxide vapors in air may dilute

the concentration of oxygen

necessary to support or sustain

life. Exposure to such an oxygen

decient atmosphere can lead

to unconsciousness and serious

injury, including death. Nitrogen,

argon and carbon dioxide are

colorless and odorless and

can replace the oxygen in the

air when released in conned

areas.

The normal oxygen content of air is approximately 21%.

Depletion of oxygen content in air, either by combustion

or by displacement with inert gas, is a potential hazard and

users should exercise suitable precautions.

One aspect of this possible hazard is the response of humans

when exposed to an atmosphere containing only 8 to 12%

oxygen. In this environment, unconsciousness can be

immediate with virtually no warning.

When the oxygen content of air is reduced to about 15

to 16%, the ame of ordinary combustible materials,

including those commonly used as fuel for heat or light,

may be extinguished. Somewhat below this concentration,

an individual breathing the air is mentally incapable of

diagnosing the situation because the onset of symptoms

such as sleepiness, fatigue, lassitude, loss of coordination,

errors in judgment and confusion can be masked by a state of

“euphoria,” leaving the victim with a false sense of security

and well being.

Human exposure to atmosphere containing 12% or less

oxygen leads to rapid unconsciousness. Unconsciousness can

occur so rapidly that the user is rendered essentially helpless.

This can occur if the condition is reached by an immediate

change of environment, or through the gradual depletion of

oxygen.

Most individuals working in or around oxygen decient

atmospheres rely on the “buddy system” for protection obviously the “buddy” is equally susceptible to asphyxiation

if he or she enters the area to assist the unconscious partner

unless equipped with a portable air supply. Best protection

is obtainable by equipping all individuals with a portable

supply of respirable air. Life lines are acceptable only if the

area is essentially free of obstructions and individuals can

assist one another without constraint.

If an oxygen decient atmosphere is suspected or known to

exist:

1. Use the “buddy system.” Use more than one “buddy” if

necessary to move a fellow worker in an emergency.

2. Both the worker and “buddy” should be equipped with

self-contained or airline breathing equipment.

Oxygen Enriched Atmospheres

An oxygen-enriched atmosphere occurs whenever the normal

oxygen content of air is allowed to rise above 23%. While

oxygen is nonammable, ignition of combustible materials

can occur more readily in an oxygen-rich atmosphere than

in air; and combustion proceeds at a faster rate although no

more heat is released.

It is important to locate an oxygen system in a well

ventilated location since oxygen-rich atmospheres may

collect temporarily in conned areas during the functioning

of a safety relief device or leakage from the system.

Oxygen system components, including but not limited to,

containers, valves, valve seats, lubricants, ttings, gaskets

and interconnecting equipment including hoses, shall have

adequate compatibility with oxygen under the conditions

of temperature and pressure to which the components may

be exposed in the containment and use of oxygen. Easily

ignitable materials shall be avoided unless they are parts of

equipment or systems that are approved, listed, or proven

suitable by tests or by past experience.

SafetyProduct Manual - Orca™ CO2 Series MicroBulk Delivery System

5

Compatibility involves both combustibility and ease of

ignition. Materials that burn in air may burn violently in pure

oxygen at normal pressure, and explosively in pressurized

oxygen. In addition, many materials that do not burn in

air may do so in pure oxygen, particularly when under

pressure. Metals for containers and piping must be carefully

selected, depending on service conditions. The various steels

are acceptable for many applications, but some service

conditions may call for other materials (usually copper or

its alloy) because of their greater resistance to ignition and

lower rate of combustion.

Similarly, materials that can be ignited in air have lower

ignition energies in oxygen. Many such materials may

be ignited by friction at a valve seat or stem packing, or

by adiabatic compression produced when oxygen at high

pressure is rapidly introduced into a system initially at low

pressure.

Warning! If clothing should be splashed

with liquid oxygen it will become

highly ammable and easily

ignited while concentrated

oxygen remains. Such clothing

must be aired out immediately,

removing the clothing if possible,

and should not be considered

safe for at least 30 minutes.

Nitrogen and argon vapors in air dilute the concentration

of oxygen necessary to support or sustain life. Inhalation

of high concentrations of these gases can cause anoxia,

resulting in dizziness, nausea, vomiting, or unconsciousness

and possibly death. Individuals should be prohibited from

entering areas where the oxygen content is below 19%

unless equipped with a self-contained breathing apparatus.

