Page 1

CHARNWOODOLX

OilFired

HearthBoiler

Operating

and

InstallationInstructions

BishopsWay,Newport,IsleofWight,PO305WS

Tel:+44(0)1983537799 Fax: +44(0)1983537788

E-Mail: charnwood@ajwells.co.uk Internet:www.charnwood.com

Page 2

Page 3

CHARNWOODOLX45

OperatingandInstallationInstructions

OperatingInstructions

GeneralPoints........................................................4

Fuel..........................................................................4

ControllingTheBoiler............................................4

ElectricFlameEffectandFanHeater......................4

IfTheBurnerFailstoLight......................................4

Maintenance............................................................4

ReplacingtheFlameEffectBulb...............................4

InstallationInstructions

Health&SafetyPrecautions....................................6

Standards&Regulations..........................................6

Performance...........................................................6

AirSupply...............................................................6

Chimney..................................................................6

Hearth&FireSurround..........................................8

OilSupply................................................................8

PreparationoftheFireplace....................................9

CentralHeatingSystem...........................................9

FittingTheFire.......................................................10

ElectricalConnection..............................................10

CombustionChamberAssembly............................10

FinishingTheInstallation.........................................11

Commissioning.......................................................12

OverallDimensions................................................12

Specifications..........................................................14

WiringDiagram......................................................15

ElectrodeSettings...................................................16

ExplodedPartsDrawing-Boiler.............................17

ExplodedPartsDrawing-Burner...........................18

BishopsWay,Newport,IsleofWight,PO305WS

TechnicalSupportTel: +44(0)1983537799 Fax: +44(0)1983537788

E-Mail: charnwood@ajwells.co.uk Internet: www.charnwood.com

Page3

OLXV5.205.04

Page 4

CharnwoodOLXOilFiredHearthBoiler

OperatingInstructions

GENERALPOINTS

Beforeusingtheboilerforthefirsttime,checkwiththe

installerthatithasbeencorrectlyinstalledand

commissioned.Donotattempttousetheboilerbefore

ithasbeencommissioned.

FUEL

Theboilerissetuptoburn28sec.viscosityoil,thisis

commonlyknownasKerosene.DonotuseGasOil.

CONTROLLINGTHEBOILER

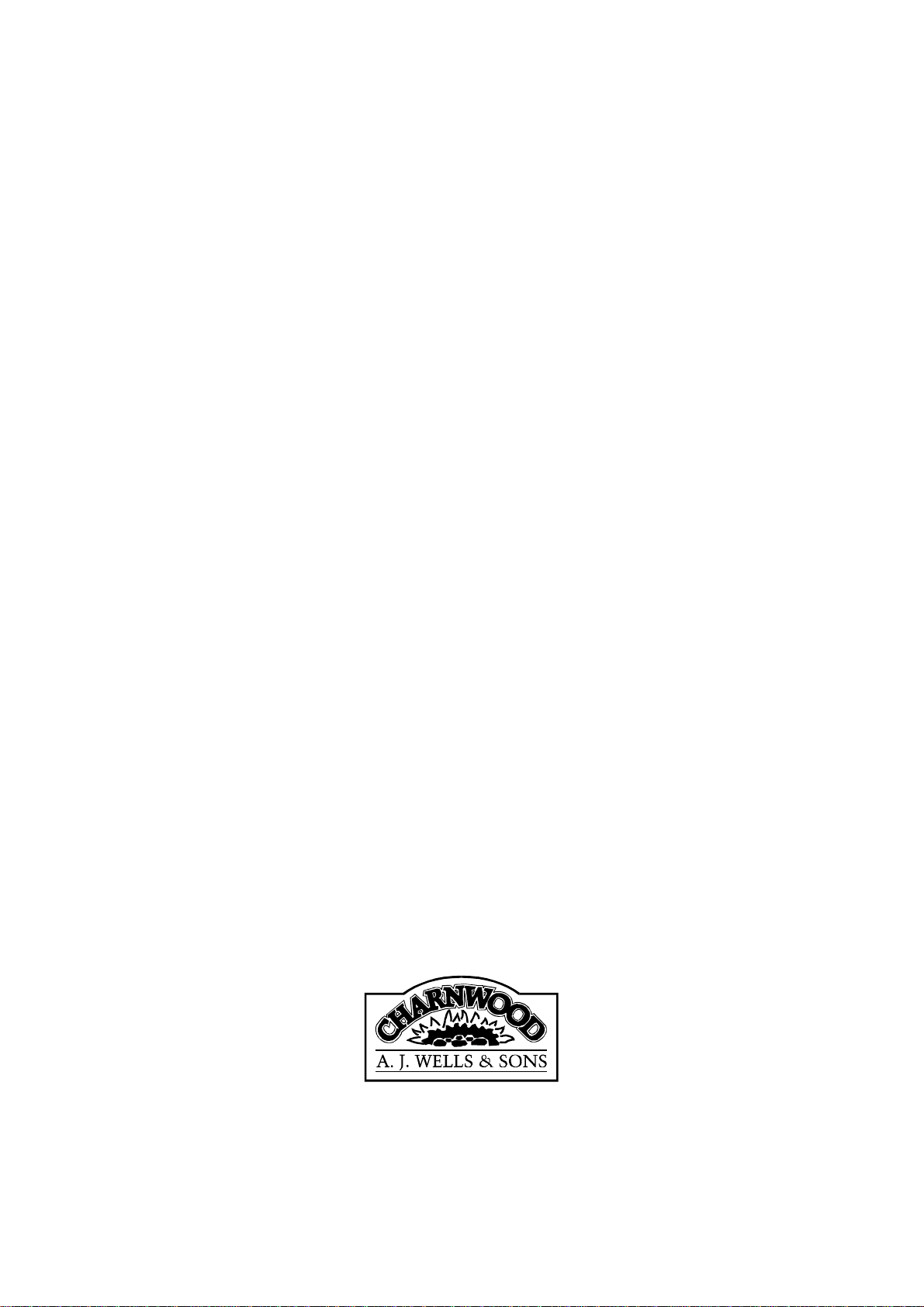

BurnerResetButton

LocatedThroughHole

InFrontPanel

Innerplate

SerialnumberLabel

Bottomplate

Theboileriscontrolledbythethermostatwhichison

thelefthandsideofthefire,itisthelowerofthetwo

controlknobs(seeFig.1.)Thissetsthetemperature

thattheboilerwilloperateat.ACentralHeatingTime

ClockorProgrammerwillnormallycontroltheheating

system.

