CHART MVE Fusion Technical Manual

MVE FUSION

Technical Manual

20994124 REV A 1

MVE FUSION

Technical Manual

PN 20994124 Rev A

1 Preface

Chart Inc.

2200 Airport Industrial Drive, Suite 500

Ball Ground, GA 30107 USA

Customer / Technical Service:

The Americas Phone: (800) 482-2473 Fax: (888) 932-2473

(770) 721-7759 (770) 721-7758

Email: techservice.usa@chart-ind.com

Asia, Australia, Pacific Rim Phone: +61 (2) 974 94333 Fax: +61 (2) 974 94666

Europe Phone: +44 (0) 1344 403100 Fax: +44 (0) 1344 429224

This manual covers the use and maintenance of MVE Fusion Freezers. READ BEFORE USING THIS EQUIPMENT.

Failure to follow the instructions in this manual can result in damage to the unit, injury to personnel, and/or poor

equipment performance. It is intended for use by trained personnel only. All service and maintenance should be

performed by an authorized MVE Distributor or Service Technician.

NOTE: All MVE Fusion models are Class I per IEC 61140, as the AC electrical supply requires a protective earth

ground. These devices are externally powered and intended for continuous operation. The models are

intended for professional use in research, while the medical device versions are intended to be used in

situations that directly support medical applications. They are not suitable for use with flammable anesthetics.

These devices have been tested to, and are in compliance with UL 61010-1:2012 Ed.3 & CSA

C22.2#61010-1:2012 Ed.3 +G1.

