CHART MVE Cryoshipper 2000, MVE Cryomoover, MVE Cryoshipper MINI, MVE SC 4/3V, MVE Mini-Moover Operating Manual

...

Operating Manual

0029

for

MVE Vapor Shippers

Table of Contents Page

English 2-10

English (SI Version) 11-19

Deutsch 20-27

Espa

ñol

Italiano 36-43

Français 44-52

Português 53-61

Certificate of Conformance 63

28-35

CHART INC.

2200 Airport Industrial Dr., Ste 500

Ball Ground, GA 30107

U.S.A

www.chartbiomed.com

Chart BioMedical Ltd.

Unit 6 – Ashville Way

Wokingham RG41 2PL

United Kingdom

Chart Australia Pty Ltd.

ABN 21 075 909 410

Sydney Business & Technology Centre

Unit 43 / 2 Railway Parade

Lidcombe, NSW 2141, Australia

Medical Product Services

Borngasse 20

35619 Braunfels, Germany

Ref 11562640 Rev U11/18

0459

MVE Vapor Shippers are ideally suited for the transportation of cryobiological materials. The liquid

nitrogen is retained in a hydrophobic absorbent material and the cold nitrogen vapors maintain the

Cryo Storage Area between -150°C and -190°C. The absorbent retains the liquid nitrogen and

prevents accidental spills.

Liquid nitrogen is classified as “Dangerous Goods” by the Department of Transportation (DOT).

At least three regulatory agencies publish dangerous goods regulations:

DOT - Department of Transportation

IATA - International Air Transportation Association

ICAO - International Civil Aviation Organization

If used outside of the USA, please consult your applicable regulatory agencies. Liquid nitrogen is

classified under the name “Nitrogen, refrigerated liquid” and has a UN 1977 code number. The name

classification and UN Code Number must be indicated on the shipping carton in addition to a “Gas

nonflammable” label. Packing and labeling requirements can be obtained from the above organizations.

Also, contact your carrier for any variances in the rules as they may apply specifically to that company

and/or the ultimate destination of the shipment.

Be aware that the regulations undergo periodic revisions. If you need current information prior to

the shipping of your cryobiological specimen, please contact your air carrier for the most recent

regulations. It is your responsibility to provide correct information, such as warning or caution, on

shipping package.

GENERAL DESCRIPTION

The cryopreservation vessel is a double-wall, vacuum-insulated vessel made of aluminum with

a fiberglass composite neck, providing the highest efficiency possible in cryogenic temperature

preservation. The liquid nitrogen absorbent is a hydrophobic blanket consisting of synthetic

amorphous silica and glass fiber. This absorbent is non-hazardous. Use the vessel for liquid nitrogen

only. Liquid oxygen is not compatible with this unit and must not be stored inside the vessel.

The MVE Vapor Shipper is designed with consideration for safety, durability and performance.

However, mishandling of the equipment, including transport or shipping units in an orientation

other than upright vertical, may damage the product. In addition, if a vessel experiences a drop,

hit, or blow, it can suffer immediate or premature vacuum failure.

Upon receipt of the product, examine both the vessel and packaging

for any evidence of damage during shipping. Contact the carrier

within the carrier’s guidelines if there are signs of shipping damage.

Some MVE shipping boxes carry the Transit Tested ISTA-3A

certificate stamp, shown to the right, which is helpful when making a

claim against the carrier, should there be damage from shipping.

Watch after the first fill for any signs of vacuum loss, such as

excessive frost or sweating on the outside jacket. Some frost near

the top just after filling is normal. It is normal for some white dust or powder-like residue from the

absorbent to accumulate at the bottom of the unit due to shipping vibrations. If desired, the owner

may wipe or vacuum it out.

This high quality vacuum insulated unit is compatible with the divergent temperature extremes and

broad applications of cryobiology. The life expectancy of this product is five (5) years.

Products bearing the CE marking as shown comply with the requirements of Directive

93/42/EEC concerning medical devices in EU.

SAFETY

WARNING: Liquid nitrogen is extremely cold. To avoid injury by frostbite, use extreme care

whenever handling liquid nitrogen, liquid nitrogen storage or transfer vessels, or any objects

which have come in contact with liquid nitrogen.

• Leave no area of skin exposed.

• Always wear proper safety attire over clothing: face shield, cryogenic gloves, and

cryogenic apron.

• Use extreme care to prevent spilling and splashing liquid nitrogen during transfer.

• Always keep vessel in upright position. Do not tilt, or lay the vessel on side.

• Immediately remove any clothing or safety attire on which liquid nitrogen has spilled.

• Get immediate medical attention for any frostbite injuries due to liquid nitrogen.

WARNING: The venting of nitrogen vapors may deplete oxygen in the air, possibly leading to

asphyxiation or even death. Do not store or use container in areas that are small and enclosed

or have poor ventilation.

WARNING: Do not tightly seal liquid nitrogen container or prevent nitrogen gas from escaping.

Also, excessive humidity levels or exposure to rainfall could result in freezing of the cork/cover,

and possible explosion.

WARNING: Never use a hollow tube to measure liquid nitrogen level. This could lead to thermal

injury.

CAUTION: Handle the cryopreservation vessel with care.

• Never overfill vessels with liquid nitrogen. Liquid nitrogen should always be below the

bottom of the neck tube. Overfilling the tank may cause immediate or premature

vacuum failure to occur.

• Never ship Vapor Shipper on its side or upside down. This can lead to vacuum failure

and loss of product inside the Vapor Shipper.

• Do not scratch neck tube area. Remove and insert inventories carefully. Scratches can

cause premature vacuum failure.

• Tampering with or removing the vacuum port will destroy vacuum and void warranty.

• Never drop, hit, or blow the vessel.

• Never spill liquid nitrogen on or near vacuum port.

• Never leave the vessel in an outdoor condition.

• Inspect vessel for any damage before and after each shipment.

• Keep the bottom of vessel clean and away from chemicals, fertilizers, soil, and moisture.

• All performance data published for these products is based on static conditions only.

Actual performance will vary upon the nature of use. Manipulation of inventories and

or accessories along with vibration will decrease the working duration/Hold time of

these products.

OPERATION

CAUTION: Consider the value of the inventory when shipping and determine if the inventory

should be split between multiple containers to reduce the risk of losing valuable and/or

irreplaceable products should the container become delayed, lost, or damaged in shipping.

CAUTION: Do not use dewars for longterm storage of human biological contents. Failure to follow

Chart’s best operating practices, as set forth in the operating manual, can result in loss of contents.

32

Liquid nitrogen is extremely cold. Make sure to wear proper gear before operation. Avoid spilling

liquid nitrogen over the vacuum port as this can shrink the seal and allow air to leak into the vacuum

space causing premature vacuum failure. To ensure maximum performance from your MVE Vapor

Shipper simply follow the listed steps prior to shipping to final destination:

1. Open container that the Vapor Shipper is in, open the lid, and remove cork/cover/accessories.

Lift cork/cover straight up (do not twist).

2. Fill unit to bottom of neck tube.

a. If you are working with a warm vessel, it is MVE’s recommendation to slowly add small

amount of liquid to the bottom of unit, and allow it to sit until the liquid nitrogen stops

rapidly boiling to cool the unit. Position the vacuum port facing away from the operator or

other personnel.

b. To obtain the optimized Hold time. You will need to refill the unit to bottom of the neck

more than once until the liquid level is steady.

c. Follow established safety practices and procedures for transferring LN2.

d. Fill the vessel with a funnel or transfer line when possible. Transfer using LN2 hose with

phase separator or pouring container using a funnel.

e. If you are filling your vessel from a pressurized source, make sure it is a low pressure

source (22 psi or below).

3. Replace cork/cover and allow unit to reach thermal equilibrium /charge for minimal 24 hours.

a. Refer to

UTILIZING THE QWICK CHARGE TECHNOLOGY section for expedited charge solution.

b. If there is excessive frost or sweating on the outside vessel after the first few hours, it

would indicate either a weak or no vacuum. Examine the unit carefully.

4. Pour off excess liquid just prior to shipment.

a. If necessary to completely dispense all liquid nitrogen, invert the unit until liquid nitrogen

dripping has stopped, set the unit upright and view if any liquid nitrogen pools at the

bottom of the unit. If liquid nitrogen starts to pool, invert the unit again. Repeat as

necessary until all liquid nitrogen is removed from the unit, in accordance with ICAO

Packaging Instruction 202.