ELECTRICFLAMEEFFECT&FANHEATER

Theelectricflameeffect operatescompletely

independentlyfromtheboilerandisswitchedonand

offbythetopcontrolknobonthelefthandsideofthe

fire(seeFig.1.)Turntheknobtoposition"1"to

operatetheflameeffect.Theflameeffectmaytakea

fewmomentstobecomeestablishedwhenfirst

switchedonafterlongperiodsofnotbeingused.

Position"2"isusedforthe1KWsettingoftheoptional

fanheateriffitted.Position“3”isthe2KWsetting.If

theroomtemperaturebecomesexcessive,theinternal

thermostatwillswitchtheheatertoblowcoolairuntil

thetemperaturefalls,whenitwillreverttoitsprevious

setting.

FlameEffect

andOptional

FanHeaterControl

Fig2.BurnerResetButton

IFTHEBURNERFAILSTOLIGHT

IftheburnerfailstolightthentheResetlightonthe

BurnerResetButtonmaylightup(seeFig.2.)This

situationisknownas“Lockout”inwhichcasewaitfor

1minuteandpressthere-setbutton(locatedthrough

theholeinthefrontpanelbehindthedoors.)The

burnerwillthentrytoigniteagain.

Iftheburnercontinuallygoestolockout,thenthecause

needstobeestablishedandtheproblemputright.The

mostcommoncausesarelackoffuel,orairinthefuel

line.Checkthattheoiltankisnotempty,andthatall

valvesareopen.Thetroubleshootingguidegives

furthersteps,someofwhichwillrequireactionbya

trainedOilEngineer.Donotpresstheresetbutton

morethanfivetimesinarowasthiscancausedamage

tothepump.

MAINTENANCE

Itisimportanttohavetheapplianceservicedeach

year.PleasearrangethiswithanOFTECapproved

Heatingengineer.Theflexibleoilsupplyhosemustbe

replacedevery2years

Boiler

Thermostat

Fig.1.Controls

TurnHandle

Clockwise

ToOpen

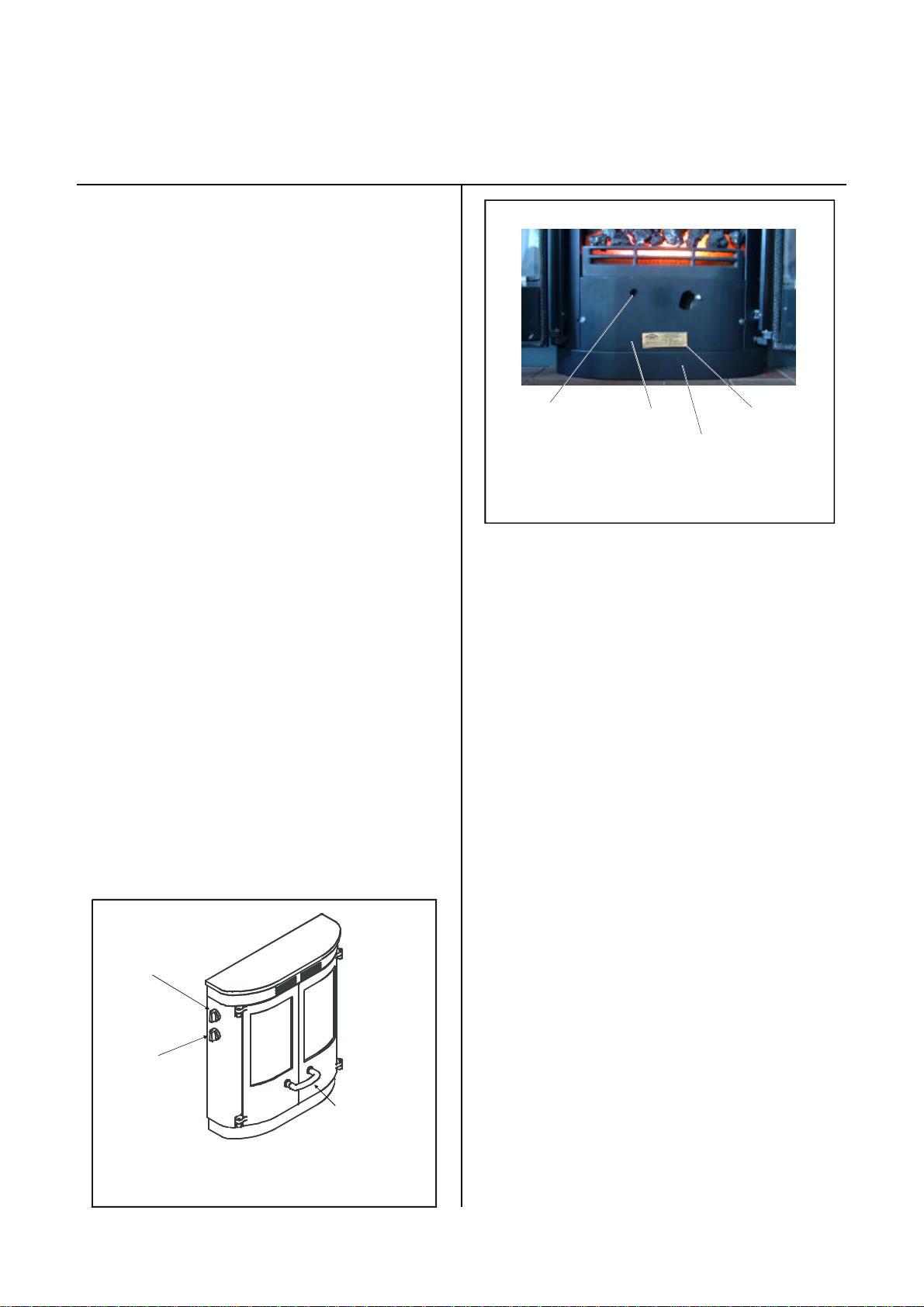

ReplacingTheFlameEffectBulb

Replacingthebulbintheflameeffectisasimple

operationthatcanbecarriedoutwithoutusingany

tools.