20994124 REV A 2

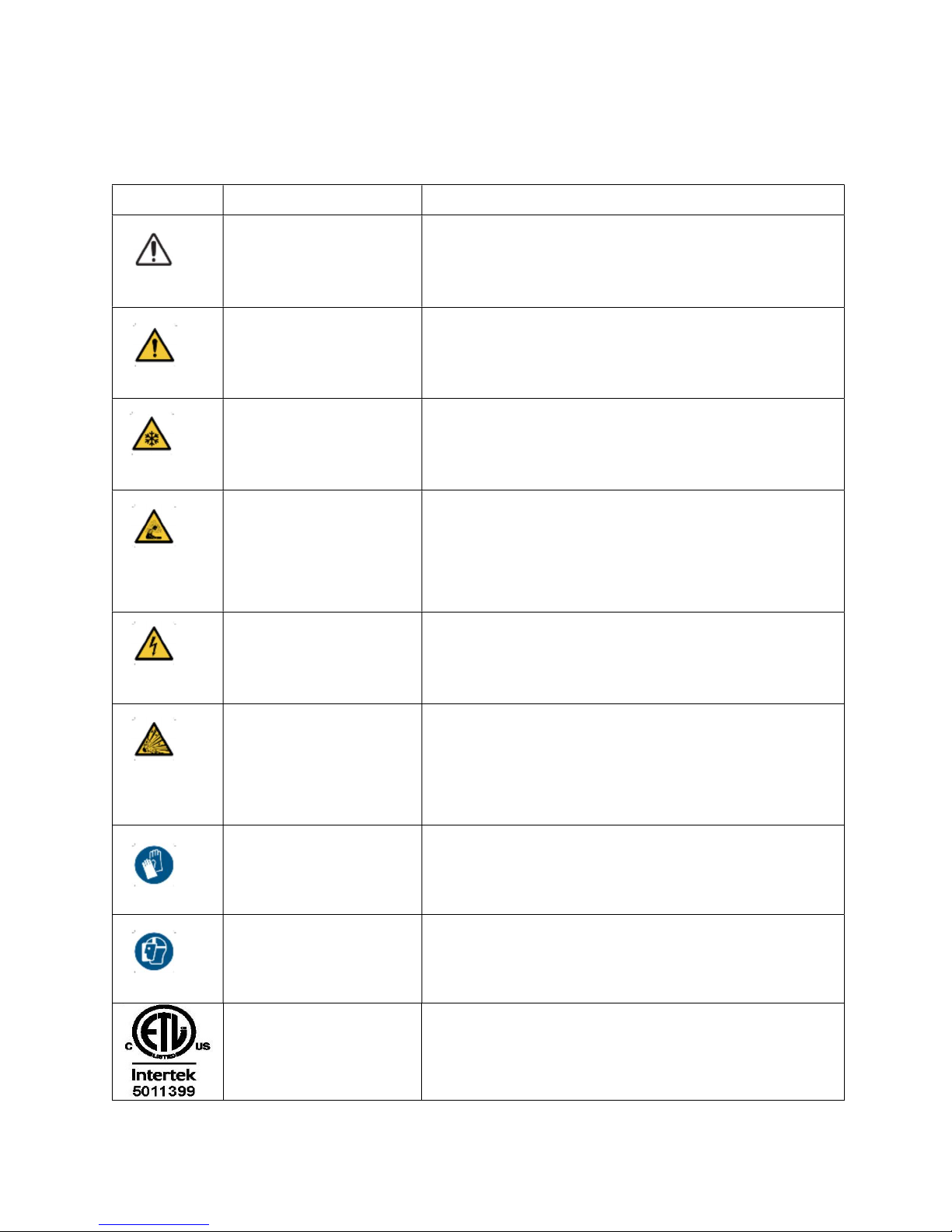

This manual includes the following symbols.

Table 1: the symbols and their descriptions

Symbol Title Description

Caution

Signifies a CAUTION of potentially hazardous

situation when operating the device that may

result in minor to moderate injury or property

damage.

Warning

Warning; Low

Temperature

Warning;

Asphyxiating

Atmosphere

Signifies a WARNING of a potentially hazardous

situation when operating the device that may

result in serious injury or property damage.

Indicates low temperature or freezing conditions.

Take care to avoid exposure to skin, eyes, and

clothing.

Indicates the potential for an oxygen-depleted

atmosphere due to nitrogen vapor. Take care to

operate device in a well-ventilated area.

Warning; Electricity Indicates a potential electrical hazard. Take care

to avoid contact with electricity.

Indicates a potential explosive hazard. The

Warning; Explosive

expansion ratio of liquid nitrogen to gas is 1:700

and can cause explosive conditions if placed into

a sealed container.

Wear Protective

Gloves

Thermal gloves must be worn during indicated

procedures.

Wear a Face Shield A face shield must be worn during indicated

procedures.

ETL Listed Mark Chart Fusion Freezer conforms to UL STD 61010-

1 and certified to CSA STD C22.2#61010-1.

20994124 REV A 3

2 Safety

READ BEFORE OPERATING THIS EQUIPMENT

General

Liquid nitrogen (LN2) is used in MVE Fusion Freezers as a refrigerant. Understanding

and following certain safety precautions is extremely important when handling LN2 and

cryogenic containers (commonly referred to as dewars).

Liquid Nitrogen Properties

Nitrogen is a colorless, odorless, tasteless gas. Gaseous nitrogen makes up about 78%

of the Earth’s atmosphere by volume. Once collected, cooled and isolated, nitrogen can

be liquefied.

Boiling Point at 1 atmosphere -195.8°C , -320.3°F , 77.4 K

Thermal Conductivity (Gas) 25.83 mW/(m·K)

Heat of Vaporization (Liquid) 198.38 kJ/kg

Liquid density at 1 atmosphere 1.782 lbs/L , 807.4 g/L , 808.6 kg/m3

Liquid Nitrogen Safety

Transferring LN2 and operating the MVE Fusion should be done in accordance with the

manufacturer/supplier instructions. It is important that all safety precautions

recommended by the manufacturer be followed.

WARNING: Do not modify this equipment without authorization

of the manufacturer.

Nitrogen vapor is a potential asphyxiant as it displaces Oxygen

(O2) in confined spaces. Rapid suffocation can occur without

warning in an Oxygen-deficient atmosphere (less than 19.5%

20994124 REV A 4

O2). Chart Cryogenic Freezers must be installed and operated

in well-ventilated areas.

DO NOT vent container in confined spaces.

DO NOT enter confined spaces where excess nitrogen gas may

be present.

If exposure has occurred move to ventilated area or fresh air. If

breathing is difficult, supplement oxygen may be required. If

not breathing, give artificial respiration. SEEK IMMEDIATE

MEDICAL ATTENTION.