5. Weigh unit and record.

a. To ensure a proper charging process is conducted, obtain both empty and charged

weights. Verify the differential between empty and charged weights is close to data in

Table 1. The differential can be calculated by using Equation 1.

Differential = Charged Weight — Empty Weight Equation 1

b. Please note that the Charged Weight is not an indication of unit performance.

6. Place inventories into unit, replace cork/cover and lid.

UTILIZING THE QWICK CHARGE TECHNOLOGY

Only units bearing QWICK charge label is equipped with QWICK charge technology

. To utilize the

QWick Charge Technology and charge in under 2 hours, do not allow unit to warm up above -150°C

between shipments. If the inside of the unit is above -150°C, it will need to be charged again for a

minimal of 24 hours to allow the unit to reach thermal equilibrium.

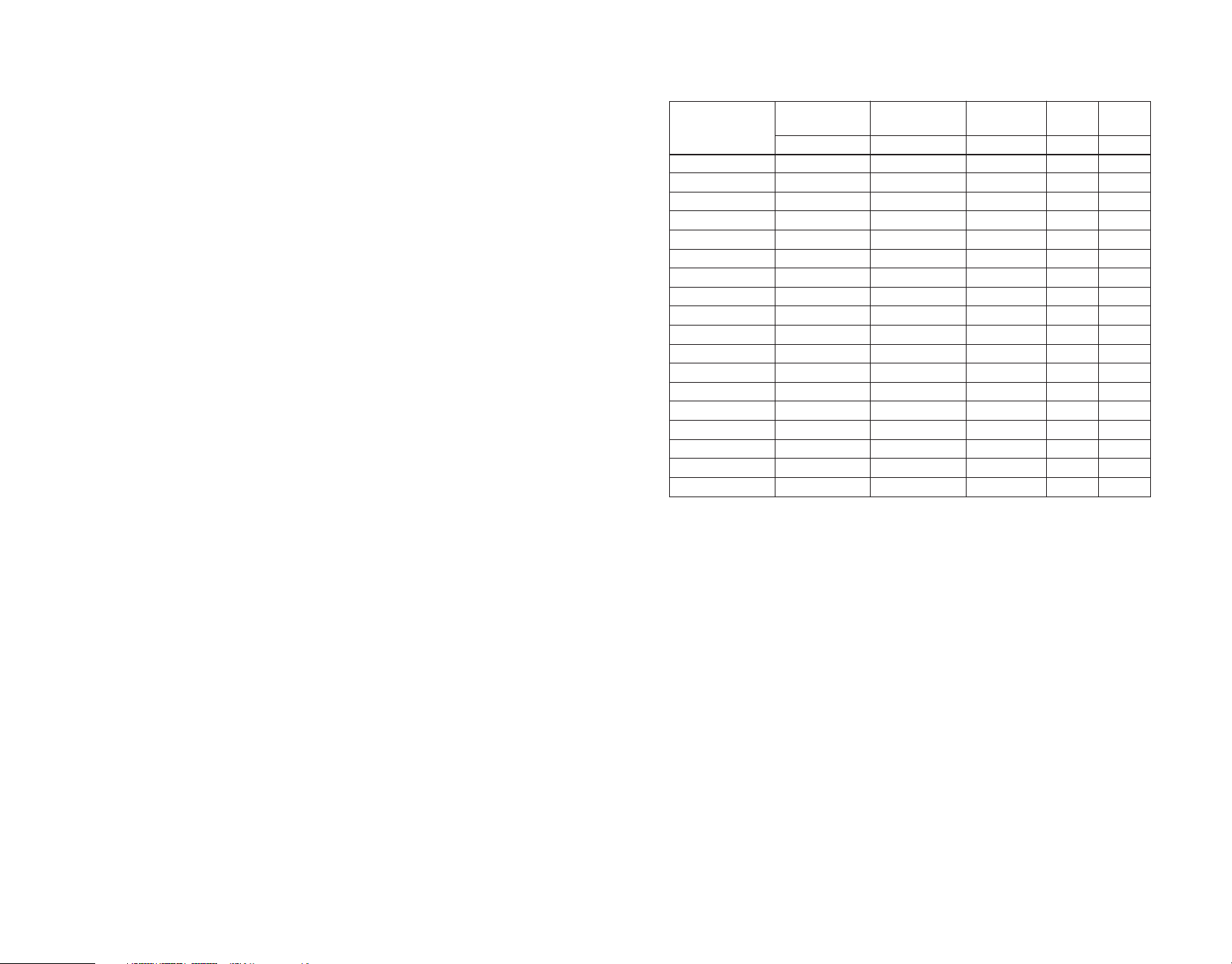

Use the following weight table as a general guide to determine if your Vapor Shipper is fully charged.

Values are for reference only. Weights can vary depending on the charging process. Refer to the

Static hold time and Normal Evaporation Rate (NER) specifications listed in the table below. Factors

such as age of unit, quantity of inventory, ambient environment, shipping condition, and use of

accessories, etc. can negatively affect unit Hold time and NER. If you do not find your model listed

here, refer to the MVE Cryopreservation Catalog or contact Customer or Technical Service for

assistance.

Table 1 Reference Unit Performance by Model

Empty Charged Static

Model

SC 2/1V 6 (2.7) 8.3 (3.7) 8 0.19 N

SC 4/2V 10.3 (4.6) 16.7 (7.5) 13 0.26 Y

SC 4/3V 11.5 (5.2) 18.5 (8.3) 21 0.20 Y

SC 20/12V 25.3 (11.4) 40.2 (18.2) 60 0.09 N

XC 30/12V 44 (20) 76 (34) 82 0.22 N

Cryoshipper 25.7 (11.6) 38.2 (17.3) 10 0.85 Y

Cryoshipper XC/IATA 32.3 (14.6) 48.9 (22.1) 14 0.70 Y

Cryoshipper 2000 65 (29.5) 95 (43.1) 15 0.79 N

Cryomoover 31 (14) 40.4 (18.3) 12 0.35 N

Cryoshipper MINI* * * * * * 0.84 N

Mini-Moover 8.5 (3.8) 13.4 (6.0) 14 0.20 N

XC 20/3V 25.1 (11.3) 36 (16.3) 16 0.35 N

Doble 11 14.3 (6.4) 19.5 (8.8) 17 0.17 N

Doble 22** 23.8 (10.7) 35 (15.8) 18 0.35 N

Doble 20 23 (10.4) 30.3 (13.7) 21 0.10 N

Doble 28 32.2 (14.6) 46.8 (21.2) 21 0.35 N

Doble 34 34.5 (15.8) 47.9 (21.7) 21 0.20 N

Doble 47 41 (18.5) 54.6 (24.7) 21 0.40 N

Note: The use of a datalogger adds approximately 0.12L/day NER

* Pending on actual configuration

** Center canister required

*** 5% variance in actual weight is typical

Weight Weight Hold Time

lbs (kg) lbs (kg) Days L/Day certified

NER

ISTA-3A

SHIPPING INSTRUCTIONS

MVE/Chart recommends the plastic protective shipping containers (PPSC) be used to help keep the

Vapor Shipper in the upright position and reduce the risk of damage to your valuable asset.

DO NOT

SHIP UNIT ON ITS SIDE OR UPSIDE DOWN. SHIPPING THE UNIT IN ANY POSITION OTHER THAN

UPRIGHT COULD REDUCE THE HOLD TIME TO LESS THAN 10% OF STATIC HOLD TIME, AND CAUSE

PERMANENT DAMAGE TO THE UNIT AND LOSS OF INVENTORY. This could also void warranty.

WARNING: If you ship the Vapor Shipper in a cardboard box, it will ship on its side, as common

carriers instruct their employees in sorting facilities to place boxes on conveyors with the most

stable side down.

Charge the unit by following all steps listed in OPERATION section before inserting into the PPSC. To

avoid damage to either the Vapor Shipper or PPSC never fill or dump the unit when inside the PPSC.

Fasten all locking latches tightly before shipping. You can also utilize cable tie, tamper proof security

seal, or any other appropriate secondary locking mechanism around existing locking latches to avoid

your asset from being tampered during shipment. Before putting PPSC into service, inspect it for any

54

damage that may jeopardize its functionality. Replace any aged/worn-out impact absorption foam

cushion inside the PPSC or any defective hardware. Remove badly damaged PPSCs from service.

Contact Customer or Technical Service for assistance in selecting the proper service parts.