Ensurethattheflameeffectisswitchedoffbefore

attemptingtoreplacethebulb.Openthedoorsand

Page4

OLXV5.205.04

Page 5

removethecoals.LiftofftheFrontFence.Liftoutthe

fibreglasscoaleffect.Lifttheright-handendofthe

bulbandcoveroutofitsclip,seeFig.3,thenunplug

thebulb,movingittowardstheright.Slidethecover

offanddiscardtheoldbulb.Slidetheoldcoveronto

thenew

bulbandinsertthebulbbaseintotheholder

ontheleft.Ensurethatthebulbispushedfully

home,thenlowertheright-handendandpressit

intotheclip.Replacethefibreglasscoaleffect,with

therearedgepassingjustunderthePerspex.Re-fit

thefrontfenceandreplacethecoals.

Sleeve

Holder

Clip

1)LiftBulbfromclip

Sleeve

Bulb

2)RemoveBulbfromHolder

Fig.3.FlameEffectBulbReplacement

Page5

OLXV5.205.04

Page 6

CharnwoodOLXOilFiredHearthBoiler

InstallationInstructions

HEALTHANDSAFETYPRECAUTIONS

Pleasetakecarewheninstallingtheappliancethatthe

requirementsoftheHealthandSafetyatWorkAct

1974aremet.

Sometypesoffirecementarecausticandshouldnot

beallowedtocomeintocontactwiththeskin.Incase

ofcontactwashwithplentyofwater.

Noasbestosisusedintheappliancebutifthereisa

possibilityofdisturbinganyasbestosinthecourseof

installationthenappropriateprotectiveequipmentmust

beused.

Whenhandlinginsulatingmaterialsasuitablefacemask

andprotectiveglovesshouldbeworn.

Takecarewhenhandlingfueloilwhichcancauseskin

irritation,avoidcontactwiththeskinorclothing,take

caretowashhandswellaftercontactwithfueloiland

beforeeating.Fueloilmustneverbetakeninternally.

STANDARDS®ULATIONS

Inadditiontotheseinstructionstherequirementsofthe

followingstandardsmustbefulfilled:

BS5410Pt1OilInstallationsUnder45kW

BS5449ForcedCirculationhotwatercentral

heatingsystemsfordomesticpremises

BS7671ElectricalWiringRegulations

boilerandaductedairsupplymustbeprovidedtothe

righthandsideoftheboileratthispoint.Atwometre

lengthofflexibleductingandfixingclipsaresupplied

withtheappliancetoconnecttheairinputfromthe

appliancesilencertotherigidplasticducting.Theair

pipeshouldbesealedintotheapplianceusingasilicone

sealant.Theductingshouldberunin50mmdia.(2")

plasticpipeandmustterminateinfreeair-preferably

eitheroutsideorinaventilatedloftspace.Theendof

theductingmustbefittedwithasuitablecageto

prevententrybybirdsorsmallmammals.Theducting

shouldbeboxedinwhereitpassesthroughlivingareas.

Thelengthofductingshouldbekepttoaminimum,

andthemaximumrecommendedlengthis10metres

incorporatingupto4bends.(Onebendisapprox.

equivalentto1metreofstraightpipe).

Providedthattheductingterminatesasdescribed

abovethereisnorequirementforaseparate

combustionairsupplyintheroominwhichthe

applianceisinstalled.However,iftheducting

terminateswithinalivingspacethentheremustbean

adequateairsupplyintothatroomtotallingatleast55

sq.cm.(8.5sq.inches)toprovidecombustionair.

CHIMNEY

LocalAuthorityBylawsandBuildingRegulations

regardingtheinstallationofOilBurningAppliances,

fluesandchimneysandTheControlofPollution(Oil)

Regulationsmustalsobeobserved.

Oilboilersshouldbeinstalledinaccordancewithgood

practiceasrecommendedbyOFTEC(TheOilFiring

TechnicalAssociationforthePetroleumIndustry,

Banstead,Surrey.Tel:01737373311.)

PERFORMANCE

Theoutputoftheboilerisadjustablebetween11-13

kW(38-44,000Btu/h),asmallamountofheatwillbe

givenouttotheroombutforpurposesofsizingthe

systemthisshouldbeignored.TheoptionalFanHeater

providesupto2KWofheattotheroom.

AIRSUPPLY

Theairsupplyforcombustionistakenfromwithin

thebuildersopeningontheright-handsideofthe

ThechimneyshouldcomplywithBS5410:Part1and

mustmeetBuildingRegulations.

Thediameterofthechimneymustnotbelessthan100

mm(4”)internaldiameter.

Astheboileroperatesathighefficiency,itisimportant

thatthechimneyiswellinsulatedinordertoprevent

condensationforming.

Brickorstonechimneysshouldbelinedwithasuitable

liner.Ifastainlesssteellinerisusedinabrickorstone

chimneythenitmustbeinsulatedbetweenthelinerand

thebrickworkinordertopreventcondensationthat

canreducethelifeofboththelinerandtheboiler.

Pumicelinerswillgivetherequiredlevelofinsulation.

Astheflueoutlettemperatureisbelow250°Cstainless

steelflexiblefluelinerssuitableforoilmaybefitted

directlyontotheappliance,althoughintheinterestsof

reducingfluenoiseitispreferabletousea600mm

lengthofrigidfluepipefromtheappliancetotheliner.

Page6

OLXV5.205.04

Page 7

Page7

OLXV5.205.04

Page 8

Iffluepipeisusedtoconnecttheappliancetothe

chimneyitmustbebetween100&125mm(4-5")

internaldiameter.

Thechimneyterminationmustnotbesubjectedto

downdraughts.Ifnecessaryananti-downdraughtcowl

maybefitted.Therequireddrawforthisapplianceis

0.17mbar(0.07inH2O).

HEARTHANDFIRESURROUND

per1moflengthdownwardsfromtheoiloutlettothe

sludgecockfittedattheoppositeend

.

PlastictanksshouldbeUVstabilisedforprotection

fromsunlight.Theydonotneedtostandonpiersbut

shouldbesupportedacrosstheentirebase.Referto

themanufacturersinstructionsforfulldetails.

Beawareofpollutionpreventionregulationsandthe

needforbundingifthetankisclosetowatercourses

ordrains.