Unconsciousness and death may occur with virtually no

warning if the oxygen concentration is below approximately

8%. Contact with cold nitrogen or argon gas or liquid can

cause cryogenic (extreme low temperature) burns and freeze

body tissue.

Persons suering from lack of oxygen should be

immediately moved to areas with normal atmospheres.

SELF-CONTAINED BREATHING APPARATUS MAY BE

REQUIRED TO PREVENT ASPHYXIATION OF RESCUE

WORKERS. Assisted respiration and supplemental oxygen

should be given if the victim is not breathing. If cryogenic

liquid or cold boil-o gas contacts worker’s skin or eyes,

the aected tissue should be ooded or soaked with tepid

water (105-115ºF or 41-46ºC). DO NOT USE HOT WATER.

Cryogenic burns that result in blistering or deeper tissue

freezing should be examined promptly by a physician.

Personal Protective Equipment

(PPE)

Nitrogen, Argon & Carbon Dioxide

Nitrogen, argon and carbon dioxide (inert gases) are simple

asphyxiates. These gases will not support or sustain life and

can produce immediate hazardous conditions through the

displacement of oxygen. Under high pressure these gases

may produce narcosis even though an adequate oxygen

supply sucient for life is present.

The following personal protective equipment is

recommended when working around cryogenic liquid:

• Safety glasses with side shields to prevent cryogenic

liquid from splashing into the eyes

• Chemical / Liquid resistant gloves to prevent cryogenic

burns on exposed hands

• Long sleeve shirts to protect the arms

• Cuess trousers worn over closed shoes

• Face shield

Safety

6

Safety — CO2 Specic

Product Manual - Orca™ CO2 Series MicroBulk Delivery System

General

The Orca CO2 Series Tank consists of an inner pressure

vessel encased within an outer carbon steel vacuum shell.

The container operates under low-to-medium pressure.

Safety relief devices are used to protect the pressure vessel

and vacuum casing, sized and selected in accordance with

ASME standards. They include a dual relieve valve system

to protect the pressure vessel, and a lift plate to protect

the vacuum casing (outer vessel). The Orca CO2 Series

is designed and engineered for safe, reliable operations

and are durable enough to provide many years of troublefree operation. Strict compliance with proper safety and

handling practices is necessary when using an Orca CO2. We

recommend that all our customers re-emphasize safety and

safe handling practices to all their employees and customers.

While every possible safety feature has been designed into

the unit and safe operations are anticipated, it is essential that

every user of the Orca CO2 carefully reads all WARNINGS

and CAUTIONS listed and enumerated in this safety section

and contained in the manual itself. Also read the information

provided in the safety bulletins for Carbon Dioxide gas.

Periodic review of this safety summary is recommended.

Warning! Carbon Dioxide vapors in air

may dilute the concentration of

oxygen necessary to support or

sustain life. Exposure to such

an oxygen decient atmosphere

can lead to unconsciousness and

serious injury, including death.

Warning! Before removing any parts or

loosening of ttings empty the

cryogenic container of liquid

contents and release any vapor

pressure in a safe manner.

External valves and ttings can

become extremely cold and may

cause painful burns to personnel

unless properly protected.

Personnel must wear protective

gloves and eye protection

whenever removing parts or

loosening ttings. Failure to do

so may result in personal injury

due to the extreme cold and tank

pressure.

Warning! Accidental contact of liquid or

solid CO2 with the skin or eyes

may cause a freezing injury

similar to a burn. Handle liquid so

that it will not splash or spill.

Protect your eyes and cover skin

where the possibility of contact

with liquid CO2 cold pipe and

cold equipment, or cold gas

exists. Safety goggles or a face

shield should be worn if liquid

ejection or splashing may occur

or if cold gas may issue

forcefully from equipment. Clean,

insulated gloves that can easily

be removed and long sleeves are

recommended for arm protection.

Cuess trousers should be worn

over the shoes to shed spilled

liquid.

Caution! Do not use oxygen equipment

that is marked “For Oxygen Use”

in CO2 service. Failure to comply

with these instructions may

result in serious damage to the

container.