Contact with liquid nitrogen or uninsulated equipment

containing nitrogen can result in cold contact burns or tissue

damage. Nitrogen vapor can cause damage to skin or eyes.

In case of frostbite, warm area with warm water not exceeding

105°F (40°C) and SEEK IMMEDIATE MEDICAL ATTENTION.

Never place LN2 in a sealed container without a pressure relief

device. The expansion ratio of liquid nitrogen to gaseous

nitrogen is 1 to 700 (1 cubic foot of liquid nitrogen becomes 700

cubic feet of gaseous nitrogen when evaporated).

The two most important safety aspects to consider when handling LN2 are adequate

ventilation and eye and skin protection. Although nitrogen gas is non-toxic, it is dangerous

in that the gas will displace oxygen in a normal breathing atmosphere. Liquid products

are of even greater threat since a small amount of liquid evaporates into a large amount

of gas. Therefore, it is imperative that cryogenic supply and storage dewars be stored

and operated in well-ventilated areas.

20994124 REV A 5

Persons transferring LN2 should make every effort to protect the eyes and skin from

accidental contact with liquid or cold vapor. Chart MVE recommends the following

protective clothing and accessories when transferring LN2 or handling hoses, valves, and

plumbing components:

Cryogenic gloves (loose fitting)

Full-face shield or chemical splash goggles

Cryogenic apron

Long sleeve shirt and cuffless pants

Closed toe shoes (no sandals)

Equipment Usage

Cryogenic containers must be operated in accordance with the manufacturer/supplier

instructions. Cryogenic dewars must be kept in a well-ventilated area protected from

weather and away from heat sources. In applications that use a modular liquid cylinder

as a source of LN2, the supply will need to be replenished at regular intervals to ensure

proper operation of the freezer.

Recommended First Aid

Every site that stores and uses LN2 should have an appropriate Material Safety Data

Sheet (MSDS) present. The MSDS may be obtained from the manufacturer/distributor.

The MSDS will specify the symptoms of overexposure and first aid to be used. Here is a

typical summary. If symptoms of asphyxia such as headache, drowsiness, dizziness,

excitation, excess salivation, vomiting, or unconsciousness are observed, remove to fresh

air. If breathing has stopped, give artificial respiration. CALL A PHSYICIAN

IMMEDIATELY.

If breathing is difficult, supplemental oxygen maybe required. If exposure to cryogenic

liquids or cold vapor occurs, restore tissue to normal, body temperature (37°C) as rapidly

as possible, and then protect the injured tissue from further damage and infection.

Rapid warming of the affected areas is best achieved by bathing it in warm water. The

temperature of the water used should not exceed 40°C. Under no circumstances should

the frozen part be rubbed either before or after warming. If the eyes are involved, flush

them thoroughly with warm water for at least 15 minutes. In case of massive exposure,

remove clothing while showering with warm water. The patient should not drink alcohol

or smoke. CALL A PHYSICIAN IMMEDIATELY.