Theboilerwaterwaystotallyenclosethecombustion

chamber.Thismeansthatthemaximumtemperature

belowtheboileris100°Candthereforea

constructionalhearthisnotrequired.

Thehearthandbasewithinthefireplaceopeningmust

bemadefromnon-combustiblematerialandmustbe

flatandlevel.Thehearthmustbeflattoalloweasy

fittingofpartsonthefire.Whenpositioningtheboiler

ensurethatthesideflangesontheboilercomelevel

withthefaceofthefiresurround.

Thefiresurroundshouldbemadefromnon

combustiblematerialandhaveopeningdimensions

showninFig.7.

OILSUPPLY

TheCharnwoodOilBoilerissetuptoburnKerosene

28secondviscosityoiltoBS2869Part21988Class

C2.Itcomescompletewithaflexibleoillineandshut

offvalve,towhichtheoilsupplylineshouldbe

connected.

Inordertoensurequietnessofoperationofthe

CharnwoodOLXasinglepipesystemisused.Theoil

storagetankshouldideallybepositionedwiththebase

ofthetankhigherthanthebaseofthefire.Whenthe

storagetankisbelowtheleveloftheburnerthenanoil

liftermustbeused.

Anoilshutoffvalveissuppliedwiththeboilertoallow

theburnertobeeasilydisconnectedandminimiseoil

spillage.

Anoilfiltershouldalsobefittedoutsidethebuilding,

adjacenttotheoiltank.

Aprotectivefirevalvemustbefittedintheoilsupply

line.Thephialsensorshouldbemountedintheburner

chamberThefirevalveshouldhaveacutout

temperatureof90°C.

Solderedjointsarenotpermittedintheoilsupplyline,

andallconnectionsmustbeproperlysealedtoprevent

oilleakageandairingress.

Someschematiclayoutsofoilsupplysystemsareshown

inFigs.4&5.

Whenconsideringwheretositetheoilstoragetank,

considerationshouldbegiventotheaccessrequiredby

fueldeliverylorries.Tankpositioningmustalsobein

accordancewithBS5410Part1andOFTECTechnical

Book3.

Oiltanksshouldhavethefollowingitems:

Avalvefittedtotheoutlet

Sludgevalve(onsteeltanks)

Oillevelindicator

Hingedfillandventcoverorseparatefill

connectionandvent.Thefillandventmustbe

eithersuitablycappedorhaveareturnbendto

keepoutdirtandwater.

Steeltanksshouldbemountedonsuitablesupports.If

theyaremountedonblocksorbricksthenadamp

proofmembraneshouldbefittedbetweenthe

supportsandthetank.Steeltanksshould slope20mm

OLXV5.205.04

Theoilsupplylineshouldentertheappliancefromthe

left-handsidebehindthesidepanel.Thefittingsupplied

withthefirefacilitatesthis.

Ifthesupplylineistoruninfrontofthefireplace

surroundthenitwillbenecessarytocutasectionfrom

theendofthebottomplateonthefiretogiveaccess

forthepipe.Itispreferabletobringthesupplyinfrom

behindthefiresurround.

Theoilsupplylinemaybeineither8or10mmdia.

copper,dependantonthelengthoftherun,however,

theconnectionontheapplianceisa10mm

compressionfitting.

ThesupplylineMUSTbeflushedoutinthefollowing

manner:-

Connectthesupplylinetothecompressionfitting

ontheservicevalveatthelefthandsideofthe

appliance,butdisconnecttheflexiblehosefromthe

othersideoftheservicevalve,andreplaceitwith

Page8

Page 9

thepushonpieceof12mmbleedtubesupplied.

Placetheotherendofthebleedtubeintoasuitable

receptacle,andflushoutthesupplylinebyturning

ontheservicevalve.Whentheoilisclean,turnoff

theservicevalve,removethebleedtube,andreattachtheflexibletubefromtheburner.Turnthe

servicevalvebackon,checkforleaks,andcleanup

anyspiltoil.

PREPARATIONOFFIREPLACE

Whenreplacinganexistingboiler,removeanyfireback

andinfillmaterialtoexposethebuildersopening.

Theopeningmustbeatleast400mmdeep(when

measuredfromthefrontfaceofthesurround,)600

mmwide(togiveaccesstotheboilerconnections,)and

650mmhigh(togiveaccesstotheflueconnection.

Ensurethatthebaseofthefireplaceislevelwiththe

hearthandthatthefaceofthesurroundisvertical.

Itisnecessarytohaveasmallcutoutinthefireplace

surroundatthebottomleftoftheopeninginorderto

bringtheoilandelectricalsupplytothefire.Itisalso

necessarytohaveasmallcutoutatthebottomrightof

theopeningtocleartheairinletduct.Seefig.7.

Vermiculiteinfill

aroundFlexible

Liner

Rockwoolinfill

aroundflexible

lineraboveclosure

ClosurePlate

Rockwool

insulation

around

Appliance

Fig.6.TypicalInstalation

usingflexibleflueliner

rightdowntoAppliance.

Theshadedareaonthefaceof

thesurroundistheminimumflat

arearequired.

670mm

100mmidsingleskin

flexiblefluepipe

Firesurroundwith

removablemetal

closurepanels

HighTemperature

Siliconesealant.

ApplianceConnector

Fluefixingbrackets

Jointcaulkedwith

glassfibreropeand

sealedwithhigh

temperaturesilicone

sealant.

CENTRALHEATINGSYSTEM

ThecentralheatingsystemmustcomplywithBS5449,

andshouldbeinstalledinaccordancewiththecurrent

goodpractiseguidelinesasadvisedbytheHVCA.

Centralheatingdesignisalargesubjectwhichitisnot

possibletodealwithadequatelyinthismanual.The

pointsthatareparticularlyrelevanttothisboilerare

dealtwithbelow.

Theheatingandhotwatersystemshouldnormallybe

fullypumped,althoughagravityhotwatersystemmay

beusedifitalreadyexists.

Therearenointernaldivisionsinthe boiler,andany

combinationofflowandreturntappingsmaybeused.

Ifitispossiblethendiagonalpairsoftappingsshouldbe

used,butpairsonthesamesidemaybeusedif

required.

Themaximumworkingpressureoftheboilermustnot

exceed3Bar(44psiorastaticheadof30m)

Inordertopreventabuildupofscaleandcorrosiona

suitableinhibitorshouldbeaddedtothesystem.