Carbon dioxide

Carbon dioxide is a compound formed by the combination

of carbon and oxygen atoms in a 1:2 ratio expressed by the

chemical symbol CO2. The weight percentages of carbon and

oxygen are 27.3% and 72.7%, respectively.

Carbon dioxide is a gas at normal atmospheric temperature

and pressure. It is colorless and somewhat pungent, although

essentially odorless and is about 1.5 times more dense than

air.

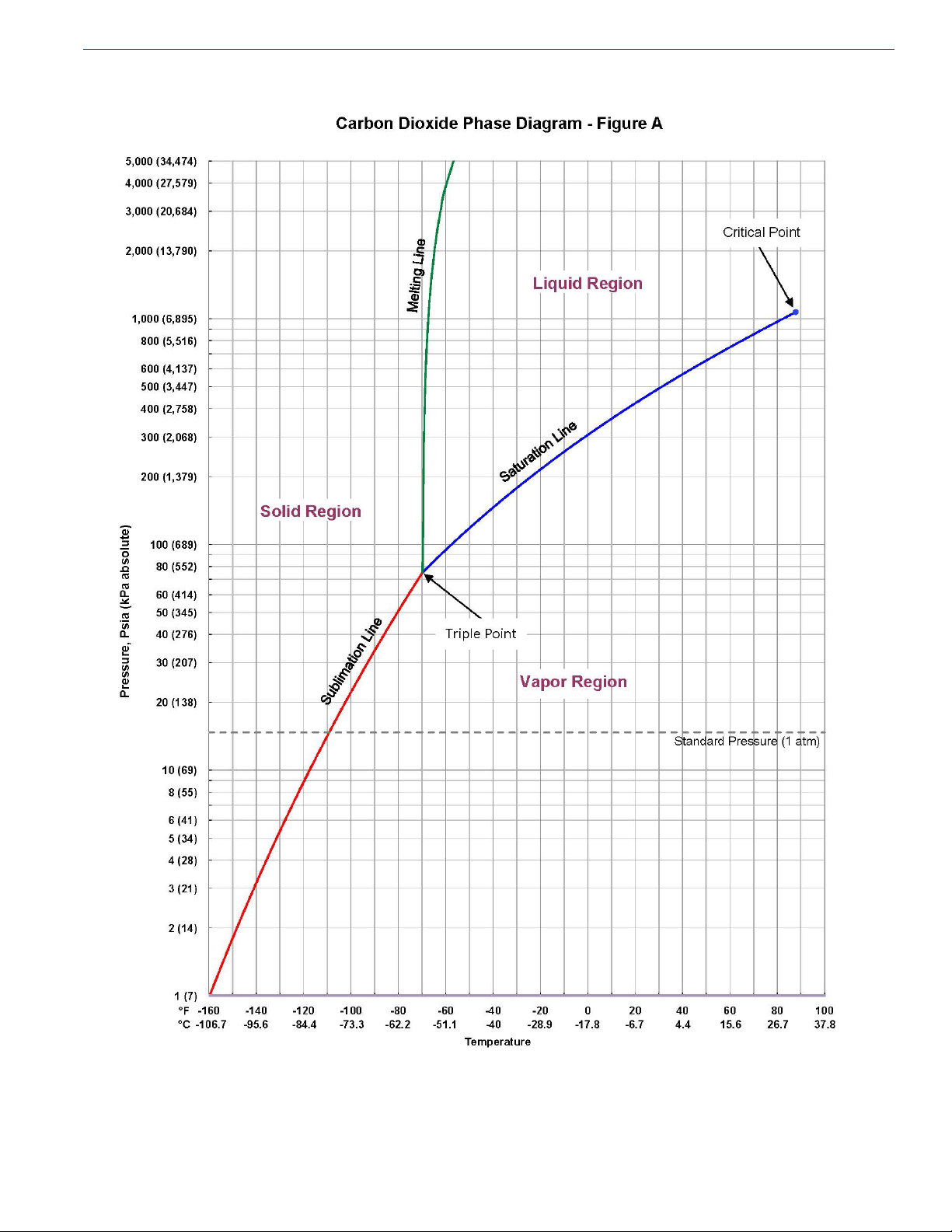

Depending on the temperature and pressure to which it

is subjected, carbon dioxide may exist in the form of a

solid, liquid or gas. At a temperature of 69.9°F (56.6°C)

and a pressure of 60.4 psig (417 kPa), CO2 can exist

simultaneously in all three phases. This condition is known

as the triple point. The phase diagram for CO2 is shown in

Figure A.