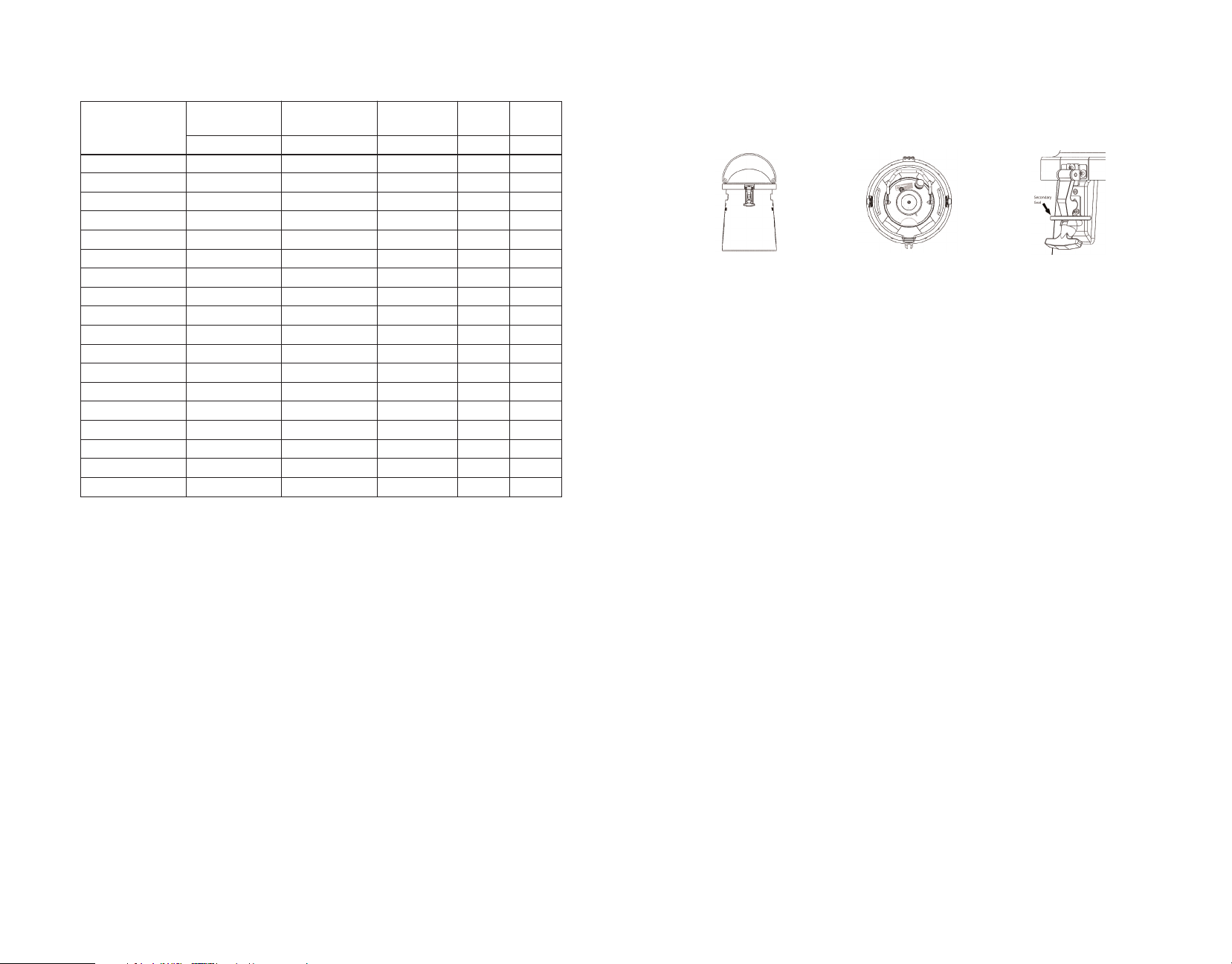

Typical PPSC shown. The

shape of the PPSC helps

keep the product upright

during shipment.

Shock absorbing foam in the

PPSC helps prevent damage to

the dewar. Illustration shows top

view of the tank in the PPSC.

The rubber latch design allows

the use of a zip tie, vet seal,

safety seal, etc. to ensure

integrity of product shipped.

Select the appropriate shipping method based on the value of contents. Common carriers handle

packages very roughly with the most stable side of the packaging down, and should be used for

low-value product shipment only. Contact carriers for shipment methods for their recommendation

on transporting valuable and/or irreplaceable contents.

MVE Vapor Shippers were primarily designed as vapor shipping containers, however, they can also

be used for immersion of samples. It is imperative that all liquid nitrogen be removed so the unit

remains classified as a Vapor Shipper for transport. If liquid nitrogen is visible in the bottom of the

inner, it then becomes a liquid shipper and the exception status is void. The liquid inside is now

classified as hazardous material.

GENERAL CLEANING

Do not use any petroleum based cleaning solution.

Inside of the vessel:

Any cleaning solution that does not react with aluminum, stainless steel, or G10 composite can be used

in the sanitation process of a MVE Vapor Shipper. In most cases, any household detergent or mild soap

solution is suitable. Other cleaners and disinfectants that can be used safely include hydrogen peroxide,

chlorine/water mixture, and denatured alcohol. The generally accepted practice of using 10% chlorine

bleach with 90% water solution holds as the best method for decontamination. It is recommended that

the unit is filled to its full capacity with the cleaning solution mixture, agitated, and then thoroughly

rinsed. It is important that all surfaces being sanitized are thoroughly rinsed and that all cleaner solution

residues are removed after cleaning. Allow the unit to dry completely before putting into service. It is

suggested that the unit is inverted to drain and dry completely.

Outside of the vessel:

Use light dampened cloth of mild soap solution.

PREVENTIVE MAINTENANCE

The owner may follow two methods of maintenance, Continuous and/or Annual.

For Continuous Maintenance (Recommended before each shipment):

If the tank is warm follow steps 1 - 3 under OPERATION section above but allow the unit with full

liquid to stand undisturbed for 2 hours. Verify no major frost or condensation on outside of unit.

Frost or condensation on the outside of unit would indicate either a weak or no vacuum. Inspect the

cork and cover for signs of damage that may affect NER and Hold Time. Inspect the outside of the

tank for signs of shipping damage, such as large dents, especially around the neck tube area.

Remove badly damaged tanks from service.

Clean up any stain, contamination or condensation on the bottom of the unit after dumping liquid

out. Keep the unit in a cool, clean, and dry location for storage. These procedures can help prevent

corrosion on the bottom of the Vapor Shipper.

For Annual Maintenance:

1. Weigh empty unit with cork/cover but without any inventory accessories and record as Empty

Weight, [lb].

Empty Weight must be taken before filling, while the inside of the Vapor Shipper is at room

temperature.

2. Fill unit to bottom of neck tube. Refer to OPERATION section step 2 for details.

3. Replace cork/cover and allow unit to stand for minimal 24 hours.

4. Weigh unit and record as First Weight, [lb].

5. Allow filled unit to sit undisturbed for another 24 (+/-0.25) hours.

a. Consider the accuracy and resolution of your scale to determine if additional days are

required between the first and second weights in order to obtain an accurate NER. Make sure

to record number of hours between first and second weight.

6. Weigh second time and record as Second Weight, [lb].

7. Calculate evaporation rate by using Equation 2. The difference between the first weight and the

second weight is the daily evaporation rate in lbs. This figure roughly signifies the normal

evaporation rate, or N.E.R, [Liter/Day]

(First Weight –Second Weight) x 13.468

NER =

Number of Hours

Equation 2

If there is major frost or condensation on outside of container during this time, it would

indicate either a weak or no vacuum.

8. Pour out LN2 per OPERATION section step 4. Replace cork/cover and take weight as Charged

Weight.

9. Calculate Hold Time, [Days], by using Equation 3. Subtract the Empty Weight from the Charged

Weight and divide by 1.782; then divide by NER.

Hold Time =

(Charged Weight –Empty Weight) ÷ 1.782

NER

Equation 3

MONITORING TEMPERATURE

MVE supplies Data Loggers for peace of mind when shipping valuable inventory in Vapor Shippers.

Contact Customer or Technical Service for assistance in selecting the proper Data Logger for

your product. The datalogger adds approximately 0.12L/day NER.

LETTER EXPLAINING EXCEPTION

This is concerning the applicability of the USA Federal Hazardous Material Regulations to the shipment of

refrigerated samples in the “Dry Shipper” container. A “Dry Shipper” package consists of an outer container that is

lined with an absorbent material. The container is charged with nitrogen refrigerated liquid which is absorbed into

the container lining. The charged, completed package serves as refrigerated container for the shipment of samples.