Whenreplacinganexistingboilerthesystemshould

770mm

50mm

Dim.A:

Max.470mm(181/2")

Min.405mm(16")

Dim.B:

Max.579mm(223/4")

Min.555mm(213/4")

50mm

65mm

110mm

Fig.7LimitingDimensionsOf

SurroundandOpening

bethoroughlycleanedbeforeconnectingthenew

boiler.

Fullyautomaticcentralheatingcontrolsmaybeusedto

givefullcontroloftheheatingandhotwater.When

designingthecontrolsystemitisimportanttonotethat

ifthesituationcanarisewheretheflowofwater

throughtheboilerisstopped,orsubstantiallyreduced,

whilsttheburnerisstillfiring,thenthiscanresultinthe

waterintheboilerreachingveryhightemperatures,or

evenboiling,beforetheboilerthermostatcansenseit

andswitchtheburneroff.Ifthisisapossibilitythen

Page9

OLXV5.205.04

Page 10

wirethecontrolstotheburnersothatitisswitchedoff

atthesametimeasthepumpormotorisedvalves.

Thisusuallymeanswiringthesupplytotheburnerinto

theoutputfromthecentralheatingprogrammer.

FITTINGTHEFIRE

ResetButton

OilPressure

GaugePort

Burner

Control

Unit

IgnitionUnit

(BehindControlUnit)

Photocell

AirControl1-10

AirControl1-10

AirInlet

Manifold

Unpackthestoveandremoveitfromitswooden

pallet..Ifafluelineristobeusedthenthisshouldbe

fittedinthechimneybeforefittingthefire.Theliner

willnormallycomedowntoafixingplateandashort

lengthof316Stainlesssteelfluepipeisthenusedto

connecttheboilertotheliner.Alternativelytheliner

maybefitteddirectlytotheboiler,inthiscaseensure

thattheliner isadequatelysupportedandthatitwill

notvibratewhentheapplianceisinuse.UsetheFlue

Fixingbracketsandselftappingscrewssuppliedtofix

thefluesecurelytotheboiler(seeFig.12.)Mineral

fibreorfibreglassshouldbeusedtoreducevibrations

andinsulatetheboilerandflue.Thespacebetweenthe

flexiblelinerandthechimneyshouldbefilledwith

loosevermiculiteinfillretainedbyasuitableplateinthe

chimneyabovetheboilertoallowfutureaccesstothe

boilerwithoutremovingtheinfill(seeFig.6).A

suitableraincapshouldbefittedtothetopofthe

chimney.

Positionthefiresothattherearfaceofthesideflanges

comesflushorveryslightlyinfrontofthefaceofthe

firesurround.

Maketheflueconnectiontotheappliance,ensuring

thatthefluepipeiswellsealedtotheboiler,andfixed

securelyusingthefixingscrewsandbrackets,seeFig.

10.

Connecttheheatingsystemtotheboilerensuringthat

thesystemventscorrectly.Fillthesystemwithwater

andcheckforleaks.

OilPump

NozzleCoverPlate

FuelSolenoidvalve

AirPressureSwitch

Fig.8.OilBurnerAssembly

ShownRemovedfromBoiler.

bafflesfitted,anditisrecommendedthatthesebe

checkedforpositionbeforeinitialfiring.Ifitbecomes

necessarytore-fitthebafflesandbricks,followthis

procedure:-

Isolatefromthemainssupply,openthedoorsandlift

upandremovethebottomplate.SeeFig2.Liftoffthe

fenceandthecoaleffect.Loosenthefixingscrewat

eachsideoftheinnerplate,slideoutwardsintothe

slot,andliftofftheinnerbottomplate.LiftthePerspex

paneloutofthefireandundothetwowingnutsonthe

backpanel.Unplugthemainscablefromthebottomof

theflameeffect.Theflameeffectmaythenbelifted

clear.Theboileraccessdoorisnowvisible,andis

removedbyundoingthe4brassnutswitha10mm

socket.

Taketheitems1-5inorderandlowertheminto

positioninthebottomofthecombustionchamber.

Assemblethemtogetherinthispositionsothatboth

sideboardsaretightinagainstthetop&backboards,

andthefrontfaceofthetopboardishardupagainst

ELECTRICALCONNECTION

Theboilercomespre-wiredwithtwolengthsof3-core

cable.Theblackcableisfortheoilburner,thewhiteis

fortheflameeffectandoptionalfanheater.Connect

theblackcabletotheoutputfromthecentralheating

programmer,ensuringthatthesupplyisviaa3amp

fusedswitchedspur.Connectthewhitecabletoa

separate3ampfusedswitchedspur.Ifafanheateris

fitted,thisfusemustbe10amp.Ensurethattheearth

connectionsaremade.

COMBUSTIONCHAMBERASSEMBLY

Theboilercomeswiththeinternalinsulationbricksand

OLXV5.205.04

Page10

BleedScrew

BleedHose

ConnectionPoint

Fig.9.OilPumpDetails

OilPressureAdjustmentscrew.

ClockwisetoIncrease,

Anti-ClockwisetoDecrease.

Page 11

TopBaffle

Nibsatfront

45°Chamfer

AssemblyOrder:

1.Base(FibreWool)

2.Back

3.RHSide

4.LHSide

5.Top

5

45°Chamfer

45°Chamfer

Note!Numbersetchedontobafflesmustbe

incorrectorientationwhenassembled.

Fig10.BaffleArrangement

theinnerfrontoftheboiler.Thereshouldbeagapat

thebackofapprox.25mm,andequalgapsatthe

sides.Thebottombaffle(No.1)isnowcarefully

loweredintoposition,sothattheguidesonits

undersideholdtheinsulationpanelsinplace.When

assembledtheNo1shouldbeclearlyvisible,theright

wayup.Theremainingbaffles(Nos.2-4)are

assembledinorder,withthenumbersfacingthefront

ofthestoveasshowninFig10.Theaccessdoorisnow

re-fitted.Ensurethattherubbersealispushedfully

hometotheframe,andthatthe4brassnutsare

tightenedevenly.