Product Manual - Orca™ CO2 Series MicroBulk Delivery System

Safety

7

Safety Product Manual - Orca™ CO2 Series MicroBulk Delivery System

8

Product Manual - Orca™ CO2 Series MicroBulk Delivery System

Introduction

9

Theory of Operation

Although the Orca CO2 Series system can have pressure

or pump delivery options, all units have the same general

functional operating characteristics. They have the ability to

be lled with liquid CO2 and deliver that product to the end

customer safely and eciently.

Terminology of Cryogenics

Cryogenic

A product retaining a temperature of -238°F (-150°C) or

colder. Orca delivery systems maintain gases eciently in a

cryogenic liquid state. Gases can be most eciently stored

as liquids. Gases may be liqueed by compression or cooling

them until they liquefy. In order to be maintained in a liquid

state, each gas must be kept at or below their respective

boiling temperatures.

Though liquid CO2 is very cold, it cannot exist below

-69.9°F. While it is technically not a cryogen, it is to be

handled as such.

Liquid density, temperature, and equilibrium pressure change

with the saturation condition of the liquid. Saturation can

also be described as an energy state. Liquid molecules at a

higher energy state (warmer) take up more space, which is

often referred to as liquid growth.

Equilibrium

In a closed vessel the gas and liquid temperatures are the

same. If there is a temperature dierence between the gas

and liquid (with the tank closed), the gas and liquid will

change their temperatures until they are equal. In stationary

tanks, stratication can take place, creating a temperature

gradient across the liquid and vapor. However, the

temperature at the liquid-vapor interface is the same for both.

Saturation Pressure

Pressure (usually in psig) that is used to describe the current

saturation condition of a liquid and gas within a closed

container.

Cryogenic Temperatures

The Orca CO2 Series delivery systems employ nearcryogenic temperatures to store the product in its liquid

state. CO2 can exist as a liquid down to -69.9°F (60.4 psig

saturation). Below that, CO2 becomes solid. CO2 is typically

transported and stored above -20°F (200 psig saturation).

States of Matter

Matter can exist as a gas, liquid, or a solid. Two phase liquid

is a liquid with gas bubbles or slugs of gas due to lack of

pressure (subcool) to maintain equilibrium. Gas and liquid

can exist at a range of temperatures.

Saturation

Dened as the point at which liquid and vapor coexist at the

same pressure and temperature.

Subcool

Raising the vapor space pressure above the current boiling

pressure of a saturated liquid is called subcool. This

contributes to the Net Positive Suction Head (NPSH) to the

pump. The higher the subcool, the less susceptible the liquid

will be to two-phase ow and pump cavitation.

Two-Phase Liquid

The mix of liquid and gas due to the pressure dropping

below the saturation pressure of the liquid caused by the

lack of proper subcool. This can damage the pump and cause

meter inaccuracy.

Cavitation

Dened as the formation of vapor bubbles in a liquid, it

manifests as partial or full loss of pump prime due to the lack

of proper subcool. The pressure of the liquid owing to the

pump has dropped below the saturation pressure. Audible

changes in the pump often are an indication of partial loss

of prime. The pump will stop pumping during full loss of

prime. Cryogenic pumps will be damaged by cavitation.

Some CO2 pumps can handle small amounts of cavitation,

however, cavitation should always be avoided.

Introduction Product Manual - Orca™ CO2 Series MicroBulk Delivery System

10

Vaporization

Changing liquid into vapor by warming the liquid for the

purpose of subcooling or for gas use. The Orca CO2 Series

delivery system uses a pressure building coil inside of a

propylene glycol/water bath heat exchanger in the cabinet.

Vapor Pressure

Pressure of the vapor space within the tank. Measured by

reading the tank pressure gauge or the Flowcom® Flow

Meter System.

Condensation

The conversion of vapors into liquid by cooling the vapors.

The Orca CO2 Series storage vessel pressure during normal

operation will rise above the saturation pressure of the

liquid. This warmer gas will condense to the colder liquid

pressure during transit. The liquid splashes into the gas space

during normal movement of the truck/trailer. The splashing

condenses the gas and drops the pressure. This is known as

"splash-down."