20994124 REV A 6

3 System Components and Function

3.1 System Overview

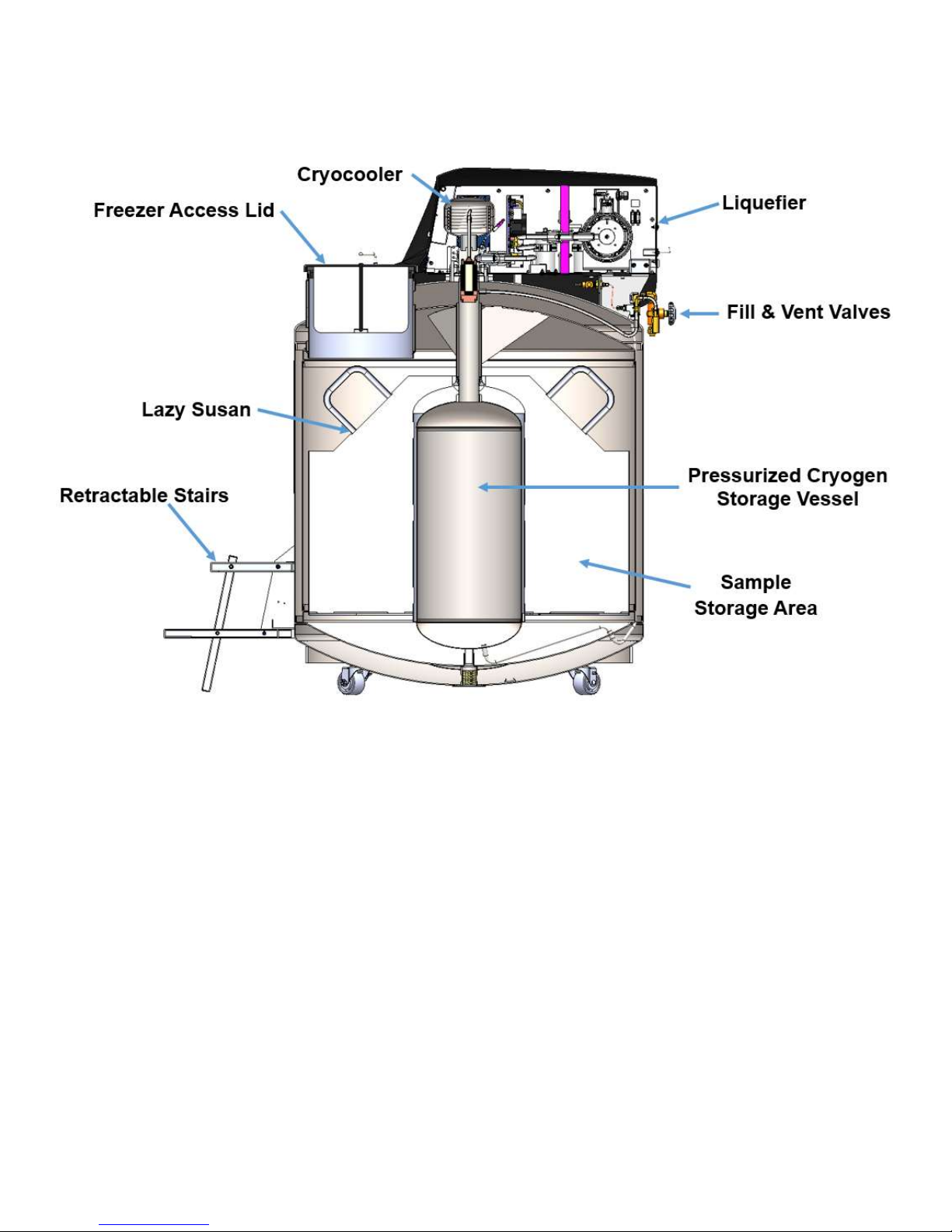

The MVE Fusion system consists of several key components identified in Figures 1 and

2: dewar, Pressure Vessel, Liquefier, Shroud, Graphical User Interface (GUI), and

Retractable Stairs.