3

2

4

CombustionChamberInsulationBoard

1

OrderofAssembly

FINISHINGTHEINSTALLATION

Onceallwater,oilandelectricalconnectionshavebeen

madeandtestedtheinstallationcanbefinished.Fit

glassfibreinsulationmaterialaroundtheboilerandflue

inthebuildersopening.Thiswillbothhelppreventheat

lossandreducenoisetransmission.Fitthefire

surround.

WARNING

Oncetheinstallationiscompleteensurethattheair

controlissetatmaximum(No.10)beforethe

burnerisfired(seeFig.8.)Otherwisesootingmay

occur.Thiswillbere-adjustedduringcommissioning.

Page11

OLXV5.205.04

Locatethisfacehard

againstinnerfront

boilerface,giving25mm

gapatrear,&40mmat

frontsides.

Fig11.CombustionChamberComponents

Page 12

COMMISSIONING

Theburnersarepre-setatthefactory,butmustbe

fine-tunedoncompletionoftheinstallation.Thisisa

conditionoftheguarantee.

Beforefiringtheboilercheckthatthebafflesandblast

chambercomponentsarefittedinthecorrectpositions

asdescribedaboveandshowninFigs.10&11.

Ensurethattheheatingsystemisconnectedandfilled

withwaterbeforeattemptingtofiretheboiler.

Tosettheoilpressureandtheairsettingitisnecessary

toremovetheinnerbottomplate.Isolatefromthe

mainssupply,openthedoorsandliftupandremove

thebottomplate.SeeFig2.Liftoffthecoals,thefence

andthecoaleffect.Loosenthefixingscrewateachside

oftheinnerplate,slideoutwardsintotheslot,andlift

offtheinnerbottomplate.Accesstotheboiler

samplingpointisbehindtheflameeffect.Togainaccess

liftthePerspexpaneloutoftheflameeffectandundo

thetwowingnutsonthebackpanel.Unplugthemains

cablefromthebottomoftheflameeffect,whichmay

thenbeliftedclear.Theboilersamplingpointisatthe

topoftheaccessdoor,usea5mmallenkeytoremove

theblankingscrew.Settheaircontrolfullyopen(No.

10)beforetheinitialfiring.Theelectricalpowermaybe

turnedbackontotesttheburner.

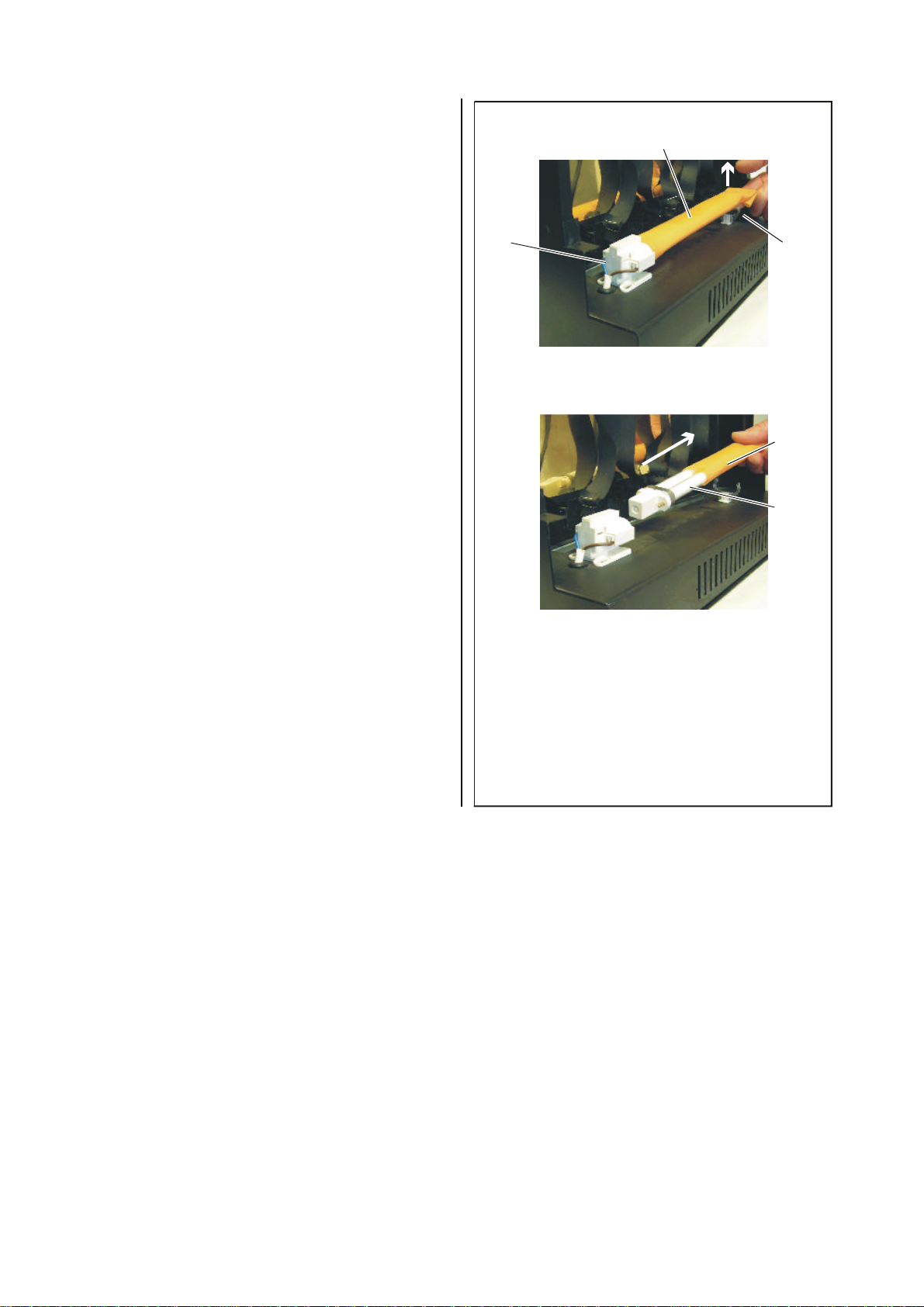

thermostattoMed.Afterafewsecondsyoushould

heartheburnerignite.Ifnecessarybleedthepump.

RefertoFig.9.Fitthepieceof4mmplastichose

providedontothebleedport,placetheendofthehose

intoasuitablereceptacleandopenthebleedscrew

takingcarenottospillanyoil.Whenbleedingthe

pumpwillbequitenoisy.Oncealloftheairisoutof

thesystemclosethebleedscrewandremovethehose.