Depressurization Flash Losses

Dropping the vapor space pressure below the saturation

pressure of the liquid causing the liquid to boil. During

the venting of the tank below the saturation pressure of

the liquid, the liquid temperature will drop, the density

will increase, weight of the liquid will decrease, and the

saturation pressure will drop.

Entrainment

Liquid carried along with venting gas. This can occur during

violent depressurization of a tank and during the top lling

of a tank with the vent valve open. Large product losses will

occur during this event.

Liquid Growth

As liquid warms to higher saturation pressures, the volume

increases. Warm liquid is less dense. Less dense liquid takes

up more volume. Liquid growth is a safety concern if the

liquid is allowed to grow until it lls the storage vessel. This

condition is called liquid full or hydraulically full. During

this condition the pressure rises rapidly, the safeties will

relieve, and the tank will vent liquid.

Condensation and the Perma-Cyl®

MicroBulk Storage System

Pressure Drop

An example of condensation can be seen in the lling theory

of a Perma-Cyl tank. Top lling a Perma-Cyl tank without

venting is possible due to condensing warmer gas into liquid.

Pressure lost due to the ow of liquid. The faster liquid ows

through the piping circuit, the higher the pressure drop.

Stratication

Warm liquid is less dense. In a tall vertical tank this less dense liquid will nd its way to the top of the tank. Colder more

dense liquid will remain at the bottom. The layering of temperature zones from top to bottom is called stratication.

Product Manual - Orca™ CO2 Series MicroBulk Delivery System

Operations

11

Modes of Operation

Orca CO2 — First Use — 11

Fill Orca CO2 from Bulk Tank Pump — 11

Fill Orca CO2 from Onboard Pump — 12

Filling Levels - MC-338 — 13

Current Saturation of Liquid — 13

Pressure Build: Heater — 13

Pressure Build: Operation — 14

Pressure Delivery: Hose Reel — 15

Pump Delivery: Bulk Hose — 16

Receiving Tank Commission: Hose Reel — 19

Receiving Tank Commission: Bulk Hose — 19

Hydraulic Power Supply — 19

Methods to Stop Pump — 20

Primary — 20

Trailer Operation — 21

I. Orca CO2 First Fill

The Orca CO2 Series delivery system is shipped under

pressure with a CO2 atmosphere to keep out moisture. It must

be purged prior to use.

1. Remove hoses from storage tubes, set in place and open

cabinet doors.

2. Open Vapor Vent (V-5) valve and vent tank until empty.

3. Open Pump Inlet/Fill (V-1), Pressure Dispense (V-4), PB

Force Feed (V-16), PB Liquid (V-28) valves.

a. Vapor Balance/PB Isolation (V-13), Inner Vessel

Gauge (V-14), Vapor Phase Isolation (V-31), Liquid

Phase Isolation (V-32) valves should already be open,

they are only closed for service.

4. From delivery tank connect vapor balance hose to Fill

Line (DC-1) connection. Use size adapters as necessary.

5. Open Bottom Fill (V-17) supply tank vapor balance

valve to pressurize to 50 psig. Close supply tank vapor

balance valve.

Note: Cryogenicballvalveshaveaow

direction; the higher pressure must

alwaysbeontheinletsideoftheball

valve.Ifthereissignicantlyhigher

pressure on the outlet side, product WILL

leak past the ball valve.

6. Open Vapor Vent (V-5) and vent tank under 5 psig.

Close Vapor Vent.

7. Open Bottom Fill (V-17) and pressurize to 250 psig.

8. Remove the cap from Vapor Balance (DC-5)

connection. Slowly open Vapor Balance (V-44) valve

and purge for 1-2 minutes. Close Vapor Balance (V-44)

valve and replace cap.

9. Remove the cap from Dispense (DC-2) and Hose Reel

Inlet (DC-3) connections. Connect Hose Reel Inlet

(DC-3) to Dispense (DC-2) connection.

10. Slowly open Dispense (V-41), Delivery Flex Hose

(V-47), Delivery Hose (V-46), and Hose Reel Line

Drain (V-6) valves and purge for 1-2 minutes. Close

Hose Reel Line Drain (V-6) valve and leave Hose Reel

Inlet (DC-3) connected to Dispense (DC-2) connection

for hose reel delivery.