Figure 1: MVE FUSION FREEZER

20994124 REV A 7

Figure 2: Cross Section of the MVE Fusion Freezer

20994124 REV A 8

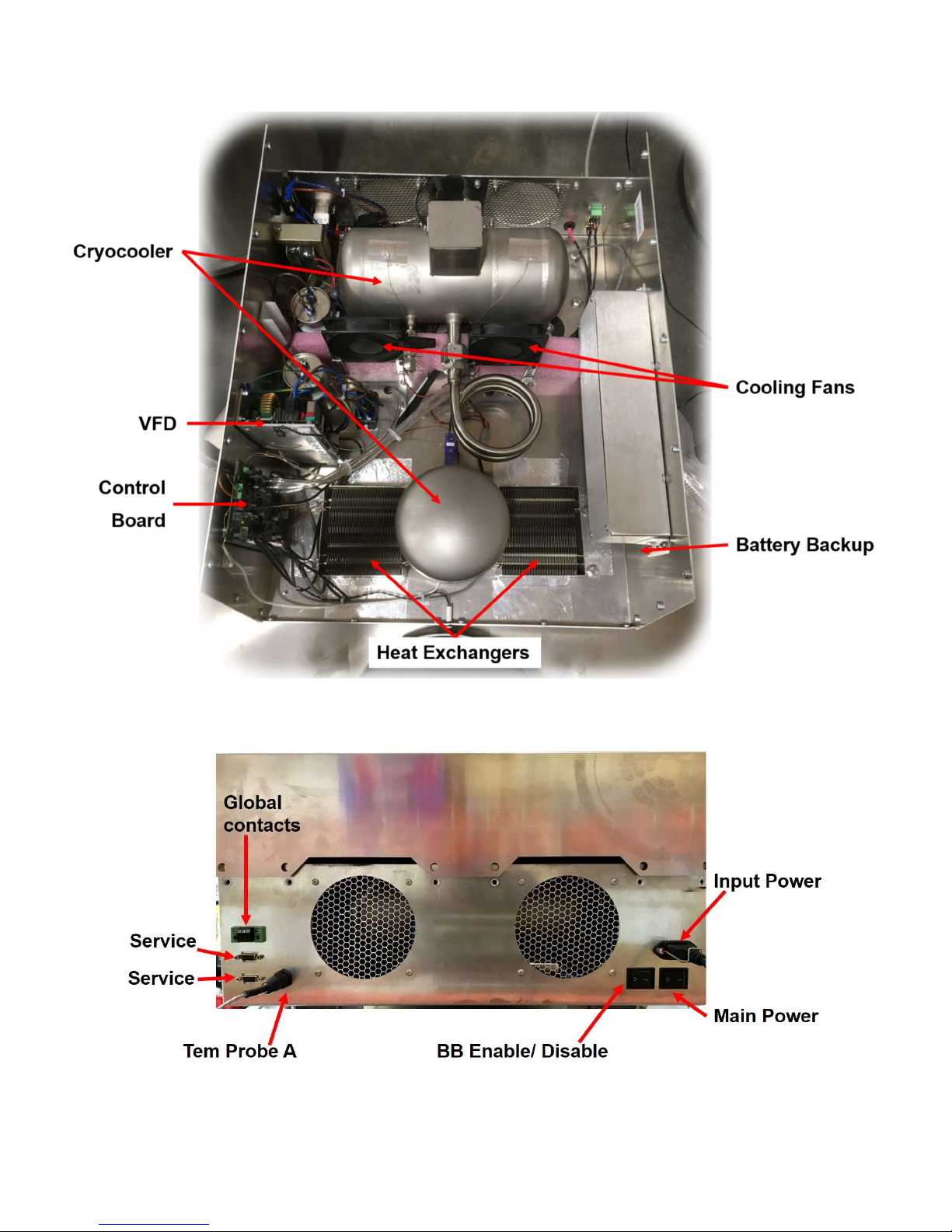

3.2 Liquefier

The Liquefier contains the cryocooler and other support / interface control systems

required to operate the MVE Fusion Freezer. Replacement of the liquefier should only be

performed by a representative from Chart Inc. or trained authorized personnel.

The Liquefier consists of the following major components and features:

Cryocooler – This is the heart of the system that maintains the liquid nitrogen

stored within the systems pressure vessel. See page 12 for more details pertaining

to the Fusions cryocooler.

Graphical User Interface (GUI) – This is a touch-screen interface with customized

software intuitively designed for monitoring the MVE Freezer. The 155mm x 87mm

backlit LED display provides system security through password protected

admission. The main screen allows quick access to and displays key parameters

such as the internal freezer temperature, the cryogen liquid level, cryocooler motor

temperatures, the cryogen pressure and system alarms.

Battery Backup – A 12V, 9.0Ah, sealed lead acid battery allows for monitoring of

the freezer parameters and alarms for a minimum of 24 hours after a power loss.

Main Control Board – An advanced printed circuited board (PCB) with control

logic and memory for storage of settings, parameters and historical events.

Variable Frequency Drive (VFD) – The cryocooler is powered by this variable

frequency, variable voltage power supply. Control of the VFD is accomplished by

signals sent from the main PCB based on the freezer status. Voltage to the

cryocooler is modulated to maintain a constant freezer temperature and optimize

power consumption.

20994124 REV A 9

Cooling Fans – Two 12 VDC, 150CFM fans with “CPU” style heat exchangers

reject heat from the cryocooler and electrical components within the liquefier to the

ambient environment.