Takecaretomopupanydropsofoilspilt.

FlueFixingBrackets

AirInlet

Connection

TheburnercomponentsareshowninFig.8.

Turnonthesupplytotheprogrammer,setthe

programmertogiveheatingandhotwaterandturnthe

Boilertappingsare1”BSPFemale,

2eachside

547

520

250

261

365 170 548

CharnwoodOLXOverallDimensions

(alldimensionsareinmm)

Fig.12.AirInletand

FlueFixings

654

(693with

optional

fanheater)

394 62

ø130

255

Page12

OLXV5.205.04

Page 13

Writethedateontheflexibleoillinelabel.The

flexibleoillineMUSTbereplacedevery2years.

Allowthefiretorunfor20-30minutesbeforechecking

thesootandCO2readings.Thesamplingpointison

theboileraccessdoor.Theaircontrolissituatedonthe

frontoftheblackrubberairmanifoldwhichistowards

therightoftheburner,asshowninFig.8.Initiallysetto

No.10,theburnerwillbeburningwithexcessairand

withtheoilpressuresetatamid-rangesetting.Fita

pressuregaugetothepressuregaugeportshownin

Fig.8andadjusttotherequiredsetting(100-140psi.)

Afteradjustingthepumppressureallowthefiretorun

forapproximately10minutesbeforecheckingthe

smokereading.Reducetheairinletbyslackeningthe

nutinthecentreofthemanifold,movingthepointer

clockwisetoalowernotchandre-tighteningthenut.

Whensootoccurs,graduallyincreaseittogive

combustionfreeofsoot.(10=maxair,1=minair).

Thisshouldgive11–12%CO2and0-1Smokewitha

fluetemperatureofapproximately180°Cabove

ambient.Measurementstakenattheboileraccessdoor

willgiveaslightlyhighertemperature(approx.220°C

aboveambient)thanreadingstakenactuallyintheflue.

Amodernburnerworkswith lessexcessairandoften

alsowithsmallernozzlesthanoldermodels.This

increasestheefficiencybutalsotheriskof

condensationinthechimney.Theriskincreasesifthe

areaofthechimneyflueistoolarge.Thetemperature

ofthefluegasesshouldexceed60°Cmeasured0.5

metresfromthechimneytop.Ifnecessarysomeofthe

followingmeasuresmaybetakentoraisethechimney

temperature:

Insulatethechimneyincoldattics.

Installachimneyliner.

Installadraughtregulator(dilutesthefluegasesduring

operationanddriesthemupduringstandstill).

Increasetheoilquantity.

Raisethefluegastemperaturebyremovingsomeof

thebaffleplatesintheboiler.

Re-fittheElectricFlameeffectandcheckitsoperation.

Theflamepatternmaytakeafewminutestobecome

established,particularlywhenthefireisswitchedonfor

thefirsttime.Arrangethecoalssuppliedwiththe

applianceontopofthefibreglasscoaleffecttoproduce

abeautifulfire.

Advisethecustomerontheuseoftheboiler,andthe

systemcontrols.Alsoadviseoftheneedforannual

servicingoftheboilerbyanOFTECtrained&

registeredtechnician.LeavetheseOperatingand

InstallationInstructionswiththecustomer.

Page13

OLXV5.205.04

Page 14

OLXBoiler-Specifications

Max.AllowableOperatingTemperature95°C

Max.AllowableOperatingPressure3bar(PressureClass2)

TestPressure4.5bar

HeatOutputRange11-13kW

HeatInputatRatedOutput15kW

OilPumpPressure110-140psi

RequiredFlueDraught0.07inHO(0.17mbar)

ExitFlueGasTemp205°C

ExitFlueGasMassFlow……kg/s

ExitFlueConnectionDiameter130mmsockettotake125mm(5in)or

100mm(4in)pipe

AirInletDiameter55mmsockettotake50mm(2in)pipe

Max.RecommendedAirPipeLength10M+4x90°SweptBends

Water-sideResistance

4.1mbar@DT=10°C

@flowrate2.9litres/min1.5mbar@DT=20°C

RangeofTemperatureControl40-90°C

SafetyThermostatTemperature 110°C

FuelTypeUsedKerosene28second

BoilerTypeOn/OffType

BoilerTappingsize1inBSPFemale

ElectricalProtectionIP20

EarthingTerminalCopperFlashedSteel

ElectricalSupply240v50Hz

ElectricalPowerInput@240vac(standard)200Watts

(withfanheater)2200watts

FuseinFlameEffect250v2Ax20mm

FusesRequiredinPowerSupply

FlameEffectonly3A240V

FlameEffect+FanHeater10A240V

Burner3A240V

FireValveOperatingTemperature90°C

BoilerWaterVolume23.4Litres

TotalWeightofStove140Kg

2

Page14

OLXV5.205.04

Page 15

MainsInput

from13Amp

FusedSpur.

MainsInput

fromTimer

SwitchedLive.

Fusedat3Amp.

CharnwoodOLX

WiringDiagram

AboveSerialNo.1562

IECLeadSocketto

FlameEffect

E

L

N

P1

1

RotarySwitchSW1

TypeRPSBC20M90

2

3

SocketTo

Optional

FanHeater

E

N

L

31

21

11

DualActing

Thermostat

32

22

12

TR

TB

TS1

OutletSocket Plugto

L1

(1+)

L2

(1-)

N

(2-)

E

(2+)

Skt3

IECChassis

Skt1

E

L

N

FanHeater

Plug

Brown

1+

Black

1-

Blue

2-

Green/

Yellow

2+

E

N

L

Skt2

IECFused

ChassisPlugin

FlameEffect

WireColours

fromFanHeater

Skt4

E

N

L

IECLead

Burner

E

1ampantisurgefuse

L

N

FluorescentLight

Ballast

Fan

FlameEffect

SatronicControlTerminals

1 2 3 4 5 6 7 8 9

A B CN N N S2

Photocell

IgnitionUnit

Oil

Pump

Fan

Diode

BurnerControl

10

AirPressure

Switch

P

SolenoidValve

(Oil)

ThermostatMountingBox

Page15

OLXV5.205.04

Page 16

CharnwoodOLX

ElectrodeSettings

3.0±0.20.5±0.5

Alldimensionsareinmm

9.0±1.0

Page16

OLXV5.205.04

Page 17

IssueC

CharnwoodOLXMk.2

PartsList

53

48

54

36

391819

29

12

11

51

35

50

32

31

21a

30

40

37

46

16

45 44

47a 47b 47c

43

7

41

42

33

25a

24b

24a

23a

21a

21a

21a

38

49

17

34

142615

NOTE!