In consideration of the above, consultation with the Research and Special Programs Administration of the DOT

has determined that the use of nitrogen refrigerated liquid charged “dry shipper” containers for the shipment of

samples fall within the regulation exception provided in 49CFR 173.320 paragraph (a) of the section states the

requirements of this subchapter do not apply to atmospheric gases and helium when used in the operation of the

process system such as refrigeration system. Paragraph (c) of 173.320 pertains to air transport of same

refrigeration system. For exception status of air shipments please refer to IATA-Dangerous Goods Regulations for

nitrogen refrigerated liquid. This falls in the class of 2.2 nonflammable gas, packing instructions 202 with special

provisions A-152. If shipping outside of the USA, please consult your applicable regulatory agencies. For answers

to questions regarding shipping regulations contact a Chart, AI-Cryobiological Tech Service Representative.

76

Limited Warranty Statement

Chart Inc., 2200 Airport Industrial Dr., Suite 500, Ball Ground, GA 30107

General Terms:

“New Product”

(collectively, the "New Products"), shall be free from defects in materials and workmanship for a period of two (2) years from the date of

shipment, except as provided in the Limited Warranty Provisions below. CHART warrants that the dewar vacuum integrity shall be free

from defects in materials and workmanship as for a period of three (3) years from the date of shipment, except as provided in the

Limited Warranty Provisions below.

“Repair/Blemished Product”

blemished equipment (collectively, the "Repair/Blemished Products") shall be free of defects in materials and workmanship for a

period of (90) days from the date of shipment, except as provided below. CHART warrants that the dewar vacuum integrity shall

be free from defects in materials and workmanship for a period of (I) year from date of shipment, except as provided below.

“Service Part”

warranted for (90) days from date of shipment to be free of defects in material and workmanship, except as provided below.

– Chart Inc. ("CHART") warrants to the original purchaser ("Purchaser") that each new Vapor Shipper Dewar

– CHART warrants to the Purchaser that all repaired equipment and factory

– CHART warrants to the Purchaser that all Service Parts and Accessory Items (each a "Service Part") are

Limited Warranty Provisions:

Purchaser agrees that before this limited warranty shall become effective, Purchaser shall fully inspect each New Product,

Repair/Blemished Product, or Service Part within three (3) days of delivery and before such Product is put to use. Purchaser also

agrees to operate the New Product, Repair/Blemished Product, or Service Part in accordance with CHART's operating instructions

and that failure to do so shall void this limited warranty. Purchaser further agrees that any claim for breach of warranty must be

made in writing within 60 days of discovery of a purported defect. CHART will not be responsible for any alleged breach of

warranty, which, as a result of CHART's inspection, CHART determines to have arisen from a cause not covered by this limited

warranty. In this case, CHART will charge the purchaser a nominal fee to repair the unit.

This limited warranty does not apply to: (A) Normal routine service items; (B) Repair or replacement necessitated by misuse,

abuse, accident, or repairs made by persons other than CHART or persons not authorized by CHART, (C) Use of external

equipment or parts with the New Product, Repair/Blemished Product, or Service Parts other than those approved by CHART,

(D) Defects caused by effects of normal wear and tear; and (E) Acts of God, or other causes not within the control of CHART.

If Purchaser believes that a New Product, Repair/Blemished Product, or Service Part does not comply with the limited warranty

stated above, Purchaser should contact CHART at the address stated above, describing the problem and providing proof of the date

of purchase. If directed by CHART, Purchaser shall return the New Product, Repair/Blemished Product, or Service Part freight

prepaid, properly packaged in a CHART approved shipping container and properly identified by a Return Material Authorization

Number issued by CHART. New Products, Repair/Blemished Product, or Service Parts returned without a Return Material

Authorization Number will be refused and returned at Purchaser's expense.

The remedies available for any breach of this limited warranty are limited to repair or replacement of the defective New Product,

Repair/Blemished Product, Service Part, or refund of the purchase price, at the sole discretion of CHART. CHART warrants that

replacement or repaired New Product, Repair/Blemished Product, or Service Part shall be free from defects in material and

workmanship for the duration of the unexpired portion of the original warranty or ninety (90) days from the date of re-shipment

to Purchaser, whichever is longer. PURCHASER'S RECOVERY FROM CHART FOR ANY CLAIM SHALL NOT EXCEED

PURCHASER’S PURCHASE PRICE FOR THE NEW PRODUCT, REPAIR/BLEMISHED PRODUCT, OR SERVICE PART

GIVING RISE TO SUCH CLAIM, IRRESPECTIVE OF THE NATURE OF THE CLAIM, WHETHER IN CONTRACT,

TORT, WARRANTY, NEGLIGENCE, STRICT LIABILITY OR OTHERWISE. CHART SHALL NOT BE LIABLE FOR AND

PURCHASER SHALL INDEMNIFY, DEFEND AND HOLD CHART HARMLESS FROM ANY CLAIMS BASED ON

CHART'S COMPLIANCE WITH PURCHASER'S DESIGNS, SPECIFICATIONS OR INSTRUCTIONS, OR

MODIFICATION OF ANY PRODUCTS BY PARTIES OTHER THAN CHART, OR USE IN COMBINATION WITH

OTHER PRODUCTS.

PURCHASER SHALL NOT IN ANY EVENT BE ENTITLED TO, AND CHART SHALL NOT BE LIABLE FOR, INDIRECT,

SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY NATURE INCLUDING, WITHOUT LIMITATION,

BUSINESS INTERRUPTION COSTS, REMOVAL AND/OR REINSTALLATION COSTS, REPROCUREMENT COSTS, LOSS

OF PROFIT OR REVENUE, LOSS OF DATA, PROMOTIONAL OR MANUFACTURING EXPENSES, OVERHEAD,

INJURY TO REPUTATION OR LOSS OF CUSTOMERS, EVEN IF CHART HAS BEEN ADVISED OF THE POSSIBILITY

OF SUCH DAMAGES.

8

EXCEPT FOR THIS LIMITED WARRANTY, CHART HAS MADE NO WARRANTIES OR REPRESENTATIONS,

EXPRESSED OR IMPLIED, AND HEREBY DISCLAIMS ANY OTHER WARRANTIES, INCLUDING, BUT NOT

LIMITED TO, IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

NO REPRESENTATION OR STATEMENT OF CHART MAY CHANGE OR ALTER THIS LIMITED WARRANTY.

Any claims for breach of this limited warranty shall be governed by Georgia law and without regard to conflict of law rules thereof

and must be brought in a state or federal court in Georgia.

Some states do not allow limitations on implied warranties or on incidental or consequential damages, so the above limitations may

not apply. This limited warranty gives the Purchaser specific legal rights. Purchaser may also have other rights, which vary from state

to state.

This product may be covered by one or more patents, US and international. Please visit our website below for

the listing of applicable patents:

Pat. patents.gtls.io

Supplement to Chart Inc.

Limited Warranty Statement for Sales in Australia (AI)

General T

“New Product” – Chart Inc. ("CHART") warrants to the original purchaser only (meaning

the party from whom CHART accepts the purchase order), whether such purchaser is a

wholesaler, distributor or end user ("Purchaser"), that each new Liquid Nitrogen Dewar

(collectively, the "New Products"), shall be free from defects in materials and workmanship for

a period of two (2) years from the date of shipment, except as provided below. CHART

warrants that the dewar vacuum integrity shall be free from defects in materials and

workmanship as listed below, except as provided in the Limited Warranty Provisions below:

Spectrum and CryoSystem Series, ET11, ET24, A-200, Workhorse 2003: 3 years / XC, SC,

and Lab Series, ET 23-JLM: 5 years.

"Repair/Blemished Product" – CHART warrants to the Purchaser that all repaired

equipment and factory blemished equipment (collectively, the "Repair/Blemished Products")

shall be free of defects in materials and workmanship for a period of (90) days from the date of

shipment, except as provided below. CHART warrants that the dewar vacuum integrity shall

be free from defects in materials and workmanship for a period of (I) year from date of

shipment, except as provided below.

"Service Part" - CHART warrants to the Purchaser that all Service Parts and Accessory Items

(each a "Service Part") are warranted for (90) days from date of shipment to be free of defects in

material and workmanship, except as provided below.

erms:

Sales of Product in Australia:

Where the Purchaser is the end user of the Product, the following additional

information is provided in relation to the warranty against defects (the Warranty)

provided by CHART (as set out in the Limited Warranty Statement).