11. Slowly open Vapor Vent (V-5) valve 1-2 turns and let

purge 1-2 minutes. Close Vapor Vent (V-5) valve.

12. Crack open the compression tting on the Inner Vessel

Front of Tank (PI-3) gauge and allow leak for 1-2

minutes. Tighten tting before line frosts. Leak check

compression tting.

13. Crack open the compression ttings on the Inner

Vessel Level Indicator (LI-1) and Inner Vessel Pressure

Indicator (PI-2) manifold gauges and allow leaks for

up to 1 minute. Tighten tting before line frosts. Leak

check compression ttings.

14. Close Pump Inlet/Fill (V-1), Pressure Dispense (V-4),

PB Force Feed (V-16), PB Liquid (V-28) and Bottom

Fill (V-17) valves.

15. Open and close Fill Line Drain (V-9) valve to

depressurize connection.

16. Disconnect supply tank vapor balance hose from Fill

Line (DC-1) connection and connect to Vapor Balance

(DC-5) connection.

17. Follow the rest of the instructions in “II. & III. Fill

Orca CO2”.

Operations Product Manual - Orca™ CO2 Series MicroBulk Delivery System

12

II. Fill Orca CO2 from Bulk Tank Pump

1. Remove hoses from storage tubes, set in place and open

cabinet doors.

2. Connect supply tank vapor balance hose to Vapor

Balance (DC-5) connection and connect ll hose from

supply tank to Fill Line (DC-1) connection.

3. Open supply tank vapor balance and dispense valves.

a. This assumes supply tank is at a lower pressure than

Orca CO2. If Orca CO2 is at a higher pressure, swap

Orca CO2 and supply tank in steps 3 and 4.

4. Open and close Vapor Balance Line Drain (V-45) and

Fill Line Drain (V-9) valve to purge air from hoses.

5. Slowly open Vapor Balance (V-44) valve to equalize

pressure in tanks.

6. Open Bottom Fill (V-17) and Pump Inlet/Fill (V-1)

valve.

7. Start supply tank pump lling and monitor liquid level.

8. When liquid level is getting close to full (3/4 of net

capacity), open Vapor Balance Line Drain (V-45) valve.

a. The vapor balance line serves as the 95% full trycock.

9. When liquid exits the Vapor Balance Line Drain (V-45),

valve stop the pump and close the Bottom Fill (V-17)

valve.

10. Close the Vapor Balance Line Drain (V-45), Pump

Inlet/Fill (V-1), and Vapor Balance (V-44), supply tank

dispense & vapor balance valves.

11. Open and close the Fill Line Drain (V-9) and Vapor

Balance Line Drain (V-45) valves to drain and release

all pressure.

Warning! Fast depressurization of liquid

CO2 can cause dry ice to

form, holding in pressure that

quickly releases when the dry

ice melts. Follow proper safety

procedures for draining and

venting liquid CO2 from hoses.

III. Fill Orca CO2 from Onboard Pump

1. In order to minimize pump cavitation and surging:

a. The liquid level in the supply tank must be above the

Orca CO2 pump inlet height. As such, supply tanks

should be limited to vertical tanks or horizontal tanks

located above the Orca CO2 pump height.

b. Additional subcool in the supply tank will be

benecial.

c. If the Orca CO2 tank pressure is signicantly lower

than the supply tank, causing the supply-tank pressure

to drop below the saturation of the supply liquid when

vapor balancing, pressure in the supply tank must be

added to subcool the liquid.

2. Start truck and engage PTO, turn on cruise control and

increase engage speed to set point.

a. Engine must be at low idle speed to engage PTO.

Caution! Engage the PTO when not at

low idle speed will damage the

PTO.

b. Engine will go to set speed with one push of the

cruise control speed increase button.

Caution! Supply tank must have a

vapor balance circuit for this

functionality otherwise pump

damage may occur.

3. Remove hoses from storage tubes, set in place and open

cabinet doors.

4. From delivery tank connect vapor balance hose to Vapor

Balance (DC-5) connection and connect ll hose from

delivery tank to Fill Line (DC-1) connection.

5. Slowly open supply tank liquid valve to ll pump supply

hose with liquid.