Alarms – In addition to the visual alarms displayed on the GUI, an alarm speaker

is provided that sounds when any preset threshold (freezer temperature, low

battery, motor temperature, VFD temperature, gas pressure, etc.) is exceeded or

if the freezer lid has been removed for more than 5 minutes.

Serial Communication – Two full-duplex RS-232 communication ports are

provided to monitor the VFD and control system and modify parameters. These

are for use by trained service technicians or other qualified personnel only.

USB port – A standard USB interface allows easy access to download the event

historical logs.

Global Alarm Contacts – A normally open and normally closed set of dry contacts

are provided for monitoring alarm conditions.

Figure 3: Front Perspective of Liquefier with the Cowling off

20994124 REV A 10

Figure 4: Internal Components of Liquefier

Figure 5 : Liquefier back panel / Physical connections (Cowling off)

20994124 REV A 11

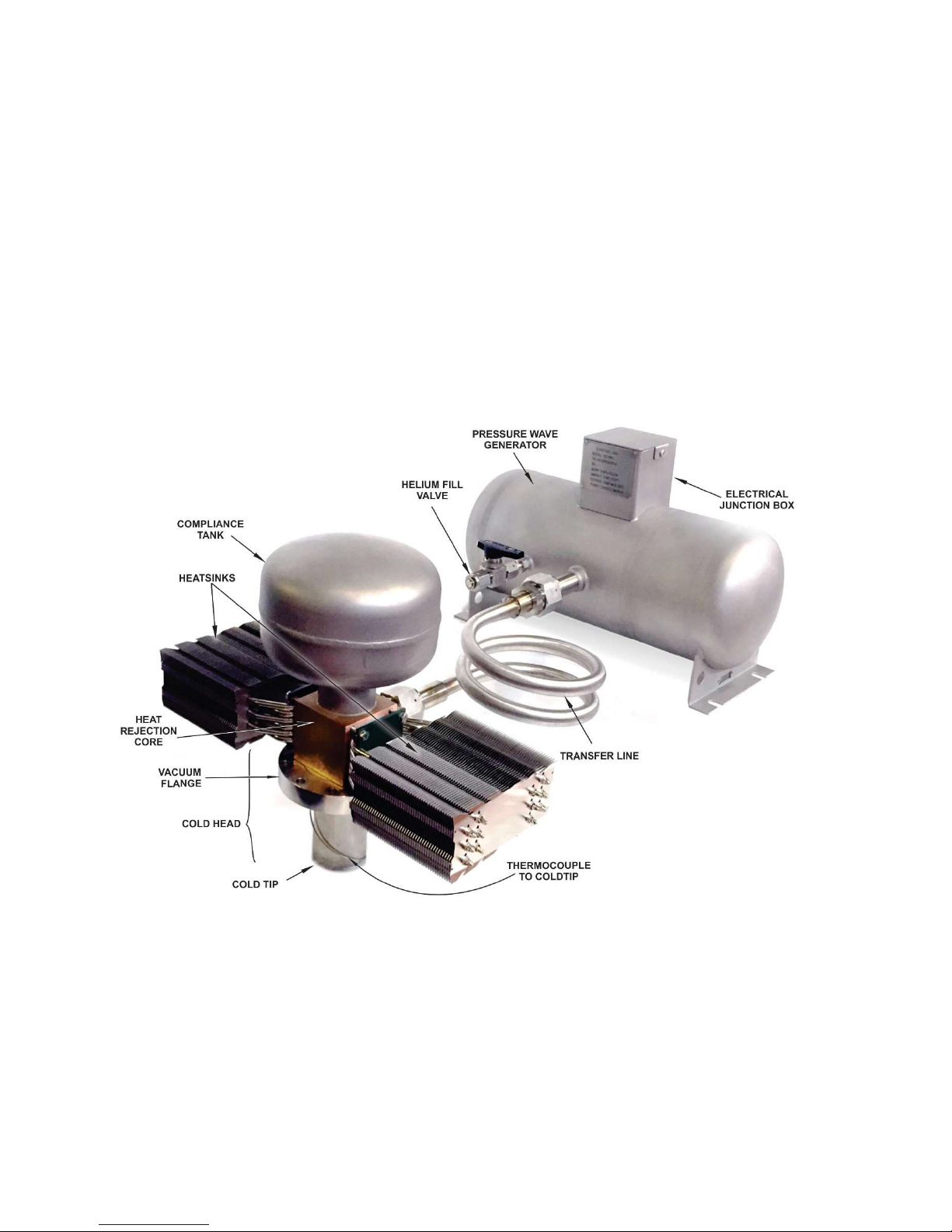

3.3 Cryocooler

The cryogenic cooler is the refrigeration device for the MVE Fusion. It is mounted on top

of the MVE Fusion dewar. It provides cryogenic cooling by mechanically compressing and

acoustically expanding the helium gas in a Stirling cycle. The base cryocooler unit

consists of a pressure wave generator (PWG) and a coaxial Stirling (pulse tube) coldhead

(see Figure 6). As liquid nitrogen boils off it rises to the top of the pressurized inner LN2

storage tank. There heat is removed from the gaseous nitrogen by the cryocooler and

converted back into a liquid. This highly efficient design eliminates the need for a constant

supply of LN2 and allows for autonomous operation. Figure 6 shows a schematic

representation of the cryocooler.