1. In circumstances where a New Product, Repair/Blemished Product or Service Part

does not comply with the Warranty, CHART will at its expense repair or replace that

defective New Product, Repair/Blemished Product or Service Part, or refund the

purchase price at the sole discretion of CHART. CHART warrants that the

replacement or repaired New Product, Repair/Blemished Product or Service Part shall

be free from defects in materials and workmanship for the duration of the unexpired

portion of the Warranty, or 90 days from the date of reshipment to the purchaser,

whichever is longer.

9

2. The Warranty is subject to the Limited Warranty Provisions set out below and all

exclusions and limitations set forth in the CHART Limited Warranty Statement.

3.

To claim the Warranty, the Purchaser must contact CHART’s affiliate in

Australia for further instruction, including the return of the defective New

Product Repair/Blemished Product or Service Part (at the Purchaser's

expense), to the following address:

Chart Australia Pty Ltd.

Unit 43/2 Railway Parade

Lidcombe, NSW 2141, Australia

Attention: Customer Service Department

Phone number: (02) 9749-4333

Email address: customerser

vice.australia@chartindustries.com

4. The Purchaser must otherwise comply with the requirements set out in the Limited

Warranty Statement when making a claim under the Warranty.

5.

Notwithstanding the Limited Warranty Statement, our Products come with

guarantees that cannot be excluded under the Australian Consumer Law

(ACL). You are entitled to a replacement or refund for a major failure and

compensation for any other reasonably foreseeable loss or damage. You are

also entitled to have the Products repaired or replaced if the Products fail to

be of acceptable quality and the failure does not amount to a major failure.

6. The provider of the Warranty is CHART. Relevant contact details are set out below

for CHART

(to claim the Warranty, please use the contact details provided in

paragraph 3 above):

(a) Customer Service Department

(b) Business Address:

Chart Inc.

2200 Airport Industrial Drive, Suite 500

Ball Ground, GA 30107 (USA)

(c) Phone number: 770-721-7759

(d) Email address: customerser

vice.usa@chart-ind.com

Repair of Products Sold in Australia

Where the Purchaser is the end user of the Product, the following additional information is

provided in relation to the repair of Products by CHART:

The Products may contain "user generated data" as defined under the Australian

Consumer Law (ACL). Repair of Products may result in the loss of user generated data.

This product may be covered by one or more patents, US and international. Please visit our

website below for the listing of applicable patents:

Pat. patents.gtls.io

Operating Manual for MVE Vapor Shippers (SI Version)

M.D.D.Representative: Medical Product Services, Borngasse 20, 35619 Braunfels, Germany

MVE Vapor Shippers are ideally suited for the transportation of cryobiological materials. The liquid

nitrogen is retained in a hydrophobic absorbent material and the cold nitrogen vapors maintain the

Cryo Storage Area between -150°C and -190°C. The absorbent retains the liquid nitrogen and

prevents accidental spills.

Liquid nitrogen is classified as “Dangerous Goods” by the Department of Transportation (DOT). At

least three regulatory agencies publish dangerous goods regulations:

DOT - Department of Transportation

IATA - International Air Transportation Association

ICAO - International Civil Aviation Organization

If used outside of the USA, please consult your applicable regulatory agencies. Liquid nitrogen is

classified under the name “Nitrogen, refrigerated liquid” and has a UN 1977 code number. The name

classification and UN Code Number must be indicated on the shipping carton in addition to a “Gas

nonflammable” label. Packing and labeling requirements can be obtained from the above organizations.

Also, contact your carrier for any variances in the rules as they may apply specifically to that company

and/or the ultimate destination of the shipment.

Be aware that the regulations undergo periodic revisions. If you need current information prior to the

shipping of your cryobiological specimen, please contact your air carrier for the most recent

regulations. It is your responsibility to provide correct information, such as warning or caution, on

shipping package.

GENERAL DESCRIPTION

The cryopreservation vessel is a double-wall, vacuum-insulated vessel made of aluminum with

a fiberglass composite neck, providing the highest efficiency possible in cryogenic temperature

preservation. The liquid nitrogen absorbent is a hydrophobic blanket consisting of synthetic

amorphous silica and glass fiber. This absorbent is non-hazardous. Use the vessel for liquid nitrogen

only. Liquid oxygen is not compatible with this unit and must not be stored inside the vessel.

The MVE Vapor Shipper is designed with consideration for safety, durability and performance.

However, mishandling of the equipment, including transport or shipping units in an orientation other

than upright vertical, may damage the product. In addition, if a vessel experiences a drop, hit, or

blow, it can suffer immediate or premature vacuum failure.

Upon receipt of the product, examine both the vessel and packaging

for any evidence of damage during shipping. Contact the carrier

within the carrier’s guidelines if there are signs of shipping damage.

Some MVE shipping boxes carry the Transit Tested ISTA-3A

certificate stamp, shown to the right, which is helpful when making

a claim against the carrier, should there be damage from shipping.

Watch after the first fill for any signs of vacuum loss, such as

excessive frost or sweating on the outside jacket. Some frost near

the top just after filling is normal. It is normal for some white dust or powder-like residue from the

absorbent to accumulate at the bottom of the unit due to shipping vibrations. If desired, the owner

may wipe or vacuum it out.

This high quality vacuum insulated unit is compatible with the divergent temperature extremes and

broad applications of cryobiology. The life expectancy of this product is five (5) years.

Products bearing the CE marking as shown comply with the requirements of Directive

93/42/EEC concerning medical devices in EU.

10

11

SAFETY

WARNING: Liquid nitrogen is extremely cold. To avoid injury by frostbite, use extreme care

whenever handling liquid nitrogen, liquid nitrogen storage or transfer vessels, or any objects

which have come in contact with liquid nitrogen.

• Leave no area of skin exposed.

• Always wear proper safety attire over clothing: face shield, cryogenic gloves, and

cryogenic apron.

• Use extreme care to prevent spilling and splashing liquid nitrogen during transfer.

• Always keep vessel in upright position. Do not tilt, or lay the vessel on side.

• Immediately remove any clothing or safety attire on which liquid nitrogen has spilled.

• Get immediate medical attention for any frostbite injuries due to liquid nitrogen.

WARNING: The venting of nitrogen vapors may deplete oxygen in the air, possibly leading to

asphyxiation or even death. Do not store or use container in areas that are small and enclosed

or have poor ventilation.

WARNING: Do not tightly seal liquid nitrogen container or prevent nitrogen gas from escaping.

Also, excessive humidity levels or exposure to rainfall could result in freezing of the cork/cover,

and possible explosion.

WARNING: Never use a hollow tube to measure liquid nitrogen level. This could lead to thermal

injury.

CAUTION: Handle the cryopreservation vessel with care.

• Never overfill vessels with liquid nitrogen. Liquid nitrogen should always be below the

bottom of the neck tube. Overfilling the tank may cause immediate or premature

vacuum failure to occur.

• Never ship Vapor Shipper on its side or upside down. This can lead to vacuum failure

and loss of product inside the Vapor Shipper.

• Do not scratch neck tube area. Remove and insert inventories carefully. Scratches can

cause premature vacuum failure.

• Tampering with or removing the vacuum port will destroy vacuum and void warranty.

• Never drop, hit, or blow the vessel.

• Never spill liquid nitrogen on or near vacuum port.

• Never leave the vessel in an outdoor condition.

• Inspect vessel for any damage before and after each shipment.

• Keep the bottom of vessel clean and away from chemicals, fertilizers, soil, and moisture.

• All performance data published for these products is based on static conditions only.

Actual performance will vary upon the nature of use. Manipulation of inventories and

or accessories along with vibration will decrease the working duration/Hold time of

these products.

OPERATION

CAUTION: Consider the value of the inventory when shipping and determine if the inventory

should be split between multiple containers to reduce the risk of losing valuable and/or

irreplaceable products should the container become delayed, lost, or damaged in shipping.

CAUTION: Do not use dewars for longterm storage of human biological contents. Failure to follow

Chart’s best operating practices, as set forth in the operating manual, can result in loss of contents.

Liquid nitrogen is extremely cold. Make sure to wear proper gear before operation. Avoid spilling

liquid nitrogen over the vacuum port as this can shrink the seal and allow air to leak into the vacuum

space causing premature vacuum failure. To ensure maximum performance from your MVE Vapor

Shipper simply follow the listed steps prior to shipping to final destination:

1. Open container that the Vapor Shipper is in, open the lid, and remove cork/cover/accessories.

Lift cork/cover straight up (do not twist).