Mk.3ReplacementBurnersfor

appliancesbeforeSerialNo.

45****1562requirebracket

toaligncontrolboxwithre-set

hole.

55

6

52

102713204

8289

ItemPartNo.DescriptionItemPartNo.Description

3*008/KV35SDoorSealSetInc.Adhesive38004/TV03AccessDoor

4006/KV18GlassInc.GlassChannel39004/TV25ThermostatMountingBox

5*008/TV95GlassSeal(Neoprene)40004/TV33ThermostatPhialClampingPlate

6004/KV23GlassRetainer41008/TV17InnerFrontInsulation

7002/TV07FrontFirebar42010/TV14InnerFrontPlate

8008/KV16R.H.DoorHandle43010/TV43InnerFrontPlateFixingBracket

9002/KV14DoorCatchCam44008/TV86AirInletGasket

10008/KV13L.H.DoorKnob45008/TV49AirInletManifold

11008/TV19ThermostatKnob46010/TV84/1AirInletSideCover

12008/TV20FlameEffectKnob47a010/TV108AirControl-LocationDisk

13008/BW39/SHingePinSet(4perset)47b010/TV109AirControl-Pointer

14008/TV80FluorescentLamp47c010/TV110AirControl-Adjuster

15008/TV78AmberLampSleeve48010/TV42SFlueFixingBracket(setof3)

16040/TV69ResetButtonExtension49011/PV27BackCeramicGasket

17008/TV09AccessDoorInsulation50040/TV77ServiceValve&Elbow

18008/TV22Thermostat51040/TV94BurnerMountingFlange

19008/TV24FlameEffectRotarySwitch52M12HalfNuts

20008/TV27HingePost53005/TV06/##LowerTopPanel-forFanHeater

21a01 1/TV106BlastChamberInsulationBoardSet54008/TV111FanHeater

23a010/TV31Baffle-No.1

24a010/TV47ABaffle-No.2.

24b010/TV47BBaffleNo.3

25a010/TV48ABaffle-No.4

26008/TV13FibreglassCoalEffect

27003/TV01/##L.H.Door

28003/TV02/##R.H.Door

29005/TV04/##L.H.SidePanel

30005/TV05/##R.H.SidePanel

31005/KV06/##LowerHoodPanel

32005/KV09/##TopHoodPanel

33005/TV16/##BottomPanel

34008/TV11FlameEffectCartridge

35008/TV15OilBurner

36001/TV10BFirebox/Boiler(OLX)

37004/KV50PanelFixingBracket

*Theseitemsarenotshownonthedrawing

##Pleasespecifycolourwhenordering

55010/TV137ControlBoxOffsetBracket

Toobtainsparepartspleasecontactyourlocalstockist

givingModel,PartnumberandDescription.Incaseof

difficultycontactthemanufacturerattheaddressshown.

ThisdrawingisforIdentificationpurposesonly.

CHARNWOOD BishopsWay,Newport,IsleofWightPO305WS,UnitedKingdom

T:+44(0)1983537799F:+44(0)1983537788charnwood@ajwells.co.ukwww.charnwood.com

Page17

OLXV5.205.04

Page 18

IssueA

CharnwoodOLXBurnerMk.3

PartsList

TheseItemsshownRotated

40

41

14

11

23

17

42

3

15

12

24

5 34 6

7

35 8

16

30

27

4

26

2

28

1

18

31

19

22

9

29

25

38

37

33

13

10

40

20

21

Item Part No. Description Item Part No. Desc ription

1 040/TV61 Nozzle - 0.4 80° EH 38 040/TV124 Solenoid V alve

2 040/TV154 ElectrodeMounting Block 39 040/TV123 Solenoid Plug & Lead

3 040/TV153 Electrode 40 040/TV161 Burner MountingFlange

4 040/TV140 Nozzle Holder 41 040/TV162 Mounting FlangeGasket

5 040/TV155 Nozzle Holder Cover Plate 42 Electrode fixingscrew

6 040/TV141 Al.Washer

7 040/TV143 Banjo Union

8 040/TV142 Fibre Washer

9 040/TV144 Banjo Bolt

10 040/TV160 FlexibleOil Line

11 040/TV63 Blast Tube Seal

12 040/TV112 Photocell Plug-in Type

13 040/TV113 Solenoid Coil Plug-in Type

14 040/TV164 Blast Tube

15 040/TV151 AirGuide in Blast Tube

16 040/TV28 Burner Chassis Plate

17 040/TV74 Fan Motor & Impeller

18 040/TV92 Pump Mounting Bracket

19 040/TV72 Oil Pump

20 040/TV71 Ignition Unit

21 040/TV75 Control Box

22 040/TV54/A Fan Mounting Ring

23 040/TV158 Photocell Plug & Cable

24 040/TV159 Photocell Holder

25 040/TV68 Air Pressure Switch

26 040/TV148 Gauge Port Elbow

27 040/TV149 Gauge Port Plug

28 040/TV150 OilT Connector

29 040/TV69 Reset Button Extension

30 040/TV152 Blast Tube Mounting Flange

31 040/TV146 OilPipe (Pump to Sol.Valve)

33 040/TV145 OilPipe (Sol.Valve to Nozzle)

34 040/TV15~1 Burner Casting

35 040/TV163 Fan Washer

37 040/TV147 OilElbow 8/10mm male/male

Toobtainsparepartspleasecontactyourlocal

stockistgivingModel,PartnumberandDescription.

Incaseofdifficultycontactthemanufactureratthe

addressshown.

Thisdrawingisforidentificationpurposesonly.

CHARNWOOD BishopsWay,Newport,IsleofWightPO305WS,UnitedKingdom

T:+44(0)1983537799F:+44(0)1983537788charnwood@ajwells.co.ukwww.charnwood.com

Page18

OLXV5.205.04

Page 19

Loading...

Loading...