Figure 6: Cryocooler

20994124 REV A 12

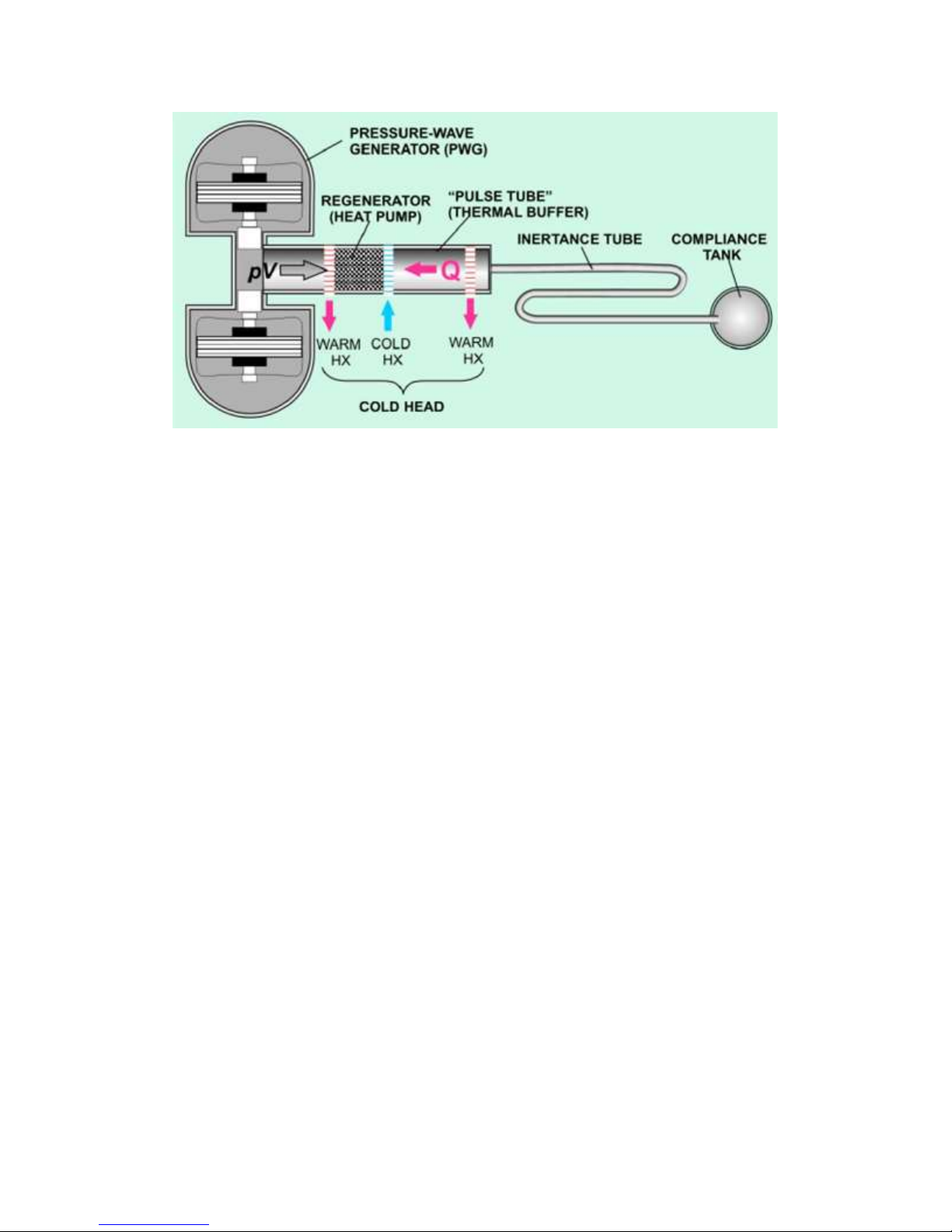

Figure 7: Schematic cross section of Cryocooler

The cryocooler system operates as follows (refer to Figure 7):

1. Helium gas is cyclically compressed and expanded relative to the mean pressure

by the pistons of the PWG.

2. With each forward stroke of the pistons helium gas moves through the first warm

heat exchanger (the “aftercooler”) where heat is removed. Helium is next forced

through the regenerator, which precools the gas before it reaches the cold heat

exchanger (see Error! Reference source not found.).

3. As the gas moves toward the cold heat exchanger, gas in the acoustic network

(thermal buffer tube, warm heat exchanger, and reservoir) also moves in the same

direction. Even as the driven gas stops advancing, when the pistons reach their

upper limits, the helium gas continues moving in the inertance tube, driven by its

own inertia. This acts like a virtual piston, moving away from the cold exchanger,

expanding the cold gas. As the cold gas expands, it gathers heat from the

surroundings (the area or substance to be cooled).

20994124 REV A 13

4. The pistons begin withdrawing, and helium then moves back through the

regenerator and aftercooler. Still delayed by its inertia, the gas in the inertance

tube follows, and the cycle begins again.

The heat exchangers and pressure wave generator are cooled by the fans which blow air

over the motor enclosure and main heat rejection core.

3.4 Dewar

Chart is the leading global manufacturer of vacuum insulated biological storage freezers.

Standard Chart MVE freezers use liquid nitrogen as the cooling medium; it boils off as

heat leaks to the outside, which maintains the internal temperature, but requires a

constant replenishing of liquid. This limits installations to areas where LN2 is readily