2. Fill unit to bottom of neck tube.

a. If you are working with a warm vessel, it is MVE’s recommendation to slowly add small

amount of liquid to the bottom of unit, and allow it to sit until the liquid nitrogen stops

rapidly boiling to cool the unit. Position the vacuum port facing away from the operator or

other personnel.

b. To obtain the optimized Hold time. You will need to refill the unit to bottom of the neck

more than once until the liquid level is steady.

c. Follow established safety practices and procedures for transferring LN2.

d. Fill the vessel with a funnel or transfer line when possible. Transfer using LN2 hose with

phase separator or pouring container using a funnel.

e. If you are filling your vessel from a pressurized source, make sure it is a low pressure

source (1.52 bar or below).

3. Replace cork/cover and allow unit to reach thermal equilibrium /charge for minimal 24 hours.

a. Refer to

b. If there is excessive frost or sweating on the outside vessel after the first few hours, it

4. Pour off excess liquid just prior to shipment.

a. If necessary to completely dispense all liquid nitrogen, invert the unit until liquid nitrogen

5. Weigh unit and record.

a. To ensure a proper charging process is conducted, obtain both empty and charged

b. Please note that the Charged Weight is not an indication of unit performance.

6. Place inventories into unit, replace cork/cover and lid.

UTILIZING THE QWICK CHARGE TECHNOLOGY

Only units bearing QWICK charge label is equipped with QWICK charge technology. To utilize the

QWick Charge Technology and charge in under 2 hours, do not allow unit to warm up above -150°C

between shipments. If the inside of the unit is above -150°C, it will need to be charged again for a

minimal of 24 hours to allow the unit to reach thermal equilibrium.

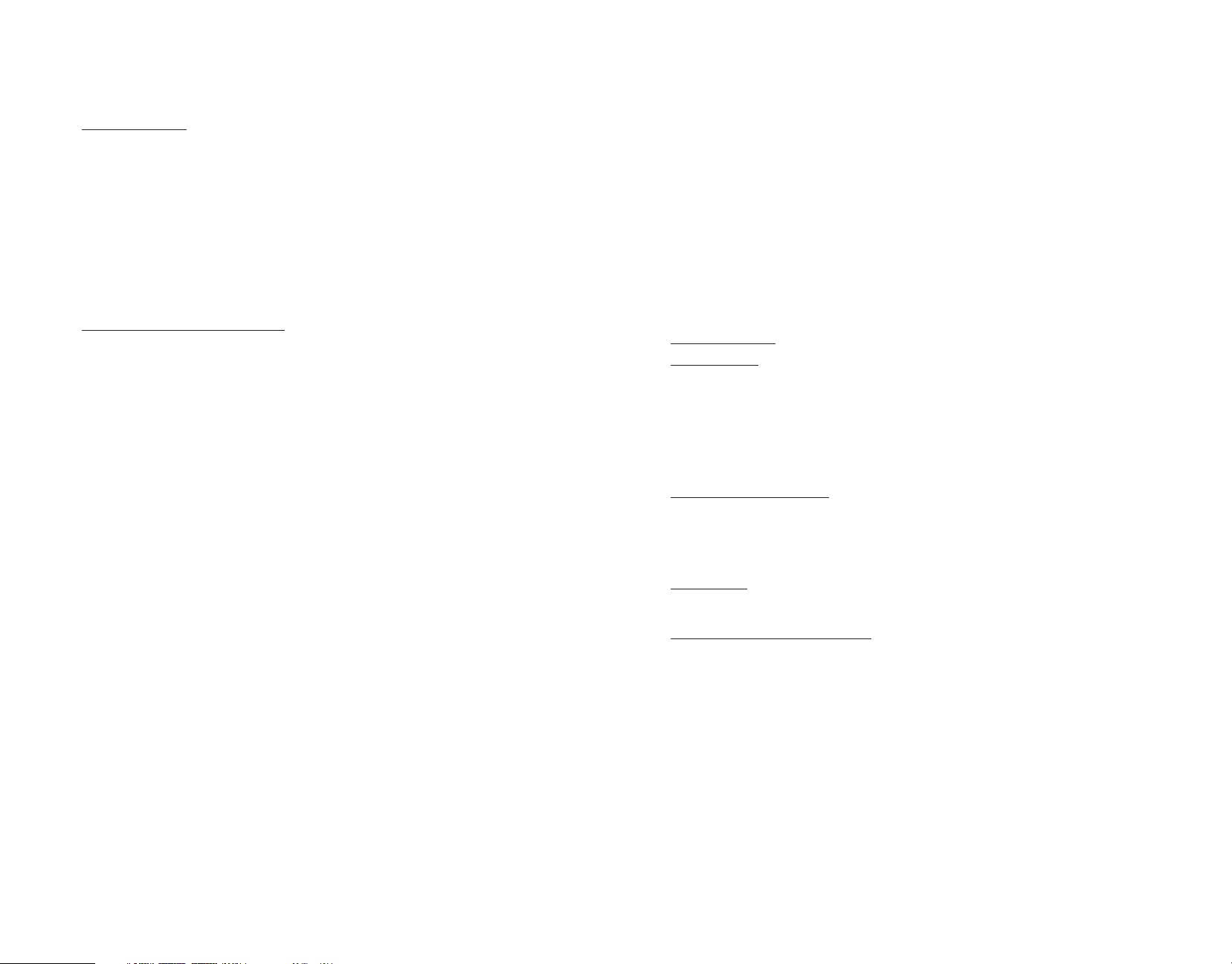

Use the following weight table as a general guide to determine if your Vapor Shipper is fully charged.

Values are for reference only. Weights can vary depending on the charging process. Refer to the Static

hold time and Normal Evaporation Rate (NER) specifications listed in the table below. Factors such as

age of unit, quantity of inventory, ambient environment, shipping condition, and use of accessories,

etc. can negatively affect unit Hold time and NER. If you do not find your model listed here, refer to

the MVE Cryopreservation Catalog or contact Customer or Technical Service for assistance.

UTILIZING THE QWICK CHARGE TECHNOLOGY section for expedited charge solution.

would indicate either a weak or no vacuum. Examine the unit carefully.

dripping has stopped, set the unit upright and view if any liquid nitrogen pools at the

bottom of the unit. If liquid nitrogen starts to pool, invert the unit again. Repeat as

necessary until all liquid nitrogen is removed from the unit, in accordance with ICAO

Packaging Instruction 202.

weights. Verify the differential between empty and charged weights is close to data in

Table 1. The differential can be calculated by using Equation 1.

Differential = Charged Weight — Empty Weight Equation 1

12

13

Table 1 Reference Unit Performance by Model

Empty Charged Static

Model

SC 2/1V 6 (2.7) 8.3 (3.7) 8 0.19 N

SC 4/2V 10.3 (4.6) 16.7 (7.5) 13 0.26 Y

SC 4/3V 11.5 (5.2) 18.5 (8.3) 21 0.20 Y

SC 20/12V 25.3 (11.4) 40.2 (18.2) 60 0.09 N

XC 30/12V 44 (20) 76 (34) 82 0.22 N

Cryoshipper 25.7 (11.6) 38.2 (17.3) 10 0.85 Y

Cryoshipper XC/IATA 32.3 (14.6) 48.9 (22.1) 14 0.70 Y

Cryoshipper 2000 65 (29.5) 95 (43.1) 15 0.79 N

Cryomoover 31 (14) 40.4 (18.3) 12 0.35 N

Cryoshipper MINI* * * * * * 0.84 N

Mini-Moover 8.5 (3.8) 13.4 (6.0) 14 0.20 N

XC 20/3V 25.1 (11.3) 36 (16.3) 16 0.35 N

Doble 11 14.3 (6.4) 19.5 (8.8) 17 0.17 N

Doble 22** 23.8 (10.7) 35 (15.8) 18 0.35 N

Doble 20 23 (10.4) 30.3 (13.7) 21 0.10 N

Doble 28 32.2 (14.6) 46.8 (21.2) 21 0.35 N

Doble 34 34.5 (15.8) 47.9 (21.7) 21 0.20 N

Doble 47 41 (18.5) 54.6 (24.7) 21 0.40 N

Note: The use of a datalogger adds approximately 0.12L/day NER

* Pending on actual configuration

** Center canister required

*** 5% variance in actual weight is typical

Weight Weight Hold Time

lbs (kg) lbs (kg) Days L/Day certified

NER

ISTA-3A

SHIPPING INSTRUCTIONS

MVE/Chart recommends the plastic protective shipping containers (PPSC) be used to help keep the

Vapor Shipper in the upright position and reduce the risk of damage to your valuable asset.