6. Open Fill Line Drain (V-9) valve until CO2 snow comes

out and close valve. This purges air and lls the hose

with liquid.

12. Disconnect hoses from Vapor Balance (DC-5) and Line

(DC-1) connections.

13. Close cabinet doors and stow hoses. Replace all dust

caps.

7. Make sure Pump Inlet/Fill (V-1) valve is closed.

8. — If supply tank is higher pressure than Orca CO2:

a. Open Bottom Fill (V-17) valve.

b. Start pump with Switch (SW-1).

c. When supply tank pressure comes within 5 psig

of Orca CO2 tank pressure, open supply tank

OperationsProduct Manual - Orca™ CO2 Series MicroBulk Delivery System

13

vapor balance and Orca CO2 Vapor Balance

(V-44) valves.

— If Orca CO2 is higher pressure than supply tank:

a. Open supply tank vapor balance and Orca CO2

Vapor Balance (V-44) valves.

b. Open Bottom Fill (V-17) valve.

c. Start pump with Switch (SW-1).

9. Monitor for pump to catch prime.

a. Pump discharge pressure should be 70 psig higher

than tank pressure (bypass valve factory setting).

b. In recirculation mode, if pump discharge pressure

is less than 50 psig higher than Orca CO2 tank, pump

did not catch prime; stop pump and restart or open the

Pressure Dispense (V-4) valve to help catch prime.

10. Open Pressure Dispense (V-4) valve and throttle to

maintain pump discharge minimum 25 psig higher than

Orca CO2 tank pressure.

a. This keeps the pump on the pump curve, maintaining

prime.

b. Too little pressure dierential can cause pump

cavitation.

c. Too much pressure dierential creates a low ow rate.

Close Fill Line Drain (V-9) and Vapor Balance Line

Drain (V-45) valves.

Warning! Fast depressurization of liquid

CO2 can cause dry ice to form,

holding in pressure that is

quickly released when dry ice

melts. Follow proper safety

procedures for draining and

venting liquid CO2 from hoses.

17. Disconnect hoses from Vapor Balance (DC-5) and Line

(DC-1) connections.

18. Close cabinet doors and stow hoses. Replace all dust

caps.

19. Disengage engine speed control and disengage PTO.

Filling Levels - MC-338

The DOT regulations limit the ll levels based on the

tank’s pressure control valve settings. This volume assures

that when the pressure control valve discharges the tank is

not liquid full. This ll volume varies with the saturation

pressure of the liquid. DOT ll levels are based on the

weight of the liquid. Dierential pressure liquid level gauges

are an approximation of the pounds of liquid in the vessel.

The true full liquid level should be determined by the full

trycock. Both are dependent on the vessel being level.

11. Monitor liquid level and pump pressure.

12. When liquid level is getting close to full (3/4 of net

capacity), open Vapor Balance Line Drain (V-45) valve.

a. The vapor balance line serves as the 95% full trycock.

Note: DonotpressurebuildwithOrcaCO

afterllinghasstarted.IfthePBcoil

isoverrun,liquidwillenterthevapor

balance/full trycock line, giving a false

indicationthatOrcaCO2 is full.

13. When liquid exits the Vapor Balance Line Drain (V-45)

valve stop the pump (SW-1) and close the Bottom Fill

(V-17) valve.

14. Close the Pressure Dispense (V-4) valve.

15. Close the Vapor Balance Line Drain (V-45), Vapor

Balance (V-44), supply tank dispense & vapor balance

valves.

16. Open the Fill Line Drain (V-9) and Vapor Balance Line

Drain (V-45) valves to drain and release all pressure.

2

Current Saturation of Liquid

Upon arriving at a delivery site, the Orca tank pressure

indicator (PI-1) will reect the current saturation pressure.

During travel the liquid splashes condensing the warmer

vapor. This is referred to as “splash down.” During pressure

building operations the tank pressure will rise. This is not

an increase in the saturation pressure but an increase in the

subcool. During normal deliveries the saturation pressure

will remain the same as at arrival.

IV. Pressure Build: Heater

Note: Instructionsarespecictothestandard

heater and programmable controller.

Otherheatersandcontrollersmaybe

used, refer to their respective manuals.

1. Review heater and heater controller manuals for

additional operational information.

Loading...

Loading...