available and easily transported to each freezer location. The MVE Fusion leverages

Chart’s vast experience and industry leading technology by incorporating these already

proven freezers into a freezer that runs solely on electricity. The only difference is that an

internal cryogen storage pressure vessel is added along with a cryocooler to maintain the

cryogen in a liquid state. The MVE dewar consists of the following major components and

features:

Stainless Steel Construction – All storage and pressure vessel components are

constructed of welded stainless-steel offering decades of service life.

Vacuum Insulation – The annular space around the sample storage compartment

is vacuum insulated to virtually eliminated conduction and convection losses.

Retractable Stairs – Offer safe, easy access to the freezer storage area.

Access Lid with Cork – Light, easily removable lid with magnetic switch that

indicates when the lid has been removed or improperly placed.

Storage Space – The MVE Fusion is designed with a rotating tray, lazy Susan,

which allows access to all samples without difficulty.

20994124 REV A 14

Temperature Monitoring – An RTD is provided to monitor the upper storage

space temperature and control the freezer operation.

Cryogen Storage Pressure Vessel – 50-liter liquid nitrogen storage tank

designed to ASME standards with safety pressure relief device and muffler.

Liquid Level Sensing – Differential pressure sensors continuously monitor the

liquid nitrogen level.

Fill and Vent Ports – Easily accessible valves are provided for initial filling and

venting of liquid nitrogen (see Figure 9).

Figure 8: Retractable Stairs, Removable Lid and lazy Susan within the Storage

Space

20994124 REV A 15

Figure 9: Left to Right: Vent (Overfill) Valve, Relief Valve, and Fill Valve

20994124 REV A 16

Loading...

Loading...