DO NOT

SHIP UNIT ON ITS SIDE OR UPSIDE DOWN. SHIPPING THE UNIT IN ANY POSITION OTHER THAN

UPRIGHT COULD REDUCE THE HOLD TIME TO LESS THAN 10% OF STATIC HOLD TIME, AND CAUSE

PERMANENT DAMAGE TO THE UNIT AND LOSS OF INVENTORY. This could also void warranty.

WARNING: If you ship the Vapor Shipper in a cardboard box, it will ship on its side, as common

carriers instruct their employees in sorting facilities to place boxes on conveyors with the most

stable side down.

Charge the unit by following all steps listed in OPERATION section before inserting into the PPSC. To

avoid damage to either the Vapor Shipper or PPSC never fill or dump the unit when inside the PPSC.

Fasten all locking latches tightly before shipping. You can also utilize cable tie, tamper proof security

seal, or any other appropriate secondary locking mechanism around existing locking latches to avoid

your asset from being tampered during shipment. Before putting PPSC into service, inspect it for any

damage that may jeopardize its functionality. Replace any aged/worn-out impact absorption foam

cushion inside the PPSC or any defective hardware. Remove badly damaged PPSCs from service.

Contact Customer or Technical Service for assistance in selecting the proper service parts.

Typical PPSC shown. The

shape of the PPSC helps

keep the product upright

during shipment.

Shock absorbing foam in the

PPSC helps prevent damage to

the dewar. Illustration shows top

view of the tank in the PPSC.

The rubber latch design allows

the use of a zip tie, vet seal,

safety seal, etc. to ensure

integrity of product shipped.

Select the appropriate shipping method based on the value of contents. Common carriers handle

packages very roughly with the most stable side of the packaging down, and should be used for

low-value product shipment only. Contact carriers for shipment methods for their recommendation

on transporting valuable and/or irreplaceable contents.

MVE Vapor Shippers were primarily designed as vapor shipping containers, however, they can also

be used for immersion of samples. It is imperative that all liquid nitrogen be removed so the unit

remains classified as a Vapor Shipper for transport. If liquid nitrogen is visible in the bottom of the

inner, it then becomes a liquid shipper and the exception status is void. The liquid inside is now

classified as hazardous material.

GENERAL CLEANING

Do not use any petroleum based cleaning solution.

Inside of the vessel:

Any cleaning solution that does not react with aluminum, stainless steel, or G10 composite can be used

in the sanitation process of a MVE Vapor Shipper. In most cases, any household detergent or mild soap

solution is suitable. Other cleaners and disinfectants that can be used safely include hydrogen peroxide,

chlorine/water mixture, and denatured alcohol. The generally accepted practice of using 10% chlorine

bleach with 90% water solution holds as the best method for decontamination. It is recommended that

the unit is filled to its full capacity with the cleaning solution mixture, agitated, and then thoroughly

rinsed. It is important that all surfaces being sanitized are thoroughly rinsed and that all cleaner solution

residues are removed after cleaning. Allow the unit to dry completely before putting into service. It is

suggested that the unit is inverted to drain and dry completely.

Outside of the vessel:

Use light dampened cloth of mild soap solution.

PREVENTIVE MAINTENANCE

The owner may follow two methods of maintenance, Continuous and/or Annual.

For Continuous Maintenance (Recommended before each shipment):

If the tank is warm follow steps 1 - 3 under OPERATION section above but allow the unit with full

liquid to stand undisturbed for 2 hours. Verify no major frost or condensation on outside of unit.

Frost or condensation on the outside of unit would indicate either a weak or no vacuum. Inspect the

cork and cover for signs of damage that may affect NER and Hold Time. Inspect the outside of the

tank for signs of shipping damage, such as large dents, especially around the neck tube area.

Remove badly damaged tanks from service.

14

15

Clean up any stain, contamination or condensation on the bottom of the unit after dumping liquid

out. Keep the unit in a cool, clean, and dry location for storage. These procedures can help prevent

corrosion on the bottom of the Vapor Shipper.

For Annual Maintenance:

1. Weigh empty unit with cork/cover but without any inventory accessories and record as

Empty Weight, [kg].

Empty Weight must be taken before filling, while the inside of the Vapor Shipper is at

room temperature.

2. Fill unit to bottom of neck tube. Refer to OPERATION section step 2 for details.

3. Replace cork/cover and allow unit to stand for minimal 24 hours.

4. Weigh unit and record as First Weight, [kg].

5. Allow filled unit to sit undisturbed for another 24 (+/-0.25) hours.

a. Consider the accuracy and resolution of your scale to determine if additional days are

required between the first and second weights in order to obtain an accurate NER. Make sure

to record number of hours between first and second weight.

6. Weigh second time and record as Second Weight, [kg].

7. Calculate evaporation rate by using Equation 2. The difference between the first weight and the

second weight is the daily evaporation rate in kg. This figure roughly signifies the normal

evaporation rate, or N.E.R, [Liter/Day]

(First Weight –Second Weight) x 29.6919

NER =

If there is major frost or condensation on outside of container during this time, it would

indicate either a weak or no vacuum.

8. Pour out LN2 per OPERATION section step 4. Replace cork/cover and take weight as

Charged Weight.

9. Calculate Hold Time, [Days], by using Equation 3. Subtract the Empty Weight from the Charged

Weight and divide by 0.8083; then divide by NER.

Hold Time =

MVE supplies Data Loggers for peace of mind when shipping valuable inventory in Vapor Shippers.

Contact Customer or Technical Service for assistance in selecting the proper Data Logger for your

product. The datalogger adds approximately 0.12L/day NER.

This is concerning the applicability of the USA Federal Hazardous Material Regulations to the

shipment of refrigerated samples in the “Dry Shipper” container. A “Dry Shipper” package consists

of an outer container that is lined with an absorbent material. The container is charged with nitrogen

refrigerated liquid which is absorbed into the container lining. The charged, completed package

serves as refrigerated container for the shipment of samples.

In consideration of the above, consultation with the Research and Special Programs Administration of

the DOT has determined that the use of nitrogen refrigerated liquid charged “dry shipper” containers

for the shipment of samples fall within the regulation exception provided in 49CFR 173.320 paragraph

(a) of the section states the requirements of this subchapter do not apply to atmospheric gases and

helium when used in the operation of the process system such as refrigeration system. Paragraph (c)

of 173.320 pertains to air transport of same refrigeration system. For exception status of air

shipments please refer to IATA-Dangerous Goods Regulations for nitrogen refrigerated liquid. This falls

in the class of 2.2 nonflammable gas, packing instructions 202 with special provisions A-152. If

shipping outside of the USA, please consult your applicable regulatory agencies. For answers to

questions regarding shipping regulations contact a Chart, AI-Cryobiological Tech Service

Representative.

Number of Hours

(Charged Weight –Empty Weight) ÷ 0.8083

NER

MONITORING TEMPERATURE

LETTER EXPLAINING EXCEPTION

Equation 2

Equation 3

Chart Inc., 2200 Airport Industrial Dr., Suite 500, Ball Ground, GA 30107

General Terms:

Limited Warranty Statement

“New Product”

(collectively, the "New Products"), shall be free from defects in materials and workmanship for a period of two (2) years from the date of

shipment, except as provided in the Limited Warranty Provisions below. CHART warrants that the dewar vacuum integrity shall be free

from defects in materials and workmanship as for a period of three (3) years from the date of shipment, except as provided in the

Limited Warranty Provisions below.

“Repair/Blemished Product”

blemished equipment (collectively, the "Repair/Blemished Products") shall be free of defects in materials and workmanship for a

period of (90) days from the date of shipment, except as provided below. CHART warrants that the dewar vacuum integrity shall

be free from defects in materials and workmanship for a period of (I) year from date of shipment, except as provided below.

“Service Part”

warranted for (90) days from date of shipment to be free of defects in material and workmanship, except as provided below.

– Chart Inc. ("CHART") warrants to the original purchaser ("Purchaser") that each new Vapor Shipper Dewar

– CHART warrants to the Purchaser that all repaired equipment and factory

– CHART warrants to the Purchaser that all Service Parts and Accessory Items (each a "Service Part") are

Limited Warranty Provisions:

Purchaser agrees that before this limited warranty shall become effective, Purchaser shall fully inspect each New Product,

Repair/Blemished Product, or Service Part within three (3) days of delivery and before such Product is put to use. Purchaser also

agrees to operate the New Product, Repair/Blemished Product, or Service Part in accordance with CHART's operating instructions

and that failure to do so shall void this limited warranty. Purchaser further agrees that any claim for breach of warranty must be

made in writing within 60 days of discovery of a purported defect. CHART will not be responsible for any alleged breach of

warranty, which, as a result of CHART's inspection, CHART determines to have arisen from a cause not covered by this limited

warranty. In this case, CHART will charge the purchaser a nominal fee to repair the unit.

This limited warranty does not apply to: (A) Normal routine service items; (B) Repair or replacement necessitated by misuse,

abuse, accident, or repairs made by persons other than CHART or persons not authorized by CHART, (C) Use of external

equipment or parts with the New Product, Repair/Blemished Product, or Service Parts other than those approved by CHART,

(D) Defects caused by effects of normal wear and tear; and (E) Acts of God, or other causes not within the control of CHART.

If Purchaser believes that a New Product, Repair/Blemished Product, or Service Part does not comply with the limited warranty

stated above, Purchaser should contact CHART at the address stated above, describing the problem and providing proof of the date

of purchase. If directed by CHART, Purchaser shall return the New Product, Repair/Blemished Product, or Service Part freight

prepaid, properly packaged in a CHART approved shipping container and properly identified by a Return Material Authorization

Number issued by CHART. New Products, Repair/Blemished Product, or Service Parts returned without a Return Material

Authorization Number will be refused and returned at Purchaser's expense.

The remedies available for any breach of this limited warranty are limited to repair or replacement of the defective New Product,

Repair/Blemished Product, Service Part, or refund of the purchase price, at the sole discretion of CHART. CHART warrants that

replacement or repaired New Product, Repair/Blemished Product, or Service Part shall be free from defects in material and

workmanship for the duration of the unexpired portion of the original warranty or ninety (90) days from the date of re-shipment

to Purchaser, whichever is longer. PURCHASER'S RECOVERY FROM CHART FOR ANY CLAIM SHALL NOT EXCEED

PURCHASER’S PURCHASE PRICE FOR THE NEW PRODUCT, REPAIR/BLEMISHED PRODUCT, OR SERVICE PART

GIVING RISE TO SUCH CLAIM, IRRESPECTIVE OF THE NATURE OF THE CLAIM, WHETHER IN CONTRACT,

TORT, WARRANTY, NEGLIGENCE, STRICT LIABILITY OR OTHERWISE. CHART SHALL NOT BE LIABLE FOR AND

PURCHASER SHALL INDEMNIFY, DEFEND AND HOLD CHART HARMLESS FROM ANY CLAIMS BASED ON

CHART'S COMPLIANCE WITH PURCHASER'S DESIGNS, SPECIFICATIONS OR INSTRUCTIONS, OR

MODIFICATION OF ANY PRODUCTS BY PARTIES OTHER THAN CHART, OR USE IN COMBINATION WITH

OTHER PRODUCTS.

PURCHASER SHALL NOT IN ANY EVENT BE ENTITLED TO, AND CHART SHALL NOT BE LIABLE FOR, INDIRECT,

SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY NATURE INCLUDING, WITHOUT LIMITATION,

BUSINESS INTERRUPTION COSTS, REMOVAL AND/OR REINSTALLATION COSTS, REPROCUREMENT COSTS, LOSS

OF PROFIT OR REVENUE, LOSS OF DATA, PROMOTIONAL OR MANUFACTURING EXPENSES, OVERHEAD,

INJURY TO REPUTATION OR LOSS OF CUSTOMERS, EVEN IF CHART HAS BEEN ADVISED OF THE POSSIBILITY

OF SUCH DAMAGES.

16

17

EXCEPT FOR THIS LIMITED WARRANTY, CHART HAS MADE NO WARRANTIES OR REPRESENTATIONS,

EXPRESSED OR IMPLIED, AND HEREBY DISCLAIMS ANY OTHER WARRANTIES, INCLUDING, BUT NOT

LIMITED TO, IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

NO REPRESENTATION OR STATEMENT OF CHART MAY CHANGE OR ALTER THIS LIMITED WARRANTY.

Any claims for breach of this limited warranty shall be governed by Georgia law and without regard to conflict of law rules thereof

and must be brought in a state or federal court in Georgia.

Some states do not allow limitations on implied warranties or on incidental or consequential damages, so the above limitations may

not apply. This limited warranty gives the Purchaser specific legal rights. Purchaser may also have other rights, which vary from state

to state.

This product may be covered by one or more patents, US and international. Please visit our website below for

the listing of applicable patents:

Pat. patents.gtls.io

Supplement to Chart Inc.

Limited Warranty Statement for Sales in Australia (AI)

General T

“New Product” – Chart Inc. ("CHART") warrants to the original purchaser only (meaning

the party from whom CHART accepts the purchase order), whether such purchaser is a

wholesaler, distributor or end user ("Purchaser"), that each new Liquid Nitrogen Dewar

(collectively, the "New Products"), shall be free from defects in materials and workmanship for

a period of two (2) years from the date of shipment, except as provided below. CHART

warrants that the dewar vacuum integrity shall be free from defects in materials and

workmanship as listed below, except as provided in the Limited Warranty Provisions below:

Spectrum and CryoSystem Series, ET11, ET24, A-200, Workhorse 2003: 3 years / XC, SC,

and Lab Series, ET 23-JLM: 5 years.

"Repair/Blemished Product" – CHART warrants to the Purchaser that all repaired

equipment and factory blemished equipment (collectively, the "Repair/Blemished Products")

shall be free of defects in materials and workmanship for a period of (90) days from the date of

shipment, except as provided below. CHART warrants that the dewar vacuum integrity shall

be free from defects in materials and workmanship for a period of (I) year from date of

shipment, except as provided below.

"Service Part" - CHART warrants to the Purchaser that all Service Parts and Accessory Items

(each a "Service Part") are warranted for (90) days from date of shipment to be free of defects in

material and workmanship, except as provided below.

erms:

Sales of Product in Australia:

Where the Purchaser is the end user of the Product, the following additional

information is provided in relation to the warranty against defects (the Warranty)

provided by CHART (as set out in the Limited Warranty Statement).

1. In circumstances where a New Product, Repair/Blemished Product or Service Part

does not comply with the Warranty, CHART will at its expense repair or replace that

defective New Product, Repair/Blemished Product or Service Part, or refund the

purchase price at the sole discretion of CHART. CHART warrants that the

replacement or repaired New Product, Repair/Blemished Product or Service Part shall

be free from defects in materials and workmanship for the duration of the unexpired

portion of the Warranty, or 90 days from the date of reshipment to the purchaser,

whichever is longer.

2. The Warranty is subject to the Limited Warranty Provisions set out below and all

exclusions and limitations set forth in the CHART Limited Warranty Statement.

3.

To claim the Warranty, the Purchaser must contact CHART’s affiliate in

Australia for further instruction, including the return of the defective New

Product Repair/Blemished Product or Service Part (at the Purchaser's

expense), to the following address:

Chart Australia Pty Ltd.

Unit 43/2 Railway Parade

Lidcombe, NSW 2141, Australia

Attention: Customer Service Department

Phone number: (02) 9749-4333

Email address: customerser

vice.australia@chartindustries.com

4. The Purchaser must otherwise comply with the requirements set out in the Limited

Warranty Statement when making a claim under the Warranty.

5.

Notwithstanding the Limited Warranty Statement, our Products come with

guarantees that cannot be excluded under the Australian Consumer Law

(ACL). You are entitled to a replacement or refund for a major failure and

compensation for any other reasonably foreseeable loss or damage. You are

also entitled to have the Products repaired or replaced if the Products fail to

be of acceptable quality and the failure does not amount to a major failure.

6. The provider of the Warranty is CHART. Relevant contact details are set out below

for CHART

(to claim the Warranty, please use the contact details provided in

paragraph 3 above):

(a) Customer Service Department

(b) Business Address:

Chart Inc.

2200 Airport Industrial Drive, Suite 500

Ball Ground, GA 30107 (USA)

(c) Phone number: 770-721-7759

(d) Email address: customerser

vice.usa@chart-ind.com

Repair of Products Sold in Australia

Where the Purchaser is the end user of the Product, the following additional information is

provided in relation to the repair of Products by CHART:

The Products may contain "user generated data" as defined under the Australian

Consumer Law (ACL). Repair of Products may result in the loss of user generated data.

This product may be covered by one or more patents, US and international. Please visit our

website below for the listing of applicable patents:

Pat. patents.gtls.io

18

19

Loading...

Loading...